Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CSG Study Trip Notes

Caricato da

Simon McCarthyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CSG Study Trip Notes

Caricato da

Simon McCarthyCopyright:

Formati disponibili

CSG Queensland Study Trip

Notes taken by David Koppers and Matthew

Date: Monday, 5 June and Tuesday, 6 June 2017

Todd-Jones

Project: Coal Seam Gas

Location: GLNG Project: Roma and Gladstone

Purpose: To inform Commissioners about coal seam gas extraction processes.

5 June 2017

Roma Gas Fields and surrounds

Attendees:

PAC Members:

Lynelle Briggs, Robyn Kruk, Roger Fisher, Andrew Hutton, Ross Carter

PAC Secretariat:

David McNamara, David Koppers and Matthew Todd-Jones

Santos:

Neale House Manager Environment and Water

Peter Mitchley General Manager East Coast Gas

Bruce Clement Vice President

Andrew Snars Maranoa Regional Manager

Carlee Miller Senior Adviser Community

Santos Presentation Roma Gas Fields

Santos has been operating in Roma for 50 years.

There have been few complaints about the project in recent years.

There is a culture of buying materials locally.

Water storage, reverse osmosis and salt crystalisation are part of the process in Roma.

Water then released is used for irrigation, stock watering, construction, dust suppression and there are

managed releases back into the environment.

The process of gas extraction and then fracking was explained.

30% of seams in the Roma LNG area are fracked, almost all are fracked in the Coopers Basin, South

Australia.

There are 2,650 production wells across 6,900 square kilometres of gas fields. This is roughly 3 times the

size of the Narrabri proposal.

Well pads are around 150 metres x 150 metres in size and are not generally constrained by space. The

larger the pad, the more cost effective it is as all infrastructure can be contained on the pad footprint.

The wells have an estimated gas output of approximately 2 terajoules per day, depending of the life cycle

of the well and operating efficiency at any given time.

There is monthly operational monitoring of the soil in areas used for treated water irrigation.

420 km high pressure gas transmission pipelines used to transport gas from the CSG fields to the LNG

processing and export facility at Gladstone.

There are 300 private landholders across the Roma Gas Fields project site.

Workers either travel locally to work or stay at the camps where a usual rotation is 2 weeks on and 2

weeks off.

Santos Presentation Narrabri Gas Project compared to Roma Gas Project

Every CSG project site is different due to varying geological compositions.

The Narrabri project is much smaller than the Roma operations in all aspects, the Roma project is roughly

3 times bigger than the Narrabri project.

Outlined the history of the process of seeking to develop facilities in the NSW Pilliga region.

Coal seams in Narrabri are already naturally fractured and fracking is not expected to be required.

NSW currently imports 95% of gas. The Narrabri project could supply up to 50% of NSWs demand,

equating to 200 terajoules per day.

There will be no exportation of Narrabri gas, as it will be for the NSW domestic market only.

The operational area for the Narrabri project accounts for only 1,000 hectares or approximately 1% of the

total 95,000 ha project area.

The sites are not located in a National Park, nature reserve or on BSAL land.

The footprint of the gas well pads will be approximately 100m x 100m (on average).

There have been no cases in the United States or Australia where fracking for coal seam gas has

contaminated an aquifer.

There is a fracking inquiry in the Northern Territory in which Santos is participating.

As the Narrabri gas is for domestic use, a pipeline is proposed to be built southwards to connect with the

Moomba-Sydney supply (subject to a separate approvals process), rather than north to Gladstone for

export.

At this point in time Santos understands that not all NSW Government agencies consulted during the

exhibition period have formally provided their response to the Department. It is challenging getting

departments or agencies to discuss issues directly with Santos.

With coal seam gas they will be looking at a 12-13% return on investment whereas conventional gas is

usually more like 25%.

Santos would like to see quantifiable/prescriptive conditions as opposed to subjective style conditions.

They contend the nature of the conditions can influence the level of investment they receive, e.g. Field

Development Protocol if this had to be revisited every 3-5 years then investors wouldnt take the risk.

They described this as a type of sovereign risk for their business if they have to revisit issues every so

often.

There are still appraisals to undertake for various issues, which are outlined in the EIS.

By the end of 25 years they would hope to have drilled less than 850 wells as it is more economical.

Any flare burn is controlled and the flame cant be taken by the wind to affect its surroundings.

The Narrabri project will have reverse osmosis and crystallisation processes onsite before water is capable

of being used for irrigation, stock watering, construction, dust suppression and managed releases to

watercourses.

The maximum output of water through the Reverse Osmosis process will be 10 megalitres per day.

There will be a brine dam and Santos are currently looking to see what they can do with excess salt which

may be as much as 48 tonnes per day at peak production.

