Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boiler Study Notes

Caricato da

Srinivasa Rao Venkumahanthi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

61 visualizzazioni5 pagineThe document discusses various boiler concepts and losses including heat losses from flue gas and moisture, the critical point of steam where water vapor converts fully to steam, evaporation ratio which is the ratio of steam generated to fuel consumed, and acid dew point where sulfuric acid can form in the boiler. It also defines concepts like slagging, fouling, proximate and ultimate analysis of coal, gross and net calorific values, circulation ratio, turn down ratio, and issues like foaming and priming in boilers.

Descrizione originale:

BSN

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document discusses various boiler concepts and losses including heat losses from flue gas and moisture, the critical point of steam where water vapor converts fully to steam, evaporation ratio which is the ratio of steam generated to fuel consumed, and acid dew point where sulfuric acid can form in the boiler. It also defines concepts like slagging, fouling, proximate and ultimate analysis of coal, gross and net calorific values, circulation ratio, turn down ratio, and issues like foaming and priming in boilers.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

61 visualizzazioni5 pagineBoiler Study Notes

Caricato da

Srinivasa Rao VenkumahanthiThe document discusses various boiler concepts and losses including heat losses from flue gas and moisture, the critical point of steam where water vapor converts fully to steam, evaporation ratio which is the ratio of steam generated to fuel consumed, and acid dew point where sulfuric acid can form in the boiler. It also defines concepts like slagging, fouling, proximate and ultimate analysis of coal, gross and net calorific values, circulation ratio, turn down ratio, and issues like foaming and priming in boilers.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

Q. What are boiler losses?

A. Generally the boiler efficiency is considered as 85%,here are the

boiler losses considered as,

1. Heat loss in dry flue gas loss-10.7%.

2. Heat loss due to moisture in fuel - 2.2 %.

3. Heat loss due moisture in air - 0.38 %.

4. Heat loss due to formations of water from H2 in fuel - 4.4%

5. Heat loss due to conversion of C to CO- 0.53%

Q. what is critical point of steam?

Ans. It is the point at which all water vapor converts to steam .The

critical point occurs at a temperature of 374 deg & 224.6 kg/cm2

.The point is called critical point and the pressure, temperature at

this corresponding saturation temperature is known as critical

pressure and critical temperature.Here the density of steam and

water will remain same.

Q. What is evaporation ratio of Boiler?

Ans. It the ratio of quantity of steam generation in kg/hr to

quantity of fuel consumed in kg/hr.

Evaporation ratio = quantity of steam generation/quantity of fuel

consumed.For example quantity of steam Is 310 ton/hr and fuel is

55 ton/hr then the evaporation ratio is 5.63. Evaporation ratio is

also known as steam fuel ratio.A drop in evaporation ratio

indicates drop in boiler efficiency.Boiler evaporation ratio depends

on fuel quality. Higher calorific value of fuel having higher

evaporation ratio.

Value of evaporation ratio for different types of boiler is listed as-

a) Coal fired boiler- 4.0-6.0.

b) Oil fired boiler- 13.0-14.5 .

c) Gas fired boiler- 11.0-13.

Q. what is acid due point in boiler ?

Ans.The temperature at which the formation of sulfuric acid

in the boiler is known as acid due point,It is generally in

between 130-140 deg celsius. As fuel contain sulfur dioxide

(SO2) & H2O at certain temperature both are condense

together and sulfuric acid(H2SO2) is formed.

It will corrode the boiler tubes.To avoid acid due point we

can use,

1>FD fan re circulation system.

2> By using steam coil air pre-heater (SCAPH).

3> FD air bypass system.

Q. What is slagging or fouling in boiler ?

A.Slagging is the formation of molten or partially fused

deposits on the furnace surface or radiation zone . Fouling is

the deposition of fused particle on convection zone such as

super heater & re- heater.

Q. What is proximate analysis of coal ?

Ans.it is the analysis of coal in which we can find

moisture,volatile matter,fixed carbon & ash.we can found

above parameter as,

moisture-Take 1gm of coal sample heat in a woven at 105

deg for 01 hr.

