Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Smart Load

Caricato da

Ahmed Mujtaba0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

134 visualizzazioni2 pagineweight bridge

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoweight bridge

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

134 visualizzazioni2 pagineSmart Load

Caricato da

Ahmed Mujtabaweight bridge

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

GE Oil & Gas

Measurement & Control

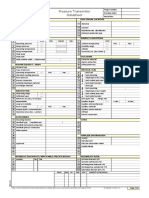

SmartLoad BATCH CONTROLLER

SmartLoad is a batch controller used for liquid product distribution at truck, rail, marine, aviation and

pipeline loading and unloading facility. It precisely delivers preset quantity of product blends from tank

storage or pipeline into vehicle, rail wagons, aviation or vessels.

Salient Features

Incorporates modern technology in a cost-effective,

self-contained enclosure providing accuracy and

reliability

Suitable for petroleum, petrochemicals, LNG / LPG,

asphalt and specialty chemical applications

Capable of loading Net LPG quantity deducting vapor

quantity

Controls loading of base or blended product (up to 4

components) with or without additives & dyes (up to 6

additives). Blending can be configured for sequential,

in-line proportional or non-proportional mode along Truck/ Rail Wagon Loading - Single Product/ Multiple Blends & Additive Injection

with additive injection using various (up to 10) recipes

User configurable transaction and batch archiving of

selected parameters for storage and ticket printing (up Communication ports One RS485 and the other port

to 2000 transactions). either with RS232 or RS485 for communication with

Configurable data logging / printing options for batch TAS / other smart devices

and transaction summery, alarm, meter proving, Supports open communication protocol Modbus-RTU

program mode change, power failure, weights &

Directly interfaces with proximity or touch key card

measures switch status etc.

readers

User configurable alarm text and alarm actions

Directly interfaces with flow meters, digital control

Optional secondary keypad and LCD display available valves, additive injector panels, safety interlocks and

for additional two-side loading or remote control Remote Interaction Terminal (RIT)

application

Temperature / Pressure compensation per API IP or

Safety and Security

linear methods Supports storage up to 500 proximity cards / touch

keys that will be validated during manual mode of

Operates as a standalone unit or integrated with any

operation

Terminal Automation System

Possible to seal weights & measures switch to restrict

User-friendly menu driven configuration facility

the change of meter factors/ k-factor

Low installation and wiring cost

Audit logs for change in weights & measures

Technology parameters, if weights & measures switch is not locked

Big hall-effect keys with user-friendly and cellular Three levels of passwords:

phone like alpha-numeric keypad for easy operation L1 Super User (Can change all the parameters except

Large easy to read text/graphical display with W&M parameters if locked)

automatic backlight and contrast adjustment L2 Intermediate (Can only view all parameters )

Display of preset and loaded quantity with engineering units L3 Operator (Only acknowledge the alarms )

Dynamic, simultaneous display over 200 data items for

Accuracy

providing real-time display of flow rate, temperature,

blend percentage, additive volumes, pressure, density Pulse security as per IP252/76, Level B

etc. 6 points meter factor linearization for increased accuracy

General Specifications Power requirements 115 V AC / 230 V + 10% AC, 28 VA

Operating temperatures : - 4oF to 140oF (-20oC to 60oC) Five cable entries - bottom entries, forward & rear

Storage temperatures : - 4oF to 158oF (-20oC to 70oC) Exd IIB T6 IP65 as per IS/IEC 60079-0:2004, IS/IEC 60079-

1:2007 & IS/IEC 60529:2001

Relative humidity : 5 to 95% non-condensing

Approvals : CMRI & CCOE - Approved / ATEX & IEC Ex

(Applied)

Enclosure Specifications

Weights & measures approval: Weights & measure

(H) 325mm x (W) 356mm x (D) 355mm (+/- 5 mm) approved by Department of Consumer Affairs,

Weight approximately 25Kg Government of India Mark # IND/09/11/548

Model # SmartLoad

GE Oil & Gas

Measurement & Control

Advanced Sys-tek Pvt. Ltd.

