Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CFSEI Tech Note X Bracing L001-09

Caricato da

Jane EyreCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CFSEI Tech Note X Bracing L001-09

Caricato da

Jane EyreCopyright:

Formati disponibili

TECHNICAL NOTE

$5.00

On Cold-Formed Steel Construction

1201 15th Street, NW, Suite 320 W ashington, DC 20005 (202) 785-2022

Design of Diagonal Strap Bracing Lateral

Force Resisting Systems for the 2006 IBC

Summary: This Technical Note is intended to discuss some of the design requirements, detailing and practical

limitations of diagonal strap bracing design. Diagonal flat strap bracing is a commonly used type of lateral force

resisting system in residential and low rise commercial cold-formed steel applications.

Disclaimer: Designs cited herein are not intended to preclude the use of other materials, assemblies, structures or

designs when these other designs and materials demonstrate equivalent performance for the intended use; CFSEI

documents are not intended to exclude the use and implementation of any other design or construction technique.

INTRODUCTION

Structures require a resisting system to transfer lateral Addendum). In the AISI Standard for Cold-Formed

loads imposed on them. Typically these loads are from Steel Framing - Lateral Design (Lateral-04) the design

wind or seismic forces. A commonly used type of of diagonal strap bracing is to be done in accordance

lateral force resisting system in residential and low to the provisions of NAS-01.

rise commercial cold-formed steel applications is

diagonal flat strap bracing. When designing this type

of force resisting system there are a number of design

and serviceability considerations that should be

TYPES OF DIAGONAL STRAP BRACING

investigated. These include loads, strap size, fastener

quantity, connection detailing, and construction Diagonal strap bracing can be detailed in a variety of

practices. different styles. Commonly diagonal strap bracing is

used on the outside flange of perimeter load bearing

studs (Figure 1). Another option is to use double sided

GENERAL BRACING REQUIREMENTS diagonal strap bracing where there are straps on both

the inside and outside flange of the studs. With either

of these styles the strap may either be a wide strap

The International Building Code (IBC) and the connecting directly to the stud and track (Figure 2), or

Uniform Building Code (UBC) contain limited a narrower strap where a gusset plate is used to make

information on requirements for designing diagonal the connection between the strap and the stud and track

strap bracing lateral force resisting systems. The (Figure 3).

designer is required to design diagonal straps and

their connections in accordance with the design Wide straps that connect directly to the stud and track

standard referenced in the model code. The 2006 IBC may be preferred over straps with gusset plates for a

references the North American Specification for the couple of reasons. First the gusset plates and

Design of Cold-formed Steel Structural Members associated fasteners add thickness to the wall which

(AISI NAS-01), including 2004 Supplement (AISI may be difficult to conceal with siding or exterior finish.

NASPEC-SUP04) and the 1997 UBC references the Second, wider straps connecting directly to the stud

AISI Specification for Design of Cold-Formed Steel and track will ultimately require fewer fasteners which

Structural Members, 1986 (with December 1989 will reduce installation time.

Cold-Formed Steel Engineers Institute 1 TECH NOTE L001-09 September 2009

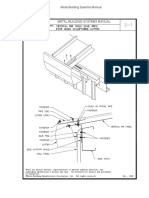

FIGURE 1

FIGURE 2

TECH NOTE L001-09 September 2009 2 Cold-Formed Steel Engineers Institute

FIGURE 3

DESIGN CONSIDERATIONS in a compression area of the track, compressive axial capacity

should be investigated. To resolve this anchor bolts may be

When designing diagonal strap bracing there are a number placed in a tension area of the bottom track, or outside of the

of items to be investigated which are influenced by the type brace. Naturally this becomes an issue if the brace is located

and geometry of the diagonal strap bracing. The provisions at a corner or end of a wall segment. Regardless of the

of the NAS-01 can be used to design these elements. anchor bolt location, bolt bearing on the web of the track

and shear transfer shall be checked.

The width of the brace will be primarily dependent on two things.

