Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AS-09.01.005 Main En.a.1

Caricato da

Yacine KaidiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AS-09.01.005 Main En.a.1

Caricato da

Yacine KaidiCopyright:

Formati disponibili

Suspension ropes

Maintenance Instruction

LUBRICATION OF SUSPENSION ROPES

Suspension

AS-09.05.001

All

(B)1995

rights

2010-07-05

KONE

reserved.

ropes

Corporation

CONTENTS

1 RELATED DOCUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 ROPE LUBRICATION GENERALLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Lubrication intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1 Maintenance method safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 ROPE LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.1 Safety measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.2 Rope lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.3 Position of lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4.4 Adjusting new lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.5 Lubricating ropes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 MANUAL LUBRICATION OF KONE MONOSPACE ROPES . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Safety measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Lubricating ropes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 APPROVALS AND VERSION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1995 KONE Corporation AS-09.05.001

All rights reserved. 1 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

1 RELATED DOCUMENTS

The following documents are related with rope lubrication:

AM-01.03.002 Take 5 Electrical Safety When Working on the Elevators.

AS-01.01.010 Lubricant recommendation

AS-01.03.101 On-site maintenance safety manual

2 ROPE LUBRICATION GENERALLY

Rope lubrication status should be checked on every maintenance visit, and also during the installation

phase and contruction time use of new elevators. Projects with long lead time and high-rise projects

require special attention.

The requirement for the rope lubrication depends on the operating conditions, the used capacity of the

ropes and the amount of the original lubricant on the rope. The values for the amount of the lubricant

and the lubrication interval, which are given in this document are only trendsetting.

2.1 Lubricants

Refer to AS-01.01.010.

2.2 Lubrication intervals

No definite time dependent interval can be given for rope lubrication. Many rope manufacturers

recommend that ropes are lubricated at least once a year.

Rope lubrication lifetime and lubrication need are measured in bend cycles: One bend cycle means

that the rope passes one pulley or traction sheave. Lubrication interval depends on the bend

frequency, roping arrangement (for example 1:1, 2:1, 4:1) ambient temperature, rope load, and so on,

Usually the lubrication interval is in the range of 40 000 ... 200 000 bend cycles.

The need of the lubrication depends the circumstances of a particular situation:

the ropes are dry or the grease is stiff (correctly lubricated rope should stick slightly to the glove

when grabbing it by hand)

red dust on the ropes or on the floor

metal dust under sheave or pulleys

the grooves of the pulleys are dry (no oil film on fingertip when wiping)

If any sign of dry suspension ropes is observed, ropes must be lubricated as soon as possible!

NOTE! There is no need to renew the lubricant, if enough lubricant exists after previous lubrication and

the lubricant is still viscous.

1995 KONE Corporation AS-09.05.001

All rights reserved. 2 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

3 SAFETY

For general safety and personal protective equipment, refer to AS-01.03.101.

3.1 Maintenance method safety

Note the following safety items when working with suspension ropes:

General KONE safety regulations are to be followed during the work. All safety measures signified

for normal elevator maintenance are to be implemented and local safety regulations followed.

Refer to AM-01.03.002 Take 5 Electrical Safety When Working on the Elevators. The Take 5

safety initiative is designed for installation, servicing, maintenance and modernisation work done

on elevators.

4 ROPE LUBRICATION

Rope lubricators are used with traction elevators with machine room (geared or gearless). Machine-

room-less elevators are lubricated manually, refer to section 5 on page 8.

4.1 Safety measures

The following safety measures must be carried out before starting actual work:

Secure the elevator against accidental start during installation time

Be extremely carefull when adjusting lubricator during elevator runs

Use rubber- or plastic gloves when handling oily substances

4.2 Rope lubricator

Nylub lubricator used before 2003-09, Delco used with MX-machines.

The lubricators are available in several widths. The width of the felt should be at least 30 mm more

than the width of the rope set.