The location of wells can change as more are sunk. You learn more about the seam and where the more

accessible gas resides and that influences future direction / location of specific wells. This is why they are

seeking flexibility in the well pad locations and the preference for the post approval field development

protocol to allow for adjustments and monitor impacts against agreed upper limits.

The degree of flexibility being sought slightly greater than what is common place for micro-siting in

relation to wind turbines.

6 June 2017

Curtis Island LNG Plant visit, Gladstone

Attendees:

PAC Members:

Lynelle Briggs, Robyn Kruk, Roger Fisher, Andrew Hutton, Ross Carter

PAC Secretariat:

David McNamara, David Koppers and Matthew Todd-Jones

Santos:

Neale House Manager Environment and Water

Bruce Clement Vice President

Gas is transferred to Santos LNG facility at Gladstone where it is cleaned and cooled down in three stages

to -160 degrees where it liquefies, which is a far more efficient form for export as the gas reduces

significantly in volume when it liquefies.

There are 3 LNG plants on the island, with one run by Santos.

There are 140,000 cubic metres of gas in each of the 2 LNG storage tanks.

Footprint of Santos LNG facility takes up 5% of the island and employs 100-120 operational staff.

It takes around 12-15 hours to load a ship, with 8-10,000 cubic metres loaded per hour.

The plant was in shutdown mode for a maintenance and warranty check at time of inspection.

The gasfield, pipeline and LNG facilities were all packaged under one main approval from the Queensland

government.

The LNG plant is currently not operating at full capacity due to the lack of gas supply.

Tour of Gladstone and surrounds (PAC only)

The Commission toured around a range of other infrastructure sites in the immediate vicinity of Gladstone

Coal loading facilities in the harbour

Alumina plants Bauxite transported in from Weipa to a washery west of town and then conveyor and

shipping transfer to the Parsons Point alumina plant on the eastern side of Gladstone for processing.

Alumina then transferred by conveyor south to the Boyne island aluminium production plant.

Gladstone Power station was originally built in the 60s/70s to provide power supply to the alumina &

aluminium plants which at the time were drawing up to 11% of the State energy. It is an old technology

coal-fired station.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- PUBLIC - CEF NSW Eraring Report - 28 March 2024Documento24 paginePUBLIC - CEF NSW Eraring Report - 28 March 2024Simon McCarthyNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 2 Submission BoidiversityAssessment Report SlidesDocumento10 pagine2 Submission BoidiversityAssessment Report SlidesSimon McCarthy100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hunter Transmission ProjectDocumento1 paginaHunter Transmission ProjectSimon McCarthyNessuna valutazione finora

- Statement of Mark Kentwell 29 March 2023Documento1 paginaStatement of Mark Kentwell 29 March 2023Simon McCarthyNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Statement of Mark Kentwell 29.03.2023 (Website)Documento3 pagineStatement of Mark Kentwell 29.03.2023 (Website)Simon McCarthyNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- FINAL Hunter Hydrogen Infrastructure Masterplan Jan24Documento65 pagineFINAL Hunter Hydrogen Infrastructure Masterplan Jan24Simon McCarthyNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- BZE 2023 - Battery Supply Chain Briefing PaperDocumento44 pagineBZE 2023 - Battery Supply Chain Briefing PaperSimon McCarthyNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Teacher's Federation: Gallop Inquiry Fact SheetDocumento2 pagineTeacher's Federation: Gallop Inquiry Fact SheetSimon McCarthyNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- FOI - Notice of Decision (002) DISERDocumento6 pagineFOI - Notice of Decision (002) DISERSimon McCarthyNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- NSW Hydrogen StrategyDocumento64 pagineNSW Hydrogen StrategySimon McCarthyNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hunter Power Project - EIS - Main ReportDocumento358 pagineHunter Power Project - EIS - Main ReportSimon McCarthyNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

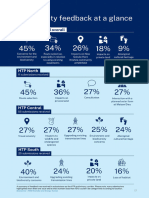

- LHWSP Public Exhibition Engagement SummaryDocumento2 pagineLHWSP Public Exhibition Engagement SummarySimon McCarthyNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Natural Resources Access Regulator V Maules Creek Coal Pty LTD (2021) NSWLEC 135Documento118 pagineNatural Resources Access Regulator V Maules Creek Coal Pty LTD (2021) NSWLEC 135Simon McCarthyNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Statement From Infrabuild WireDocumento1 paginaStatement From Infrabuild WireSimon McCarthyNessuna valutazione finora

- Gloucester Water Security Fact Sheet May 2020Documento1 paginaGloucester Water Security Fact Sheet May 2020Simon McCarthyNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- M1 Pacific Motorway Extension To Raymond TerraceDocumento4 pagineM1 Pacific Motorway Extension To Raymond TerraceSimon McCarthyNessuna valutazione finora