First, it must be properly sized to resist the imposed tensile forces in During construction it is important that the strap is installed

the member. Second, if it is not desirable to use a gusset plate at taut. This is contained in section C5.5 of the AISI Standard

each end of the strap a wider strap may be required to allow the strap for Cold-Formed Steel Framing - Lateral Design, 2004

to connect to both the stud and track. Edition. A taut strap will ensure that the strapping

immediately engages when a lateral load is applied. Section

Connections and members must also be adequately sized to 2211.4.6 of the 2003 IBC suggests pre-tensioning as a means

transfer loads. Where the studs are load bearing the effects to guard against loose straps. It is important, however, to

of gravity loads in resisting and adding to overturning loads ensure the strap is not overly pre-tensioned. Doing so can

must be considered. Other potential design checks include potentially reduce the load carrying capacity of the strap.

induced eccentricity in the wall from a single sided strap,

material over strength, and axial capacity of the chord studs. The IBC uses response modification factors, or R-Factors,

Finally, it will be necessary to properly design overturning to provide an appropriate level of strength design load

restraints (holdowns), collectors and boundary elements. These based on the type of lateral system. The IBC and ASCE 7

items are not included in the scope of this Technical Note. assign an R-Factor of 4 to ordinary steel concentrically

braced frames. It should be recognized that there is a

It should be noted that because diagonal strap braces are great deal of research available regarding the code

tension only members the bottom track may be in compression assigned R-Factors and it may be beneficial to investigate

between the diagonal strap and in tension outside of the this before using strap diagonal strap bracing, particularly

brace. Often an anchor bolt is used to transfer shear loads in high seismic areas. This research is briefly discussed

from the bottom track to the foundation. If anchor bolts are later.

Cold-Formed Steel Engineers Institute 3 TECH NOTE L001-09 September 2009

The 2004 North American Standard for Cold-Formed Steel

Framing - Lateral Design discusses the use of diagonal

strap bracing and contains additional specific requirements

for use in seismic areas. These special seismic requirements

are contained in section C5 of the document and are included

to ensure properly controlled ductility in the system.

Specifically, the document gives additional requirements for

connections, straps, studs and boundary members.

EXISTING RESEARCH

The Shear Wall Design Guide published by the Steel Framing is a no rational basis for the establishment of these values.

Alliance in 1998 (Publication RG-9804) included diagonal As was stated in FEMA 303, section 5.2 the R values,

strap bracing as one of the lateral systems investigated. contained in the current Provisions, are largely based on

This document highlights two important issues the engineering judgment of the performance of the various

designer must consider. materials and systems in past earthquakes. The values of

R must be chosen and used with careful judgment.

1. Straps are often constructed with material

having yield strength higher than specified; therefore it Wilcoski also points out that when straps yield during a

is important to consider this in the design of the end cyclic event the slack developed will influence the

connection. Ideally, to ensure ductile behavior the response of the system. As the system cycles between

controlling design value should be the capacity of the each tension strap it is not providing any resistance until

strap. An over-strength strap will naturally be capable of a strap become taut again. The acceleration developed in

transferring higher loads before reaching its yield point. the system during the slack time will cause shock loading

This may result in a less ductile failure mode if the end of the members and connections. During cyclic testing

connections are not sufficiently sized. this is represented as a pinched hysteretic envelope.

2. Diagonal strap bracing on one side of a wall With this research in mind, it is important for the designer

will introduce eccentric loading on the end chord and to recognize the potential limitations of diagonal strap

tracks. bracing, particularly if used in seismic areas. Specifically,

it is important that the capacity of the system is controlled

Other research available includes McGill Universitys strap by the yielding of the strap while the rest of the system

braced wall research program (2006) where the objective remains elastic. Similarly, the potential for material

was to evaluate the ductility of diagonal strap bracing overstrength should be considered. Depending on the

through monotonic and cyclic testing. This research specific application the design may find the use of shear

discusses the difficulty in ensuring ductile behavior for panels to be more appropriate.

diagonal strap bracing because of potential material over

strength. In addition, the research suggests the ductility The 2007 edition of the AISI Standard for Cold-Formed

the system is also influenced by the stiffness of the Steel Framing - Lateral Design (S213-07) has added new

holdown, anchor bolt and track detail. Also, the use of special seismic requirements and commentary for diagonal

gusset plates will likely increase the wall stiffness strap bracing. Included in this are expected yield and

compared to what flat straps alone would provide. The tensile strength factors (Ry and R t) which should be used

paper concludes that capacity based performance, where in the absence of verified physical properties.

strap bracing would be selected as the fuse element,

would improve the performance of the system. Additional

design steps are required to achieve this.

