Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PFI ES-7 Min Spacing For Welding

Caricato da

Nguyen Anh TungTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PFI ES-7 Min Spacing For Welding

Caricato da

Nguyen Anh TungCopyright:

Formati disponibili

PFI Standard ES-7

|Denotes Revision (Revised December 2013)

MINIMUM LENGTH AND SPACING

FOR WELDED BRANCH CONNECTIONS

Prepared by

Pipe Fabrication Institute Engineering Committee

All PFI Standards are advisory only. There is no

agreement to adhere to any PFI Standard and

their use by anyone is entirely voluntary.

Copyright by

PIPE FABRICATION INSTITUTE

Dedicated to Technical Advancements and Standardization in

the Pipe Fabrication Industry

Since 1913

USA CANADA

511 Avenue of Americas, # 601 655, 32nd Avenue, # 201

New York, NY 10011 Lachine, QC H8T 3G6

WEB SITE

www.pfi-institute.org

--`,,,```,```,```,`,`,,``,`,,``-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Licensee=Vietnam/5940240043

No reproduction or networking permitted without license from IHS Not for Resale, 05/08/2017 21:13:05 MDT

PFI Standard ES-7

|Denotes Revision (Revised December 2013)

MINIMUM LENGTH AND SPACING FOR WELDED BRANCH

CONNECTIONS

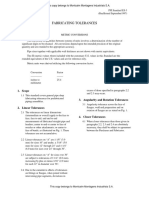

METRIC CONVERSIONS

The conversion of quantities between systems of units involves a determination of the number of significant digits to

be retained. All conversions depend upon the intended precision of the original and are rounded to the appropriate

accuracy.

Pipe sizes together with applicable wall thicknesses are not shown with metric equivalents.

The SI (metric) values where included with the customary U. S. values in this Standard are the rounded equivalents of

the U. S. values and are for reference only.

Metric units were derived utilizing the following conversion factor:

Conversion Factor

inches to millimeter 25.4

1. Scope welded to a header may result in distortion of the

header pipe. The elimination or reduction of such

1.1 This Standard covers the minimum recommended distortion is beyond the scope of this Standard.

branch connection length, branch connection For some recommendations to reduce or eliminate

distance from open end on run, and spacing such distortion refer to PFI standard ES-49.

dimensions of adjacent welded branch

connections. 5.2 All branch connection welds should be checked

for compliance with the applicable Code

2. Branch Connection s without Saddles or requirements.

Reinforcement

5.3 It is preferred that multiple branch openings of in-

2.1 The branch connection spacings are based on line branch connections be spaced so that their

practical access requirements for fit-up, welding reinforcement zones do not overlap. If closer

and examination. Dimensions recommended for spacing is necessary, the reinforcement

branch connections without saddles or requirements of the applicable construction Code

reinforcements are as shown in Fig. l and Table l. shall be met.

3. Branch Connections with Reinforcing 5.4 Some configurations of integrally reinforced

Saddles or Rings branch connections in combination with certain

header sizes may present a problem in the

3.1 Dimensions recommended for branch connections

radiographic examination of the attachment weld

with saddles or rings are as shown in Fig. 2 and

due to inability to meet the geometric

Table 2.

unsharpness requirements of the construction

Code.

4. Branch Connections Integrally

Reinforced 5.5 Where attachments such as flanges, fittings,

4.1 Dimensions recommended for integrally valves and pipe insulation are involved, minimum

--`,,,```,```,```,`,`,,``,`,,``-`-`,,`,,`,`,,`---

reinforced branch connections are as shown in dimensions tabulated may have to be increased to

Fig. 3 and Table 3. These dimensions do not allow for required clearances.

apply to integrally reinforced insert butt weld

branch connections. 5.6 In special cases, it may be possible to reduce the

dimensions given in the tabulation. Such design

should then be submitted to the fabricator for

5. Design Considerations individual consideration, as close spacing may

5.1 Certain materials and combinations of branch involve additional shop operations to prevent, or

connection and header pipe size and wall correct distortion.

thickness together with multiple branch openings

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Licensee=Vietnam/5940240043

No reproduction or networking permitted without license from IHS Not for Resale, 05/08/2017 21:13:05 MDT

PFI Standard ES-7

|Denotes Revision (Revised December 2013)

5.7 Integrally reinforced branch connections are

considered to be the commercially available

types.

