Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Nitobond EP TDS

Caricato da

engr_nhelCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Nitobond EP TDS

Caricato da

engr_nhelCopyright:

Formati disponibili

Fosroc

Nitobond EP constructive solutions

High strength epoxy bonding agent Properties

for new to old concrete and primer for

Test method Typical result

repair mortars to concrete substrates

Compressive strength: 50 MPa

Uses Tensile strength: 20 MPa

For bonding fresh wet cementitious materials to existing Flexural strength: 35 MPa

cementitious surfaces. For use on horizontal or vertical surfaces Shear strength: 25 MPa

where mortar or concrete can be supported by formwork. The

Adhesive bond to In general, the bond will

long open life makes it suitable for use with formwork or where

concrete: exceed the tensile strength of

additional steel reinforcement has to be fitted. The product is

the host concrete

ideal for roads, bridges, pavements, loading bays and factories,

and for bonded or granolithic floor toppings. Nitobond EP is

equally suited to internal and external applications. The following properties were measured at 20C:

Nitobond EP may also be used as part of a repair system where Pot life: 35 - 45 minutes

a substrate/repair barrier is required or where the substrate is Initial hardness: 24 hours

likely to remain permanently damp or wet. Full cure: 7 days

Max. overlay time: 90 minutes

Advantages

High strength adhesion - exceeds that of the tensile

strength of the host concrete Note: at temperatures below 20C, the cure rate will be slower.

Conversely, at temperatures above 20C, the cure rate will be

Exhibits high mechanical strength faster.

Can be applied on to dry or SSD damp substrates

Specification clauses

Solvent free - can be used in enclosed locations

Epoxy bonding agent

Description The bonding agent shall be Nitobond EP, a two-component

Nitobond EP is based on solvent-free epoxy resins containing solvent-free epoxy resin. The 2 components shall be differentially

pigments and fine fillers. It is supplied as a two-component pigmented in order to ensure visually that correct mixing has

material in pre-weighed quantities ready for on-site mixing and taken place prior to the application. The product shall achieve

use. The base component is white and the hardener component 50MPa compressive strength, 20MPa tensile strength, 35 MPa

is black, providing visual evidence (uniform grey colour) that flexural strength and 25MPa shear strength. The adhesive

adequate mixing has been achieved. bond to the concrete substrate shall exceed the tensile strength

of the host concrete.

Technical support

Application instructions

Parchem offers a comprehensive range of high performance,

high quality concrete repair and construction products. In Preparation

addition, Parchem offers a technical support package to

specifiers, end-users and contractors, as well as on-site technical Clean the surface and remove any dust, unsound material,

assistance. plaster, oil, paint, grease, corrosion deposits or algae. Roughen

the surface and remove any laitance and expose aggregate by

light scabbling or grit-blasting.

Design criteria

Oil and grease deposits should be removed by steam cleaning,

Nitobond EP is designed to have an overlay time of 90 minutes

detergent scrubbing or the use of a proprietary degreaser. The

at 20C. The minimum application temperature for Nitobond

effectiveness of decontamination and soundness of the substrate

EP is 5C. Consult your local Parchem sales office for further

should then be assessed by a pull-off test.

information.

Mixing

Any steel reinforcement and formwork should be prepared, cut

to size and shape, and made ready for assembly before mixing

commences.

Care should be taken to ensure that Nitobond EP is thoroughly

mixed. The hardener and base components should be stirred

separately before mixing to disperse any settlement. The entire

contents of the hardener tin should then be poured into the

base tin and the two materials thoroughly mixed using a suitable

Sept 2016 Page 1

Fosroc

Nitobond EP

slow-speed heavy duty drill and mixing paddle for 2 minutes Cleaning

until a fully uniform colour is obtained. The sides of the tin should

Nitobond EP should be removed from tools, equipment and

then be scraped and mixing should continue for a further 2

mixers with Solvent 10 immediately after use. Hardened material

minutes.

can only be removed mechanically.

