Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

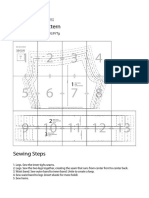

Stitch Guide

Caricato da

felipeCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stitch Guide

Caricato da

felipeCopyright:

Formati disponibili

Sewingcontract.

com

Stitch Guide

Most Common Stitch Types in ASTM D-6193 and

ISO 4915:1991 Standards

This quick reference guide is to help communication be-

tween designers, production managers and sewing con-

tractors. The guide is freely distributed.

Images courtecy of www.garmento.org, www.wikipedia.org, www.

merrow.com

First Edition October 17, 2007

Second Editon June 3, 2008

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

ASTM D-6193 ISO

101 ISO# 101 Chainstitch

Stitch formed by a needle thread passing through

the material and interlooping with itself on the

Sewingcontract.com

underside of the seam.

103 ISO# 103 Blindstitch

Stitch is formed with one needle thread which

interloops with itself on the top surface of the ma-

terial. The thread passes through the top ply and

horizontally through portions of the bottom ply.

104 Blindstitch

One thread Blinstitch for hemming, See page 4

301 ISO# 301 Lockstitch

Stitch formed by a needle thread passing through

the material and interlocking with a bobbin thread.

Threads are meeting in the center of the seam.

Stitch appear the same on the top as well as the

bottom.

ISO# 301 Twin Needle Lockstitch

Same s 301 except that two rows of stitch are

formed. Common needle spacing is 1/4 (6mm)

however, the machines are available from 3/16

up to 1(6-25mm)

304 ISO# 304 Zig Zag

Lockstitch is formed with a needle and bobbin

thread forming a symmetrical zig zag pattern. This

stitch is also used in bartacking and lockstitch

buttonsewing and buttonholing.

401 ISO# 401 -Chainstitch

Stitch formed by 1 needle thread and being

interlooped with 1 looper thread that is set on the

underside of the seam.

ISO# 401 Twin Needle Chainstitch

Stitch formed by 2 needle threads being inter-

looped with 2 looper threads, forming 2 indepen-

dent rows of stitch set.

406 ISO# 406 Bottom Coverstitch

Stitch formed by 2 needle threads passing

through the material and interlooping with 1 looper

thread with the stitch set on the underside of the

seam. Looper thread interlooped between needle

threads, providing seam coverage on the bottom

side.

407 ISO# 407 Bottom Coverstitch

Stitch formed by 3 needle threads passing

through the material and interlacing with 1 looper

thread with the stitch set on the underside of the

seam. Looper thread is interlooped between

needle threads, providing seam coverage on the

bottom side only.

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

ASTM D-6193 ISO

503 ISO# 503 Overedge

Formed by 1 needle thread and 1 looper

thread producing a purl on the edge of the

Sewingcontract.com

seam. Use: serging or blindhemming.

504 ISO# 504 Overedge

Formed by 1 needle thread and 2 looper

threads producing a purl on the edge of the

seam. Use: overedge seaming and serging.

ISO# 505 Overedge

505 Formed by 1 needle thread and 2 looper

threads forming a double purl on the edge of

the seam. Use: serging

512 ISO# 512 Overedge

Stitch formed with 2 needle threads and

2 looper threads with the looper threads

forming a purl on the edge of the seam.

512-right needle only enters the upper

looper loop.

ISO# 514 Overedge

514 Formed with 2 needle threads and 2 looper

threads with the looper threads forming a

purl on the edge of the seam. 514-both

needles enter the upper looper loop.

516 ISO# 516 Safety Stitch

5-thread safety stitch. Combining a single-

needle chainstitch (401) and a 3-thread

overedge stitch (504) that are formed

simultaneously.

602 ISO# 602 Coverstitch

Formed with 2-needle threads, a top cover

thread and a bottom looper thread.

605

ISO# 605 Coverstitch

Formed with 3-needle threads, using a top

cover thread and a bottom looper thread.

607 ISO# 607 Coverstitch

Formed with 4-needle threads, a top cover

thread and a bottom looper thread.

