Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

05 Chapter 5 PPK

Caricato da

fuadkusumaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

05 Chapter 5 PPK

Caricato da

fuadkusumaCopyright:

Formati disponibili

Chemical Plant Design 1210384 Chapter-5

V

BATCH PROCESS

Dr.Eng. Yulius Deddy Hermawan

Department of Chemical Engineering

UPN Veteran Yogyakarta

Outline

1. Introduction to Batch Processes

2. Batch Reactor

3. Batch Separation

4. Gantt Chart

5. Production Schedules for Single Products

6. Production Schedules for Multiple Products

7. Equipment Cleaning and Material Transfer

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 1 of 21

Chemical Plant Design 1210384 Chapter-5

V.1

INTRODUCTION TO

BATCH PROCESSES

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Batch and Continuous Processes

(Smith, R, 2005)

However, not all processes operate continuously.

In a batch process, the main steps operate discontinuously.

In contrast with a continuous process, a batch process does

not deliver its product continuously but in discrete amounts.

This means that heat, mass, temperature, concentration and

other properties vary with time.

In practice, most batch processes are made up of a series of

batch and semicontinuous steps.

A semicontinuous step runs continuously with periodic start-

ups and shutdowns.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 2 of 21

Chemical Plant Design 1210384 Chapter-5

Various modes of operation for batch and semibatch reactors.

(Smith, R, 2005)

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Batch Processes:

(R. Smith)

are economical for small volumes;

are exible in accommodating changes in product formulation;

are exible in changing production rate by changing the

number of batches made in any period of time;

allow the use of standardized multipurpose equipment for the

production of a variety of products from the same plant;

are best if equipment needs regular cleaning because of fouling

or needs regular sterilization;

are amenable to direct scale-up from the laboratory and

allow product identication.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 3 of 21

Chemical Plant Design 1210384 Chapter-5

Batch Processes:

(R. Smith)

One of the major problems with batch processing is batch to-

batch conformity.

Minor changes to the operation can mean slight changes

in the product from batch to batch.

Fine and specialty chemicals are usually manufactured in

batch processes. Yet, these products often have very tight

tolerances for impurities in the nal product and demand

batch-to-batch variation being minimized.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Batch Processes:

(James M. Dauglas)

Select batch, if:

1. Production rate

a. Sometimes batch if less than 10million lb/year

b. Usually batch if 1million lb/year

c. Multiproduct plant

2. Market forces:

a. Seasonal production

b. Short product lifetime

3. Scale up problems:

a. Very long reaction times

b. Handling slurries at low flowrates

c. Rapidly fouling materials

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 4 of 21

Chemical Plant Design 1210384 Chapter-5

V.2.

BATCH REACTOR

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Example of parallel reaction

Ratio:

Minimize Byproduct:

If a2 > a1 and b2 > b1: The concentration of both feeds should be minimized

and each added progressively as the reaction proceeds. Predilution of the feeds

might be considered.

If a2 > a1 and b2 < b1: The concentration of FEED1 should be minimized by

charging FEED2 at the beginning of the batch and adding FEED1 progressively

as the reaction proceeds. Predilution of FEED1 might be considered.

If a2 < a1 and b2 > b1: The concentration of FEED2 should be minimized by

charging FEED1 at the beginning of the batch and adding FEED2 progressively

as the reaction proceeds. Predilution of FEED2 might be considered.

If a2 < a1 and b2 < b1: The concentration of FEED1 and FEED2 should be

maximized by rapid addition and mixing.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 5 of 21

Chemical Plant Design 1210384 Chapter-5

A temporal superstructure for a well-mixed batch reactor.

(Smith, R., 2005)

The greater the number of the time intervals, the closer the

model approaches the batch reactor modeled.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

A temporal superstructure for a multiphase well-mixed batch reactor

(Smith, R., 2005)

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 6 of 21

Chemical Plant Design 1210384 Chapter-5

Some examples of mixing compartment networks to represent agitated

vessels.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 7 of 21

Chemical Plant Design 1210384 Chapter-5

V.3.