Application

Limitations

Nitobond EP should be applied as soon as the mixing process

Nitobond EP should not be applied when the temperature is

has been completed. It should be brush or spray applied to the

below 5C or is 5C and falling. If any doubts arise concerning

prepared surfaces. Spray application requires a heavy duty

temperature or substrate conditions, consult your local Parchem

airless spray machine such as Graco airless spray fitted with

sales office. Before the application of any repair material or

19 -20 thou tip. Refer to Graco for specific advice.

topping, Nitobond EP should be allowed to become tacky after

The new concrete or screed should be applied to the coated its application to the host substrate. Due to the relatively slow

substrate after the Nitobond EP has become tacky and within setting time of Nitobond EP, care should be taken when the

90 minutes at 20C, ie. while the Nitobond EP is still tacky. If product is used in cold conditions and or when the material

the Nitobond EP is allowed to become tack-free, a second coat being subsequently applied to the Nitobond EP is rapid setting.

will be required. This second coat must be applied the same In cold conditions (<15oC) the Nitobond may not set quick

day as the first coat otherwise the first coat will need to be enough to bond to a rapidly setting topping which may then

mechnically removed. curl due to shrinkage tension. This would result in delamination

of the topping away from the host substrate. If there is a possibility

As soon as the Nitobond EP has been applied, any required

of these conditions on site, users are advised to contact Parchem

steel reinforcement and/or formwork should be erected and

Technical Helpline for specific guidance.

fixed securely in place.

When required to form a barrier between chloride Estimating

contaminated concrete and Renderoc repair material, the

prepared concrete should be primed with Nitobond EP and Supply

allowed to cure for 8 to 24 hours. This coating should be

imperforate and any unfilled voids (blow-holes) should be 1.5 L pack PC: 321020

filled with Nitomortar AP before proceeding. Apply a second

6 L pack PC: 321030

coat of Nitobond EP and leave for 30 minutes before the

Renderoc is applied to the tacky surface. Solvent 10: 4 and 20 litre cans

Low temperature working Coverage

To facilitate mixing and application at temperatures below 15C,

Nitobond EP: 4 - 5 m2/litre

the separate components should be warmed up to a maximum

temperature of 25C before beginning to mix. If heated to 25C, Note: the coverage figures for Nitobond EP is theoretical

the subsequently mixed material will need to be used more due to wastage factors and the variety and nature of possible

speedily as the pot-life will be reduced to 20 minutes. Alternatively, substrates, practical coverage figures will be reduced.

the material should be stored in an environment heated to 20C

and only removed immediately before use.

Storage

High temperature working

Shelf life

At ambient temperatures above 30C, the material should be

Nitobond EP has a shelf life of 12 months from date of

stored in the shade or in an air-conditioned environment for

manufacture if kept in a dry store in the original unopened

12 hours before use.

packs. Refer to Use by Date on packaging.

Storage conditions

Store in dry conditions in the original unopened packs. If

stored at high temperatures, the shelf life may be reduced.

Important notice

A Safety Data Sheet (SDS) and Technical Data Sheet (TDS) are available from the Parchem website or upon request from the nearest Parchem sales office. Read the SDS and TDS carefully

prior to use as application or performance data may change from time to time. In emergency, contact any Poisons Information Centre (phone 13 11 26 within Australia) or a doctor for advice.

Product disclaimer

This Technical Data Sheet (TDS) summarises our best knowledge of the product, including how to use and apply the product based on the information available at the time. You should read this

TDS carefully and consider the information in the context of how the product will be used, including in conjunction with any other product and the type of surfaces to, and the manner in which, the

product will be applied. Our responsibility for products sold is subject to our standard terms and conditions of sale. Parchem does not accept any liability either directly or indirectly for any losses

suffered in connection with the use or application of the product whether or not in accordance with any advice, specification, recommendation or information given by it.

*Manufactured and sold under license from Fosroc Parchem Construction Supplies Pty Ltd

International Limited. Fosroc and the Fosroc logo are trade 7 Lucca Road, Wyong NSW 2259

marks of Fosroc International Limited, used under license. Phone: 1300 737 787

*Denotes a trade mark of Fosroc International Limited. www.parchem.com.au

ABN 80 069 961 968

constructive solutions Page 2

Distributed in New Zealand by: Concrete Plus Ltd

23 Watts Rd, Sockburn 8042 Ph: 0800 657 156

Potrebbero piacerti anche

- Box 1.5m 1.5mDocumento22 pagineBox 1.5m 1.5mveevimalNessuna valutazione finora

- Mechanics of Deformable Bodies Module 1Documento14 pagineMechanics of Deformable Bodies Module 1jhuascute06Nessuna valutazione finora

- E985F8E88F069BF1BB6F005056AC67B7Documento1 paginaE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoNessuna valutazione finora

- Epoxy Resins, Curing Agents, Compounds, and Modifiers: An Industrial GuideDa EverandEpoxy Resins, Curing Agents, Compounds, and Modifiers: An Industrial GuideValutazione: 5 su 5 stelle5/5 (2)