NYLUB Lubricator: Type: Width / Effective width

NCL-3 73 mm / 43 mm

NCL-7 171 mm / 141 mm

NCL-9 220 / 190 mm

1018098.wmf

1995 KONE Corporation AS-09.05.001

All rights reserved. 3 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

NCL-12 290 mm / 260 mm

NCL-16 391 mm / 361 mm

1018101.wmf

DELCO Oiler:

Type: Width:

209-53000 4

209-53001 7

209-53002 10

209-53003 13

209-53009 16

1018379.wmf

4.3 Position of lubricator

X- minimum = 15 mm

X

1018104.wmf

1018113.wmf

1018116.wmf

1995 KONE Corporation AS-09.05.001

All rights reserved. 4 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

NOTE! In PU-elevators the lubrication should be performed separately on

both sides.

1018119.wmf

1018122.wmf

Place the rope lubricator as near as possible to the rope pulley to avoid the wearing of the inaccurate

notch in the felt wick, caused by the vibration of the ropes.

DELCO Oiler in MX40/32 machines

1995 KONE Corporation AS-09.05.001

All rights reserved. 5 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

4.4 Adjusting new lubricator

Step Action Illustration/Note

1 Advance the lubricator toward the ropes

until grooves half the diameter of the ropes

have been worn in the felt wick.

Once the grooves are formed, adjust the

lubricator so the wick has approximately 1.5

mm clearance to the ropes.

NOTE! The lubricator operates despite

clearance between ropes and wick.

The same felt wick can be used in other

machinery only if the rope size, the amount

of ropes, and the spacing of ropes are the

same. Max D/2

D 1018110.wmf

2 Ensure that the lubricator is properly In order to function properly, the

grounded. lubricator must have solid ground

connection to the machine.

4.5 Lubricating ropes

Step Action Illustration/Note

1 When the felt is new (Not oiled) fill the Additional amount of oil for the first filling

lubricator according to the values (With new felt):

Additional amount for the first filling + 0.1 l / 100m / 8 mm rope,

Average amount for refilling. 0.15 l / 100m /10 mm rope

The flow of the oil from the lubricator takes 0.3 l / 100m / 13 mm rope

1-2 weeks. The lubrication will stop when 0.45 l / 100m / 16 mm rope

the lubricator runs out of oil. NOTE! The flow of the oil from the lubricator

NOTE! When filling the lubricator, rather takes 1-2 weeks. The lubrication will

pour too little lubricant than too stop when the lubricator runs out of

much. Add lubricant when needed oil.

1995 KONE Corporation AS-09.05.001

All rights reserved. 6 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

Step Action Illustration/Note

2 When refilling the lubricator, take into Average amount of oil for refilling:

account the amount of the old lubricant and NCL-3 with 0.07 l

the dryness of the ropes. The average need NCL-7 with 0.15 l

of the oil for the first re lubrication is shown

NCL-9 with 0.2 l

on the next table.

NCL-12 with 0.25

NCL-16 with 0.35 l

NCL-3 with 0.07 l

3 If the ropes are covered with thick hard

grease or if they are dusty, the lubricator can

be filled with petroleum oil based diluent up

to the amount given in table Additional

amount of oil for the first filling The ropes

should be wiped clean afterwards and, if

needed, the proper lubrication could be

performed after ropes are dry.

4 Check the rope slip before and after the

lubrication.

5 Check that rope termination spring lengths Maximum allowed deviation between

are equal (that is, ropes are equally shortest and longest spring is 3mm, adjust if

tensioned). necessary. Check both car and

counterewight side rope terminations.

1995 KONE Corporation AS-09.05.001

All rights reserved. 7 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

5 MANUAL LUBRICATION OF KONE MONOSPACE ROPES

This section describes lubrication method for machineroomless KONE MonoSpace elevators.

Table 1: Amount of lubrication for ropes.

Rope diameter 8 mm 10 mm 13 mm 16 mm 19 mm

Amount of lubricant 32 ml 40 ml 52 ml 64 ml 76 ml

per 10m of rope

5.1 Tools

The following tools are recommended:

Paint roller

Brush

Bowl for oil

5.2 Safety measures

The following safety measures must be carried out before starting actual work:

Secure the elevator against accidental start during lubrication time.

Lubricate only when the elevator has stopped.

Use rubber- or plastic gloves when handling oily substances.