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

ASTM D-6193

104 Blindstitch

Sewingcontract.com

One thread Blinstitch for hemming,

202 Handstitch

Chainstitch provides stretchability for knits

205 Handstitch

One Thread True Handstitch for Topstitching ASTM D-6193

Stitches

Not shown in

This quide

Stitch Class &

Thread Count

306 Blindstitch

Two Thread blindstitch

102 One Thread

105 One Thread

201 Two Thread

203 One Thread

204 One Thread

302 Three Thread

315 Three Step Zig-Zag

Lockstitch zig-zag with more stretch 303 Four Thread

305 Three Thread

307 Five Thread

308 Two Thread

309 Three Thread

310 Three Thread

311 Three Thread

312 Three Thread

316 Lockstitch 313 Two Thread

One Thread lockstitch using autoloading bobbin 314 Two Thread

402 Three Thread

403 Four Thread

404 Two Thread

405 Three Thread

407 Four Thread

501 One Thread

502 Overedgestitch 505 Three Thread

One needle overedge stitch used for serging 506 Four Thread

507 Four Thread

508 Three Thread

509 Three Thread

510 Two Thread

511 Two Thread

517 Five Thread

518 Four Thread

515 True Safetystitch 519 Six Thread

Chainstitch provides stretchability for knits 520 Eight Thread

521 Three Thread

522 Four Thread

601 Three Thread

603 Five Thread

604 Six Thread

606 Nine Thread

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

Buttonholes

Sewingcontract.com

Photos: Juki

Single Double Purl Whip Keyhole

Stitched Stitched Stitching Stitching Buttonhole

Basting Joining

Stitch Stitch

Button -Flat

Button Stitches

Button -Shank

Cross Stitch Four Hole Stitch Two Hole Stitch

Button Wrapped

Label Tacking, Webbing Attachment

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

Types of Overlock Stitches

Overlock stitches are classified in a number of ways. The most basic classification is by the number

of threads used in the stitch. Industrial overlock machines are generally made in 1, 2, 3, 4, or 5 thread

formations. Each of these formations has unique uses and benefits: 1-thread formations are used for

end-to-end seaming, or butt-seaming. Two- and three-thread formations, also known as merrowing,

are the most common, used for edging and seaming, especially on knits and wovens. Four-thread

Sewingcontract.com

formations are called mock safety stitches and create extra strength while retaining flexibility. 5-thread

formations, which utilize 2 needles, are called safety stitches, creating a very strong seam used for

apparel manufacturing.

Overlocking is also referred to as overedging, merrowing or serging. Though serging technically

refers to overlocking with cutters, in practice the four terms are used

2-thread, 1/8 wide, 20 stitches per inch, with differential

feed: Photo: Merrow

Merrow rolled blanket stich

Purl Stich, Photo: Merrow Sewing Machine

Company

Narrow blanket Stitch

3-thread, wide, 7 stitches per inch 4-thread, 5/32 wide, 17 Merrow blanket Stitch

stitches per inch

Photo: Merrow Sewing

Machine Company

4-thread, 5/32 wide, 17 stitch-

Traditional Blanket Stitch es per inch, Photo: Merrow

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

Crochet Shell Stitches

22-FJ Large Shell

Sewingcontract.com

22-FJ

27-FJ

27FJ

35-FJ Small Shell

35-FJ

Crochet Stitches

15-CA-1

17-F

18-A

18-E

18-G

18-S

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

Sewingcontract.com

Dewellton LLC, Helsinki, TexUp O, Estonia, Wapductions Inc. New York

Potrebbero piacerti anche

- Carr and Latham's Technology of Clothing ManufactureDa EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerValutazione: 4 su 5 stelle4/5 (1)

- 8.STITCHES & ClassificationDocumento56 pagine8.STITCHES & ClassificationUmer MushtaqNessuna valutazione finora

- 3stitch Matrix 10 8 10Documento4 pagine3stitch Matrix 10 8 10Shohan KhanNessuna valutazione finora