BATCH SEPARATION

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Batch Distillation

Advantages Disadvantages

The same equipment can be used to process High purity products require the careful

many different feeds and produce different control of the column because of its dynamic

products state

There is exibility to meet different product The mixture is exposed to a high temperature

specications for extended periods

One distillation column can separate a Energy requirements are generally higher.

multicomponent mixture into relatively pure

products

Simple distillation from a batch pot

Find other examples of

batch separation!

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 8 of 21

Chemical Plant Design 1210384 Chapter-5

V.4.

GANTT CHART

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Gantt Chart for a simple batch process

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 9 of 21

Chemical Plant Design 1210384 Chapter-5

Overlapping batches allows the batch cycle time to be

decreased

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Example 5.4.1: determine reactor capacity

Filling time = 0.25 h

Reaction time = 2.5 h Cycle time = 3 h

Reactor emptying = 0.25 h

Production capacity = 3000 ton/year (active: 330 day/year)

30001000 kg

Production rate ton

378.8

kg

30024 h h

1 kg of FEED produces 0.8 of main product

378.8 kg

Reactor capacity 3 h 1420.5 kg

0.8 h

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 10 of 21

Chemical Plant Design 1210384 Chapter-5

Single Step Single Reactor

time

STEP Hour

FILLING 0.25

REACTION 2.50

EMPTYING 0.25

total 3.00

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Single Step 3 Parallel Reactors

1

time STEP Hour

FILLING 0.25

REACTION 2.50

1

EMPTYING 0.25

2 total 3.00

time

time

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 11 of 21

Chemical Plant Design 1210384 Chapter-5

V.5.

PRODUCTION

SCHEDULE FOR

SINGLE PRODUCTS

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Production schedules for a three-step process.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 12 of 21

Chemical Plant Design 1210384 Chapter-5

Subsequent batches are only started once the previous batch

has been completely nished. For this sequential production

schedule, the cycle time is 20 h. This clearly leads to very poor

utilization of equipment.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

It has already been noted that overlapping batches can reduce the cycle time.

Subsequent batches are started as soon as the appropriate equipment becomes

available. Cycle time decreases to 10 h for overlapping batches (the length of the

longest step).

If a specied volume of production needs to be achieved over a given period of

time, then the equipment in the process that uses overlapping batches in Figure

(b) can in principle be half the size of the equipment for sequential production in

Figure (a).

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 13 of 21

Chemical Plant Design 1210384 Chapter-5

There are two items of equipment operating Step A, but in parallel.

This allows both Step B and Step C to be carried out with complete utilization.

If the sizes of the equipment are compared to the sequential production schedule,

then each of the two Steps A1 and A2 in Figure (c) can in principle be one-quarter

the size of the equipment for Step A for sequential production in Figure (a).

The size of the equipment for Steps B and C in Figure (c) will also be one-quarter

the size of those in the sequential production schedule in Figure (a).

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

The nal option shown in Figure (d) is to use intermediate storage for the limiting

step.

Material from Step A is sent to storage, from which Step B draws its feed. Material

is still passed directly from Step B to Step C. Now all three steps are fully utilized.

For the same rate of production over a period of time, the size of Step A can in

principle be half that relative to the sequential production in Figure (a) and the

sizes of Steps B and C can in principle be one-quarter those for sequential

production. However, this is at the cost of introducing intermediate storage.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 14 of 21

Chemical Plant Design 1210384 Chapter-5

V.6.

PRODUCTION

SCHEDULE FOR

MULTIPLE PRODUCTS

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Production schedule for two products with a

three-step process.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 15 of 21

Chemical Plant Design 1210384 Chapter-5

Figure (a) shows a production cycle involving a sequential

production schedule.

Production alternates between Product 1 and Product 2.

The cycle time to produce a batch each of Product 1 and 2 is

30 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

The rst thing that can be considered in order to reduce the

cycle time and increase equipment utilization is to overlap the

batches as shown in Figure (b).

This reduces the cycle time to 18 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 16 of 21

Chemical Plant Design 1210384 Chapter-5

All of the schedules considered so far involved transferring material from one step

to another, from a step to storage or from storage to a step without any time

delay. This is known as zero-wait transfer.