5.3 Lubricating ropes

Step Action Illustration/Note

1 Drive the car to the topmost level. Provide access to the car top.

2 Using inspection drive the car up to land the

counterweight.

1995 KONE Corporation AS-09.05.001

All rights reserved. 8 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

Step Action Illustration/Note

3 Apply rope oil with the paint brush to the

accessible hoist ropes from the static

hitches as far down as safely possible.

Ensure all the ropes are oiled around.

4 Drive the car down a metre to expose some

more unlubricated hoist rope.

Lightly apply rope oil with the paint roller to

the ropes.

Also any other sections of hoist rope missed

the last time due to being located at the

traction or car sheave(s) or under the car.

5 Repeat the lubrication until the car and

counterweight reach each other in the

elevator well, or until the ropes are

completely lubricated.

NOTE! After repeting this action two or

three times, it should only become

necessary to lubricate the

counterweight side section from the

static hitch, because all the other

sections have already been

lubricated during the previous

steps.

1018185.wmf

6 Drive the car using inspection drive from top Allow 15 minutes for the oil to soak fully into

most landing to bottom landing. the ropes and for the carrier solvent to

Check, that no oil has found its way onto the evaporate.

brake drum or any other critical Wipe any excess oil off the ropes with a rag.

components, such as guide rollers or guide

rail surfaces (if the job had dry rails).

7 Remove the lubricating equipment from on

top of the car.

8 Check that rope termination spring lengths Maximum allowed deviation between

are equal (that is, ropes are equally shortest and longest spring is 3mm, adjust if

tensioned). necessary. Check both car and

counterewight side rope terminations.

1995 KONE Corporation AS-09.05.001

All rights reserved. 9 (10) (B) 2010-07-05

Disclosure prohibited

Suspension ropes

Maintenance Instruction

6 APPROVALS AND VERSION HISTORY

Compiled by: Information Product Author Janne Kaskimies

Checked by: PCM Manager Seppo Hyrinen

SEB Maintenance Specialist Jukka Lindberg

Approved by: SEB Maintenance Development Manager Seppo Valliovuo

Issue Date Description of Change Ref CR Approved by

- First issue

A 2004-01-26 Manual lubrication added M. Williams

B 2010-07-05 Rope tension checks, quantities of lubricant, CA- S. Valliovuo

lubricant intervals, lubricator grounding, safety 020462

measures, other updates.

1995 KONE Corporation AS-09.05.001

All rights reserved. 10 (10) (B) 2010-07-05

Disclosure prohibited

Potrebbero piacerti anche

- Step Chain MaintenanceDocumento4 pagineStep Chain MaintenanceRenato KaindoyNessuna valutazione finora

- FC 3000s PDFDocumento60 pagineFC 3000s PDFAgnelo FernandesNessuna valutazione finora

- 思迈特 零件Documento78 pagine思迈特 零件Jeremy LinNessuna valutazione finora

- Dokumen Dari Jon@Th@n Verrell-2-1Documento101 pagineDokumen Dari Jon@Th@n Verrell-2-1omotu79Nessuna valutazione finora

- TSD Annex En81-20 ReportDocumento6 pagineTSD Annex En81-20 ReportAli DiabNessuna valutazione finora

- Fujitec BrakesDocumento10 pagineFujitec Brakesjeferson_camiloNessuna valutazione finora

- Fundamentals V3F18: Fine Adjustment of The. LWD (With The Weights of Half and 90 of The CarDocumento1 paginaFundamentals V3F18: Fine Adjustment of The. LWD (With The Weights of Half and 90 of The CarOsman Elmaradny100% (1)

- Installation Manual Omega 2016 - Version04!10!16Documento49 pagineInstallation Manual Omega 2016 - Version04!10!16Diego Félix Esparza DiantaNessuna valutazione finora

- Mitsubishi Escalator SpecificationsDocumento3 pagineMitsubishi Escalator SpecificationsFERNSNessuna valutazione finora

- Mev Ins en PDFDocumento157 pagineMev Ins en PDFNam LibraNessuna valutazione finora

- Kone Service Technician Factsheet - tcm92 18804 PDFDocumento2 pagineKone Service Technician Factsheet - tcm92 18804 PDFMD Omar FarukNessuna valutazione finora

