Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

All SRM Appa

Caricato da

Liney Jharitza Escobar BonillaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

All SRM Appa

Caricato da

Liney Jharitza Escobar BonillaCopyright:

Formati disponibili

BHT-ALL-SRM

APPENDIX A MATERIAL INFORMATION

TABLE OF CONTENTS

Paragraph Page

Number Title Number

MATERIAL INFORMATION

A-1 Curing Times for Sealants and Miscellaneous Adhesives .................................. A-3

A-2 Ordering Repair Material..................................................................................... A-4

A-2-1 Composite Bond Sheet Metal Repair Stock (Bell Standard 150-021) ........... A-4

A-2-2 Repair Angle (Bell Standard 151-028)........................................................... A-6

A-2-3 Flanged Hole Repair Material ........................................................................ A-8

A-2-4 Honeycomb Core Repair Material ................................................................. A-10

A-3 Material Identification .......................................................................................... A-12

A-3-1 Identifying Magnetic from Non-magnetic Material ......................................... A-14

A-3-2 Identifying Magnetic Materials ....................................................................... A-14

A-3-3 Identifying Non-magnetic Materials ............................................................... A-14

A-3-3-1 Identifying Magnesium ........................................................................... A-14

A-3-3-2 Identifying 7075 Aluminum Alloy ............................................................ A-14

A-3-3-3 Identifying 2024 Aluminum Alloy from 6013 Aluminum Alloy ................. A-15

A-3-3-4 Identifying Corrosion Resistant Steel (CRES) ....................................... A-15

A-3-3-5 Identifying Hastalloy X from CRES 321 or N-155 .................................. A-15

A-3-3-6 Identifying Cress 321 from CRES N-155 ............................................... A-15

A-4 Material Specifications ........................................................................................ A-16

A-5 Blind Rivets Equivalencies.................................................................................. A-18

A-6 Approved Fasteners for Use in Carbon Fiber Reinforced Composite Materials . A-19

A-7 Materials Compatibility........................................................................................ A-21

TABLES

Table Page

Number Title Number

A-1 Curing Time for Sealants .................................................................................... A-3

A-2 Composite Bond Material.................................................................................... A-5

A-3 Preformed Repair Angles.................................................................................... A-7

A-4 Flanged Hole Repair Material Data..................................................................... A-8

A-5 Polyamide Honeycomb Core (Basic Number = T1) ............................................ A-10

A-6 Fiberglass Honeycomb Core (Basic Number = T2) ............................................ A-11

A-7 Aramid Paper Honeycomb Core (Basic Number = T3)....................................... A-11

A-8 5052 Aluminum Honeycomb Core (Basic Number = T4).................................... A-11

A-9 5056 Aluminum Honeycomb Core (Basic Number = T5(3)) ............................... A-11

A-10 Most Common Material Specifications................................................................ A-16

A-11 Titanium Equivalencies ....................................................................................... A-18

A-12 Blind Rivet Alternate Part Numbers .................................................................... A-18

A-13 Approved Fasteners for Use in Fiber Reinforced Composite Parts .................... A-20

ECCN EAR99 14 DEC 2010 A-1/A-2

BHT-ALL-SRM

MATERIAL INFORMATION

A-1. CURING TIMES FOR SEALANTS AND MISCELLANEOUS ADHESIVES

Table A-1. Curing Time for Sealants

Military

Application Mix Ratio Pot Life Curing Time

Description

Pro-Seal 890 B2

Sealant for

MIL-S-8802 B-2,

semi-permanent 10:1 2 hours 75F/3 days

Type I or II,

joints

Class B-2

Pro-Seal 700 Repair sealant of 48 hours to tack

100:1 12 hours

MIL-S-38249 firewall free

PR-1436-G Sealant for joints

MIL-S-81733, that must be opened 10:1 2 hours 75F/3 days

Type I or II periodically

EC3549 Polycarbonate duct

BHT 299-947-066, repair with 109:100 35 minutes 160F/3 hours

Type I Fiberglass

PS-30

Acrylic plastics Use all of 50 Gram

BHT 299-947-152, 2 hours 75F/24 hours

bonding kit

Type I, Class 1

ECCN EAR99 14 DEC 2010 A-3

BHT-ALL-SRM

A-2. ORDERING REPAIR MATERIAL

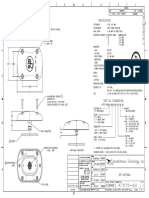

A-2-1. COMPOSITE BOND SHEET METAL REPAIR STOCK (BELL STANDARD 150-021)