- Denimstitchmatrix2 PDFDocumento4 pagineDenimstitchmatrix2 PDFK.s. RameshNessuna valutazione finora

- Denim Stitch Matrix 2Documento4 pagineDenim Stitch Matrix 2atulpvermaNessuna valutazione finora

- Assignment of Stitch Class and Sub-Class Including All Features and UsesDocumento25 pagineAssignment of Stitch Class and Sub-Class Including All Features and UsesJahidul IslamNessuna valutazione finora

- Types of Stitch Used in Garments SewingDocumento10 pagineTypes of Stitch Used in Garments SewingMasudur RahmanNessuna valutazione finora

- 4d... Overedge Stitch FormationDocumento8 pagine4d... Overedge Stitch FormationAbhinav Verma100% (1)

- Stitches TheoryDocumento9 pagineStitches Theorysunita nasta100% (1)

- Ornamantation in SelvagesDocumento18 pagineOrnamantation in SelvagesSatish Kulkarni100% (1)

- - - - â - - - د - - - - - - - - - ç 2Documento4 pagine- - - â - - - د - - - - - - - - - ç 2weamnorafashionNessuna valutazione finora

- Stitch 140503091259 Phpapp01Documento35 pagineStitch 140503091259 Phpapp01Steve ShamNessuna valutazione finora

- 3 Bed TypesDocumento42 pagine3 Bed Typesrajurana25Nessuna valutazione finora

- Weft Knitting (Suza)Documento16 pagineWeft Knitting (Suza)Suza Ahmed AuporboNessuna valutazione finora

- Sewing Thread ConsumptionDocumento1 paginaSewing Thread Consumptionsazia nituNessuna valutazione finora

- Spme IIIDocumento202 pagineSpme IIIYogesh SharmaNessuna valutazione finora

- Needle: Functions of Needle in The Sewing M/CDocumento11 pagineNeedle: Functions of Needle in The Sewing M/CDewan Ajuad Hossain RifatNessuna valutazione finora

- Overlock Machine Brands and PartsDocumento45 pagineOverlock Machine Brands and Partsvijay mahar100% (2)

- Range of StitchesDocumento19 pagineRange of StitchesKrishna K.R.Nessuna valutazione finora

- Stitch: Methods of Stitch FormationDocumento7 pagineStitch: Methods of Stitch FormationM SarfrazNessuna valutazione finora

- Cut & Sew Knit WearDocumento4 pagineCut & Sew Knit WearshponNessuna valutazione finora

- Different Types of Dry Process For Denim WashDocumento11 pagineDifferent Types of Dry Process For Denim WashRana Muhammad Arif KhanNessuna valutazione finora

- KnittingDocumento13 pagineKnittingrakibNessuna valutazione finora

- Apparel Production Techniques of Formal ShirtDocumento19 pagineApparel Production Techniques of Formal ShirtSWARNIKA SRIVASTAVANessuna valutazione finora

- Analysis of Weft Knitted Jersey FabricDocumento6 pagineAnalysis of Weft Knitted Jersey FabricNaimul HasanNessuna valutazione finora

- Folders Used IN Sewing MachinesDocumento24 pagineFolders Used IN Sewing MachinesrajasekaranvgNessuna valutazione finora

- 100 Class StitchesDocumento9 pagine100 Class StitchesVishakha ChopraNessuna valutazione finora

- TP 38691Documento15 pagineTP 38691Rocio Terrel AvilaNessuna valutazione finora

- Fabric Spec KnittedDocumento2 pagineFabric Spec KnittedakshatgargmoderniteNessuna valutazione finora

- BGMEA University of Fashion & Technology: Chapter: Knitting ElementsDocumento16 pagineBGMEA University of Fashion & Technology: Chapter: Knitting ElementsRatul HasanNessuna valutazione finora

- Tech Pack - Formal Long Sleeve Shirt (1) (1) .ITQWT20Documento2 pagineTech Pack - Formal Long Sleeve Shirt (1) (1) .ITQWT20joynahidNessuna valutazione finora

- Crown Textile ProfileDocumento18 pagineCrown Textile ProfileBilalNessuna valutazione finora

- Measurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaDocumento7 pagineMeasurement of Seam Puckering and Influence of Its Causes: Sandun Fernando Tss JayawardenaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Steps To Garment MakingDocumento12 pagineSteps To Garment MakingKhandaker Sakib FarhadNessuna valutazione finora

- Types of ZipperDocumento1 paginaTypes of Zippersakshi ranadeNessuna valutazione finora

- Seam PuckeringDocumento16 pagineSeam PuckeringIshika100% (2)

- Lab Manual: Course Title: Apparel Manufacturing IV (Lab) Course Code: TE-428 Level and Term: L TDocumento45 pagineLab Manual: Course Title: Apparel Manufacturing IV (Lab) Course Code: TE-428 Level and Term: L TMD OHiNessuna valutazione finora

- Where The Textile Industry Assembles To Learn: Knitting NeedlesDocumento3 pagineWhere The Textile Industry Assembles To Learn: Knitting Needlesfarooq jalalNessuna valutazione finora

- Idm Sem 3 Tech PackDocumento11 pagineIdm Sem 3 Tech PackAnkit AkashNessuna valutazione finora

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionDocumento4 pagineEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionElias KhalilNessuna valutazione finora

- Apparel Glossary 08Documento3 pagineApparel Glossary 08Arslan ShaukatNessuna valutazione finora

- Looper and Spreader Mechanism of Flatlock MachineDocumento5 pagineLooper and Spreader Mechanism of Flatlock MachineTauqeer Raza100% (1)

- Fabric Supplier Quality & Process Guide: Updated Date: 5-20-2015Documento37 pagineFabric Supplier Quality & Process Guide: Updated Date: 5-20-2015Anastasia LovaNessuna valutazione finora

- Evaluation of Different Seam and Stitches On Jacket, Trouser, Woven Shirt, JeansDocumento14 pagineEvaluation of Different Seam and Stitches On Jacket, Trouser, Woven Shirt, JeansMahmudul HasanNessuna valutazione finora

- Finish Fabrics: ShirtingDocumento3 pagineFinish Fabrics: ShirtingKasra GolbanNessuna valutazione finora

- BixbyDocumento19 pagineBixbyjoynahidNessuna valutazione finora

- I K G TDocumento37 pagineI K G TAbhishek kushwahaNessuna valutazione finora

- Chapter 1Documento31 pagineChapter 1ProfessorTextechNessuna valutazione finora

- Reviused Ds-1to TprintDocumento22 pagineReviused Ds-1to Tprintapi-3797815Nessuna valutazione finora

- Sewn Products Machinery and Equipment - II (Pre & Post Production Machines & Equipment)Documento14 pagineSewn Products Machinery and Equipment - II (Pre & Post Production Machines & Equipment)Suganya ArumugamNessuna valutazione finora

- Jahitan SumberDocumento32 pagineJahitan SumberMizaa RamizahNessuna valutazione finora

- Knit Prod Dev ProjectDocumento67 pagineKnit Prod Dev Projectshuvo792Nessuna valutazione finora

- 1.5 - Textile Fibers Yarns and Fabrics - 03Documento5 pagine1.5 - Textile Fibers Yarns and Fabrics - 03maya_muth100% (1)

- OB of Basic 5 PKT Denim PantDocumento2 pagineOB of Basic 5 PKT Denim PantMoin AhmedNessuna valutazione finora

- Knitting ProcessDocumento8 pagineKnitting ProcessDhana SeelanNessuna valutazione finora

- Knitting ScienceDocumento24 pagineKnitting ScienceKathirrveluSubramainanNessuna valutazione finora

- Thread Consumption TemplateDocumento7 pagineThread Consumption TemplateEmdad ApmNessuna valutazione finora

- Sewing ProbDocumento18 pagineSewing ProbAminur RahmanNessuna valutazione finora

- 91 MesurmentsDocumento25 pagine91 MesurmentsKazi Abdullah All MamunNessuna valutazione finora