5.8 In cases of different branch connection diameters,

dimension "C", (Fig. & Tables 1 thru 3) should be

determined on the basis of the larger of the two

adjacent branch connections. For some branch

connection sizes, the recommended minimum

spacing in the tables may result in overlapping

reinforcement zones.

--`,,,```,```,```,`,`,,``,`,,``-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Licensee=Vietnam/5940240043

No reproduction or networking permitted without license from IHS Not for Resale, 05/08/2017 21:13:05 MDT

PFI Standard ES-7

|Denotes Revision (Revised December 2013)

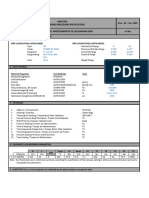

MINIMUM RECOMMENDED DIMENSIONS FOR FIGURE 1

NOMINAL BRANCH CONNECTIONS WITHOUT

PIPE SIZE OF

BRANCH

CENTER OF BRANCH

CONNECTION TO END

O.D. OF RUN TO END OF

BRANCH CONNECTION

O.D. TO O.D. OF

BRANCH CONNECTION

SADDLES OR RING REINFORCEMENT

CONNECTION OF RUN B C

(in) A A C

in. (mm) in. (mm) in. (mm)

2-1/2 4-1/2 (114) 3 ( 76) 3 ( 76)

B

3 5 (127) 3-1/2 ( 89) 3-1/2 ( 89)

4 6 (152) 4 (102) 4 (102)

5 7 (178) 4-1/2 (114) 4-1/2 (114)

6 8 (203) 5 (127) 5 (127)

8 10 (254) 6 (152) 6 (152)

10 12 (305) 7 (178) 7 (178)

12 14 (356) 8 (203) 8 (203) FIGURE 1

14 15 (381) 8-1/2 (216) 8-1/2 (216)

16 17 (432) 9 (229) 9 (229)

18 19 (483) 10 (254) 10 (254)

20 21 (533) 11 (279) 11 (279)

24 24 (610) 12 (305) 12 (305)

TABLE 1

MINIMUM RECOMMENDED DIMENSIONS FOR FIGURE 2

NOMINAL

PIPE SIZE OF CENTER OF BRANCH O.D. OF RUN TO END OF O.D. TO O.D. OF

BRANCH CONNECTION TO END BRANCH CONNECTION BRANCH CONNECTION

CONNECTION OF RUN B C*

(in) A

BRANCH CONNECTIONS WITH

in. (mm) in. (mm) in. (mm) REINFORCING SADDLES OR RINGS

2-1/2 6 (152) 4-1/2 (114) 6 (152)

3 7 (178) 5 (127) 7 (178) A C

4 8 (203) 5-1/2 (140) 8 (203)

5 9-1/2 (241) 6 (152) 9-1/2 (241)

B

6 11 (279) 6-1/2 (165) 11 (279)

8 14 (356) 8 (203) 14 (356)

10 17 (432) 9-1/2 (241) 17 (432)

12 20 (508) 11 (279) 20 (508)

14 22 (559) 12 (305) 22 (559)

16 25 (635) 13 (330) 25 (635)

18 28 (711) 14 (356) 28 (711)

FIGURE 2

20 31 (787) 15 (381) 31 (787)

24 36 (914) 16 (406) 36 (914)

TABLE 2

MINIMUM RECOMMENDED DIMENSIONS FOR FIGURE 3

NOMINAL

PIPE SIZE OF CENTER OF BRANCH O.D. OF RUN TO END OF O.D. TO O.D. OF

BRANCH CONNECTION TO END BRANCH CONNECTION BRANCH CONNECTION

CONNECTION OF RUN B C*

--`,,,```,```,```,`,`,,``,`,,``-`-`,,`,,`,`,,`---

(in) A

in. (mm) in. (mm) in. (mm)

2-1/2 5-1/2 (140) MANUFACTURERS 3 ( 76) BRANCH CONNECTIONS -

3 6 (152) STANDARDS 3 ( 76) INTEGRALLY REINFORCED

4 7 (178) 3-1/2 ( 89)

A C

5 8 (203) 4 (102)

6 10 (254) 5 (127)

8 12 (305) 6 (152)

B

10 14 (356) 7 (178)

12 16 (406) 8-1/2 (216)

14 17 (432) 9 (229)

16 19 (483) 10 (254)

18 21 (533) 11 (279)

20 23 (584) 12 (305) FIGURE 3

24 26 (660) 14 (356)

TABLE 3

*Minimum dimension C should be that tabulated for the larger of two adjacent branch connections.