In his paper R-Factor Project Validation Test Plan author

Jim Wilcoski suggests the following regarding R-Factors:

These values are intended to represent the degree of

ductility, overstrength, redundancy and energy dissipation

capacity of the structural system. These factors have a

tremendous impact on the design of buildings, yet there

TECH NOTE L001-09 September 2009 4 Cold-Formed Steel Engineers Institute

DESIGN EXAMPLE

Following is a design example for diagonal strap bracing using gusset plates to resist wind loads. The dimensions and load

are shown in the drawing below. The flanges of the wall studs are considered to be braced and gravity loads are ignored.

Design Data

Loads: Horizontal wind load at top of wall from diaphragm = 3500 lb

Material Properties: ASTM A653 SS 33 (Fy = 33 ksi; Fu = 45 ksi)

Wall Dimensions: 8 ft. (length) by 9 ft. (height)

Member Sizes: Wall Studs: 600S162-43

Track: 600T125-43

Straps: 43 mil (0.0451 design thickness)

ASD Design

Resolution of forces considering a tension only strap:

Post load = 3938 lb

Track load = 3500 lb

Strap load = 5268 lb

Equations and code references shown are for the AISI NAS-01.

Cold-Formed Steel Engineers Institute 5 TECH NOTE L001-09 September 2009

DESIGN EXAMPLE (CONT.)

Compression Post (Chord Stud)

Assume flexural buckling in the plane of the wall is prevented by bridging at 1/3 points and does not control.

P = 3938 lb

From Table III-5 of the 2002 AISI Manual, for 600S162-43, where KLx = 9:

Pn = 7100 lb

For = 1.80

Pa = 3944 lb

Number of studs required = 3938/3944 = 1.0 Use two studs

Check the studs for combined axial load and bending:

P = 1969 lb each stud

Mx = 1969 6/2 = 5907 in lb (due to straps on one side of 6 wall)

c P / Pn = 0.50 > 0.15 Check eq. C5.2.1-1 and C5.2.1-2 (not eq. C5.2.1-3)

c P / Pn = 0.50 (C5.2.1-1)

b Cmx Mx / Mnx x = 0.38

0.50 + 0.38 < 1.0 o.k.

c P / Pno = 0.23 (C5.2.1-2)

b Mx / Mnx = 0.36

0.23 + 0.36 < 1.0 o.k.

Two studs o.k.

Flat Tension Strap

For strap yielding:

Tn = Ag Fy (Eq. C2-1)

Where: Ta (req'd) = 5268 lb

= 1.67

Tn = 5268 1.67 = 8798 lb

Solve for w (strap width) Tn = (w t) (Fy)

8798 = w 0.0451 33,000 ksi

w = 5.91 in. Use 6 in. wide strap

For fracture away from connection:

Tn = An Fu (Eq. C2-2)

Where: An = Ag

Ta (reqd) = 5268 lb

= 2.0

Tn = 5268 2.0 = 10,536 lb

TECH NOTE L001-09 September 2009 6 Cold-Formed Steel Engineers Institute

DESIGN EXAMPLE (CONT.)

Solve for w Tn = (w t) (Fu)

10536 = w 0.0451 45,000 ksi

w = 5.91 in. Use 6 in. wide strap

Strap to Gusset plate Connection

Assume: #10 screws

d = 0.190 in

Pns = 735 lb

For = 3.0

Pa = 245 lb

Number of screws required = 5268/245 = 21.5 Use 22 #10 screws

Gusset to Post Connection

Number of screws required = 3938/245 = 16.1 Use 17 #10 screws

Gusset to Track Connection

Number of screws required = 3500/245 = 14.3 Use 15 #10 screws

For guidance on the design and detailing of diagonal strap bracings with gusset plates please reference the article Detailing

Help for Gusseted Flat Strap X-Braces written by John Lyons in the September 2004 LGSEA Newsletter. Once the gusset

plate has been dimensioned and the screw spacing determined, fracture at the connection can be checked with section E5.3.