299-300, G.I.D.C., Makarpura,

Vadodara - 390 010, India

Ph.: + 91 265 3041100

sales@advancedsystek.com www.ge-mcs.com

Potrebbero piacerti anche

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979Da EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNessuna valutazione finora

- 000 in DTS 404Documento16 pagine000 in DTS 404ssmith2007Nessuna valutazione finora

- Process Control System A Complete Guide - 2020 EditionDa EverandProcess Control System A Complete Guide - 2020 EditionNessuna valutazione finora

- Aceh Cogeneration Plant Control System SpecificationsDocumento26 pagineAceh Cogeneration Plant Control System SpecificationsIlham RamdaniNessuna valutazione finora

- Pressure Transmitter DatasheetDocumento1 paginaPressure Transmitter DatasheetsurendharNessuna valutazione finora

- Tank Gauging Measurement StandardsDocumento5 pagineTank Gauging Measurement StandardsbsarkarNessuna valutazione finora

- Calculate Number of Plate and Pipe EarthingDocumento7 pagineCalculate Number of Plate and Pipe EarthingheroNessuna valutazione finora

- Smith Meter UPTDocumento6 pagineSmith Meter UPTvalimironescuNessuna valutazione finora

- PUB060-001-00 - 1110 RCL NetworksDocumento8 paginePUB060-001-00 - 1110 RCL NetworksapisituNessuna valutazione finora

- Project number pressure transmitter datasheetDocumento2 pagineProject number pressure transmitter datasheetdiksha surekaNessuna valutazione finora

- Honeywell Enraf Blender Referen 2012Documento6 pagineHoneywell Enraf Blender Referen 2012Javier Alejandro QuingaNessuna valutazione finora

- Fitter CTS2.0 NSQF-4Documento63 pagineFitter CTS2.0 NSQF-4Anil Fauzdar100% (1)

- Sensepoint XCD TechMan MAN0873 Iss8 0913 EMEAIDocumento84 pagineSensepoint XCD TechMan MAN0873 Iss8 0913 EMEAImusajcNessuna valutazione finora

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Documento138 pagineOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- Access Control ITPDocumento2 pagineAccess Control ITPehteshamNessuna valutazione finora

- Elster-Instromet M2000 FCDocumento0 pagineElster-Instromet M2000 FCsaid_rahmansyah4750Nessuna valutazione finora

- Plantpax Process Automation Solution For Oil and GasDocumento24 paginePlantpax Process Automation Solution For Oil and GaszkaticNessuna valutazione finora

- ISA-18.02 Draft1 BallotDocumento75 pagineISA-18.02 Draft1 BallotAlbatross123Nessuna valutazione finora

- ITP - 031 (Earthing)Documento2 pagineITP - 031 (Earthing)mohamed wahebNessuna valutazione finora

- Control Systems Guide For Inteface Between Control Systems and ElectricalDocumento4 pagineControl Systems Guide For Inteface Between Control Systems and Electricalaugur886Nessuna valutazione finora

- Subsea Production Control Systems: 1 ForewordDocumento25 pagineSubsea Production Control Systems: 1 ForewordBSFNessuna valutazione finora

- FS 3210 - FS-Gas Flow ComputerDocumento6 pagineFS 3210 - FS-Gas Flow ComputerBinu ManiNessuna valutazione finora

- Catalogue PlantpAxDocumento16 pagineCatalogue PlantpAxaharnishaNessuna valutazione finora

- ControlLogix® 5560M03SE Combination Controller and SERCOS Interface - 1756-In593a-En-PDocumento48 pagineControlLogix® 5560M03SE Combination Controller and SERCOS Interface - 1756-In593a-En-PElder MartinsNessuna valutazione finora

- SF 06015Documento4 pagineSF 06015ricky100% (1)

- Product List: Pressure MeasurementDocumento6 pagineProduct List: Pressure MeasurementSr FarezNessuna valutazione finora

- ON-LINE TURBIDIMETER COMPARISONDocumento1 paginaON-LINE TURBIDIMETER COMPARISONmaserrasNessuna valutazione finora

- Phosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15Documento6 paginePhosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15HassanSobohNessuna valutazione finora

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDocumento3 pagineEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNessuna valutazione finora

- Honeywell Prover PDFDocumento12 pagineHoneywell Prover PDFMelina SbhNessuna valutazione finora

- POB User Manual v1.2.2 1Documento61 paginePOB User Manual v1.2.2 1Vladimirs ArzeninovsNessuna valutazione finora

- CSIKSDocumento52 pagineCSIKSGustavoSilvinoSilvinoNessuna valutazione finora

- Process Control (Level)Documento12 pagineProcess Control (Level)Gino GalanoNessuna valutazione finora