- Advances in Materials Technology For Fossil Power PlantsDocumento1.121 pagineAdvances in Materials Technology For Fossil Power Plantsadadamovicines100% (5)

- Fosroc Nitobond EP TDSDocumento2 pagineFosroc Nitobond EP TDSsouravjnuNessuna valutazione finora

- Nitobond EPDocumento2 pagineNitobond EPabhay_joshi2002Nessuna valutazione finora

- TDS Nitobond EP India4Documento3 pagineTDS Nitobond EP India4SHIVANSHUNessuna valutazione finora

- Nitobond EP2Documento4 pagineNitobond EP2Sanjeev KumarNessuna valutazione finora

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocumento2 pagineNitobond EP: Epoxy Resin Concrete Bonding AgentAnonymous XVEucVMsE0% (1)

- TDS Nitobond EP Saudi Arabia2Documento3 pagineTDS Nitobond EP Saudi Arabia2subhashisNessuna valutazione finora

- Fosroc Nitobond EP: Constructive SolutionsDocumento4 pagineFosroc Nitobond EP: Constructive SolutionsganmosesNessuna valutazione finora

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocumento2 pagineNitobond EP: Epoxy Resin Concrete Bonding AgentjitendraNessuna valutazione finora

- Tds Nitobond Ep VNDocumento4 pagineTds Nitobond Ep VNBejay BermudezNessuna valutazione finora

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocumento3 pagineNitobond EP: Epoxy Resin Concrete Bonding AgentDinesh HastakNessuna valutazione finora

- Nitobond EP 0608Documento2 pagineNitobond EP 0608James PittsNessuna valutazione finora

- TDS - Nitobond PC - IndiaDocumento2 pagineTDS - Nitobond PC - IndiaccNessuna valutazione finora

- Nitobond PC PDFDocumento2 pagineNitobond PC PDFAarish khanNessuna valutazione finora

- TDS Nitobond EP Saudi ArabiaDocumento3 pagineTDS Nitobond EP Saudi ArabiaSCCPL UKNessuna valutazione finora

- Nitobond PC PDFDocumento2 pagineNitobond PC PDFAnonymous XVEucVMsENessuna valutazione finora

- Nitobond EP : Constructive SolutionsDocumento4 pagineNitobond EP : Constructive SolutionsChidi OkoloNessuna valutazione finora

- Fosroc Nitocote EP410: Constructive SolutionsDocumento4 pagineFosroc Nitocote EP410: Constructive SolutionsVJ QatarNessuna valutazione finora

- Fosroc Nitocote Ep410 AdmixtureDocumento2 pagineFosroc Nitocote Ep410 Admixturemahesh579Nessuna valutazione finora

- Fosroc Nitocote EP405 TDSDocumento3 pagineFosroc Nitocote EP405 TDSEmilAbdoNessuna valutazione finora

- Fosroc Nitobond SBA: Constructive SolutionsDocumento2 pagineFosroc Nitobond SBA: Constructive SolutionsVincent JavateNessuna valutazione finora

- Nitobond TMDocumento2 pagineNitobond TMVincent JavateNessuna valutazione finora

- TDS Nitobond AR India3Documento3 pagineTDS Nitobond AR India3reshmitapallaNessuna valutazione finora

- TDS Nitobond AR IndiaDocumento3 pagineTDS Nitobond AR IndiaAnonymous XVEucVMsENessuna valutazione finora

- Tds Nitobond Ep IdDocumento4 pagineTds Nitobond Ep IdMartin TioNessuna valutazione finora

- Nitobond EP STD: Constructive SolutionsDocumento2 pagineNitobond EP STD: Constructive SolutionsYtyus BlackNessuna valutazione finora

- Nitobond AR PDFDocumento4 pagineNitobond AR PDFRajNessuna valutazione finora

- Conbextra EP: T T T T T TDocumento4 pagineConbextra EP: T T T T T TFeri Oktara IrawanNessuna valutazione finora

- Nitozinc Primer: Two Component Epoxy Zincrich PrimerDocumento3 pagineNitozinc Primer: Two Component Epoxy Zincrich PrimerjackNessuna valutazione finora

- Nitobond EP : Constructive SolutionsDocumento4 pagineNitobond EP : Constructive SolutionsmilanbrasinaNessuna valutazione finora

- Nitocote ET402: Constructive SolutionsDocumento4 pagineNitocote ET402: Constructive SolutionsSinan A AzizNessuna valutazione finora