- XJ Schindler Passazhirskiy LiftDocumento32 pagineXJ Schindler Passazhirskiy Liftkonsuba teknik perkasaNessuna valutazione finora

- Entrance CPSI Test - Ver 2Documento10 pagineEntrance CPSI Test - Ver 2Ali DiabNessuna valutazione finora

- Hydrofit General Contractors Guide 2012Documento79 pagineHydrofit General Contractors Guide 2012Jawad MerhyNessuna valutazione finora

- Safed Guidelines June 2020.Documento95 pagineSafed Guidelines June 2020.eduardoNessuna valutazione finora

- NICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFDocumento232 pagineNICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFAsdrubal Fredy GutierrezNessuna valutazione finora

- Appendix 2: System TroubleshootingDocumento4 pagineAppendix 2: System Troubleshootingعلاء صقرNessuna valutazione finora

- System Galaxy Quick Guide: Configuration and OperationDocumento47 pagineSystem Galaxy Quick Guide: Configuration and OperationTushar ImranNessuna valutazione finora

- 5elevator Installation Manual For Elevator With Machine Room V1.4 - 1Documento113 pagine5elevator Installation Manual For Elevator With Machine Room V1.4 - 1aneesh tNessuna valutazione finora

- 1 Buttons and Icons: Lobbyvision 3 Quick Reference CardDocumento2 pagine1 Buttons and Icons: Lobbyvision 3 Quick Reference CardAli DiabNessuna valutazione finora

- Acceptance Test Guidelines - Safety Gear - Overspeed Governor ProtectionDocumento6 pagineAcceptance Test Guidelines - Safety Gear - Overspeed Governor ProtectionCarlos BarrosNessuna valutazione finora

- AR-03.12.037 - AMD Car DoorDocumento5 pagineAR-03.12.037 - AMD Car DoorYacine Kaidi100% (1)

- Copia de VF7 Doc 2017Documento25 pagineCopia de VF7 Doc 2017Edgar ZamoraNessuna valutazione finora

- Commissioning: SAIS Information For BuffersDocumento16 pagineCommissioning: SAIS Information For BuffersAli DiabNessuna valutazione finora

- Hyundai Elevator Preventive Maintenance ProcedureDocumento19 pagineHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- Fermator Operation Manual PDFDocumento8 pagineFermator Operation Manual PDFMuhammad Dzulfiqar100% (1)

- 7502.9041 MANUAL ES 5000 Escalator PDFDocumento48 pagine7502.9041 MANUAL ES 5000 Escalator PDFMohammed ansarNessuna valutazione finora

- Technology On The Move.: The W 191 Drive SystemDocumento2 pagineTechnology On The Move.: The W 191 Drive Systemangela1590Nessuna valutazione finora

- Installation Manual Omega 2016Documento50 pagineInstallation Manual Omega 2016Elton GomesNessuna valutazione finora

- Measurements: 35X15X10 Price: 79 (Eol Product, So Price May Vary)Documento1 paginaMeasurements: 35X15X10 Price: 79 (Eol Product, So Price May Vary)Việt Thảo TrầnNessuna valutazione finora

- CPSI - Safe and Efficient Inspection: Core Module Trainer Manual T181 Edition 2012-02Documento13 pagineCPSI - Safe and Efficient Inspection: Core Module Trainer Manual T181 Edition 2012-02Ali DiabNessuna valutazione finora

- Manual Sidoor At12 En-UsDocumento48 pagineManual Sidoor At12 En-UsPabloScurraNessuna valutazione finora

- Wiring Monarch Nice3000Documento32 pagineWiring Monarch Nice3000Rachmad Maulana RamadhanNessuna valutazione finora

- ARES Escalator BDocumento2 pagineARES Escalator BGutmonarchNessuna valutazione finora

- PU3200 English ManualDocumento71 paginePU3200 English Manualعلاء صقرNessuna valutazione finora

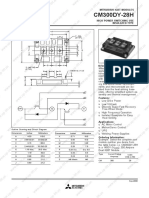

- Mitsubishi IGBT CM300DY-28HDocumento4 pagineMitsubishi IGBT CM300DY-28HRaul Gutierrez100% (1)