- 01 Installation of Ratio Flow ControllersDocumento1 pagina01 Installation of Ratio Flow ControllersBrandon TrocNessuna valutazione finora

- Inspection & Test PlanDocumento1 paginaInspection & Test PlanRonNessuna valutazione finora

- Parking Guidance System (PGS)Documento23 pagineParking Guidance System (PGS)Pimen AjjahNessuna valutazione finora

- Technical Doc 1 - Technical Scope of Work Drs Eac181Documento25 pagineTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09Nessuna valutazione finora

- INTRON-D Plus: System Overview, Key Components, Networking Capabilities and MoreDocumento28 pagineINTRON-D Plus: System Overview, Key Components, Networking Capabilities and MoreEhsan RohaniNessuna valutazione finora

- Manuals 310a 32a Pressure Reducing Regulator Instruction Manual Fisher en en 5939670Documento20 pagineManuals 310a 32a Pressure Reducing Regulator Instruction Manual Fisher en en 5939670walidNessuna valutazione finora

- Instrument Power Cable Sizing Part 1Documento2 pagineInstrument Power Cable Sizing Part 1Art G. EnziNessuna valutazione finora

- Tutorial 4Documento40 pagineTutorial 4LEDNessuna valutazione finora

- 1492 sg121 - en PDocumento116 pagine1492 sg121 - en PAnonymous Wu6FDjbNessuna valutazione finora

- Training Kit PEK 408 EngDocumento38 pagineTraining Kit PEK 408 EngSyed Mohammad NaveedNessuna valutazione finora

- Previews MSS SP 61 2013 PreDocumento4 paginePreviews MSS SP 61 2013 PreHoàng Vinh0% (1)

- 3100/3150 - LTQ Limitorque Valve Actuator Master Module: Revision 1.7Documento41 pagine3100/3150 - LTQ Limitorque Valve Actuator Master Module: Revision 1.7Marcos VasconcelosNessuna valutazione finora

- Aircraft Obstruction Light MaintenanceDocumento8 pagineAircraft Obstruction Light MaintenanceBe Sar WicaksonoNessuna valutazione finora

- (SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Documento3 pagine(SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Roberto Carlos TeixeiraNessuna valutazione finora

- Pub059-020-00 - 0100 (Pakscan Integral FCU (Field Control Unit) Technical Manual) PDFDocumento34 paginePub059-020-00 - 0100 (Pakscan Integral FCU (Field Control Unit) Technical Manual) PDFapisituNessuna valutazione finora

- Process Instrumentation Terminology Performance CharaDocumento12 pagineProcess Instrumentation Terminology Performance CharaPriNessuna valutazione finora

- SPLMV9Install ChecklistDocumento3 pagineSPLMV9Install Checklistanon_908554203Nessuna valutazione finora

- METHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFDocumento5 pagineMETHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFCarlos ImmanuelNessuna valutazione finora

- Common Interview QuestionsDocumento5 pagineCommon Interview QuestionsMary CorpuzNessuna valutazione finora

- SATR-J-6503 - Rev 0 PDFDocumento5 pagineSATR-J-6503 - Rev 0 PDFAdel KlkNessuna valutazione finora

- FGS SymbolsDocumento3 pagineFGS Symbolsykresna1631Nessuna valutazione finora

- Point-Infrared Gas Detector Buyer's GuideDocumento4 paginePoint-Infrared Gas Detector Buyer's GuideSatyasrinivas PulavarthiNessuna valutazione finora

- 04 Instrument IndexDocumento52 pagine04 Instrument IndexAnanthan SrijithNessuna valutazione finora

- Procurement of Electronic Odorizer UnitDocumento21 pagineProcurement of Electronic Odorizer Unitbmanojkumar16Nessuna valutazione finora

- CM44PDocumento52 pagineCM44PSadot GutierrezNessuna valutazione finora

- DPT Smart Pressure TransmitterDocumento15 pagineDPT Smart Pressure Transmitterprasanta_bbsrNessuna valutazione finora

- ASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1Documento23 pagineASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1John PaulNessuna valutazione finora

- Detail To Clarify Our Position On Mentioned Environmental IssuesDocumento1 paginaDetail To Clarify Our Position On Mentioned Environmental IssuesAhmed MujtabaNessuna valutazione finora