- Expanbond EPDocumento3 pagineExpanbond EPAliNessuna valutazione finora

- Nitomortar TC2000Documento3 pagineNitomortar TC2000talatzahoorNessuna valutazione finora

- Nitokit Surface Sealant: Constructive SolutionsDocumento2 pagineNitokit Surface Sealant: Constructive SolutionstalatzahoorNessuna valutazione finora

- Fosroc Nitoflor Levelcrete: Cementitious Floor Levelling CompoundDocumento4 pagineFosroc Nitoflor Levelcrete: Cementitious Floor Levelling CompoundVincent JavateNessuna valutazione finora

- Nitofi LL EPLV: Low Viscous Epoxy Injection Resin GroutDocumento2 pagineNitofi LL EPLV: Low Viscous Epoxy Injection Resin Grout8108295484Nessuna valutazione finora

- Nitomortar FC PDFDocumento2 pagineNitomortar FC PDFganmosesNessuna valutazione finora

- Fosroc Nitomortar FC (FS) : Constructive SolutionsDocumento2 pagineFosroc Nitomortar FC (FS) : Constructive SolutionsVincent JavateNessuna valutazione finora

- Conbextra EP40 UAEDocumento2 pagineConbextra EP40 UAEjasonNessuna valutazione finora

- TDS Nitofill EPLV BFLDocumento2 pagineTDS Nitofill EPLV BFLanandswarupNessuna valutazione finora

- Nitomortar FCDocumento2 pagineNitomortar FCMansoor AliNessuna valutazione finora

- Nitozinc Primer: Two Component Epoxy Zincrich PrimerDocumento3 pagineNitozinc Primer: Two Component Epoxy Zincrich Primeryash shahNessuna valutazione finora

- Nitozinc® PrimerDocumento3 pagineNitozinc® PrimerArun KumarNessuna valutazione finora

- Nitobond Tile AdhesiveDocumento2 pagineNitobond Tile AdhesiveVincent JavateNessuna valutazione finora

- Specifications of Nitofill EPLV PDFDocumento2 pagineSpecifications of Nitofill EPLV PDFTrung Nguyen ThanhNessuna valutazione finora

- Nitofill EPLVDocumento2 pagineNitofill EPLVSean Harsha100% (1)

- Nitozinc Primer: Two Component Epoxy Zincrich PrimerDocumento4 pagineNitozinc Primer: Two Component Epoxy Zincrich PrimerCMM INFRAPROJECTS LTDNessuna valutazione finora

- Fosroc Nitomortar AP TDSDocumento2 pagineFosroc Nitomortar AP TDSmrameshceNessuna valutazione finora

- Nitocote Primer SealerDocumento2 pagineNitocote Primer SealerVJ QatarNessuna valutazione finora

- Fosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveDocumento2 pagineFosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveVincent JavateNessuna valutazione finora

- Expoband One: Flexible Expansion Joint MembraneDocumento3 pagineExpoband One: Flexible Expansion Joint MembraneSure Tech TrivandrumNessuna valutazione finora

- Nitobond AR STD.: Constructive SolutionsDocumento4 pagineNitobond AR STD.: Constructive SolutionsVarun GuggilamNessuna valutazione finora

- Nitozinc Primer: Two Component Epoxy Zincrich PrimerDocumento4 pagineNitozinc Primer: Two Component Epoxy Zincrich Primervelmurug_balaNessuna valutazione finora

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocumento2 pagineFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNessuna valutazione finora

- Nitocote EP403Documento3 pagineNitocote EP403Syed HassaanNessuna valutazione finora

- Nitomortar FCDocumento2 pagineNitomortar FCMOHAMED.NOUSARNessuna valutazione finora

- RCT-ConFloor EP SLDocumento2 pagineRCT-ConFloor EP SLfahadNessuna valutazione finora

- Conbextra Ep40Documento3 pagineConbextra Ep40talatzahoorNessuna valutazione finora

- Nitocote EP405: Constructive SolutionsDocumento4 pagineNitocote EP405: Constructive SolutionsrayNessuna valutazione finora

- Fosroc Nitomortar 908 TDSDocumento2 pagineFosroc Nitomortar 908 TDSmrameshceNessuna valutazione finora

- Snag ListDocumento1 paginaSnag Listengr_nhelNessuna valutazione finora

- Repair Procedure For Ceramic Wall TileDocumento1 paginaRepair Procedure For Ceramic Wall Tileengr_nhelNessuna valutazione finora