Example of Part Number 150-021- ( ) ( ) ( ) -( )

Basic Number

Length in 1 foot increment, 4 feet max2

Dash Number from Table B-2

Width in 1 foot increments, 2 feet max2

A = Adhesive ply both sides 1

B = Adhesive ply one side

C = No adhesive ply

D = Primed both sides

Examples: 150-021-16B2-4 = 2024-T3 5WL pattern repair sheet, 0.020 inch (0.51 mm) thick, 2 feet

(609.60 mm) wide by 4 feet (1219.20 mm) long, adhesive and peel ply on one side.

150-021-58C2-4 = 7075-T6 smooth repair sheet, 0.016 inch (0.41 mm) thick, 2 feet (609.60 mm)

wide by 4 feet (1219.20 mm) long, without adhesive and peel ply.

1) A code designates adhesive and peel ply on both faces of sheet, valid for smooth surfaces only.

B code designates adhesive and peel ply on one face of sheet only, valid for smooth and rigidized surfaces.

C code designates no adhesive and peel ply on both faces of sheet, valid for smooth and rigidized surfaces.

D code designates chemical film and primer without adhesive and peel ply on both faces of sheet, valid for

rigidized surfaces only.

2) Materials may be available in one of either of the two following sizes: 1 x 2 feet (304.80 x 609.60 mm), 2 x 4

feet (609.60 x 1219.20 mm). Some materials are also available in the following sizes: 1 x 1 feet (304.80 x

304.80 mm), 2 x 2 feet (609.60 x 609.60 mm).

A-4 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

Table A-2. Composite Bond Material

MATERIAL TYPE(5)(7)

2024-T3 7075-T6 6013-T6(4) TITANIUM 301 CRES

Thickness(1)

SMOOTH 5WL(2) 6WL(2) SMOOTH SMOOTH SMOOTH 5WL(2) HARD

RIGIDIZED RIGIDIZED RIGIDIZED SMOOTH

0.008

-69

(0.20)

0.012

-2 -12 -56 -81 -31 -41 -71

(0.30)

0.016

-4 -24 -58 -82 -33 -43

(0.41)

0.020

-6 -16 -60 -83 -73

(0.51)

0.025

-8 -20 -28 -62 -84 -77

(0.64)

0.032

-10 -80 -64 -85 -39 -79

(0.81)

0.040

-14 -88 -66 -86 -75

(1.02)

0.050

-18 -68 -87 -76

(1.27)

0.063

-21 -72 -70

(1.60)

0.071

-74

(1.80)

NOTES:

1. Thickness of repair sheet material not including thickness of adhesive. Values are in inches. Values between

parentheses are in millimeters (mm).

2. 5WL and 6WL designations are rigidizing pattern numbers of Rigidized Metal Corporation, Buffalo NY.

3. A code is no longer available.

4. Use with Bell Helicopter Textron Product Support Engineering approval only.

5. All thicknesses may be ordered, although they may not be actively stocked.

6. Materials may be available in one of either of the two following sizes: 1 X 2 feet (304.80 x 609.60 mm), 2 x 4 feet

(609.60 x 1219.20 mm). Some materials are also available in the following sizes: 1 x 1 feet (304.80 x 304.80

mm), 2 x 2 feet (609.60 x 609.60 mm).

7. Material Specifications:

Aluminum, 2024-T3 per AMS-QQ-A-250/4,

Aluminum, 6013-T6 per AMS 4216,

Aluminum, 7075-T6 per AMS-QQ-A-250/12,

Titanium, commercially pure per MIL-T-9046, CP-1,

Steel, Corrosion Resistant CRES 301 1/2 Hard per 299-947-133, Type II or AMS 5518.

ECCN EAR99 14 DEC 2010 A-5

BHT-ALL-SRM

A-2-2. REPAIR ANGLE (BELL STANDARD 151-028)

Example of Part Number 151-028 ( ) ( ) ( )

Basic Number

Length in 1 foot increment, 4 feet max1

Material Code from Table A-3

Thickness Code from Table A-3

Examples: 151-028A50324 = 7075-T62 repair angle, 0.032 inch (0.81 mm) thick, 4 feet (1200 mm) long with

0.06 inch (1.52 mm) bend radius.

