Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Motor Milwaukee BB5000 PDF

Caricato da

Eduardo Efrain Rubio0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni2 pagineTitolo originale

Motor Milwaukee BB5000.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni2 pagineMotor Milwaukee BB5000 PDF

Caricato da

Eduardo Efrain RubioCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 2

*

SRRSHASSSVMRRRESE NER

BULLETIN NO.

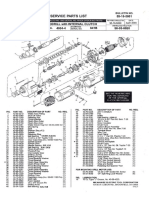

SERVICE PARTS LIST 55-16-5001

SR

pxampte [CATALOG NO. 4004-4

02.04.1229

DYMODRILL with INTERNAL CLUTCH

OR ate

SERIAL NO.

WIRING WISTRUCTION

8416 58-03-0020

Component Parts (Small #)

Are Included When Ordering

The: oni (Large #).

DESCRIPTION OF PART NO. REQ.

Water oe rng ‘i

Ser ate i}

Fetanng i}

Gig Bio Stee 5

‘Gtch Dac-nner =)

‘rater Svival Fig incl 06-89-2420 Ser(t)

Bee Soo

‘lashor (B09 of2)

ee ‘ ss )

Bal eoainy’szosts evace

iiazon ea Taptte 730

Sea Cane Ane 0681805 Pp

Spincle Geer

Nets Soaring cE 1212

Sat'Beanng "Bzoi aKa,

Prion Shak assy

‘Wood Ko

‘Shining. Spring

$Shifing Plunger

‘Thrust Bearing Washer

‘Thaust Bearing

Glitch Gear Azsombiy

{Clutch Pinion shat

rust Bearing

Shifting Yoxe

Diaphragm Assy (inc. 06-65-1155 Pin)

Biaphragm Asey y

arn Gasket

{ex 314" Groove Pin

‘Shitting Knob

‘Ball Beering szoi nce

)

>

)

)

)

>

)

i

»

i

.

)

)

.

i

i

1

)

)

)

)

)

aaapasaspsassaa3ppssaBs32

PARTNO, DESCRIPTION OF PART NO. REQ.

16-76-0325 230V Armature

2254-0790 Fan

42-14-0291

Battle

[2-04-1041 Ball Bearing, 620018

Ose2e162 10240291 Pan Ha. Som, 7-25

18740120 220V. Fels

2346-1410 Motor Inauator

2220-0680 Brush Tube

2218-0708 Carbon Bruch Assombly

Oes2-8985 — &32% 8/16" Pan He. Sem.T-20

22.56.0470 Terminal Block

2238-0140 Wie Trap

‘Cord Clamp

deaz7aze © B16x 7" Pan Hd. Plasto 7-20

2531-0150 Gono! Assy. (Soe Bul

Oe72-1720 Rivet

1259-1815 See Nameplate

22.32.0350 Brush Gower

0682-5316 6.32 x 17 Pan Hd. SI Tepite T-20

2850-6903 Motor Housing

Geaasze8 440 x the Pan Hd. TapteT-10

12.98.2100 instructon Plato

96-95-5200 8.52 x 8/16" Slotted Hex Hd. Scrow

22-36-0090 PRGD (Soe Bulli No. 88-03-0020)

4836-0275 Gear 5;

42:96-4700 Tale" Open End Wrench

48.36.0050 132" Hex Socket Wrench

61-10-0660" Retaining Nut Spanner Too!

FOR MOUNTING DRILL MOTOR USE:

FIG.

a

06-75-3090 1/4:20.x7/6" Socket Hd. Screw

(06-97-8080 1/4" Spit Ring Lock Washer

LUBRICATION

18 Oz. Type °" Grease, No, 49-08-4220,

MILWAUKEE ELECTRIC TOOL CORPORATION

1135 W. LISBON RD, BROOKFIELD, WI

53005

Servicing the Clutch Mechanism-

Torque Value for the Clutch Mechanism Retaining Nut (fig. no. 3).

Grease / Lubrication — when assembling the intemal clutch component parts:

the Clutch Discs (fig. nos. § and 6), Thrust Washers (fig. no. 4) and

Dise Springs (fig. no. 8) q th

(Cat. No. 49-08-4220 type ‘J') during their assembly

into the spindle gear.

Grease / Lubrication specification includes

‘coating intemal bore of the spindle gear.

45-88-1140 Thrust Washers 2)

43-06-0180 Clutch Dises-Outer (@)

43-06-0150 Clutch Discs-Inner (6)

40-50-2150 Spring Dises (4)

32-75-3430 Spindle Gear (1)

Service note: the assembly torque for the Clutch Mechanism Retaining Nut,

No. 06-57-1050 (fig. no. 3), which insures the static torque required to slip

the clutch mechanism, as lubricated, should be 45.80 ft-lbs (61-68 Nm). petating Wut Spennar

Service Too!

With the gear case separated from the diaphragm & motor housing of the nied

(Clutch Dymo-Drill motor —

+ insert & engage a 61-10-0660 retaining nut spanner with the notches

in the 06-57-1050 clutch adjustment retaining nut.