- Icontrol DC Aug 08 Rel 42-02-7222 B7Documento788 pagineIcontrol DC Aug 08 Rel 42-02-7222 B7ElputoAmo XDNessuna valutazione finora

- 100-170 ManualDocumento59 pagine100-170 ManualReza KühnNessuna valutazione finora

- Project Managers Program: Technical NoteDocumento20 pagineProject Managers Program: Technical NotealfreliaNessuna valutazione finora

- Passenger Elevator (Compact Machine Room System) Series-IP/AP Version2 Series-IPDocumento13 paginePassenger Elevator (Compact Machine Room System) Series-IP/AP Version2 Series-IPyounesNessuna valutazione finora

- 1260000.EN - GS800-NX Maintenance ManualDocumento34 pagine1260000.EN - GS800-NX Maintenance ManualReynold Suarez100% (1)

- Unidrive SP Elevator Issue 1Documento100 pagineUnidrive SP Elevator Issue 1thanggimme.phanNessuna valutazione finora

- MUSE ED Elevator: Installation ManualDocumento29 pagineMUSE ED Elevator: Installation ManualMoises PerelloNessuna valutazione finora

- TAC32T Customized Product Cutsheet 070214-1Documento2 pagineTAC32T Customized Product Cutsheet 070214-1Jms Quintero100% (1)

- Operation and Maintenance Manual For WYJ 250 Series Permanent-Magnet Synchronous Gearless Traction MachineDocumento20 pagineOperation and Maintenance Manual For WYJ 250 Series Permanent-Magnet Synchronous Gearless Traction MachineJULIONessuna valutazione finora

- Prijslist of 21-10-2105Documento2 paginePrijslist of 21-10-2105AliRouyou100% (1)

- Am-11.65.029 Kdl32-Mini InstalDocumento69 pagineAm-11.65.029 Kdl32-Mini InstalMike RusheNessuna valutazione finora

- Door Operation Controller Drive BLDCDocumento20 pagineDoor Operation Controller Drive BLDCБахтияр ЮмачиковNessuna valutazione finora

- Troubleshooting Schindler Miconic TX and TX-GCDocumento31 pagineTroubleshooting Schindler Miconic TX and TX-GCDon Luong100% (1)

- Preventive Maintenance Instruction For V3F16L DriveDocumento14 paginePreventive Maintenance Instruction For V3F16L DriveMarta Silva VenturaNessuna valutazione finora

- Wire Rope Lubricant PDFDocumento1 paginaWire Rope Lubricant PDFGutmonarchNessuna valutazione finora

- IMC Performa ASME 2000 42-02-7205 Rev B3Documento470 pagineIMC Performa ASME 2000 42-02-7205 Rev B3ElputoAmo XDNessuna valutazione finora

- Digital VVVF Synchronized Door Operator Installation InstructionDocumento26 pagineDigital VVVF Synchronized Door Operator Installation InstructionYing Dang100% (1)

- Wittur Car Mechanism Fixing On Car Front PanelDocumento4 pagineWittur Car Mechanism Fixing On Car Front PanelBhupiisterSinghNessuna valutazione finora

- Motion 4000 Traction v9 42-02-2P25 A6Documento480 pagineMotion 4000 Traction v9 42-02-2P25 A6ElputoAmo XDNessuna valutazione finora

- KoneDocumento3 pagineKoneTemoNessuna valutazione finora

- Elevator Inspector: Passbooks Study GuideDa EverandElevator Inspector: Passbooks Study GuideNessuna valutazione finora

- AS-07.08.003 - en - .1 - Main Huiler AutoDocumento16 pagineAS-07.08.003 - en - .1 - Main Huiler Autosamuel_ventura4Nessuna valutazione finora

- Lubricant 034405Documento10 pagineLubricant 034405enkelectricalttNessuna valutazione finora

- Hidrostatico SandvikDocumento256 pagineHidrostatico Sandvikjuan yanayaco ramosNessuna valutazione finora

- MetDocumento41 pagineMetadityaNessuna valutazione finora

- Lesson Notes Lecture 14Documento5 pagineLesson Notes Lecture 14Quantum SaudiNessuna valutazione finora

- Dwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFDocumento13 pagineDwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFcomfortdehm1350100% (7)

- ESM-4810A1 Energy Storage Module User ManualDocumento31 pagineESM-4810A1 Energy Storage Module User ManualOscar SosaNessuna valutazione finora

- PositioningDocumento2 paginePositioningKishan AndureNessuna valutazione finora

- 2019 - High Levels of Polypharmacy in RheumatoidDocumento7 pagine2019 - High Levels of Polypharmacy in RheumatoidGustavo ResendeNessuna valutazione finora

- Quality Traits in Cultivated Mushrooms and Consumer AcceptabilityDocumento40 pagineQuality Traits in Cultivated Mushrooms and Consumer AcceptabilityShivendra SinghNessuna valutazione finora

- MAP V6.3: Reference ManualDocumento106 pagineMAP V6.3: Reference ManualGkou DojkuNessuna valutazione finora

- Manual de Electronica HardbookDocumento970 pagineManual de Electronica HardbookninoferNessuna valutazione finora

- Nurtured Womb e BookDocumento22 pagineNurtured Womb e BookSteph's Desserts100% (1)

- Water Vapor Permeability of Polypropylene: Fusion Science and TechnologyDocumento5 pagineWater Vapor Permeability of Polypropylene: Fusion Science and TechnologyBobNessuna valutazione finora

- Motorcycle Troubleshooting ManualDocumento15 pagineMotorcycle Troubleshooting ManualJan Warmerdam100% (1)

- Wet Chemical Pre E PresentationDocumento310 pagineWet Chemical Pre E PresentationEdwardAlexanderGarciaNessuna valutazione finora

- Legend Of Symbols: Chú Thích Các Ký HiệuDocumento9 pagineLegend Of Symbols: Chú Thích Các Ký HiệuKiet TruongNessuna valutazione finora

- 65 ActsDocumento178 pagine65 ActsComprachosNessuna valutazione finora

- Veg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenDocumento2 pagineVeg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenmusicalcarpetNessuna valutazione finora

- List ToolingDocumento10 pagineList Toolingyohanes adi saputroNessuna valutazione finora

- Effect of Vino Gano Ginger and Herbal Liquor On The Heamatological Parameters of The Wistar RatsDocumento5 pagineEffect of Vino Gano Ginger and Herbal Liquor On The Heamatological Parameters of The Wistar RatsInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Soccer Training DiaryDocumento1 paginaSoccer Training DiaryMark DeaconNessuna valutazione finora

- Nitofloor NDocumento3 pagineNitofloor Nkiranmisale7Nessuna valutazione finora

- Handbook For ASHA On Home Based Care For Young Child-EnglishDocumento116 pagineHandbook For ASHA On Home Based Care For Young Child-EnglishDr. Vanitha BNessuna valutazione finora

- Spina 2002Documento10 pagineSpina 2002hasantapNessuna valutazione finora

- Barium SulphateDocumento11 pagineBarium SulphateGovindanayagi PattabiramanNessuna valutazione finora

- Theory of Earth's Magnetism and It's Relation ToDocumento15 pagineTheory of Earth's Magnetism and It's Relation ToMaster Irvin100% (1)

- CFD Analysis of Flow Through Compressor CascadeDocumento10 pagineCFD Analysis of Flow Through Compressor CascadeKhalid KhalilNessuna valutazione finora

- Scalextric Arc One GuideDocumento46 pagineScalextric Arc One GuidenotifyatpriNessuna valutazione finora

- May New 2011 NYBMA (Web)Documento15 pagineMay New 2011 NYBMA (Web)Erik HooverNessuna valutazione finora

- Health Problems Vocabulary Esl Matching Exercise Worksheet For KidsDocumento2 pagineHealth Problems Vocabulary Esl Matching Exercise Worksheet For KidsTarisubhNessuna valutazione finora

- EMV Card Reader Upgrade Kit Instructions - 05162016Documento6 pagineEMV Card Reader Upgrade Kit Instructions - 05162016Shashi K KumarNessuna valutazione finora

- Titan GelDocumento6 pagineTitan GelVladi Salas100% (1)