Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vishay Soldering Film Capacitors

Caricato da

Benjamin DoverCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vishay Soldering Film Capacitors

Caricato da

Benjamin DoverCopyright:

Formati disponibili

V I S H AY I N T E R T E C H N O L O G Y, I N C .

www.vishay.com

Film Capacitors Application Note

Soldering Guidelines for Film Capacitors

Vishay recommends that users observe the following guidelines for soldering our film capacitors. Adherence to these

recommendations will help to safeguard product specifications and reliability while preventing damage to the capacitors during

soldering.

SOLDERING GUIDELINES AND RECOMMENDED WAVE SOLDERING PROFILE

With regard to the resistance to soldering heat and the solderability, our products comply with IEC 60384-1 and the additional

type specifications.

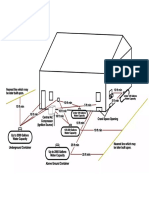

The recommended wave soldering profile for our leaded components is defined as follows:

Temperature (C)

Total contact time < 5 s

260 Maximum solder temperature

tp

Tp

Tpreheat Tp - 5 C

Tmax.

t

Tcomponent (body)

Tsolder profile

Preheating

0 < 150 Time (s)

APPLICATION NOTE

Tp: Peak temperature of the component body (top)

Tmax.: Maximum application temperature of the component

Temperature of the component body (top)

Revision: 04-Aug-15 1 Document Number: 28171

For technical questions, contact: dc-film@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Application Note

www.vishay.com

Vishay

Soldering Guidelines for Film Capacitors

The PSL (Process Sensitivity Level) is classified according JEDEC standard J-STD-075 Classification of Non-IC Electronic

Components for Assembly Processes and summarized in following tables per product family and pitch size of the component:

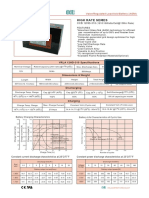

RADIAL POLYESTER TYPES

PRODUCT PITCH SIZE

FAMILY

5 mm 7.5 mm 10 mm 15 mm 22.5 mm 27.5 mm 37.5 mm 52.5 mm

MKT 303 W4C (1)(3) W4C (1)(3)

MKT 365 W4Y (2)(4)) W4Y (2)(4)

MKT 366 W4Y (2)(4) W4Y (2)(4)

MKT 367 W4Y (2)(4) W4Y (2)(4)

MKT 368 W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3)

MKT 369 W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3)

MKT 370 W4Y (2)(4)

MKT 371 W4Y (2)(4)

MKT 372 W4C (1)(3)

MKT 373/MKT 373M W4C (1)(3) W4C (1)(3) W4C (1)(3)

MKT 468 W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3)

MKT 470 W4Y (2)(4)

MKT 1817 W4Y (2)(4)

MKT 1818 W4Y (2)(4)

MKT 1820 W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3)

MKT 1822 W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3)

MKT 1710 W4C (1)(3) W4C (1)(3)

MKT 1772 W4C (1)(3) W4C (1)(3) W4C (1)(3) W4C (1)(3)

Notes

(1) No risk

(2) Risk for parameter change if PSL is not strictly followed

(3) C: The component has a preheat limitation of 150 C

(4) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 125 C

During soldering: Tp 135 C, tp 30 s, t 50 s

APPLICATION NOTE

Revision: 04-Aug-15 2 Document Number: 28171

For technical questions, contact: dc-film@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Application Note

www.vishay.com

Vishay

Soldering Guidelines for Film Capacitors

RADIAL POLYPROPYLENE TYPES

PRODUCT PITCH SIZE

FAMILY

5 mm 7.5 mm 10 mm 15 mm 22.5 mm 27.5 mm 37.5 mm 52.5 mm

MKP 375 W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 376 W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 378 W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 379 W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 380 W4Y (3)(4)

MMKP 383 W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 385 W4Y (2)(5) W4C (1)(6)

MKP 416/MKP 417/MKP 418/

W4Y (3)(4) W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 419/MKP 420

MKP 422 W4Y (3)(4)

MKP 336 1 W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 336 2 W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 336 6 W4Y (2)(5) W4C (1)(6)

MKP 338 1 W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 338 2 W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 338 4 W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 338 6 W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 339 W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 339M W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 339T W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 479 W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 1778 W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6) W4C (1)

KP1830 W4Y (3)(4)