Bottom Track

For bearing strength of the bottom track:

Pn = mf C d Fu

Where: mf = 1.0 (Table E3.3.1-2)

C = 2.5 (Table E3.3.1-1)

d = 0.625 5/8 in. anchor bolts

= 2.5

Pn = 3023 lb

Pa = 1209 lb

Number of 5/8 in anchor bolts req. = 3500/1209 = 2.89 Use 3 anchor bolts

Note: The capacity of the embedded anchor bolts also needs to be checked

For track yielding (assuming tensile loads):

Tn = Ag Fy (Eq. C2-1)

Where: Ag = 0.383 in2

= 1.67

Tn = 0.383 33,000 = 12,639 lb

Ta = 12,639 lb > 3500 lb Track yielding is ok

Cold-Formed Steel Engineers Institute 7 TECH NOTE L001-09 September 2009

DESIGN EXAMPLE (CONT.)

For track fracture at anchor bolt:

Tn = Ae Fu (Eq. E3.2-8)

Where: Ae = An U

An = 0.383 - (0.043 0.66) = 0.355 in2

U = 1.0

= 2.22

Tn = 0.355 45,000 = 15,968 lb

Ta = 7188 lb Track fracture is ok

Depending on anchor bolt locations relative to the gusset plate compression of the bottom track may need to be checked

instead.

Holdown Anchors

Holdown anchors must be either designed or selected from a manufacturers catalog to resist the uplift forces at the tension

post of the resisting system. For this example the holdown would need an allowable capacity of 3938 lb. The anchor bolt

used with the holdown will be in addition to the anchor bolts required for shear. Also, the deflection of the holdown device

and its influence on the overall rotation of the system shall be checked.

References

1. International Building Code, 2006 Edition. International Code Council, Falls Church, Virginia.

2. Standard for Cold-Formed Steel Framing - General Provisions, American Iron and Steel Institute, Washington, DC, 2004.

3. Standard for Cold-Formed Steel Framing - Lateral Design, American Iron and Steel Institute, Washington, DC, 2004.

4. North American Specification for the Design of Cold-Formed Steel Structural Members (AISI-NASPEC), American Iron and Steel

Institute, Washington, DC, 2001.

5. Uniform Building Code (UBC), International Council of Building Officials, Whittier, California, 1997.

6. Shear Wall Design Guide, Steel Framing Alliance, Washington, DC, 1998.

7. Wilcoski, J.,2004, R-Factor Project Validation Test Plan

8. Al-Kharat, M., Rogers, C. A., (2005) Testing of Light Gauge Steel Strap Braced Walls, Department of Civil Engineering and Applied

Mechanics, McGill University, Montreal, Quebec, Canada

9. International Building Code, 2003 Edition. International Code Council, Falls Church, Virginia.

10. 2004 Supplement to the North American Specification for the Design of Cold-Formed Steel Structural Members, American Iron and Steel

Institute, Washington, DC.

11. AISI Manual - Cold-Formed Steel Design. American Iron and Steel Institute, Washington, DC, 2002.

12. Lyons, John C. Detailing Help for Gusseted Flat Strap X-Braces, article in the Newsletter of the Light Gauge Steel Engineers Association

(LGSEA). September, 2004.

13. North American Standard for Cold-Formed Steel Framing - Lateral Design (S213-07). American Iron and Steel Institute, Washington,

DC, 2007.

Primary Author of this Technical Note:

Greg Greenlee, P.E., USP Structural Connectors

CFSEI Technical Review Committee: Rob Madsen, P.E., Devco

Engineering, Inc., chairman.

This Technical Note on Cold-Formed Steel Construction is published by the Cold-Formed Steel Engineers Institute (CFSEI). The

information provided in this publication shall not constitute any representation or warranty, express or implied, on the part of CFSEI

or any individual that the information is suitable for any general or specific purpose, and should not be used without consulting with a

qualified engineer, architect, or building designer. ANY INDIVIDUAL OR ENTITY MAKING USE OF THE INFORMATION

PROVIDED IN THIS PUBLICATION ASSUMES ALL RISKS AND LIABILITIES ARISING OR RESULTING FROM SUCH

USE. CFSEI believes that the information contained within this publication is in conformance with prevailing engineering standards of

practice. However, none of the information provided in this publication is intended to represent any official position of the CFSEI or

to exclude the use and implementation of any other design or construction technique.

