Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sludge Drying Bed

Caricato da

AshokCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sludge Drying Bed

Caricato da

AshokCopyright:

Formati disponibili

Technology: Sludge Drying Bed TDS-BIO-12-2014

Description Performance

A sludge drying bed is a common method utilized In terms of its efficiency, while dried sludge is not fully

to dewater sludge via filtration and evaporation. disinfected, the solid content is increased to 50%70%

Perforated pipes situated at the bottom of the bed are of total solids.

used to drain seepage water or filtrate. A reduction of

about 35% or less in moisture content is expected after Cost

drying. Sludge drying beds are usually situated beside Among the available sludge dewatering methodologies,

treatment plants to readily receive and treat incoming investment cost for sludge drying beds is considered the

sludge coming from primary or secondary treatment lowest. For operation and maintenance, the only item

facilities. to be considered is the labor cost.

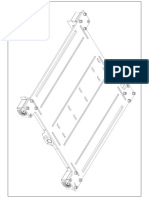

The basic design components of the drying bed are Advantages

composed of (i) concrete structure for bed and walls, Sludge drying beds are simple to operate and

(ii) sand and gravel to be used as filter media, (iii) splash energy-efficient.

block, (iv) underdrain,and (v) inlet. It presents the least cost technology option for

dewatering sludge.

Applicability

Sludge drying beds are suitable for treatment plants Disadvantages

serving a population ranging from 1,000 to 20,000. Treatment is required for seepage water.

These facilities exhibit reliability and good process Solar power is required.

flexibility. However, during the wet season, its efficiency The beds are prone to odor and insect problems.

decreases.

Process

Robert Domingo

Source: Indian Standard.

References:

Indian Standard. Requirements for Sludge Dewatering Equipment, Part I Sludge Drying Beds - Sand Gravel and Underdrains. http://bit.ly/1hozrtC.

Department of Environment and Natural Resources, Department of Health and the Local Water Utilities Administration. 2005. Philippines Sanitation Sourcebook and Decision Aid.

Potrebbero piacerti anche

- Secondary Treatment PDFDocumento56 pagineSecondary Treatment PDFRagib Nur Alam ShuvoNessuna valutazione finora

- Ozone PaDocumento8 pagineOzone PaAmbar AmKaNessuna valutazione finora

- Sanitary Engineer II: Passbooks Study GuideDa EverandSanitary Engineer II: Passbooks Study GuideNessuna valutazione finora

- Bar ScreenDocumento16 pagineBar ScreenamaranthussativaNessuna valutazione finora

- Shortcut Nitrogen Removal-Nitrite Shunt and DeammonificationDa EverandShortcut Nitrogen Removal-Nitrite Shunt and DeammonificationNessuna valutazione finora

- Course Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungDocumento50 pagineCourse Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungAnnisa MaulinaNessuna valutazione finora

- Design—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaDa EverandDesign—Operation Interactions at Large Treatment Plants: Proceedings of a Workshop Held in ViennaS. H. JenkinsNessuna valutazione finora

- CH 9 - Attached Growth ProcessDocumento30 pagineCH 9 - Attached Growth Processxuantra92100% (1)

- Project Report On STPDocumento24 pagineProject Report On STPRinku SinghNessuna valutazione finora

- V3i4 Ijertv3is040786 PDFDocumento5 pagineV3i4 Ijertv3is040786 PDFsarikagNessuna valutazione finora

- FiltrationDocumento41 pagineFiltrationkevalNessuna valutazione finora

- Project Report On Extended Aeration and Step AerationDocumento38 pagineProject Report On Extended Aeration and Step AerationHakim Asif Haider100% (2)

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanDocumento47 pagineDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALANessuna valutazione finora

- Sewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDocumento38 pagineSewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDhruv MudgalNessuna valutazione finora

- SE WA GE TR EA TM EN T: Intro. Waste Water (Sewage) TreatmentDocumento49 pagineSE WA GE TR EA TM EN T: Intro. Waste Water (Sewage) TreatmentRefisa JiruNessuna valutazione finora

- ENVI Trickling FiltersDocumento23 pagineENVI Trickling FiltersbaBy daBy AnNetTeNessuna valutazione finora

- Waste Water EngineeringDocumento65 pagineWaste Water EngineeringAjit DyahadrayNessuna valutazione finora

- Hospital Waste Water TreatmentDocumento5 pagineHospital Waste Water TreatmentNP100% (1)

- Ee IiDocumento10 pagineEe IiKrithikaVenkatNessuna valutazione finora

- Chapter 9 Primary SedimentationDocumento21 pagineChapter 9 Primary SedimentationAce ThunderNessuna valutazione finora