Moisture + volatile matter- Take 1gm of coal sample heat in

a woven at 950 deg for 07 minute.

Ash- Take 1gm of coal sample heat in a woven at 720 deg

until the coal is completely burnt.

Q. What is the ultimate analysis of coal ?

A. This is the most accurate method of coal analysis.In this

analysis we can found the components of the mass of

carbon,hydrogen,oxygen,nitrogen,sulfur,moisture,ash.

so (c+h+o+n+s+m+a)= 100% mass.

Q. What is gross calorific value and net calorific value of

coal?

Ans.

1.calorific value:- It is the amount of heat liberated with a

unit mass of coal for 1g Kcal.

2.Gross calorific value:-It is the amount of heat liberated by

the complete combustion of unit weight of fuel with

subsequent cooling of product(moisture/water vapor) .

G.C.V is more than N.C.V.

3. Net calorific value :- It is the heat produced in complete

combustion when the product of combustion are allowed to

escaped.

N.C.V = G.C.V - Latent heat of water vapor.

N.C.V = (G.C.V-0.09x587) cal/gm.

Q. What is circulation ratio of a boiler?

Ans.

It is the ratio of the quantity of water-steam mixture flowing

through the circuit to the quantity of steam produced in the

circuit , The circulation ratio of once through / super

critical boiler is one because all water Is converted to

steam.More circulation ratio means less efficient is the

Boiler.

The circulation ratios of,

1. Natural circulation industrial boiler - 10 to 25

2. Natural circulation utility boiler - 7 to 9

3. Assisted circulation boilers - 2 to 4

4. Forced circulation / once through boiler - 1

Q. What is turn down ratio of boiler?

Ans. It is the operating range of boiler from maximum

capacity to minimum capacity in which the boiler can run

efficiently without any external fuel support . The higher turn

down ratio greater the efficiency of boiler. For example if the

boiler is designed 80mw and can operate up to 20mw

without any external fuel support and any variations of

parameter then the turn down ratio is 80/20=4.

Q. What is boiler efficiency?

Ans.

It is the ratio of heat output to heat input of the boiler.

Boiler efficiency= Heat output / heat input *100.

=steam flow (enthalpy of steam -enthalpy of feed water) / coal

flow * gcv.

For example if there is a 80mw boiler with 540 dig centigrade of

main steam temperature, feed water temperature of 300 dig

centigrade , coal flow 56 ton, gcv 4000 kcal/kg then the boiler

efficiency will be =307(826.28-242.58)/56*4000=80%.

Q. What is foaming of boiler?

Ans. It is the generation of foam In boiler due to high

concentration of solids, organic matter, bubbles are build up

on the surface of boiler water and passed out with the

steam. This is generally caused due to high concentration of

solids in boiler.

Q. What is priming of boiler ?

Ans. It Is the carrying amount of droplet water in the steam,

witch leads to carryover of Salt crystals on the super heater

and turbines. priming may be caused due to sudden change

of load and maintaining of high level of water.

Prevention of priming and foaming :-

The best remedy for foaming and priming carryover is

the proper blow down of TDS. The continuous blow

down should be regulated to maintain the TDS at

3,000 to 4,000 ppm. More blow down means less TDS but

more blow down is the more loss of the boiler so the blow

down should be within control level.

Potrebbero piacerti anche

- Boiler EconomyDocumento64 pagineBoiler EconomyKhurram ShahzadNessuna valutazione finora

- JBC Common Boiler FormulasDocumento12 pagineJBC Common Boiler Formulasnesrine10Nessuna valutazione finora

- Thermal SystemsDocumento192 pagineThermal SystemsCornel HatieganNessuna valutazione finora

- Question 1 (15 Marks)Documento5 pagineQuestion 1 (15 Marks)Farouk BassaNessuna valutazione finora