TECH NOTE L001-09 September 2009 8 Cold-Formed Steel Engineers Institute

Potrebbero piacerti anche

- Cold-Formed Steel Slip Track DesignDocumento4 pagineCold-Formed Steel Slip Track DesignZebNessuna valutazione finora

- Vicwest DiaphragmsDocumento62 pagineVicwest Diaphragmsrmsa17Nessuna valutazione finora

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNessuna valutazione finora

- AISI tn-d100-13Documento4 pagineAISI tn-d100-13Edison BecerraNessuna valutazione finora

- Meet The Experts - Steel JoistsDocumento2 pagineMeet The Experts - Steel Joistsseth_gzbNessuna valutazione finora

- Technical Note: Durability of Cold-Formed Steel Framing MembersDocumento8 pagineTechnical Note: Durability of Cold-Formed Steel Framing MembersZubair ShafiqueNessuna valutazione finora

- Technical Note: Introduction To Curtain Wall Design Using Cold-Formed SteelDocumento10 pagineTechnical Note: Introduction To Curtain Wall Design Using Cold-Formed SteelalbertoxinaNessuna valutazione finora

- CFSEI-Design of Non-Structural MembersDocumento6 pagineCFSEI-Design of Non-Structural MemberssandeepsharmafjNessuna valutazione finora

- ConnectionDocumento3 pagineConnectionCebeiller Sdn BhdNessuna valutazione finora

- Draft Use or Cite: Chapter 31 Wind Tunnel ProcedureDocumento6 pagineDraft Use or Cite: Chapter 31 Wind Tunnel ProceduresharethefilesNessuna valutazione finora

- Roof Framing Forces: Use MWFRS LoadsDocumento9 pagineRoof Framing Forces: Use MWFRS LoadsBlhoe KhoethoexNessuna valutazione finora

- Technical Note Cold-Formed SteelDocumento8 pagineTechnical Note Cold-Formed SteelIshwarya SrikanthNessuna valutazione finora

- MBMA What's New in The AISI Spec 2009Documento153 pagineMBMA What's New in The AISI Spec 2009LeoNessuna valutazione finora

- TN-F701-12 - Evaluation of Screw StrengthDocumento4 pagineTN-F701-12 - Evaluation of Screw StrengthDavid ArndtNessuna valutazione finora

- Cfsei 2015 Award Winners - CemcoDocumento3 pagineCfsei 2015 Award Winners - CemcokrlosNessuna valutazione finora

- Ensuring Seismic Safety Trough Properly Specified AnchoringDocumento59 pagineEnsuring Seismic Safety Trough Properly Specified AnchoringStelian ConstantinescuNessuna valutazione finora

- AISI S310-16 (2018 IBC) Steel and Composite Deck DiaphragmsDocumento187 pagineAISI S310-16 (2018 IBC) Steel and Composite Deck DiaphragmsCarsonBakerNessuna valutazione finora

- Roof Details Section 1Documento27 pagineRoof Details Section 1parthi banNessuna valutazione finora

- One Way SlabDocumento69 pagineOne Way Slabforlogin018Nessuna valutazione finora

- Analysis of Irregular-Shaped Diaphragms - Civil + Structural Engineer MagazineDocumento4 pagineAnalysis of Irregular-Shaped Diaphragms - Civil + Structural Engineer MagazinemuathNessuna valutazione finora

- Combined Systems SEAOC Blue BookDocumento3 pagineCombined Systems SEAOC Blue BookHirad GrivaniNessuna valutazione finora

- S3LDocumento1 paginaS3LkcarmachNessuna valutazione finora

- Ultimate Load Capacity of Reinforced Concrete SlabDocumento8 pagineUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- BIA - Steel Lintel DesignDocumento7 pagineBIA - Steel Lintel Designgpax42Nessuna valutazione finora

- Concrete Slender Wall DesignDocumento9 pagineConcrete Slender Wall Designamokhta100% (1)

- Design of Steel HangerDocumento2 pagineDesign of Steel HangerMostafa Saleh100% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- TEK 03-04C Bracing CMU Walls Under ConstructionDocumento12 pagineTEK 03-04C Bracing CMU Walls Under ConstructionAdam JonesNessuna valutazione finora

- Basement Modeling and The Backstay Effect - Sanya LeviDocumento20 pagineBasement Modeling and The Backstay Effect - Sanya Levisyl29100% (2)

- Behaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingDocumento12 pagineBehaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingKLNessuna valutazione finora