- Sewage Treatment PlantDocumento3 pagineSewage Treatment PlantPranshu Singh BirthalNessuna valutazione finora

- Chapter 1 Basic Design ConsiderationDocumento38 pagineChapter 1 Basic Design ConsiderationAce ThunderNessuna valutazione finora

- Bar Screen-Grit ChamberDocumento10 pagineBar Screen-Grit ChamberRaja ManiNessuna valutazione finora

- Assignment IV PDFDocumento4 pagineAssignment IV PDFAmit KushwahaNessuna valutazione finora

- Wastewater Treatment Plant Construction (Package E)Documento270 pagineWastewater Treatment Plant Construction (Package E)Glen GuxhoNessuna valutazione finora

- Calculation Maturation and Pond From Literature PDFDocumento7 pagineCalculation Maturation and Pond From Literature PDFanon_51960941Nessuna valutazione finora

- Membrane Bioreactor (MBR) Technology PPT - FERA MEILASARI - 21080122420021Documento14 pagineMembrane Bioreactor (MBR) Technology PPT - FERA MEILASARI - 21080122420021fera meilasariNessuna valutazione finora

- OM Extended Aeration PDFDocumento25 pagineOM Extended Aeration PDFHendra SusantoNessuna valutazione finora

- Surface Water Treatment Operations Plan TemplateDocumento8 pagineSurface Water Treatment Operations Plan TemplateSkid RowNessuna valutazione finora

- Unit II Plain SedimentationDocumento5 pagineUnit II Plain Sedimentationधीरज कुमारNessuna valutazione finora

- Ate Huber-1Documento47 pagineAte Huber-1Ravena RemaditaNessuna valutazione finora

- Yanbu WWTW Process Group PresentationDocumento52 pagineYanbu WWTW Process Group Presentationyxp2237Nessuna valutazione finora

- Wastewater Treatment Plants (WWTP) : General Flow Diagram For The Wastewater Treatment PlantDocumento12 pagineWastewater Treatment Plants (WWTP) : General Flow Diagram For The Wastewater Treatment PlantAhmed AmediNessuna valutazione finora

- BlaDocumento264 pagineBlaReymandha Aprilia Hutami100% (1)

- Treatment of Seafood Processing Wastewater Using A Moving Bed Biofilm Reactor (MBBR)Documento4 pagineTreatment of Seafood Processing Wastewater Using A Moving Bed Biofilm Reactor (MBBR)Dương Ánh100% (1)

- Design of A Sedimentation BasinDocumento8 pagineDesign of A Sedimentation BasinCOLLEN KGAODINessuna valutazione finora

- M13 - L17 Grit ChamberDocumento6 pagineM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- Sanitary Sewer Design and Modeling WorksDocumento117 pagineSanitary Sewer Design and Modeling WorksNassif Abi AbdallahNessuna valutazione finora

- 2015 CVL300 Tutorial 4 SolutionDocumento7 pagine2015 CVL300 Tutorial 4 SolutionAhmed Abuzour100% (2)

- CH 4 Sewage TreatmentDocumento134 pagineCH 4 Sewage TreatmentGetu BogaleNessuna valutazione finora

- EE-2 Mini Project ReportDocumento7 pagineEE-2 Mini Project Report63GANESH SINGHCIVILNessuna valutazione finora

- Boq 196423Documento87 pagineBoq 196423sanjaygkpNessuna valutazione finora

- Grit Chamber and Sedimentation TankDocumento45 pagineGrit Chamber and Sedimentation TankShantnu RanaNessuna valutazione finora

- SBR Asbr SBBRDocumento10 pagineSBR Asbr SBBRThanh LanNessuna valutazione finora

- Mini Project ReportDocumento5 pagineMini Project ReportSaj BhaiNessuna valutazione finora

- Water Supply EngineeringDocumento3 pagineWater Supply EngineeringSujan SinghNessuna valutazione finora

- 7 Inclined Plate Settler Clarification PDFDocumento63 pagine7 Inclined Plate Settler Clarification PDFSYifa ShuhaIli100% (1)

- 1 Introduction To Water Supply EngineeringDocumento18 pagine1 Introduction To Water Supply Engineeringenviron13Nessuna valutazione finora

- Building Services I: SanitationDocumento58 pagineBuilding Services I: SanitationMeghana B KNessuna valutazione finora

- Handling Dairy Milk House WastewaterDocumento31 pagineHandling Dairy Milk House WastewaterAndreea CalcanNessuna valutazione finora

- TC Owtu 502 PDFDocumento288 pagineTC Owtu 502 PDFRon100% (1)

- 1.85 Water and Wastewater Treatment Engineering Homework 8Documento1 pagina1.85 Water and Wastewater Treatment Engineering Homework 8MuhammadUsmanNessuna valutazione finora