- Boi PDFDocumento7 pagineBoi PDFdoyanNessuna valutazione finora

- Azucar HojaDocumento9 pagineAzucar HojaJorge PerezNessuna valutazione finora

- Cooling Tower Evaporation, Heat and Mass Balance CalculationDocumento1 paginaCooling Tower Evaporation, Heat and Mass Balance CalculationSachin TechguideNessuna valutazione finora

- Topic 5 - BoilersDocumento85 pagineTopic 5 - BoilersOk SokNessuna valutazione finora

- 1.3.2 Air Cooler: T Tin ToutDocumento3 pagine1.3.2 Air Cooler: T Tin ToutRita YuliandaNessuna valutazione finora

- Formulas BoilerDocumento0 pagineFormulas BoilerJopha S Deva100% (1)

- Boiler FormulasDocumento3 pagineBoiler FormulasCaliman SabinaNessuna valutazione finora

- Air Monitoring Combustion Air Power BoilersDocumento189 pagineAir Monitoring Combustion Air Power BoilersAnonymous zdCUbW8HfNessuna valutazione finora

- Detailed Project Report ON Temperature Indicator Controller (Mangalore Tile Cluster)Documento38 pagineDetailed Project Report ON Temperature Indicator Controller (Mangalore Tile Cluster)abhianand123Nessuna valutazione finora

- Energy Audit Methology For Turbine Cycle - M.V. Pande & Dy - Director PDFDocumento33 pagineEnergy Audit Methology For Turbine Cycle - M.V. Pande & Dy - Director PDFtolga ALTINTAŞ100% (1)

- Thermal Design of Heat ExchangersDocumento24 pagineThermal Design of Heat ExchangersArunNessuna valutazione finora

- 3194 PDF PDFDocumento7 pagine3194 PDF PDFdillipsh123Nessuna valutazione finora

- Eff. of HarmonicsDocumento7 pagineEff. of HarmonicsSwapnil SawantNessuna valutazione finora

- TPP Steel PlantDocumento25 pagineTPP Steel PlantPRASANTHNessuna valutazione finora

- Efficiency Calculations of BagasseDocumento4 pagineEfficiency Calculations of BagasseOmar Ahmed ElkhalilNessuna valutazione finora

- Steam GeneratorDocumento8 pagineSteam GeneratorFrancesco CordellaNessuna valutazione finora

- 4report of Mugher CementDocumento76 pagine4report of Mugher CementMustefa TurkaNessuna valutazione finora

- Boilers and Steam Systems ..BoeDocumento151 pagineBoilers and Steam Systems ..BoeMV AmohanAKarthicK100% (1)

- Eat Transfer Coefficients For Submerged CoilsDocumento13 pagineEat Transfer Coefficients For Submerged Coilsvitcon87100% (1)

- 1996 - Misplon - Pinhole Grate Conversions ofDocumento4 pagine1996 - Misplon - Pinhole Grate Conversions ofmchoi23Nessuna valutazione finora

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsDa EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNessuna valutazione finora

- Steam Trap & InsulationDocumento16 pagineSteam Trap & Insulationreach_arindomNessuna valutazione finora

- CondenserDocumento26 pagineCondenserFRANCISCO JOSE GARCIA IBAÑEZNessuna valutazione finora

- Guide To Furnace SootblowingDocumento40 pagineGuide To Furnace SootblowingnarayananaliveNessuna valutazione finora

- Boiler Efficiency FactsDocumento21 pagineBoiler Efficiency FactschikukotwalNessuna valutazione finora

- Calculation of PHRDocumento13 pagineCalculation of PHRSiddhant SatpathyNessuna valutazione finora

- 12-Design Fundamentals of BoilerDocumento12 pagine12-Design Fundamentals of BoilerVishalVaishNessuna valutazione finora

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocumento12 pagineEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNessuna valutazione finora

- Chapter 5 Energy Balance April 10 2017.v2Documento31 pagineChapter 5 Energy Balance April 10 2017.v2kennethmsorianoNessuna valutazione finora

- Steam Table For Saturated Steam: (Continued)Documento1 paginaSteam Table For Saturated Steam: (Continued)ChristianGuerreroNessuna valutazione finora