- Sharma Et Al-2017-Structural Concrete As PublishedDocumento9 pagineSharma Et Al-2017-Structural Concrete As PublisheddebiNessuna valutazione finora

- PCA - CI-Economical-Concrete-Formwork PDFDocumento4 paginePCA - CI-Economical-Concrete-Formwork PDFMIKHA2014Nessuna valutazione finora

- 8 Kircher 2015 PDFDocumento40 pagine8 Kircher 2015 PDFpazz0Nessuna valutazione finora

- NCSEA Annual Conference - Cold-Formed Steel Design SupportDocumento30 pagineNCSEA Annual Conference - Cold-Formed Steel Design SupportkrlosNessuna valutazione finora

- CFSEI Tech Notes Guide Cold-Formed Steel DesignDocumento5 pagineCFSEI Tech Notes Guide Cold-Formed Steel DesignponjoveNessuna valutazione finora

- Application of AISC Design Provisions For Tapered Members PDFDocumento13 pagineApplication of AISC Design Provisions For Tapered Members PDFclam2014Nessuna valutazione finora

- C4-1 Lecture 5-NBCC Provisons - 2018-B&W PDFDocumento47 pagineC4-1 Lecture 5-NBCC Provisons - 2018-B&W PDFYang LiNessuna valutazione finora

- Calculation Report Peninggian Cleaning Area Sulzer R.03Documento235 pagineCalculation Report Peninggian Cleaning Area Sulzer R.03Lukman Sitanggang0% (1)

- Development of Cold Formed Steel Seismic Design RecommendationsDocumento364 pagineDevelopment of Cold Formed Steel Seismic Design Recommendationsjackcan501Nessuna valutazione finora

- E Hconsulting CC: Civil and Structural DesignDocumento4 pagineE Hconsulting CC: Civil and Structural DesignGaurav MalyaNessuna valutazione finora

- Building Code 2019 SummaryDocumento9 pagineBuilding Code 2019 Summaryapi-236315161Nessuna valutazione finora

- RISA Seismic Moment ConnectionsDocumento11 pagineRISA Seismic Moment ConnectionsJackNessuna valutazione finora

- The Boundary Element Method for Plate AnalysisDa EverandThe Boundary Element Method for Plate AnalysisNessuna valutazione finora

- AISI S211-07 (Raffirmed 2012) - E1Documento2 pagineAISI S211-07 (Raffirmed 2012) - E1Jon JacobsNessuna valutazione finora

- ACI 318/350 P-M Interaction Diagram: US Customary UnitsDocumento6 pagineACI 318/350 P-M Interaction Diagram: US Customary UnitsMohit VatsNessuna valutazione finora

- CFSEI Shear Wall Design GuideDocumento45 pagineCFSEI Shear Wall Design GuideDaniel AielloNessuna valutazione finora

- Roof Details Section 2.pdf MBMADocumento31 pagineRoof Details Section 2.pdf MBMASilvanaNessuna valutazione finora

- I S C e R C S: ACI 364.2T-08Documento4 pagineI S C e R C S: ACI 364.2T-08jasminetsoNessuna valutazione finora

- Tek 10-03Documento4 pagineTek 10-03Thai DamNessuna valutazione finora

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Documento11 pagineMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiNessuna valutazione finora

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocumento12 pagineThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNessuna valutazione finora

- Composite Steel Deck-Slabs With Supplimental Reinforcing BarsDocumento4 pagineComposite Steel Deck-Slabs With Supplimental Reinforcing BarsHyunkyoun JinNessuna valutazione finora

- Blast Resistant StructuresDocumento3 pagineBlast Resistant Structuresprabhay123456Nessuna valutazione finora

- Notes On Design of Steel Parking Structures IncludDocumento42 pagineNotes On Design of Steel Parking Structures IncludSudhakar KrishnamurthyNessuna valutazione finora

- Serviceability MBMADocumento2 pagineServiceability MBMAabdulloh_99100% (1)

- CIDECT 1 - CHS Joint Under Static Loading PDFDocumento68 pagineCIDECT 1 - CHS Joint Under Static Loading PDFozzieaiffilNessuna valutazione finora

- Pula, DA - No Concurr-4Documento1 paginaPula, DA - No Concurr-4Scott WayneNessuna valutazione finora