- Amigurumi Bear Free PatternDocumento8 pagineAmigurumi Bear Free PatternMonica Farias100% (1)

- Newsletter For WebDocumento24 pagineNewsletter For Webapi-188373529Nessuna valutazione finora

- Final+Report +++Raymond+Chhindwara1 1Documento94 pagineFinal+Report +++Raymond+Chhindwara1 1Neeraj Kumar40% (5)

- Market Overview of Knitting IndustryDocumento13 pagineMarket Overview of Knitting Industrydyuti singhNessuna valutazione finora

- Crochet Minion Pencil CaseDocumento4 pagineCrochet Minion Pencil Casemarjorieluna100% (1)

- M Tech (Part Time) SyllabusDocumento21 pagineM Tech (Part Time) SyllabusKrishna PrasadNessuna valutazione finora

- Blanca Nieves Hermo 123Documento15 pagineBlanca Nieves Hermo 123Deverlyn Argueta100% (6)

- Grade 7-8 - Handicraft Q1 W1-W2Documento30 pagineGrade 7-8 - Handicraft Q1 W1-W2Arlie Jean Bioneda AbilaNessuna valutazione finora

- Masha PatternDocumento8 pagineMasha PatternApoorva GowdaNessuna valutazione finora

- Free Crochet Pattern: Pink Owl Amigurumi DollDocumento7 pagineFree Crochet Pattern: Pink Owl Amigurumi DollSayo Carrero100% (3)

- Sara Dukke UsDocumento14 pagineSara Dukke UsCharlotte VardyNessuna valutazione finora

- куколка сакура в японском стилеDocumento21 pagineкуколка сакура в японском стилеRicky White100% (7)

- Textile Presentation - BambooDocumento11 pagineTextile Presentation - BambooFizz Hasif100% (1)

- Strawberry Tea SetDocumento20 pagineStrawberry Tea Settobi maniaNessuna valutazione finora

- Auto ConerDocumento34 pagineAuto ConerJai Patel0% (1)

- PortfolioDocumento19 paginePortfolioAP SURENNessuna valutazione finora

- Hannah Doll: MaterialsDocumento15 pagineHannah Doll: Materialsjazmin100% (1)

- Illikal SareeDocumento9 pagineIllikal Sareeswathi aradhyaNessuna valutazione finora

- Rope Making (1) AaaDocumento7 pagineRope Making (1) Aaaalefe gebrieNessuna valutazione finora

- Picture Dictionary of Hand Embroidery Stitches by SarahDocumento25 paginePicture Dictionary of Hand Embroidery Stitches by Sarahhuzefa7barodawala100% (4)

- Beginning Garment MakingDocumento69 pagineBeginning Garment MakingHanisha Mulchandani100% (4)

- Phone PoohDocumento10 paginePhone PoohApoorva Gowda100% (2)

- Product And/or Service Positioning: Baju Melayu, Kurta, Baju KurungDocumento2 pagineProduct And/or Service Positioning: Baju Melayu, Kurta, Baju KurungAeliza100% (1)

- Laporan Data Dan Stok Office 2000 Keseluruhan (Khusus Stationery)Documento90 pagineLaporan Data Dan Stok Office 2000 Keseluruhan (Khusus Stationery)Dina SyaffutriNessuna valutazione finora

- Biker Shorts All SizesDocumento14 pagineBiker Shorts All SizesbeeNessuna valutazione finora

- SPL - Polyesters - Presentation - 02 12 2019Documento15 pagineSPL - Polyesters - Presentation - 02 12 2019Nirlep ChoksiNessuna valutazione finora

- Assignment (10 Bedsheets, Towels, Napkins) (Mohit Kumar (Group 1J) )Documento36 pagineAssignment (10 Bedsheets, Towels, Napkins) (Mohit Kumar (Group 1J) )swarnim srivastawNessuna valutazione finora

- Ca 7 AfcDocumento9 pagineCa 7 AfcChinmay Kumar SahooNessuna valutazione finora

- Crossstitcher 3632020Documento84 pagineCrossstitcher 3632020Елена Черванева100% (6)