151-028C10500 = 301 CRES 1/2 HARD repair angle, 0.050 inch (1.27 mm) thick, 4 feet (1200

mm) long with 0.25 inch (6.35 mm) bend radius.

A-6 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

Table A-3. Preformed Repair Angles

MATERIAL / BEND RADIUS(2) (BR)

THICKNESS(2) ALUMINUM CRES TITANIUM(3)

(T)

2024-T42 7075-T62 301 1/2 HARD CP-1

A4 A5 C1 T1

0.012 0.03 0.06 0.06 0.03

(0.30) (0.8) (1.5) (1.5) (0.8)

0.016 0.03 0.06 0.09 0.06

(0.41) (0.8) (1.5) (2.3) (1.5)

0.020 0.06 0.06 0.09 0.06

(0.51) (1.5) (1.5) (2.3) (1.5)

0.025 0.06 0.06 0.13 0.06

(0.64) (1.5) (1.5) (3.3) (1.5)

0.032 0.06 0.06 0.16 0.09

(0.81) (1.5) (1.5) (4.1) (2.3)

0.040 0.09 0.09 0.16 0.13

(1.02) (2.3) (2.3) (4.1) (3.3)

0.050 0.09 0.09 0.25 0.13

(1.27) (2.3) (2.3) (6.4) (3.3)

0.063 0.13 0.13 0.25 0.16

(1.60) (3.3) (3.3) (6.4) (4.1)

NOTES:

1. Material is available in the following length: 4 feet.

Some materials are also available in the following length: 2 feet.

2. Values are in inches. Values between parentheses are in millimeters (mm).

3. These parts are not actively stocked but may be ordered on special order basis.

ECCN EAR99 14 DEC 2010 A-7

BHT-ALL-SRM

A-2-3. FLANGED HOLE REPAIR MATERIAL

Example of Part Number 151-032 - ( ) ( )

Basic Number T Thickness Code1

A 0.025 (0.64)

Figure Number from next page B 0.032 (0.81)

Examples: 151-032-3A = 2024-T42 repair angle, 0.025 inch (0.64 mm) thick, with 5 lightening holes per

Figure 3.

151-032-4B = 2024-T42 repair angle, 0.032 inch (0.81 mm) thick, with 14 lightening holes per

Figure 4.

1) Values are in inches. Values between parentheses are in millimeters (mm).

2) Flanged hole repair material only available in 2024-T42 aluminum alloy per AMS-QQ-A-250/4 with chemical

film per MIL-C-5541 and primed with epoxy polyamide primer per MIL-PRF-23377.

Table A-4. Flanged Hole Repair Material Data

FIGURE HOLE D DIA(1) C DIA(1) H(1)

A 6.50 (165.1) 6.00 (152.4) 0.25 (6.4)

B 6.00 (152.4) 5.50 (139.7) 0.25 (6.4)

3 C 4.50 (114.3) 4.00 (101.6) 0.25 (6.4)

D 4.75 (120.7) 4.25 (108.0) 0.25 (6.4)

E 4.00 (101.6) 3.50 (88.9) 0.25 (6.4)

F 5.00 (127.0) 4.50 (114.3) 0.25 (6.4)

G 3.50 (88.9) 3.00 (76.2) 0.25 (6.4)

H 3.25 (82.6) 2.75 (69.9) 0.25 (6.4)

J 2.75 (69.9) 2.37 (60.2) 0.19 (4.8)

K 2.25 (57.2) 1.87 (47.5) 0.19 (4.8)

L 1.75 (44.5) 1.37 (34.8) 0.19 (4.8)

M 1.25 (31.8) 1.01 (25.7) 0.12 (3.0)

4

N 1.00 (25.4) 0.76 (19.3) 0.12 (3.0)

P 1.50 (38.1) 1.12 (28.4) 0.19 (4.8)

Q 2.00 (50.8) 1.62 (41.1) 0.19 (4.8)

R 2.50 (63.5) 2.12 (53.8) 0.19 (4.8)

S 3.00 (76.2) 2.62 (66.5) 0.19 (4.8)

T 3.75 (95.3) 3.25 (82.6) 0.25 (6.4)

V 4.25 (108.0) 3.75 (95.3) 0.25 (6.4)

NOTE:

1. Values are in inches. Values between parentheses are in millimeters (mm).

A-8 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

ECCN EAR99 14 DEC 2010 A-9

BHT-ALL-SRM

A-2-4. HONEYCOMB CORE REPAIR MATERIAL

Example of Part Number T4 3.1 x.125 x1/8 x12 x24

Basic Number

Panel Length in inches1

Density

Panel Width in inches1

Cell Size2

Panel Thickness code (Thks Code)

from Table B-5 thru Table B-9.