- Design and Construction of Bridge DecksDocumento8 pagineDesign and Construction of Bridge DeckschatxxnoirNessuna valutazione finora

- Jose V. Yap Sr. Access RoadDocumento3 pagineJose V. Yap Sr. Access RoadRobin PabustanNessuna valutazione finora

- 150+ Building Materials and Construction Interview QuestionsDocumento29 pagine150+ Building Materials and Construction Interview Questionsmir imran100% (1)

- Your Safety is Our Top Priority: Sthapona Consultants Company ProfileDocumento30 pagineYour Safety is Our Top Priority: Sthapona Consultants Company ProfileSohagNessuna valutazione finora

- Steel tripod, wrench, frame and arch beam load calculationsDocumento19 pagineSteel tripod, wrench, frame and arch beam load calculationsRenne Jude Rollorata100% (1)

- Collapse of The Quebec Bridge 1907Documento9 pagineCollapse of The Quebec Bridge 1907BanooNessuna valutazione finora

- 2770 - 1 (Method of Testing Bond in Reinforced Concrete Part-1 PDFDocumento12 pagine2770 - 1 (Method of Testing Bond in Reinforced Concrete Part-1 PDFRaj BharaliNessuna valutazione finora

- Cap Plate Trial CalculationDocumento18 pagineCap Plate Trial CalculationStar100% (1)

- Structural Analysis - WikipediaDocumento10 pagineStructural Analysis - WikipediaEn Iyisi İnşaat MühendisiNessuna valutazione finora

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocumento3 pagineEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiNessuna valutazione finora

- Billing Format RevisedDocumento6 pagineBilling Format RevisedArch Ariel PJNessuna valutazione finora

- Rankawat - Nonlinear Seismic Evaluation of Confined Masonry Structures Using Equivalent Truss ModelDocumento18 pagineRankawat - Nonlinear Seismic Evaluation of Confined Masonry Structures Using Equivalent Truss ModelSergio Alonso SunleyNessuna valutazione finora

- Estimation GuideDocumento98 pagineEstimation GuideAkhil Joseph100% (1)

- W1, W2 Long Span StructureDocumento81 pagineW1, W2 Long Span StructureMuhammad AizatNessuna valutazione finora

- Pile Foundation Basement: Main Types of PilesDocumento1 paginaPile Foundation Basement: Main Types of PilesPranavNessuna valutazione finora

- Underground sump reservoir specification and designDocumento30 pagineUnderground sump reservoir specification and designAnand SoniNessuna valutazione finora

- Properties of Structural Materials: Chapter-2Documento13 pagineProperties of Structural Materials: Chapter-2Kreepa TimsinaNessuna valutazione finora

- Building-Estimation Excel SheetDocumento3 pagineBuilding-Estimation Excel Sheetsadam mohamedNessuna valutazione finora

- M Tech Syllabus NewDocumento4 pagineM Tech Syllabus Newkingston roseNessuna valutazione finora

- RCD Lecture Note 4 - USD of Non-Rectangular Beams PDFDocumento2 pagineRCD Lecture Note 4 - USD of Non-Rectangular Beams PDFAugosto FraceNessuna valutazione finora

- Final TEC Report 2 PDFDocumento124 pagineFinal TEC Report 2 PDFrisingrishuNessuna valutazione finora

- ASCE-PartB - P4Documento10 pagineASCE-PartB - P4Singh RichaNessuna valutazione finora

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Documento34 pagine9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- Eqsv Unit 1Documento61 pagineEqsv Unit 1SaikiranNessuna valutazione finora

- The Revolutionary Bridges of Robert MaillartDocumento8 pagineThe Revolutionary Bridges of Robert MaillartHamilton Reporter100% (1)

- 15) W Beam Crash BarrierDocumento2 pagine15) W Beam Crash BarrierRakibul JamanNessuna valutazione finora

- Development of Cylindrical Shear Connector Inserted in Perforated Steel Plate and Apply To The Hybrid StructureDocumento12 pagineDevelopment of Cylindrical Shear Connector Inserted in Perforated Steel Plate and Apply To The Hybrid Structureerky arkvathonejhNessuna valutazione finora

- Chapter 6 - BEAMS and Girders-PrefinalDocumento29 pagineChapter 6 - BEAMS and Girders-PrefinalKhaled WaleedNessuna valutazione finora