- Burner-Comparison - Uso InternoDocumento1 paginaBurner-Comparison - Uso InternoRICARDO PINTONessuna valutazione finora

- Indirect MethodDocumento6 pagineIndirect MethodFarurrodin Syah AlfahrobiNessuna valutazione finora

- Atd Boilers Unit-4Documento78 pagineAtd Boilers Unit-4Solanki YagnikNessuna valutazione finora

- Boiler Efficiency Combustion EfficiencyDocumento8 pagineBoiler Efficiency Combustion EfficiencyBelalNorNessuna valutazione finora

- HBDs 01Documento4 pagineHBDs 01deepdaman18891Nessuna valutazione finora

- Dearator Calculations Book1 Rev1Documento8 pagineDearator Calculations Book1 Rev1MechanicalVee18Nessuna valutazione finora

- Glaxo Vol IDocumento164 pagineGlaxo Vol IPrakash WarrierNessuna valutazione finora

- Heat BalanceDocumento18 pagineHeat Balancehafidhrahadiyan2Nessuna valutazione finora

- Boiler CalculationDocumento4 pagineBoiler Calculationmohsin husen BargirNessuna valutazione finora

- Condenser 69-83Documento15 pagineCondenser 69-83DIPAK VINAYAK SHIRBHATENessuna valutazione finora

- Boiler Drum Level Measurement and ControlDocumento13 pagineBoiler Drum Level Measurement and ControlasdmoomNessuna valutazione finora

- Nrs 1-50 GestraDocumento28 pagineNrs 1-50 Gestramike tsakirisNessuna valutazione finora

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocumento2 pagineVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNessuna valutazione finora

- 880 Series Inverted Bucket Steam TrapsDocumento2 pagine880 Series Inverted Bucket Steam TrapsCherbee FerrerNessuna valutazione finora

- Cogenerations of Energy From Sugar Factory BagasseDocumento8 pagineCogenerations of Energy From Sugar Factory BagasseTade GaromaNessuna valutazione finora

- Operating Experience On Single and Three Pass BoilersDocumento7 pagineOperating Experience On Single and Three Pass Boilersbonginkosi mathunjwaNessuna valutazione finora

- 5.IMP. - QUESTIONS - AND - ANSWERS of BoeDocumento71 pagine5.IMP. - QUESTIONS - AND - ANSWERS of BoeRaag SNessuna valutazione finora

- QADocumento40 pagineQANarmad RavalNessuna valutazione finora

- Boiler Questions and AnswersDocumento45 pagineBoiler Questions and AnswersArsalan AliNessuna valutazione finora

- Q A BoilerDocumento19 pagineQ A Boilerlavpandey8719Nessuna valutazione finora

- Boiler RatingDocumento5 pagineBoiler RatingEdy Suprayitno0% (1)

- G.Vignesh Assistant Professor VIT UniversityDocumento41 pagineG.Vignesh Assistant Professor VIT UniversitymansurNessuna valutazione finora

- Fuels & CombustionDocumento44 pagineFuels & CombustionKaran Thakur100% (1)

- Boiler QuestionsDocumento39 pagineBoiler Questionssk3146100% (11)

- SAPDocumento16 pagineSAPsourav84Nessuna valutazione finora

- Boiler Functions and Main Categories: 3. BoilersDocumento17 pagineBoiler Functions and Main Categories: 3. BoilersMusa KaleemNessuna valutazione finora

- PMT-HelponExceltool Demo LockedDocumento253 paginePMT-HelponExceltool Demo LockedSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Steam Trap Selection: Understanding SpecificationsDocumento5 pagineSteam Trap Selection: Understanding SpecificationsSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Project (Mechanical) Department - Attendance Sheet For The Month of September - 2017Documento3 pagineProject (Mechanical) Department - Attendance Sheet For The Month of September - 2017Srinivasa Rao VenkumahanthiNessuna valutazione finora