Dimensions: Inches (Millimeters).

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Licensee=Vietnam/5940240043

No reproduction or networking permitted without license from IHS Not for Resale, 05/08/2017 21:13:05 MDT

CURRENT INDEX OF 2014-2015

PFI STANDARDS & TECHNICAL BULLETINS

Engineering and Design

ES02 R13 Method of Dimensioning Piping Assemblies

ES07 R13 Minimum Length and Spacing for Welded Nozzles

ES16 R13 Access Holes, Bosses, and Plugs for Radiographic Inspection of Pipe Welds

ES26 R13 Welded Load Bearing Attachments to Pressure Retaining Piping Materials

ES36 R13 Branch Reinforcement Work Sheets.

ES36 R13 Branch Reinforcement Work Sheets ELECTRONIC VERSION

ES40 RA10 Method of Dimensioning Grooved Piping Assemblies

ES44 R13 Drafting Practices Standard

Welding and Fabrication

ES01 R10 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds

ES21 R10 Internal Machining and Fit-up of GTAW Root Pass Circumferential Butt Welds

ES24 R13 Pipe Bending Methods, Tolerances, Process and Material Requirements

ES35 RA03 Nonsymmetrical Bevels and Joint Configurations for Butt Welds

ES45 R13 Recommended Practice for Local Post-Weld Heat Treatment

ES47 R13 Welding of Internally Clad Piping

ES49 R13 Guidelines for Installation of Integrally Reinforced Branch Connection Fittings

Cleaning, Painting, and Shipping

ES05 R13 Cleaning of Fabricated Piping

ES29 R06 Internal Abrasive Blast Cleaning of Ferritic Piping Materials

ES31 RA04 Standard for Protection of Ends of Fabricated Piping Assemblies

ES34 R03 Temporary Painting/Coating of Fabricated Piping

ES37 RA10 Standard for Loading and Shipping of Piping Assemblies

Quality Control

--`,,,```,```,```,`,`,,``,`,,``-`-`,,`,,`,`,,`---

ES03 R09 Fabricating Tolerances

ES11 R03 Permanent Marking on Piping Materials

ES22 R13 Recommended Practice for Color Coding of Piping Materials.

ES32 R13 Tool Calibration

ES39 RA10 Fabricating Tolerances for Grooved Piping Systems

ES41 RA03 Standard for Material Control and Traceability of Piping Components

ES43 RA13 Standard for Protection of Austenitic Stainless Steel and Nickel Alloy Materials

Examination and Testing

ES04 R13 Hydrostatic Testing of Fabricated Piping

ES20 R13 Wall Thickness Measurement by Ultrasonic Examination

ES27 R10 "Visual Examination" The Purpose, Meaning and Limitation of the Term

ES42 R05 Standard for Positive Material Identification of Piping Components using Portable X-Ray Emission Type Equipment

ES48 R13 Random Examination

Technical Bulletins

TB1 R13 Pressure - Temperature Ratings of Seamless Pipe Used in Power Plant Piping Systems - ELECTRONIC VERSION

TB3 R13 Guidelines Clarifying Relationships and Design Engineering Responsibilities Between Purchasers Engineers and Pipe Fabricator or Pipe

Fabricator or Pipe Fabricator Erector

TB5 R13 Information Required for the Bidding of Pipe Fabrication

TB7 R04 Guidelines for Fabrication and Installation of Stainless Steel High Purity Distribution Systems

TB8 R13 Recommended practice for the fabrication of polyvinylidene fluoride (PVDF) piping

TB9 R13 Customary Fitting, Forging, Plate and Bar Materials used with Pipe

ELECTRONIC VERSION

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Licensee=Vietnam/5940240043

No reproduction or networking permitted without license from IHS Not for Resale, 05/08/2017 21:13:05 MDT

1913 2013

Visit our website www.pfi-institute.org

for;

A complete list of PFI members and available membership

CHARTER MEMBERS

CONTRACTOR MEMBERS

ASSOCIATE MEMBERS

AFFILIATE MEMBERS

HONORARY MEMBERS

Associate and Affiliate member contributors

Walter Sperko Sperko Engineering Services, Inc. Greensboro, NC

Thomas Warrelmann Victaulic Company of America Easton, PA

Sheryl Michalak Welding Outlets, Inc. Houston, TX

PFI Standards and Technical Bulletins are published to serve proven needs of the pipe

fabricating industry at the design level and in actual shop operations. Hence, such needs

are continually considered and reviewed by the Engineering Committee of the Pipe

Fabrication Institute to provide recommended procedures, which have been demonstrated

by collective experiences to fulfill requirements in a manner for Code compliance.