An alternative is to exploit the equipment in which a production step has taken

place to provide hold-up.

In this situation, material is held in the equipment until it is required by the

production schedule. A schedule using equipment hold-up is shown in Figure (c).

This reduces the cycle time to 15 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Finally, Figure (d) shows the use of intermediate storage.

The use of storage is only necessary for Product 2.

Use of intermediate storage in this way reduces the cycle timeto14 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 17 of 21

Chemical Plant Design 1210384 Chapter-5

Single versus mixed-product campaigns for

three batches each of two products.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

The production cycle for three batches each of Product 1 and Product 2.

The batches have been overlapped to increase equipment utilization.

In order to produce three products each of Product 1 and Product 2, the

schedule involves single-product campaigns.

Three batches of Product 1 and three batches of Product 2 follow directly

from each other.

The cycle time is 47 h.

The total time required to produce a given number of batches, in this case

three batches of each Product 1 and Product 2, is known as the

makespan, it is 53 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 18 of 21

Chemical Plant Design 1210384 Chapter-5

An alternative production schedule can be suggested by

following a mixed-product campaign.

Alternating between batches of Product 1 and Product 2 in

allows the cycle time to be reduced to 45 h and the makespan

to be reduced to 51 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 19 of 21

Chemical Plant Design 1210384 Chapter-5

V.7.

EQUPIMENT CLEANING

AND

MATERIAL TRANSFER

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Cleaning between product changes extends the cycle times.

Once cleaning is introduced, the

mixed-product campaigns are

seen to be less efcient than

single-product campaigns

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 20 of 21

Chemical Plant Design 1210384 Chapter-5

Transfer times extend the cycle times.

Compare to the the

schedule without

transfer time,

Cycle time increases

from 20 h to 24 h.

Compare to the the

schedule without

transfer time,

Cycle time increases

from 10 h to 12 h.

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Good luck

Dr. Eng. Y. D. Hermawan ChemEng - UPNVY

Department of Chemical Engineering - UPN Veteran Yogyakarta Page 21 of 21

Potrebbero piacerti anche

- 01 Chapter 1 ppk1Documento26 pagine01 Chapter 1 ppk1Stanley YohanesNessuna valutazione finora

- Reactor Design Lectures Notes: Third YearDocumento38 pagineReactor Design Lectures Notes: Third YearkarmelaidNessuna valutazione finora

- Group No 9.CRK Course Project Report 30, 33,36, 42, 48Documento29 pagineGroup No 9.CRK Course Project Report 30, 33,36, 42, 48Rankhamb ShubhamNessuna valutazione finora

- Unit Operations and Unit ProcessesDocumento5 pagineUnit Operations and Unit ProcesseslaurenNessuna valutazione finora

- Tüm NotlarDocumento1.271 pagineTüm NotlarGöksel VATANNessuna valutazione finora

- Batch Vs ContiniousDocumento4 pagineBatch Vs ContiniousShilajit BaruaNessuna valutazione finora

- CHE 410 Unit Process and Operations Part2Documento20 pagineCHE 410 Unit Process and Operations Part2Eilyza AballaNessuna valutazione finora

- Tarun Summer Internship Report FormattedDocumento52 pagineTarun Summer Internship Report FormattedGOVIND SINGHNessuna valutazione finora

- SCH 421 Reactor Design WEEK 1 & 2 Notes-1Documento15 pagineSCH 421 Reactor Design WEEK 1 & 2 Notes-1vivaline AchiengNessuna valutazione finora

- Chemical Engineering Science: Xin Gao, Xinshuang Liu, Xingang Li, Jinsong Zhang, Yongjin Yang, Hong LiDocumento14 pagineChemical Engineering Science: Xin Gao, Xinshuang Liu, Xingang Li, Jinsong Zhang, Yongjin Yang, Hong LiMihir ShahNessuna valutazione finora

- A Constant Volume Batch Reactor For Saponification Reaction PDFDocumento49 pagineA Constant Volume Batch Reactor For Saponification Reaction PDFanuri nwagbaraNessuna valutazione finora