- Benitez Cap9Documento44 pagineBenitez Cap9Srinivasa Rao VenkumahanthiNessuna valutazione finora

- To, Income Tax Department - CPC, Post Bag No - 1, Electronic City Post Office, BENGALURU - 560 100, Karnataka - IndiaDocumento1 paginaTo, Income Tax Department - CPC, Post Bag No - 1, Electronic City Post Office, BENGALURU - 560 100, Karnataka - IndiaSrinivasa Rao VenkumahanthiNessuna valutazione finora

- 1 X 650 Tds Chemical Recovery Boiler - Pressure Parts Manufacuring Discrepancies (Tirchy)Documento1 pagina1 X 650 Tds Chemical Recovery Boiler - Pressure Parts Manufacuring Discrepancies (Tirchy)Srinivasa Rao VenkumahanthiNessuna valutazione finora

- Tectyl 506 OilDocumento1 paginaTectyl 506 OilSrinivasa Rao VenkumahanthiNessuna valutazione finora

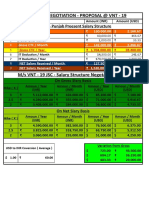

- VNT - 19Documento1 paginaVNT - 19Srinivasa Rao VenkumahanthiNessuna valutazione finora

- Employee Certification LetterDocumento1 paginaEmployee Certification LetterSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Group Erw Seamless Product BrochureDocumento6 pagineGroup Erw Seamless Product BrochureSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Tectyl 506 PDFDocumento4 pagineTectyl 506 PDFjaskaran singhNessuna valutazione finora

- Commissioning Schedule 01Documento30 pagineCommissioning Schedule 01Srinivasa Rao VenkumahanthiNessuna valutazione finora

- NEW 1 X 2100 M Induced Drfat Cooling Tower: Data For Pumps Sl. No Description UOM Specification RemarksDocumento1 paginaNEW 1 X 2100 M Induced Drfat Cooling Tower: Data For Pumps Sl. No Description UOM Specification RemarksSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Kirana Items ListDocumento10 pagineKirana Items ListSrinivasa Rao Venkumahanthi100% (1)

- Scheduel For 1 X 400 Tds Upgradtion To 1 X 600 TdsDocumento1 paginaScheduel For 1 X 400 Tds Upgradtion To 1 X 600 TdsSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Aew - 003Documento3 pagineAew - 003Srinivasa Rao VenkumahanthiNessuna valutazione finora

- Bfs Deaerator RFQDocumento2 pagineBfs Deaerator RFQSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Welding Manual Nov 2010Documento187 pagineWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Chimney Calculation SheetDocumento14 pagineChimney Calculation SheetSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Dial GaadgeDocumento2 pagineDial GaadgeSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Belt Sway Control PDFDocumento29 pagineBelt Sway Control PDFSrinivasa Rao Venkumahanthi0% (1)

- Loss Incurred Due To Low Steam Economy in Evaporaor For The Month of Dec-16Documento1 paginaLoss Incurred Due To Low Steam Economy in Evaporaor For The Month of Dec-16Srinivasa Rao VenkumahanthiNessuna valutazione finora

- Total 183,051.21: SL - No Particulars Qty. Rate Weight in KG Amount Rs. PDocumento2 pagineTotal 183,051.21: SL - No Particulars Qty. Rate Weight in KG Amount Rs. PSrinivasa Rao VenkumahanthiNessuna valutazione finora

- Name: Liberty E. Antonio: 3 Gage 2Documento3 pagineName: Liberty E. Antonio: 3 Gage 2yeng botzNessuna valutazione finora

- RAC (7th&8th) Dec2016 PDFDocumento3 pagineRAC (7th&8th) Dec2016 PDFMuDas IrNessuna valutazione finora

- Chemistry g11Documento2 pagineChemistry g11Madelleine PaduaNessuna valutazione finora

- MHD Power GenerationDocumento25 pagineMHD Power Generationomg786Nessuna valutazione finora

- Practice Sheet: HH H H H HHDocumento4 paginePractice Sheet: HH H H H HHArvin PudotaNessuna valutazione finora