Examples: T45.7X.125X1/2X12X24 = 5052 Aluminum honeycomb core, 5.7 lbs/cu.ft, 0.187 inch (4.75 mm)

cells, 0.500 inch (12.70 mm) thick, 12 inch (300 mm) wide by 24 inch (600 mm) long.

T53.1X.125X1/8X12X12 = 5056 Aluminum honeycomb core, 3.1 lbs/cu.ft, 0.125 inch (3.18 mm)

cells, 0.125 inch (3.18 mm) thick, 12 inch (300 mm) wide by 12 inch (300 mm) long.

Table A-5. Polyamide Honeycomb Core (Basic Number = T1)

MATERIAL DENSITY (lbs/cu.ft) PANEL SIZE(1)

PANEL Thks

THICKNESS(1) Code

3.0 4.0 6.0 8.0 12x12 12x24 24x48

(300x300) (300x600) (600x1219)

0.125 (3.18) 1/8 X

0.250 (6.35) 1/4 X

0.375 (9.53) 3/8 X

0.500 (12.70) 1/2 X

0.750 (19.05) 3/4 X X X

1.000 (25.40) 1 X X

A-10 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

Table A-6. Fiberglass Honeycomb Core (Basic Number = T2)

MATERIAL DENSITY (lbs/cu.ft) PANEL SIZE(1)

PANEL Thks

THICKNESS(1) Code 3.0 4.5 6.0 8.0 12x12 12x24 24x48

(300x300) (300x600) (600x1219)

0.375 (9.53) 3/8 X

Table A-7. Aramid Paper Honeycomb Core (Basic Number = T3)

MATERIAL DENSITY (lbs/cu.ft) PANEL SIZE(1)

PANEL Thks

THICKNESS(1) Code 3.0 4.5 6.0 12x12 12x24 24x48

(300x300) (300x600) (600x1219)

0.500 (12.70) 1/2 X

0.625 (15.88) 5/8 X X

0.750 (19.05) 3/4 X X X

Table A-8. 5052 Aluminum Honeycomb Core (Basic Number = T4)

MATERIAL DENSITY (lbs/cu.ft) PANEL SIZE(1)

PANEL Thks

THICKNESS(1) Code 3.1 4.5 5.7 8.1

12x12 12x24 24x48

(300x300) (300x600) (600x1219)

0.125 (3.18) 1/8 X - - - - X -

0.250 (6.35) 1/4 X - - - - X X

0.375 (9.53) 3/8 X - - - - X X

0.500 (12.70) 1/2 X X X X - X X

0.563 (14.29) 9/16 X - - - - X -

0.625 (15.88) 5/8 X - - - X - -

0.750 (19.05) 3/4 X - - - - X -

1.000 (25.40) 1 X - - X X X X

1.250 (31.75) 5/4 X - - - X X -

1.500 (38.10) 1.5 - - X X - X -

2.000 (50.80) 2 X - - - X - -

Table A-9. 5056 Aluminum Honeycomb Core (Basic Number = T5(3))

MATERIAL DENSITY (lbs/cu.ft) PANEL SIZE(1)

PANEL Thks

THICKNESS(1) Code 3.1 4.5 5.7 8.1 12x12 12x24 24x48

(300x300) (300x600) (600x1219)

2.000 (50.80) 2 X X

NOTES: (Applicable to Table A-5 through Table A-9)

1. Values are in inches. Values between parentheses are in millimeters (mm).

2. All cell sizes are 0.125 inch (3.18 mm) except for 5.7 lbs/cu.ft core density, which has a cell size of 0.187 inch

(4.75 mm).

3. 5056 aluminum honeycomb core (T5) is not to be used unless specifically required by application. Use 5052

aluminum honeycomb core (T4) instead.

ECCN EAR99 14 DEC 2010 A-11

BHT-ALL-SRM

A-3. MATERIAL IDENTIFICATION

Correct identification of material being repaired and hence the material to be used in the repair is of vital

importance because of the wide range of material strengths.