- 02 Choice of Reactor NewDocumento96 pagine02 Choice of Reactor NewGlenn Muhammad AnsofNessuna valutazione finora

- Hysys Project of Chemical Reaction Engineering: Prepared By: Mahmoud Mohamed ID: 141761Documento9 pagineHysys Project of Chemical Reaction Engineering: Prepared By: Mahmoud Mohamed ID: 141761Mahmoud HendawyNessuna valutazione finora

- ReactorsDocumento38 pagineReactorsFransiska Adelia Froggers100% (1)

- TutoDocumento2 pagineTutoFfmohamad NAdNessuna valutazione finora

- Tarun Summer Internship Report FormattedDocumento51 pagineTarun Summer Internship Report FormattedPatel NeelkumarNessuna valutazione finora

- CPI - PPE-209 - Week #2aDocumento13 pagineCPI - PPE-209 - Week #2afaiquaNessuna valutazione finora

- DarshancoDocumento29 pagineDarshancoDarshan SolankiNessuna valutazione finora

- Revise Chemistry Live! Option ChaptersDocumento44 pagineRevise Chemistry Live! Option Chaptersbookwormie101Nessuna valutazione finora

- Lecture 8 - NC - Revised PDFDocumento55 pagineLecture 8 - NC - Revised PDFsukhmaniNessuna valutazione finora

- Chapter Two: Multiple ReactionsDocumento13 pagineChapter Two: Multiple ReactionsKORAMA KIENNessuna valutazione finora

- Gujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryDocumento24 pagineGujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryPradeep SutharNessuna valutazione finora

- Department of Ice: Name of The Staff Section Office Office Hours Mail IDDocumento3 pagineDepartment of Ice: Name of The Staff Section Office Office Hours Mail IDVishal WaghmodeNessuna valutazione finora

- Materi Pelatihan UniSimDocumento34 pagineMateri Pelatihan UniSimAditya KurniawanNessuna valutazione finora

- Tutorial Experiment Batch ReactorDocumento2 pagineTutorial Experiment Batch Reactorkhaito K5Nessuna valutazione finora

- NBL and Scale UpDocumento8 pagineNBL and Scale UppratikNessuna valutazione finora

- Forbidden Chemistries Go Flow in API SynthesisDocumento8 pagineForbidden Chemistries Go Flow in API SynthesisisosicaNessuna valutazione finora

- On Line Class ON Safety in Petrochemical IndustryDocumento57 pagineOn Line Class ON Safety in Petrochemical IndustryMayank KoparkarNessuna valutazione finora

- Control of A Fluidized Bed Polyethylene ReactorDocumento16 pagineControl of A Fluidized Bed Polyethylene ReactorĐức Kiều TríNessuna valutazione finora

- CHE 410 Chemcal Process Industries Rev (Part 1)Documento32 pagineCHE 410 Chemcal Process Industries Rev (Part 1)Benedick Jayson MartiNessuna valutazione finora

- Chemical Process IndustriesDocumento14 pagineChemical Process IndustriesRida akhtarNessuna valutazione finora

- Evaluation of Spinning Disk Reactor Technology ForDocumento9 pagineEvaluation of Spinning Disk Reactor Technology Forsoumia boudjenaneNessuna valutazione finora

- Process Intensification Through Microreactor Application: A. Pohar and I. PlazlDocumento8 pagineProcess Intensification Through Microreactor Application: A. Pohar and I. Plazlmajster19Nessuna valutazione finora

- Reactors - Industrial Plant EngineeringDocumento31 pagineReactors - Industrial Plant EngineeringBea Loryll TarlacNessuna valutazione finora

- 1-S2.0-S0255270196041682-Main Westerterp PDFDocumento11 pagine1-S2.0-S0255270196041682-Main Westerterp PDFnicocarraraNessuna valutazione finora

- Reactor Lecture 1-2Documento3 pagineReactor Lecture 1-2زياد طارق محمد براكNessuna valutazione finora