MKP 1840/MKP 1840M W4Y (3)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 1841/MKP 1841M W4Y (2)(4) W4Y (2)(5) W4Y (2)(5) W4C (1)(6) W4C (1)(6) W4C (1)(6) W4C (1)(6)

MKP 1848 W4C (1)(6) W4C (1)(6) W4C (1)(6)

Notes

(1) No risk

(2)

APPLICATION NOTE

Risk for parameter change if PSL is not strictly followed

(3) Risk for product damage if PSL is not strictly followed

(4) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 100 C

During soldering: Tp 110 C, tp 20 s, t 30 s

(5) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 110 C

During soldering: Tp 120 C, tp 20 s, t 30 s

(6) C: The component has a preheat limitation of 150 C

Revision: 04-Aug-15 3 Document Number: 28171

For technical questions, contact: dc-film@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Application Note

www.vishay.com

Vishay

Soldering Guidelines for Film Capacitors

AXIAL POLYESTER TYPES

PRODUCT BODY LENGTH

FAMILY

11 mm 14 mm 19 mm 26.5 mm 31.5 mm 41.5 mm

MKT 1813 W4Y (3)(5) W4Y (3)(5) W4C (2)(4) W4C (1)(4) W4C (1)(4) W4C (1)(4)

F1773 W4C (2)(4) W4C (1)(4) W4C (1)(4) W4C (1)(4)

Notes

(1) No risk

(2) Risk for parameter change if PSL is not strictly followed

(3) Risk for product damage if PSL is not strictly followed

(4) C: The component has a preheat limitation of 150 C

(5) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 125 C

During soldering: Tp 135 C, tp 30 s, t 50 s

AXIAL POLYPROPYLENE TYPES

PRODUCT BODY LENGTH

FAMILY

11 mm 14 (17) mm 19 (22) mm 26.5 (29) mm 31.5 (34) mm 41.5 (44) mm

MKP 1839 / MKP 1839 HQ W4Y (3)(4) W4Y (3)(4) W4Y (3)(5) W4Y (2)(5) W4Y (1)(5) W4Y (1)(5)

MKP 1845 W4Y (3)(4) W4Y (3)(5) W4Y (2)(5) W4Y (1)(5) W4Y (1)(5)

Notes

(1) No risk

(2) Risk for parameter change if PSL is not strictly followed

(3) Risk for product damage if PSL is not strictly followed

(4) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 100 C

During soldering: Tp 110 C, tp 20 s, t 30 s

(5) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 110 C

During soldering: Tp 120 C, tp 20 s, t 30 s

WARNINGS

Excessive soldering heat (preheating or soldering above the recommended limits) can result in product damage and

malfunctioning and should be thus strictly avoided. If PSL limits have been exceeded at any point in time during the soldering

process, the products could possibly show a change in certain parameters (e.g. capacitance value, tan , insulation resistance,

breakdown level, etc.) Exceeding PSL limits can even result in destruction of the product. Warning signs include a bulged or

deformed product encapsulation. Such an appearance may also be the result of other causes, such as interruptions, cooling

malfunctioning of the soldering machine, etc.

Axial components can better protected from direct heat conducted by the PCB, when a distance is kept from the product to

the PCB as follows:

APPLICATION NOTE

Revision: 04-Aug-15 4 Document Number: 28171

For technical questions, contact: dc-film@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Application Note

www.vishay.com

Vishay

Soldering Guidelines for Film Capacitors

TRIMMER CAPACITORS

PRODUCT BODY LENGTH

FAMILY

ALL SIZES

808 / 809 W4Y (3)(4)

Notes

(1) No risk

(2) Risk for parameter change if PSL is not strictly followed

(3) Risk for product damage if PSL is not strictly followed

(4) Y: Temperature is measured at the body top and must be kept as follows:

During preheating: Tmax. 85 C

During soldering: Tp 100 C, tp 20 s, t 30 s

Due to the sensitivity of these electromechanical components, it is critical to solder these components in a wave soldering

method. We recommend to use manual soldering, see below.

SOLDERING CONDITIONS FOR MANUAL SOLDERING

1. Use a soldering iron with sufficient wattage and a regulated temperature. The adequacy of the soldering iron can be judged

by the amount of time needed to reflow the solder. Beginning at 650 F (343 C), adjust the temperature so that the solder

reflows within 1.5 s to 3 s.

- If the solder reflow occurs in less than 1 s to 1.5 s, this indicates that the tip temperature is excessive.