However, as the PFI Standards are for minimum requirements the designer or fabricator

always has the option of specifying supplementary conditions in the form of requirements

beyond the scope of the PFI publications.

--`,,,```,```,```,`,`,,``,`,,``-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Licensee=Vietnam/5940240043

No reproduction or networking permitted without license from IHS Not for Resale, 05/08/2017 21:13:05 MDT

Potrebbero piacerti anche

- PFI ES-2-2000 Method of Dimension Ing Piping AssembliesDocumento4 paginePFI ES-2-2000 Method of Dimension Ing Piping Assembliessekharsappa2100% (3)

- Pfi-Es-3 (2000) PDFDocumento4 paginePfi-Es-3 (2000) PDFBarnum Pebble Darrel100% (1)

- Pfi Es-24Documento10 paginePfi Es-24kingstonNessuna valutazione finora

- PFI ES-03 Fabricating TolerancesDocumento4 paginePFI ES-03 Fabricating TolerancesAL DOMANessuna valutazione finora

- ES-03 - PFI - Fabricationg TolerancesDocumento5 pagineES-03 - PFI - Fabricationg TolerancesGiám đốc Tín MinhNessuna valutazione finora

- PFI Standard ES-7 - 2013Documento6 paginePFI Standard ES-7 - 2013HeiderHuerta100% (1)

- Pfi-Es-22 (1999)Documento4 paginePfi-Es-22 (1999)jothish100% (5)

- PFI ES 27 (2000) VisualExaminationDocumento4 paginePFI ES 27 (2000) VisualExaminationWilson AnteNessuna valutazione finora

- MSS SP-79-2018Documento18 pagineMSS SP-79-2018Денис Пекшуев100% (1)

- MSS SP-43-2008Documento15 pagineMSS SP-43-2008cadbulldogNessuna valutazione finora

- PFI ES-3 Fabricating TolerancesDocumento2 paginePFI ES-3 Fabricating TolerancesaplicacionesNessuna valutazione finora

- Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationDocumento4 paginePipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationsaerinNessuna valutazione finora

- b31 1Documento14 pagineb31 1abdul malik al fatah15% (13)

- Asme B16.9 2018aDocumento41 pagineAsme B16.9 2018aWUMING100% (1)

- Pfi Es-5 2002Documento2 paginePfi Es-5 2002bayu212100% (1)

- Astm A 960 PDFDocumento11 pagineAstm A 960 PDFEdwinMauricioMacabeoNessuna valutazione finora

- Asme b16.25 Buttwelding EndsDocumento22 pagineAsme b16.25 Buttwelding Endsgst ajahNessuna valutazione finora

- Asme B16.10 - 2009 PDFDocumento50 pagineAsme B16.10 - 2009 PDFTECNICONessuna valutazione finora

- PFI-ES-05 (1999) - Cleaning PDFDocumento4 paginePFI-ES-05 (1999) - Cleaning PDFRamesh Kumar Ramisetti100% (1)

- Mss SP 81 PDFDocumento10 pagineMss SP 81 PDFselva nayagamNessuna valutazione finora

- Case 2864 9Cr - 1Mo-V Material Section I: Table 1 Table 2Documento1 paginaCase 2864 9Cr - 1Mo-V Material Section I: Table 1 Table 2Alevj Db100% (1)

- MSS SP 97 PDFDocumento15 pagineMSS SP 97 PDFOlinser BacelisNessuna valutazione finora

- BS 5352 PDFDocumento31 pagineBS 5352 PDFSalik Siddiqui100% (1)

- MSS SP 95Documento16 pagineMSS SP 95JUAN DAVID GOMEZ PATIÑONessuna valutazione finora

- Asme B31.5-2019Documento16 pagineAsme B31.5-2019Jonathan Espinoza Mejia30% (10)

- Astm A860Documento5 pagineAstm A860Marcelo ColomboNessuna valutazione finora

- Asme B16.11 2005Documento30 pagineAsme B16.11 2005Starla Hill100% (4)