- The Integration of Process Safety Into A Chemical Reaction Engineering Course: Kinetic Modeling of The T2 IncidentDocumento6 pagineThe Integration of Process Safety Into A Chemical Reaction Engineering Course: Kinetic Modeling of The T2 IncidentMachhi VishalNessuna valutazione finora

- Che 307 Lec1 2Documento12 pagineChe 307 Lec1 2Zabo TrewNessuna valutazione finora

- Technical Paper SeriesDocumento8 pagineTechnical Paper SeriesJuan Alejandro Cañas ColoradoNessuna valutazione finora

- Comparative Experiments On Polymer Degradation OilfieldDocumento7 pagineComparative Experiments On Polymer Degradation Oilfieldxxtryxx48Nessuna valutazione finora

- Chương 6-Green Chem - Week 13 - Emerging Greener Technologies and Alternative Energy Sources - Student - 2023-11-27Documento22 pagineChương 6-Green Chem - Week 13 - Emerging Greener Technologies and Alternative Energy Sources - Student - 2023-11-27Nhi TranNessuna valutazione finora

- Industrial Chemistry: Syllabus June 2014Documento9 pagineIndustrial Chemistry: Syllabus June 2014Mahmud HridoyNessuna valutazione finora

- Chinese Journal of Chemical Engineering: Jin Lang, Jiao ZhaoDocumento8 pagineChinese Journal of Chemical Engineering: Jin Lang, Jiao ZhaoLydia DAHMOUNNessuna valutazione finora

- Chinese Journal of Chemical Engineering: Jin Lang, Jiao ZhaoDocumento8 pagineChinese Journal of Chemical Engineering: Jin Lang, Jiao ZhaoLydia DAHMOUNNessuna valutazione finora

- Fundamentals of Bioengineering Ii: Asst. Prof. Betül GürünlüDocumento33 pagineFundamentals of Bioengineering Ii: Asst. Prof. Betül GürünlübettieboomNessuna valutazione finora

- Dynamics and Control of A Biodiesel TransterificationvReactor, S. Mjalli, Kim San. Et Al., Chem. Eng. Techol.,2009,32.Documento14 pagineDynamics and Control of A Biodiesel TransterificationvReactor, S. Mjalli, Kim San. Et Al., Chem. Eng. Techol.,2009,32.Mario Sampedro CruzNessuna valutazione finora

- Process Intensification, Transforming Chemical EngineeringDocumento13 pagineProcess Intensification, Transforming Chemical EngineeringseelampremNessuna valutazione finora

- A Comparative Study of Dried Apple Using Hot Air Intermittent and Continuous Microwave Evaluation of Kinetic Parameters and Physicochemical Quality AttributesDocumento8 pagineA Comparative Study of Dried Apple Using Hot Air Intermittent and Continuous Microwave Evaluation of Kinetic Parameters and Physicochemical Quality Attributeschedli melkiNessuna valutazione finora

- Scaling Chemical Processes: Practical Guides in Chemical EngineeringDa EverandScaling Chemical Processes: Practical Guides in Chemical EngineeringNessuna valutazione finora

- Chemical Plant and Its Operation: Including Safety and Health AspectsDa EverandChemical Plant and Its Operation: Including Safety and Health AspectsValutazione: 5 su 5 stelle5/5 (1)

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringDa EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringNessuna valutazione finora

- In situ Spectroscopic Techniques at High PressureDa EverandIn situ Spectroscopic Techniques at High PressureNessuna valutazione finora

- Recovery ImprovementDa EverandRecovery ImprovementQiwei WangNessuna valutazione finora

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlDa EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNessuna valutazione finora

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationDa EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationNessuna valutazione finora

- Fixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsDa EverandFixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsValutazione: 4 su 5 stelle4/5 (5)

- ABC Press Release and AllocationDocumento28 pagineABC Press Release and AllocationAndrew Finn KlauberNessuna valutazione finora

- Variable Frequency DriveDocumento8 pagineVariable Frequency DriveNAYEEM100% (1)

- How To ComboDocumento15 pagineHow To Combosapabapjava2012Nessuna valutazione finora