- If more than 3 s to 3.5 s are needed for solder reflow, either the tip temperature is insufficient or the tip is cooling down

when applied to the circuit board.

2. Apply a small amount of flux to the component termination and the pad layout.

3. After tinning the iron, place the iron tip on the circuit pad at the edge furthest from the component. The soldering should be

completed in 1.5 s to 3 s. If it is necessary to keep the iron on longer than 3 s, replace the component with a fresh device.

4. Add the solder at the solder tip to ensure that it flows from the pad to the termination of the component. Be careful not to

add too much solder. The minimum is the best.

5. Never touch the component being worked on or any adjacent components with the soldering iron.

APPLICATION NOTE

Revision: 04-Aug-15 5 Document Number: 28171

For technical questions, contact: dc-film@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Determination of Emf by Compensation MethodDocumento8 pagineDetermination of Emf by Compensation MethodalyNessuna valutazione finora

- Cable Schedule TemplateDocumento1 paginaCable Schedule TemplatevarunNessuna valutazione finora

- TV Rptrs RPTR 118Documento10 pagineTV Rptrs RPTR 118Benjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 122Documento10 pagineTV Rptrs RPTR 122Benjamin DoverNessuna valutazione finora

- Battleship IOWA EventDocumento1 paginaBattleship IOWA EventBenjamin DoverNessuna valutazione finora

- Merci Train Box CarsDocumento2 pagineMerci Train Box CarsBenjamin DoverNessuna valutazione finora

- Bogen Amplifier - Gs-SeriesDocumento20 pagineBogen Amplifier - Gs-SeriesBenjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 135Documento11 pagineTV Rptrs RPTR 135Benjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 120revDocumento12 pagineTV Rptrs RPTR 120revBenjamin DoverNessuna valutazione finora

- Nature Power 110 Watt Solar Panel KitDocumento10 pagineNature Power 110 Watt Solar Panel KitBenjamin DoverNessuna valutazione finora

- Radio Shack Pro-2040Documento44 pagineRadio Shack Pro-2040Benjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 121 1Documento12 pagineTV Rptrs RPTR 121 1Benjamin DoverNessuna valutazione finora

- ZyXEL - NAS326 - 6Documento6 pagineZyXEL - NAS326 - 6Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-109Documento9 pagineBoulder Amateur TV Repeater's Newsletter-109Benjamin DoverNessuna valutazione finora

- Rca Remote Rcr412s - OmDocumento21 pagineRca Remote Rcr412s - OmBenjamin DoverNessuna valutazione finora

- Camera Lens Sizes, Mounts & AdaptersDocumento11 pagineCamera Lens Sizes, Mounts & AdaptersBenjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-112Documento13 pagineBoulder Amateur TV Repeater's Newsletter-112Benjamin DoverNessuna valutazione finora

- ZyXEL - NAS326 - V5.21 - Ed4Documento341 pagineZyXEL - NAS326 - V5.21 - Ed4Benjamin DoverNessuna valutazione finora

- HR9670 Amateur Radio Emergency Preparedness ActDocumento14 pagineHR9670 Amateur Radio Emergency Preparedness ActBenjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-111revDocumento9 pagineBoulder Amateur TV Repeater's Newsletter-111revBenjamin DoverNessuna valutazione finora

- Hoshizaki IM-500SAA Icemaker Service ManualDocumento39 pagineHoshizaki IM-500SAA Icemaker Service ManualBenjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-107Documento11 pagineBoulder Amateur TV Repeater's Newsletter-107Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-108Documento9 pagineBoulder Amateur TV Repeater's Newsletter-108Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-110Documento11 pagineBoulder Amateur TV Repeater's Newsletter-110Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-105Documento10 pagineBoulder Amateur TV Repeater's Newsletter-105Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-106-2Documento13 pagineBoulder Amateur TV Repeater's Newsletter-106-2Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-101Documento12 pagineBoulder Amateur TV Repeater's Newsletter-101Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-104Documento14 pagineBoulder Amateur TV Repeater's Newsletter-104Benjamin DoverNessuna valutazione finora

- Propane Tank Location GuideDocumento1 paginaPropane Tank Location GuideBenjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-98Documento11 pagineBoulder Amateur TV Repeater's Newsletter-98Benjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 113Documento11 pagineTV Rptrs RPTR 113Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-99Documento11 pagineBoulder Amateur TV Repeater's Newsletter-99Benjamin DoverNessuna valutazione finora