- MSS SP-97Documento15 pagineMSS SP-97ali karar100% (2)

- Class 3000 Steel Pipe Unions Socket Welding and Threaded: MSS SP-83-2006Documento12 pagineClass 3000 Steel Pipe Unions Socket Welding and Threaded: MSS SP-83-2006ISRAEL PORTILLONessuna valutazione finora

- MSS SP 70-2011 PDFDocumento16 pagineMSS SP 70-2011 PDFthiagorep1767% (3)

- Proposed New ASMEB31P Standard On Preheat & PWHT PDFDocumento34 pagineProposed New ASMEB31P Standard On Preheat & PWHT PDFWitchfinder General100% (1)

- Astm A671 2020Documento7 pagineAstm A671 2020امينNessuna valutazione finora

- Asme NM.3.1-2020Documento555 pagineAsme NM.3.1-2020Dmitriy50% (2)

- Flanges ASME B 16.47 Serie ADocumento2 pagineFlanges ASME B 16.47 Serie Aprabhuarunkumar100% (1)

- MSS SP-71Documento10 pagineMSS SP-71jemorpeNessuna valutazione finora

- Hdpe Bps Sab355Documento1 paginaHdpe Bps Sab355Benjamin Enmanuel Mango DNessuna valutazione finora

- ASME B16.48 Juntas CiegasDocumento54 pagineASME B16.48 Juntas CiegasVictor TorresNessuna valutazione finora

- Swage (D) Nipples and Bull Plugs: MSS SP-95-2018Documento22 pagineSwage (D) Nipples and Bull Plugs: MSS SP-95-2018Bruce HuynhNessuna valutazione finora

- TR 33 Generic Butt Fusion Joining Gas PipeDocumento40 pagineTR 33 Generic Butt Fusion Joining Gas PipeRamonezeNessuna valutazione finora

- Asme NM.2-2018Documento126 pagineAsme NM.2-2018aneeshjokay75% (4)

- New Standard For FRP PipingDocumento37 pagineNew Standard For FRP PipingKamatchi NathanNessuna valutazione finora

- MSS SP-83-2014 Class 3000 and 6000 Pipe Unions, Socket Welding and Threaded (Carbon Steel, Alloy Steel, Stainless Steels, and Nickel Alloys)Documento16 pagineMSS SP-83-2014 Class 3000 and 6000 Pipe Unions, Socket Welding and Threaded (Carbon Steel, Alloy Steel, Stainless Steels, and Nickel Alloys)arnoldbatista55100% (1)

- Pfi Es 3Documento2 paginePfi Es 3EstefaníaNessuna valutazione finora

- Asme B16.47-2011Documento120 pagineAsme B16.47-2011Asad100% (4)

- PFI ES 2 - 2013 EditionDocumento5 paginePFI ES 2 - 2013 EditionArcadio DuranNessuna valutazione finora

- Pfi Es-40Documento3 paginePfi Es-40Ecruz Cruz LNessuna valutazione finora

- PFI ES 16 - 2013 EditionDocumento11 paginePFI ES 16 - 2013 EditionArcadio Duran100% (1)

- Pfi Es-3Documento5 paginePfi Es-3Ecruz Cruz LNessuna valutazione finora

- Pfi Es-47Documento10 paginePfi Es-47Ecruz Cruz LNessuna valutazione finora

- PFI ES 24 Pipe Bending and TollerancesDocumento12 paginePFI ES 24 Pipe Bending and TollerancesArcadio DuranNessuna valutazione finora

- Pfi Es-1Documento9 paginePfi Es-1Ecruz Cruz LNessuna valutazione finora

- Drafting Practices StandardDocumento14 pagineDrafting Practices StandardJonathanNessuna valutazione finora

- Fabricating Tolerance - PFIDocumento3 pagineFabricating Tolerance - PFIAbdülHak ÖZkaraNessuna valutazione finora

- Pfi Es-3 (2000)Documento4 paginePfi Es-3 (2000)Esteban Calderón NavarroNessuna valutazione finora

- Pfi Es-48Documento7 paginePfi Es-48Ecruz Cruz LNessuna valutazione finora

- PFI ES-26-1993 Welded Load Bearing Attachments To Pressure Retaining Piping MaterialsDocumento8 paginePFI ES-26-1993 Welded Load Bearing Attachments To Pressure Retaining Piping MaterialsThao NguyenNessuna valutazione finora