- 2013 - To and Fro. Modernism and Vernacular ArchitectureDocumento246 pagine2013 - To and Fro. Modernism and Vernacular ArchitecturesusanaNessuna valutazione finora

- Reader of The Year - PDF: Learning Activity 1.1 PortfolioDocumento20 pagineReader of The Year - PDF: Learning Activity 1.1 PortfolioAtenaNessuna valutazione finora

- Ineo+ 200 Parts Guide ManualDocumento90 pagineIneo+ 200 Parts Guide ManualOláh GyörgyNessuna valutazione finora

- Op Amps and Linear Integrated Circuits 4th Edition by Gayakwad Ramakant A Textbook PDF Download PDFDocumento1 paginaOp Amps and Linear Integrated Circuits 4th Edition by Gayakwad Ramakant A Textbook PDF Download PDFNiraj KapoleNessuna valutazione finora

- Tankless Vs TankDocumento2 pagineTankless Vs TankClick's PlumbingNessuna valutazione finora

- Building The Gws Slow Stick PlaneDocumento21 pagineBuilding The Gws Slow Stick PlaneNUFA88Nessuna valutazione finora

- Carnot Cycle and EngineDocumento18 pagineCarnot Cycle and EngineXYZNessuna valutazione finora

- Action Research MethodDocumento27 pagineAction Research MethodNiño Czar RaroNessuna valutazione finora

- Group 2 PBA - ScriptDocumento6 pagineGroup 2 PBA - ScriptruciNessuna valutazione finora

- Soft-Starter: Programming ManualDocumento162 pagineSoft-Starter: Programming ManualThaylo PiresNessuna valutazione finora

- The Law of CosinesDocumento4 pagineThe Law of Cosinesapi-213604106Nessuna valutazione finora

- Chapter 4 Calculations ANSWERSDocumento2 pagineChapter 4 Calculations ANSWERSmollicksoham2907Nessuna valutazione finora

- UFO and PentagonDocumento69 pagineUFO and PentagonNur Agustinus100% (3)

- Prudence and FrugalityDocumento17 paginePrudence and FrugalitySolaiman III SaripNessuna valutazione finora

- Inventory Counting in Inventory ManagementDocumento15 pagineInventory Counting in Inventory ManagementDinesh GuptaNessuna valutazione finora

- Rotak: Downloaded From Manuals Search EngineDocumento18 pagineRotak: Downloaded From Manuals Search EngineOvidiu BrinzanNessuna valutazione finora

- LED Lighting Applications Design GuideDocumento20 pagineLED Lighting Applications Design GuideBank100% (3)

- Character QuestionsDocumento3 pagineCharacter QuestionsAaron FarmerNessuna valutazione finora

- Ee - Lab ReportDocumento36 pagineEe - Lab ReportNoshaba Noreen75% (4)

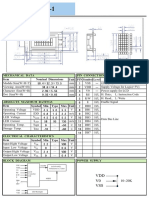

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocumento1 paginaV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriNessuna valutazione finora

- Section A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentDocumento22 pagineSection A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentThanh PhongNessuna valutazione finora

- Hatton National Bank PLC: Instance Type and TransmissionDocumento2 pagineHatton National Bank PLC: Instance Type and TransmissiontaraNessuna valutazione finora

- Remembering Thanu Padmanabhan - The HinduDocumento3 pagineRemembering Thanu Padmanabhan - The HinduIucaa libraryNessuna valutazione finora

- The Big Table of Quantum AIDocumento7 pagineThe Big Table of Quantum AIAbu Mohammad Omar Shehab Uddin AyubNessuna valutazione finora

- Probability of Event Intersections: Vietnamese-German UniversityDocumento17 pagineProbability of Event Intersections: Vietnamese-German UniversityĐặng ThưNessuna valutazione finora

- London A Day in The Citypdf 2 PDF FreeDocumento18 pagineLondon A Day in The Citypdf 2 PDF FreePuri RodriguezNessuna valutazione finora

- Experiment 13 Ultrafiltration UnitDocumento13 pagineExperiment 13 Ultrafiltration UnitKishen NaniNessuna valutazione finora