- CCM - Mr. ChoDocumento1 paginaCCM - Mr. Choengr_nhelNessuna valutazione finora

- Above Ceiling Cleaning ScheduleDocumento2 pagineAbove Ceiling Cleaning Scheduleengr_nhelNessuna valutazione finora

- OCP Remedial Works Zone 5 - Part 1Documento2 pagineOCP Remedial Works Zone 5 - Part 1engr_nhelNessuna valutazione finora

- Kinetic Theory of MatterDocumento5 pagineKinetic Theory of Matterapi-3839633Nessuna valutazione finora

- Sorona - Product InformationDocumento4 pagineSorona - Product InformationchristianNessuna valutazione finora

- Intermolecular Forces and Its Applications: For General Chemistry 2/grade 12 (STEM) Quarter 3/week 1.a-DDocumento19 pagineIntermolecular Forces and Its Applications: For General Chemistry 2/grade 12 (STEM) Quarter 3/week 1.a-DSherwin Jay PalaspasNessuna valutazione finora

- Class X Sample Paper 03 For Board Exam 2019 PDFDocumento4 pagineClass X Sample Paper 03 For Board Exam 2019 PDFApex Institute100% (1)

- PFM920I-6U-U Datasheet 20221020Documento2 paginePFM920I-6U-U Datasheet 20221020GgopNessuna valutazione finora

- (Tom Schanz) Experimental Unsaturated Soil MechaniDocumento490 pagine(Tom Schanz) Experimental Unsaturated Soil MechaniChristopher CarrilloNessuna valutazione finora

- v91 247 PDFDocumento6 paginev91 247 PDFbariah al-bashirahNessuna valutazione finora

- Frank Girgsdies Phase Analysis and Structure Refinement 131129Documento91 pagineFrank Girgsdies Phase Analysis and Structure Refinement 131129MegaTypers100% (1)

- Cape Physics 2008 Unit 1Documento10 pagineCape Physics 2008 Unit 1kesnaNessuna valutazione finora

- ASCO Series 307 Solenoid Valves No Voltage ReleaseDocumento6 pagineASCO Series 307 Solenoid Valves No Voltage Releasehacene omarNessuna valutazione finora

- MasterTemp 125 High Performance Heater Installation and Users Guide EnglishDocumento56 pagineMasterTemp 125 High Performance Heater Installation and Users Guide Englishjesus javier ceme kooNessuna valutazione finora

- Methods and Techiniques in PathologyDocumento15 pagineMethods and Techiniques in PathologyKiran100% (1)

- R. Meredith, U.S. Patent 2,274,631Documento5 pagineR. Meredith, U.S. Patent 2,274,631Erivaldo ConstantNessuna valutazione finora

- Techno-Economic Assessment About Propylene GlycolDocumento4 pagineTechno-Economic Assessment About Propylene GlycolIntratec SolutionsNessuna valutazione finora

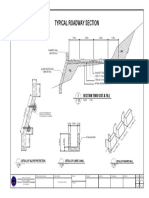

- Typical Roadway SectionDocumento1 paginaTypical Roadway SectionCarmela Ayessa PiguerraNessuna valutazione finora

- MicromeriticsDocumento109 pagineMicromeriticsSan GalNessuna valutazione finora

- Fino ClassicDocumento2 pagineFino ClassicRicette FaciliNessuna valutazione finora

- Manual For Water Filter SystemDocumento2 pagineManual For Water Filter Systemgjnxjbm8pbNessuna valutazione finora

- Avt 200 #1 Aircarft StructureDocumento99 pagineAvt 200 #1 Aircarft StructureStrause Vince Jansen RetuyaNessuna valutazione finora

- Micro EdmDocumento58 pagineMicro EdmPranes RainaNessuna valutazione finora

- Theoretical Framework: Compressive Strength TestDocumento11 pagineTheoretical Framework: Compressive Strength TestqwertasdfgNessuna valutazione finora

- MSDS083 Rev2 - Photochromic Powder - ESTEE LAUDERDocumento4 pagineMSDS083 Rev2 - Photochromic Powder - ESTEE LAUDERSanketh GuptaNessuna valutazione finora

- Nuri ProposalDocumento26 pagineNuri Proposalkassahun meseleNessuna valutazione finora

- 496 GDJGGJGFDocumento2 pagine496 GDJGGJGFRaluca FarcasNessuna valutazione finora

- 21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsDocumento13 pagine21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsbelavelosoNessuna valutazione finora

- General Chemistry Grade 12 ModuleDocumento86 pagineGeneral Chemistry Grade 12 ModuleprincessssmtlbNessuna valutazione finora