- ARF-01 Applicant Registration FormDocumento1 paginaARF-01 Applicant Registration FormAhmed Mujtaba100% (1)

- Combustible Dust Incident Report: Over 150 Injured and Killed in Coal Mine Ventilation FireDocumento55 pagineCombustible Dust Incident Report: Over 150 Injured and Killed in Coal Mine Ventilation FireAhmed MujtabaNessuna valutazione finora

- Appendix D Emergency Response Plan PDFDocumento23 pagineAppendix D Emergency Response Plan PDFAhmed Mujtaba100% (1)

- Fire Safety Equipment ListDocumento1 paginaFire Safety Equipment ListAhmed MujtabaNessuna valutazione finora

- FINAL PHI EXPLOSIVE-4 List PDFDocumento1 paginaFINAL PHI EXPLOSIVE-4 List PDFAhmed MujtabaNessuna valutazione finora

- D104 PDFDocumento13 pagineD104 PDFAhmed MujtabaNessuna valutazione finora

- Emergency Procedures Plan - Site ADocumento44 pagineEmergency Procedures Plan - Site AAhmed MujtabaNessuna valutazione finora

- Port Botany LPG Terminal Emergency Response PlanDocumento76 paginePort Botany LPG Terminal Emergency Response PlanAhmed Mujtaba100% (2)

- Final Phi Explosive-4 ListDocumento1 paginaFinal Phi Explosive-4 ListAhmed MujtabaNessuna valutazione finora

- OHSASDocumento12 pagineOHSASSuman MukherjeeNessuna valutazione finora

- FurnaceDocumento3 pagineFurnaceAhmed MujtabaNessuna valutazione finora

- Ohsas18001 ChecklistDocumento7 pagineOhsas18001 Checklistshujad77Nessuna valutazione finora

- BSI BSOHSAS18001 Assessment Checklist UK enDocumento2 pagineBSI BSOHSAS18001 Assessment Checklist UK enasimnaqvi2008Nessuna valutazione finora

- OHSASDocumento12 pagineOHSASSuman MukherjeeNessuna valutazione finora

- Fire Extinguisher Chekclist PDFDocumento1 paginaFire Extinguisher Chekclist PDFAhmed MujtabaNessuna valutazione finora

- Revised Syllabus CE-2016 10 Jul 2015Documento158 pagineRevised Syllabus CE-2016 10 Jul 2015Muhammad Faisal TahirNessuna valutazione finora

- Fire Safety Equipment List - ITTDocumento1 paginaFire Safety Equipment List - ITTAhmed MujtabaNessuna valutazione finora

- Muslim Rule in India 712 1857Documento29 pagineMuslim Rule in India 712 1857Mir Ahmad Feroz100% (1)

- Chloroform MSDS PDFDocumento8 pagineChloroform MSDS PDFDeacy SulaimanNessuna valutazione finora

- Explosives Rules, 2010 PDFDocumento203 pagineExplosives Rules, 2010 PDFAhmed MujtabaNessuna valutazione finora

- 24koffel PresentationDocumento21 pagine24koffel PresentationAhmed MujtabaNessuna valutazione finora

- Final Year Project Copy Submission RegulationsDocumento2 pagineFinal Year Project Copy Submission RegulationsAhmed MujtabaNessuna valutazione finora

- Heating Coil Sizing For Fuel Oil TankDocumento2 pagineHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- Chemical Engineer Cover LetterDocumento2 pagineChemical Engineer Cover LetterAhmed MujtabaNessuna valutazione finora

- PalindromeDocumento7 paginePalindromeZy AdrianneNessuna valutazione finora

- (Mamoru Hosaka (Auth.) ) Modeling of Curves and SuDocumento363 pagine(Mamoru Hosaka (Auth.) ) Modeling of Curves and Suamalendu_biswas_1Nessuna valutazione finora

- FD FX Brochure Update 072020Documento9 pagineFD FX Brochure Update 072020Alex PomaNessuna valutazione finora

- Concrete Pipe Installation Guide-CPMDocumento17 pagineConcrete Pipe Installation Guide-CPMSankar CdmNessuna valutazione finora

- Vista 128BPT Program ManualDocumento72 pagineVista 128BPT Program ManualyalmanzaNessuna valutazione finora

- The NT Insider: Writing Filters Is Hard WorkDocumento32 pagineThe NT Insider: Writing Filters Is Hard WorkOveja NegraNessuna valutazione finora