- Hunter Water - LHWSP Engagement Summary - 2019 To October 2020Documento1 paginaHunter Water - LHWSP Engagement Summary - 2019 To October 2020Simon McCarthyNessuna valutazione finora

- Letter To CN - Former Waratah GasworksDocumento5 pagineLetter To CN - Former Waratah GasworksSimon McCarthyNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Organics Processing Facility - Business Model ROIDocumento4 pagineOrganics Processing Facility - Business Model ROISimon McCarthyNessuna valutazione finora

- PM CorrespondenceDocumento3 paginePM CorrespondenceSimon McCarthyNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- AGL Newcastle Power StationDocumento12 pagineAGL Newcastle Power StationSimon McCarthyNessuna valutazione finora

- Tender - Organics Processing FacilityDocumento20 pagineTender - Organics Processing FacilitySimon McCarthyNessuna valutazione finora

- PFA LetterDocumento1 paginaPFA LetterSimon McCarthyNessuna valutazione finora

- The Importance of Venture Capital: Irina Anghel-EnescuDocumento7 pagineThe Importance of Venture Capital: Irina Anghel-EnescuEwan afiqNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Case Notes - Topic 7Documento2 pagineCase Notes - Topic 7meiling_1993Nessuna valutazione finora

- ACC108 Lecture 2 3Documento32 pagineACC108 Lecture 2 3Shivati Singh KahlonNessuna valutazione finora

- Issuances On Archax FlyerDocumento3 pagineIssuances On Archax FlyerWalid El AmineNessuna valutazione finora

- Manual of Economic Analysis of Chemical ProcessesDocumento478 pagineManual of Economic Analysis of Chemical Processesachmaddach100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Unit 5 - 08 - Financial Ratios FinalDocumento57 pagineUnit 5 - 08 - Financial Ratios Finalbabitjha664Nessuna valutazione finora

- Management Accounting ServicesDocumento16 pagineManagement Accounting ServicesDaniel RaeNessuna valutazione finora

- Failure of C.K. TangDocumento5 pagineFailure of C.K. Tangsophisticated_fahadNessuna valutazione finora

- Project Report - Project FinanceDocumento10 pagineProject Report - Project Financeanon_266246835Nessuna valutazione finora

- General Management Project On Bank of BarodaDocumento44 pagineGeneral Management Project On Bank of BarodaVaishaliNessuna valutazione finora

- Living Off The Grid Volume11 BookDocumento91 pagineLiving Off The Grid Volume11 BookAmanda Jones100% (1)

- Capital & RevenueDocumento7 pagineCapital & RevenueDr Sarbesh Mishra50% (2)

- Theories ExerciseDocumento1 paginaTheories ExerciseZeneah MangaliagNessuna valutazione finora

- Business Plan Template InteractiveDocumento18 pagineBusiness Plan Template InteractiveAlex GranderNessuna valutazione finora

- TrustsDocumento94 pagineTrustsChad Au100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- FgregDocumento1 paginaFgregHanu BiradarNessuna valutazione finora

- Appointment LetterDocumento4 pagineAppointment LetterLance AunzoNessuna valutazione finora

- Business Plan TemplateDocumento19 pagineBusiness Plan TemplatebiffinNessuna valutazione finora

- Corporation Law ReviewerDocumento14 pagineCorporation Law ReviewerYANG FLNessuna valutazione finora

- Report On The Study Case Analysis: "Blackberry Between Change and Forward "Documento9 pagineReport On The Study Case Analysis: "Blackberry Between Change and Forward "andreea143100% (2)

- Financial Statement Analysis of GrameenphoneDocumento15 pagineFinancial Statement Analysis of Grameenphonezicobaby100% (3)

- Pramod Final RepotDocumento80 paginePramod Final Repotbinupandey2020Nessuna valutazione finora

- SIP Project ReportDocumento62 pagineSIP Project ReportNiharika MathurNessuna valutazione finora

- Sample Business Plan 1 2021 2022Documento23 pagineSample Business Plan 1 2021 2022Claudio MatarazzoNessuna valutazione finora

- Functions of Central Bank Final PresentationDocumento27 pagineFunctions of Central Bank Final PresentationZayed Mohammad JohnyNessuna valutazione finora

- Bank President in Houston Austin TX Resume Lynn KraussDocumento4 pagineBank President in Houston Austin TX Resume Lynn KraussLynnKraussNessuna valutazione finora

- Chap 7 Feasibility StudyDocumento25 pagineChap 7 Feasibility Studymeenac_4100% (1)

- Metincan Duruel IE 399Documento15 pagineMetincan Duruel IE 399Ekin GulumNessuna valutazione finora

- Recent Trend of Bancassurance in IndiaDocumento8 pagineRecent Trend of Bancassurance in IndiaAshu Amit BhatiaNessuna valutazione finora

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDa EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItDa EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItValutazione: 4 su 5 stelle4/5 (25)