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetDocumento14 pagineJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekNessuna valutazione finora

- Properties of Pure Substance and Steam Power Cycle Pure SubstanceDocumento43 pagineProperties of Pure Substance and Steam Power Cycle Pure SubstanceSachin SinghNessuna valutazione finora

- Sharjah CondensateDocumento3 pagineSharjah CondensateFaker HighlightsNessuna valutazione finora

- 49 CFRDocumento10 pagine49 CFRCarlos Cázares CastellanosNessuna valutazione finora

- Chapter 10 Refrigeration SystemDocumento95 pagineChapter 10 Refrigeration SystemMinh Hiếu CaoNessuna valutazione finora

- IB Topic 3 Thermal Physics Question BookletDocumento19 pagineIB Topic 3 Thermal Physics Question Bookletpixelhobo67% (3)

- MFET Magnetic Field Effect Transistor With Spin Transport Control by Mahalu & Graur PDFDocumento4 pagineMFET Magnetic Field Effect Transistor With Spin Transport Control by Mahalu & Graur PDFScutul_CrestinNessuna valutazione finora

- PLP P-2-2003, Glycol Dehydration-2nd Ed-RosenDocumento41 paginePLP P-2-2003, Glycol Dehydration-2nd Ed-Rosenivanov5559100% (1)

- Chapter 1: Basic ConceptsDocumento14 pagineChapter 1: Basic Conceptsmhd slmnNessuna valutazione finora

- L3-Reservoir Fluids ClassificationDocumento91 pagineL3-Reservoir Fluids ClassificationadeeyoNessuna valutazione finora

- Densities Liquid-Acetone-Water Solutions Up To Their Normal Boiling PointsDocumento4 pagineDensities Liquid-Acetone-Water Solutions Up To Their Normal Boiling PointsEric RodriguezNessuna valutazione finora

- Chemistry s4 Notes - Unit 3Documento9 pagineChemistry s4 Notes - Unit 3UDAHEMUKA DeniseNessuna valutazione finora

- Viscometer-Group 7Documento25 pagineViscometer-Group 7Camille Millondaga100% (1)

- Fluid Flow Basics OF Throttling ValvesDocumento43 pagineFluid Flow Basics OF Throttling ValvesSandro AraújoNessuna valutazione finora

- Liquefin™ - An Innovative Process To Reduce LNG CostDocumento15 pagineLiquefin™ - An Innovative Process To Reduce LNG CostBriand VallejoNessuna valutazione finora

- Capstone Design Project For Plant Design Steam Methane Reforming PlantDocumento251 pagineCapstone Design Project For Plant Design Steam Methane Reforming PlantArman Jade LazarteNessuna valutazione finora

- Fluid Mechanics and Hydraulic Machines DR R K Bansal PDFDocumento287 pagineFluid Mechanics and Hydraulic Machines DR R K Bansal PDFVaddi Dushyanth KumarNessuna valutazione finora

- Functional Specification Pressure GaugeDocumento9 pagineFunctional Specification Pressure GaugeSurendra ReddyNessuna valutazione finora

- 9.flow Through Pipes Jan 2015 PDFDocumento25 pagine9.flow Through Pipes Jan 2015 PDFburhanuddin100% (1)

- Grinding and CuttingDocumento20 pagineGrinding and Cuttinggaur1234Nessuna valutazione finora

- MCZ Zero Gas System NGA 19SDocumento2 pagineMCZ Zero Gas System NGA 19SAbdul RasheedNessuna valutazione finora

- Padhle 11th - States of MatterDocumento29 paginePadhle 11th - States of MatterLAVISH JAINNessuna valutazione finora

- Mercury ManometerDocumento7 pagineMercury ManometerKoser IrshadNessuna valutazione finora

- HWK 5Documento1 paginaHWK 5Kelly SmithNessuna valutazione finora

- Lewis SymbolDocumento20 pagineLewis SymbolVivian May J. GuibalaNessuna valutazione finora