- Secondary TreatmentDocumento14 pagineSecondary TreatmentNasirNessuna valutazione finora

- Manual On The Causes and Contril of Activated SludgeDocumento21 pagineManual On The Causes and Contril of Activated SludgeRiianti WidiiNessuna valutazione finora

- 03 Conventional Water TreatmentDocumento80 pagine03 Conventional Water Treatmentbksri1239561Nessuna valutazione finora

- ETP Plant ProposalDocumento12 pagineETP Plant ProposalRoshan KaluarachchiNessuna valutazione finora

- ETP PROCESS FLOW-ModelDocumento1 paginaETP PROCESS FLOW-ModelAshokNessuna valutazione finora

- Brochure 2020Documento4 pagineBrochure 2020AshokNessuna valutazione finora

- Mastering Candlestick Charts Part I PDFDocumento51 pagineMastering Candlestick Charts Part I PDFrandy100% (1)

- Guide Way Driving AsslyDocumento1 paginaGuide Way Driving AsslyAshokNessuna valutazione finora

- Activated Sludge Calculations With ExcelDocumento22 pagineActivated Sludge Calculations With ExcelKaustav Patnaik88% (8)

- 03 SBRDocumento1 pagina03 SBRAshokNessuna valutazione finora

- Elctorde MountingDocumento1 paginaElctorde MountingAshokNessuna valutazione finora

- Inlet ShaftDocumento1 paginaInlet ShaftAshokNessuna valutazione finora

- Sprocket Blank Diameter Calculator (Version 02 - 09/09/2008) Author: Douglas AndersonDocumento5 pagineSprocket Blank Diameter Calculator (Version 02 - 09/09/2008) Author: Douglas AndersonAshokNessuna valutazione finora

- Worksheet in Roller ChainDocumento5 pagineWorksheet in Roller ChainAshokNessuna valutazione finora

- 04Documento1 pagina04AshokNessuna valutazione finora

- Motor Selection GuideDocumento56 pagineMotor Selection GuideAshokNessuna valutazione finora

- Feeding PDFDocumento1 paginaFeeding PDFAshokNessuna valutazione finora

- Motor For ResonatorDocumento2 pagineMotor For ResonatorAshokNessuna valutazione finora

- LayoutDocumento1 paginaLayoutAshokNessuna valutazione finora

- Center To Center Chain Distance CalculationsDocumento4 pagineCenter To Center Chain Distance CalculationsAshokNessuna valutazione finora

- Power (P) = T X Ω Torque (T) =F X R FORCE (F) = M X a =M X9.81: Let Us Consider 7Hp Motor For ShaftDocumento3 paginePower (P) = T X Ω Torque (T) =F X R FORCE (F) = M X a =M X9.81: Let Us Consider 7Hp Motor For ShaftAshokNessuna valutazione finora

- Motor Selection GuideDocumento56 pagineMotor Selection GuideAshokNessuna valutazione finora

- Chapter 7 - Unplanted Drying Beds PDFDocumento14 pagineChapter 7 - Unplanted Drying Beds PDFAshokNessuna valutazione finora

- Spring Design: GD N PC yDocumento2 pagineSpring Design: GD N PC yAshokNessuna valutazione finora

- Serial NumberDocumento1 paginaSerial NumberFrancisco Sanchez RasgadoNessuna valutazione finora

- Plant LayoutDocumento1 paginaPlant LayoutAshokNessuna valutazione finora

- Catalog C v5 PDFDocumento80 pagineCatalog C v5 PDFAshokNessuna valutazione finora

- Autocad Plant3d Quick Reference GuideDocumento2 pagineAutocad Plant3d Quick Reference GuideHanna Obeid100% (1)

- Biogas HandbookDocumento126 pagineBiogas HandbookmoemuneeNessuna valutazione finora

- WR WQ Pub Design Criteria Ch12Documento23 pagineWR WQ Pub Design Criteria Ch12AshokNessuna valutazione finora

- BasicSewageGuide2002 5 PDFDocumento16 pagineBasicSewageGuide2002 5 PDFAshokNessuna valutazione finora

- Biogas Plant ConstructionDocumento27 pagineBiogas Plant ConstructionAnkit Anurag NaikNessuna valutazione finora

- Wrd-Ot-Clarifiers 445261 7Documento99 pagineWrd-Ot-Clarifiers 445261 7AshokNessuna valutazione finora

- Chapter Three - Sources of WaterDocumento75 pagineChapter Three - Sources of WaterBEZU A.GERESUNessuna valutazione finora