- Unit 2: Heat Treatment ProcessesDocumento53 pagineUnit 2: Heat Treatment ProcessesAmit KumarNessuna valutazione finora

- Linux CommandsDocumento2 pagineLinux CommandsVishwas BeedeNessuna valutazione finora

- Emergency CallDocumento6 pagineEmergency CallNugrohoNessuna valutazione finora

- Xtract V 3 0 8Documento72 pagineXtract V 3 0 8Don Ing Marcos LeónNessuna valutazione finora

- Tli R3.0 PDFDocumento6.465 pagineTli R3.0 PDFz_sadiq25% (4)

- (1)Documento119 pagine(1)Virginia Rosales OlmosNessuna valutazione finora

- Shiela S. Portillo Ang Specification 09112021Documento9 pagineShiela S. Portillo Ang Specification 09112021JR De LeonNessuna valutazione finora

- Lightning Protection System Testing & Commissioning Method StatementDocumento3 pagineLightning Protection System Testing & Commissioning Method Statementvin ssNessuna valutazione finora

- CNA09016 SGDocumento8 pagineCNA09016 SGSatyarth SampathNessuna valutazione finora

- SQL Server 2008 R2 Express Installation GuideDocumento53 pagineSQL Server 2008 R2 Express Installation GuideGersonGamas100% (2)

- Multi-disciplinary profile of IS/IT outsourcing researchDocumento47 pagineMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNessuna valutazione finora

- Sooad ManualDocumento19 pagineSooad ManualRakhiNessuna valutazione finora

- Standard For Safety UL ADocumento49 pagineStandard For Safety UL ANhất NgônNessuna valutazione finora

- Peanut Brittle LabDocumento2 paginePeanut Brittle LabMary Bacon HillebrandNessuna valutazione finora

- Transmission ErrorDocumento7 pagineTransmission ErrorTapas JenaNessuna valutazione finora

- The History of PumpsDocumento8 pagineThe History of Pumpsdhanu_aquaNessuna valutazione finora

- Husky Air Assignment 5 and 6Documento15 pagineHusky Air Assignment 5 and 6varunkalra6Nessuna valutazione finora

- Especificaciones LuminariasDocumento3 pagineEspecificaciones LuminariasRoni DominguezNessuna valutazione finora

- GM300 SMDocumento46 pagineGM300 SMSrboljub Milosavljevic100% (1)

- Metronidazole AnalysisDocumento5 pagineMetronidazole AnalysisHendri WasitoNessuna valutazione finora

- Shop Manual WA380-3LE SN A50001Documento758 pagineShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Chapter 4.1 Basic Call Procedure (ED01 - 53 - EN)Documento53 pagineChapter 4.1 Basic Call Procedure (ED01 - 53 - EN)quaderbtech06Nessuna valutazione finora

- Nitobond EP 0608Documento2 pagineNitobond EP 0608James PittsNessuna valutazione finora

- Study of Buffer Overflows and Keyloggers in The Linux Operating SystemDocumento8 pagineStudy of Buffer Overflows and Keyloggers in The Linux Operating Systemrobyrulz100% (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- Control of Power Electronic Converters and Systems: Volume 1Da EverandControl of Power Electronic Converters and Systems: Volume 1Valutazione: 5 su 5 stelle5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (50)

- Renewable Energy: A Very Short IntroductionDa EverandRenewable Energy: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (12)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDa EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureValutazione: 3.5 su 5 stelle3.5/5 (48)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Albert Einstein's Theory Of Relativity Explained SimplyDa EverandAlbert Einstein's Theory Of Relativity Explained SimplyNessuna valutazione finora

- The Laws of Thermodynamics: A Very Short IntroductionDa EverandThe Laws of Thermodynamics: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (10)

- Build Your Own Electric Vehicle, Third EditionDa EverandBuild Your Own Electric Vehicle, Third EditionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansDa EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerValutazione: 4 su 5 stelle4/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Way Home: Tales from a life without technologyDa EverandThe Way Home: Tales from a life without technologyValutazione: 4 su 5 stelle4/5 (45)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDa EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyDa EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNessuna valutazione finora

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationDa EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationValutazione: 1 su 5 stelle1/5 (1)

- Oil and Gas Pipelines: Integrity and Safety HandbookDa EverandOil and Gas Pipelines: Integrity and Safety HandbookNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)