- PFI ES 40 1994 R1997 Method of DimensioningDocumento4 paginePFI ES 40 1994 R1997 Method of Dimensioningahmad effendiNessuna valutazione finora

- Method of Dimensioning Piping Assemblies: Prepared by Pipe Fabrication Institute Engineering CommitteeDocumento4 pagineMethod of Dimensioning Piping Assemblies: Prepared by Pipe Fabrication Institute Engineering CommitteeHarry Ccayascca FloresNessuna valutazione finora

- PFI ES 2 2000 Method of Dimensioning Piping AssembliesDocumento4 paginePFI ES 2 2000 Method of Dimensioning Piping AssembliesedwinNessuna valutazione finora

- Outside Plant Volume Op 02 Construction StandardsDocumento71 pagineOutside Plant Volume Op 02 Construction StandardsMohammed IrfanNessuna valutazione finora

- Process Design QuestionaryDocumento30 pagineProcess Design QuestionaryNguyen Anh TungNessuna valutazione finora

- Training Program On Basic Process Engineering PracticesDocumento14 pagineTraining Program On Basic Process Engineering PracticesNguyen Anh TungNessuna valutazione finora

- PML Course IranpipingDocumento150 paginePML Course IranpipingNguyen Anh TungNessuna valutazione finora

- Manual of Process Economic EvaluationDocumento480 pagineManual of Process Economic EvaluationNguyen Anh Tung100% (2)

- Basic Process Design Requirements and CriteriaDocumento23 pagineBasic Process Design Requirements and CriteriaNguyen Anh Tung100% (1)

- Process Engineering Design GuideDocumento296 pagineProcess Engineering Design GuideNguyen Anh TungNessuna valutazione finora

- P&ID Preparation ProcedureDocumento38 pagineP&ID Preparation ProcedureNguyen Anh Tung100% (1)

- Asme B16.28Documento20 pagineAsme B16.28Nguyen Anh Tung100% (1)

- Technip-Process-Manual For P&IDDocumento62 pagineTechnip-Process-Manual For P&IDNguyen Anh Tung67% (3)

- ASME B31.1 Vs B31.3 Vs B31.8Documento9 pagineASME B31.1 Vs B31.3 Vs B31.8Nguyen Anh Tung67% (3)

- A790a790m 17Documento10 pagineA790a790m 17Nguyen Anh TungNessuna valutazione finora

- Classification of Hazardous AreasDocumento26 pagineClassification of Hazardous AreasNaveen ReddyNessuna valutazione finora

- Materials and CorrosionDocumento34 pagineMaterials and CorrosionNguyen Anh TungNessuna valutazione finora

- Asme B16.44 2012Documento24 pagineAsme B16.44 2012Nguyen Anh TungNessuna valutazione finora

- NDT Method SummaryDocumento3 pagineNDT Method SummaryNguyen Anh TungNessuna valutazione finora

- Piping Construction StandardDocumento42 paginePiping Construction StandardNguyen Anh Tung100% (3)

- Preservation of Coated Pipes For Long Term Storage in Tropical Environment PDFDocumento8 paginePreservation of Coated Pipes For Long Term Storage in Tropical Environment PDFNguyen Anh TungNessuna valutazione finora

- Flange Data ComparisonDocumento21 pagineFlange Data ComparisonRiki FernandesNessuna valutazione finora

- Negotiation Skills: Prepared by Do Ngoc ThanhDocumento24 pagineNegotiation Skills: Prepared by Do Ngoc ThanhNguyen Anh Tung100% (1)

- Piping Typical Installation DrawingsDocumento51 paginePiping Typical Installation DrawingsNguyen Anh Tung100% (3)

- Process Drain & Vent PhilosophyDocumento92 pagineProcess Drain & Vent PhilosophyNguyen Anh Tung100% (1)

- BD00MS0351 - 0 Specification For Non-API Centrifugal PumpsDocumento31 pagineBD00MS0351 - 0 Specification For Non-API Centrifugal PumpsNguyen Anh TungNessuna valutazione finora

- A Typical Material Selection ReportDocumento92 pagineA Typical Material Selection ReportNguyen Anh Tung70% (10)

- Introduction Pipe BendingDocumento34 pagineIntroduction Pipe BendingNguyen Anh TungNessuna valutazione finora