- LG OLED TV Owner's Manual For OLED CX ModelsDocumento33 pagineLG OLED TV Owner's Manual For OLED CX ModelsTom KakanowskiNessuna valutazione finora

- 3DOF Ball On Plate Using Closed Loop Stepper MotorDocumento14 pagine3DOF Ball On Plate Using Closed Loop Stepper Motorlongcasey90Nessuna valutazione finora

- Fig. 4.1: Different TransistorsDocumento10 pagineFig. 4.1: Different Transistorsmsicoie1851Nessuna valutazione finora

- Pasolink V4 v1.3 PDFDocumento108 paginePasolink V4 v1.3 PDFDragan Stanic100% (2)

- System Components Installation Instructions: NotesDocumento2 pagineSystem Components Installation Instructions: NotesBeto LexNessuna valutazione finora

- Monsoon Preparedness: 2.1. General PrecautionsDocumento6 pagineMonsoon Preparedness: 2.1. General PrecautionsArsh Alam100% (1)

- Boca Semiconductor Corp. BSC: Continental Device India LimitedDocumento3 pagineBoca Semiconductor Corp. BSC: Continental Device India LimitedNadia Ayelen GonzalezNessuna valutazione finora

- Ellight Catalog 2019 - FNL - LR - 22619 - UpdateDocumento72 pagineEllight Catalog 2019 - FNL - LR - 22619 - UpdateYudha SetiawanNessuna valutazione finora

- Ft0107ma PDFDocumento4 pagineFt0107ma PDFAnatoly WolkoffNessuna valutazione finora

- Best Control ManualDocumento16 pagineBest Control ManualVictor BecerraNessuna valutazione finora

- EPT - MICCROPROJECT - PRAPOSAL - 1321 - TO - 1325 FinalDocumento12 pagineEPT - MICCROPROJECT - PRAPOSAL - 1321 - TO - 1325 FinalPrasad KumbharNessuna valutazione finora

- AERMEC PAC System CatalogueDocumento5 pagineAERMEC PAC System CatalogueSaiful Islam SagorNessuna valutazione finora

- 651R PF00295Documento12 pagine651R PF00295intrudentalertNessuna valutazione finora

- EmtDocumento115 pagineEmtRaj SharmaNessuna valutazione finora

- Basic Op-Amp CircuitsDocumento58 pagineBasic Op-Amp CircuitsNuman khanNessuna valutazione finora

- Instruction Manual: DT-311A & DT-315A StroboscopeDocumento4 pagineInstruction Manual: DT-311A & DT-315A StroboscopeAlejandro DallosNessuna valutazione finora

- Password Based Circuit BreakerDocumento4 paginePassword Based Circuit Breakersulthan_81100% (1)

- FX2N-2LC - User's Manual JY992D85801-D (03.07)Documento100 pagineFX2N-2LC - User's Manual JY992D85801-D (03.07)Ani SerNessuna valutazione finora

- Slides 1, Power Electronics Circuits Devices and Applications 3ed Ed M H RashidDocumento43 pagineSlides 1, Power Electronics Circuits Devices and Applications 3ed Ed M H Rashidjohnyrock07100% (2)

- Ni 9208Documento24 pagineNi 9208Ricardo MayoralNessuna valutazione finora

- High Rate Series: CCB 12HD-310Documento1 paginaHigh Rate Series: CCB 12HD-310orunmila123Nessuna valutazione finora

- Ps 11034Documento5 paginePs 11034Tanvon MalikNessuna valutazione finora

- Puolop-Pt4435 C351420Documento3 paginePuolop-Pt4435 C351420Hyppo BolangiNessuna valutazione finora

- Yas 106 - Ats 1060Documento30 pagineYas 106 - Ats 1060廖智辉Nessuna valutazione finora

- GLX, Catalogue 2004 - 09Documento4 pagineGLX, Catalogue 2004 - 09victorNessuna valutazione finora

- Actulux Manual SV 24V 48V Control PanelDocumento11 pagineActulux Manual SV 24V 48V Control Panel123vb123Nessuna valutazione finora

- Toshiba TV 20AF45 - 20AF45C - SVM PDFDocumento50 pagineToshiba TV 20AF45 - 20AF45C - SVM PDFcarlos avilaNessuna valutazione finora

- MV, LV, Control & Bare (Specification)Documento13 pagineMV, LV, Control & Bare (Specification)- Docs Tài liệuNessuna valutazione finora