+ with a 1/2" hex socket bit driver attached to a torque wrench,

interlock the male hex with the female hex found in the threaded end

of the dymo-drill spindle. 4/2" Hex Bit Socket Driver,

Snap-On #psaié,

+ tum the torque wrench clockwise ©, observing the torque reading and Pronto#5441%

tighten the clutch agjustment retaining nut on the rear of the spindle oF equivalent

shaft until a value of 45-50 ftubs (61-68 Nm) is obtained.

Potrebbero piacerti anche

- Micro atDocumento2 pagineMicro atEduardo Efrain RubioNessuna valutazione finora

- Busch R 5 RA 0165, 0205, 0255, 0305 DDocumento20 pagineBusch R 5 RA 0165, 0205, 0255, 0305 DEduardo Efrain Rubio100% (2)

- Zero Inex Blast Cabinet Spare Parts PDFDocumento13 pagineZero Inex Blast Cabinet Spare Parts PDFEduardo Efrain RubioNessuna valutazione finora

- Zero Inex Blast CabinetDocumento8 pagineZero Inex Blast CabinetEduardo Efrain RubioNessuna valutazione finora

- Busch R5 RA0250 RA 0250 Single Stage Rotary Vane Vacuum Pump Rebuilt RefurbishedDocumento2 pagineBusch R5 RA0250 RA 0250 Single Stage Rotary Vane Vacuum Pump Rebuilt RefurbishedEduardo Efrain RubioNessuna valutazione finora

- Motor Milwaukee BB5000Documento2 pagineMotor Milwaukee BB5000Eduardo Efrain RubioNessuna valutazione finora

- Dynamics Research Corp 10,000 Lbs CapacityDocumento2 pagineDynamics Research Corp 10,000 Lbs CapacityEduardo Efrain RubioNessuna valutazione finora

- Tooling Catalog Herramanientas de LevanteDocumento30 pagineTooling Catalog Herramanientas de LevanteEduardo Efrain RubioNessuna valutazione finora

- Formulario Entrega EPP PDFDocumento5 pagineFormulario Entrega EPP PDFEduardo Efrain RubioNessuna valutazione finora

- Dynamic Research Corp 5000 Lbs EconomyDocumento2 pagineDynamic Research Corp 5000 Lbs EconomyEduardo Efrain RubioNessuna valutazione finora

- Milwaukee Tool BrushesDocumento31 pagineMilwaukee Tool BrushesEduardo Efrain RubioNessuna valutazione finora

- Service Manual for Minarc 150/150 VRD/151 Welding MachinesDocumento27 pagineService Manual for Minarc 150/150 VRD/151 Welding MachinesSimpalean NicolaeNessuna valutazione finora

- AC System PrecautionsDocumento263 pagineAC System PrecautionsAndrej Krajnc100% (2)

- Rapid GatorDocumento1 paginaRapid GatorEduardo Efrain RubioNessuna valutazione finora

- PHENIX TECHNOLOGIES - High Voltage, High Current, High Power Test Systems and ComponentsDocumento2 paginePHENIX TECHNOLOGIES - High Voltage, High Current, High Power Test Systems and ComponentsEduardo Efrain RubioNessuna valutazione finora

- 2.2l (Vin 4) Ecm WirinDocumento1 pagina2.2l (Vin 4) Ecm WirinEduardo Efrain RubioNessuna valutazione finora

- You TubeDocumento2 pagineYou TubeEduardo Efrain RubioNessuna valutazione finora

- Preston Blair - Advanced AnimationDocumento41 paginePreston Blair - Advanced Animationvoskie100% (9)

- LoaderDocumento4 pagineLoaderEduardo Efrain Rubio100% (2)

- Can Communication System: PrecautionDocumento106 pagineCan Communication System: PrecautionRicardo Watson100% (1)

- Unidad Hidraulica Climax 5000Documento6 pagineUnidad Hidraulica Climax 5000Eduardo Efrain RubioNessuna valutazione finora

- Energy Efficient ElectronicsDocumento37 pagineEnergy Efficient ElectronicsEduardo Efrain RubioNessuna valutazione finora

- AlumbradoDocumento1 paginaAlumbradocalquijijeNessuna valutazione finora

- 2.2l (Vin 4) Ecm WirinDocumento1 pagina2.2l (Vin 4) Ecm WirinEduardo Efrain RubioNessuna valutazione finora

- RominfoDocumento1 paginaRominfoweskkerNessuna valutazione finora

- ChargingDocumento17 pagineChargingkadeer1989Nessuna valutazione finora

- 1994 Chevrolet Camaro & Pontiac Firebird Service Manual Volume 2Documento1.175 pagine1994 Chevrolet Camaro & Pontiac Firebird Service Manual Volume 2Sean88% (8)

- Part 1 - 1998-99 PCM Connector Pin Out Charts (GM 4.3L, 5.0L, 5Documento6 paginePart 1 - 1998-99 PCM Connector Pin Out Charts (GM 4.3L, 5.0L, 5Eduardo Efrain Rubio33% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)