- NDT Method SummaryDocumento3 pagineNDT Method SummaryNguyen Anh TungNessuna valutazione finora

- Pipe Support StandardDocumento42 paginePipe Support StandardNguyen Anh Tung100% (3)

- Basic Control Valve and Sizing and SelectionDocumento38 pagineBasic Control Valve and Sizing and SelectionNguyen Anh Tung50% (2)

- SRP Catalog 7-19-11Documento36 pagineSRP Catalog 7-19-11Martin WilliamsNessuna valutazione finora

- Equipment Hire Rate PDFDocumento5 pagineEquipment Hire Rate PDFDinesh Poudel0% (1)

- Gears PDFDocumento29 pagineGears PDFbiranchi satapathy0% (1)

- 15419Documento29 pagine15419tushar11singhNessuna valutazione finora

- Cutting Force Measurement: New Rotating Dynamometer For The Analysis of High Speed Cutting ProcessesDocumento15 pagineCutting Force Measurement: New Rotating Dynamometer For The Analysis of High Speed Cutting ProcessesAmR El SHeNaWyNessuna valutazione finora

- Benchman 5000 ManualDocumento133 pagineBenchman 5000 Manualamo38Nessuna valutazione finora

- Footwear Machinery Part IIDocumento13 pagineFootwear Machinery Part IIsanjana sadhukhanNessuna valutazione finora

- Case Study Analysis of Rubco Huat PVT LTDDocumento16 pagineCase Study Analysis of Rubco Huat PVT LTDUma MaheswariNessuna valutazione finora

- Bench Grinders SafetyDocumento3 pagineBench Grinders SafetyHafidzManafNessuna valutazione finora

- 12Documento110 pagine12SarjitoNessuna valutazione finora

- CA ND StarteraDocumento816 pagineCA ND StarteraSIVARAMANJAGANATHAN100% (1)

- Hot and Cold WorkingDocumento5 pagineHot and Cold Workingmuhammad al afiqNessuna valutazione finora

- CNC Part Programming LLDocumento8 pagineCNC Part Programming LLRajendra Kumar YadavNessuna valutazione finora

- ASTM A36 MildLow Carbon SteelDocumento2 pagineASTM A36 MildLow Carbon SteelCésar TapiaNessuna valutazione finora

- Advanced Machining Processes by Prof. Vijay Kumar JainDocumento70 pagineAdvanced Machining Processes by Prof. Vijay Kumar JainArvind Razdan88% (24)

- Tail Shaft SurveyDocumento9 pagineTail Shaft SurveyrajishrrrNessuna valutazione finora

- Unit II - Turning MachinesDocumento137 pagineUnit II - Turning MachinesKanda SamyNessuna valutazione finora

- Solid Carbide Gundrill Type 113 HP MDocumento2 pagineSolid Carbide Gundrill Type 113 HP MarvinupNessuna valutazione finora

- Din 931Documento1 paginaDin 931Showkath Ali100% (2)

- Ch17 Metal FormingDocumento37 pagineCh17 Metal FormingSaman BrookhimNessuna valutazione finora

- Ut Calibration Blocks DetailsDocumento44 pagineUt Calibration Blocks Detailsmdsajidalam100% (4)

- HAISUNG Good3 - Reducer&Drive - CatalogDocumento154 pagineHAISUNG Good3 - Reducer&Drive - Catalog032indesignNessuna valutazione finora

- 01.sundram Fasteners LTDDocumento59 pagine01.sundram Fasteners LTDJaiNessuna valutazione finora

- Cost SequenceDocumento6 pagineCost SequenceCharanjeet SinghNessuna valutazione finora

- Samputensili ToolsDocumento24 pagineSamputensili Toolsmaryam KAHRIZINessuna valutazione finora

- Group Technology and Cellular ManufacturingDocumento107 pagineGroup Technology and Cellular ManufacturingchristywwwwNessuna valutazione finora

- Deming's List - L - 2011Documento6 pagineDeming's List - L - 2011Ranganath PanditNessuna valutazione finora

- Hardinge Mill FinalDocumento14 pagineHardinge Mill FinalshailNessuna valutazione finora

- Molding Machine & MoldingDocumento24 pagineMolding Machine & MoldingJyoti KaleNessuna valutazione finora

- Manual MC Vmc2240xlDocumento89 pagineManual MC Vmc2240xlchidambaram kasiNessuna valutazione finora