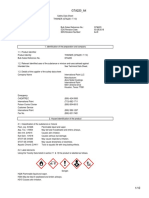

- Solar Panel Wash SDS NAM enDocumento6 pagineSolar Panel Wash SDS NAM enDr. Ghulam FareedNessuna valutazione finora

- Sea Transport of Liquid Chemicals in Bulk PDFDocumento131 pagineSea Transport of Liquid Chemicals in Bulk PDFDiana MoralesNessuna valutazione finora

- Horizontal Barriers For Controlling Water ConingDocumento8 pagineHorizontal Barriers For Controlling Water ConingBahman MatouriNessuna valutazione finora

- Clinical Chemistry 1 Basic PrinciplesDocumento2 pagineClinical Chemistry 1 Basic PrinciplesJorella Marisol MarquezNessuna valutazione finora

- ATAE Proceedings 2015 PDFDocumento884 pagineATAE Proceedings 2015 PDFSorica CristianNessuna valutazione finora

- Isol Job Reference 2008-2017 PDFDocumento9 pagineIsol Job Reference 2008-2017 PDFAbu Zafeera Saqib SipahiNessuna valutazione finora

- Bug Out Bag Essentials PDFDocumento26 pagineBug Out Bag Essentials PDFJonathan Rea100% (2)

- (F 1.0) DensetsuKemononoAnaDocumento57 pagine(F 1.0) DensetsuKemononoAnaJumper AnonNessuna valutazione finora

- Thinner Gta220Documento10 pagineThinner Gta220mohd zaim abd wahab100% (1)

- Position PaperDocumento2 paginePosition Paperapi-457379441Nessuna valutazione finora

- 500 MW Generator, Salient FeaturesDocumento10 pagine500 MW Generator, Salient FeaturesSandeep MishraNessuna valutazione finora

- Growing Plants On SandstoneDocumento4 pagineGrowing Plants On SandstoneAnon BoletusNessuna valutazione finora

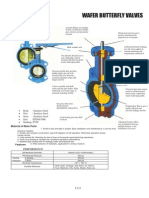

- Wafer Butterfly ValvesDocumento2 pagineWafer Butterfly ValvesSandi AslanNessuna valutazione finora

- Groundwater Exploration Using 1D and 2D Electrical Resistivity MethodsDocumento10 pagineGroundwater Exploration Using 1D and 2D Electrical Resistivity Methodsrizal montazeriNessuna valutazione finora

- 3212.1 - WC Flush Volume and Water Seal DepthDocumento4 pagine3212.1 - WC Flush Volume and Water Seal Depthsmupy.122Nessuna valutazione finora

- Aqua Regia Refining InstructionsDocumento3 pagineAqua Regia Refining Instructionsdives13Nessuna valutazione finora

- Tutor Marked Assignment Course Code: BEVAE-181 Assignment Code: BEVAE-181/TMA/2020-21Documento26 pagineTutor Marked Assignment Course Code: BEVAE-181 Assignment Code: BEVAE-181/TMA/2020-21IGNOU ASSIGNMENT100% (1)

- Eco-Friendly Technologies: A PresentationDocumento51 pagineEco-Friendly Technologies: A Presentationrupeshpanda92Nessuna valutazione finora

- Environment & Ecosystem Notes PDFDocumento26 pagineEnvironment & Ecosystem Notes PDFK 309 Divya ChaudharyNessuna valutazione finora

- EPA NOI (Notice of Intent) Vessel General Permit - Clean Water ActDocumento5 pagineEPA NOI (Notice of Intent) Vessel General Permit - Clean Water ActLakeMichiganFilesNessuna valutazione finora

- Kurunegala Summary Water Quality-FinalDocumento4 pagineKurunegala Summary Water Quality-FinalmimrusfanNessuna valutazione finora

- River NavigationDocumento7 pagineRiver NavigationKenneth MadroñalNessuna valutazione finora

- 330 PDFDocumento2 pagine330 PDFnicerizwanNessuna valutazione finora

- Envirn-Engg Iit KanpurDocumento6 pagineEnvirn-Engg Iit KanpurNbisht25Nessuna valutazione finora

- Initial Environmental Examination (Iee) Checklist For Small Scale Lime Extraction ProjectDocumento18 pagineInitial Environmental Examination (Iee) Checklist For Small Scale Lime Extraction ProjectavieNessuna valutazione finora

- MSDS Ammonium Hydroxide PDFDocumento1 paginaMSDS Ammonium Hydroxide PDFciscaNessuna valutazione finora

- Danfoss Non Return ValvesDocumento28 pagineDanfoss Non Return Valveskostaviga777Nessuna valutazione finora

- D3285Documento3 pagineD3285Anil Pandey0% (1)

- Ionic Bath Brochure2Documento1 paginaIonic Bath Brochure2cananianNessuna valutazione finora