In order to identify the material from which the damaged part is made, some or all of the following solutions must be

prepared:

WARNING

AVOID BODILY CONTACT WITH ANY CHEMICAL OR SOLUTION. WASH HANDS WITH

SOAP AND WATER AFTER HANDLING CONTAINERS, APPARATUS, AND WIPING

CLOTH.

ENSURE THAT ACIDS ARE ADDED TO WATER, AND NOT WATER TO ACID. STIR OR

MIX DURING THE ADDITION.

CAUTION

PREPARATION FOR USE AND USAGE OF CHEMICALS SHOULD BE

PERFORMED BY QUALIFIED PERSONNEL ONLY.

PREPARATION AND MANIPULATION OF CHEMICALS SHALL ALWAYS BE

PERFORMED IN A WELL VENTILATED AREA. CAUTION, SUCH AS WEARING

A MASK, MUST BE TAKEN NOT TO INHALE VAPORS.

AFTER PERFORMING TEST, THOROUGHLY RINSE TEST AREA WITH

WATER.

ALWAYS SAFELY DISPOSE OF ALL TEST SOLUTION WASTE ACCORDING

TO LOCAL ENVIRONMENTAL AND HEALTH AND SAFETY REQUIREMENTS.

NOTE

It is recommended that test solutions be transferred to individual, clean

medicine-type bottles, incorporating a dropper integral with cap. Affix appropriate

labels and keep tightly capped when not in use.

The use of chemical solutions should be performed at a temperature close to

room temperature and in good lighting conditions. Unfiltered daylight is preferable.

Metal surfaces that are examined shall be chemically clean. Degrease the surface

by swabbing with a degreasing solvent. The metal surface may be polished if

required.

SOLUTION 1: Copper Sulfate Solution.

Copper Sulfate Crystals (CuSO4) is CuSO45 H2O, Cupric Sulfate reagent A.C.S., CAS

7758-99-8. 98% minimum, blue crystals or blue crystalline granules or powder. 10% sulfuric acid

solution.

A-12 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

Slowly add 10 cc of Sulfuric Acid to 90 cc of distilled water. Sulfuric Acid, reagent A.C.S., formula

weight 98.08, Sp. Gr. 1.84, CAS 7664-93-9.

Appearance: oily liquid, colorless, very corrosive, battery acid.

Dissolve 0.055 pound (25 g) of copper sulfate crystals (CuSO4) in 100 cc of distilled water, and

add 2 or 3 cc of 10% Sulfuric acid (H2SO4).

SOLUTION 2: Hydrochloric (C-431) Solution.

Hydrochloric Acid. Reagent A.C.S. formula weight 36.46, CAS 7647-01-0. Hydrogen chloride 38%

in an aqueous solution.

Appearance: colorless or slightly yellow, fuming pungent liquid.

Slowly add 50 cc of hydrochloric acid (HCl) to 50 cc of distilled water. Stir during acid addition.

SOLUTION 3: Cadmium Sulfate Solution.

Cadmium sulfate, CdSO4, Anhydrous, Reagent, A.C.S. Grade, CAS 10124-36-4.

Appearance: Colorless, odorless, crystals.

Mix 0.011 pound (5 g) of cadmium sulfate (CdSO4), 5 cc of concentrated hydrochloric acid (HCl),

and 0.007 pound (3 g) of sodium chloride (NaCl). Dissolve and dilute with distilled water to make

100 cc.

SOLUTION 4: Scratch Test Solution.

Potassium Nitrate KNO3. Crystals, Reagent, A.C.S., CAS 7757-79-1, formula weight 101.10.

Appearance: colorless or white crystalline powder or crystals, slightly hygroscopic, pungent saline

taste.

Slowly add 0.044 pound (20 g) of potassium nitrate (KNO3) and 0.022 pound (10 g) of sodium

hydroxide pellets (NaOH) in 100 cc of distilled water. Do not allow pellets to stick to bottom of

mixing container.

SOLUTION 5: Sodium Hydroxide (C-118) Solution

Sodium Hydroxide, Pellets, Reagent A.C.S., CAS 1310-73-2.

Appearance: White deliquescent solid, in white pellets form, highly absorbs water.

Slowly add and dissolve, 0.055 pound (25 g) of sodium hydroxide pellets (NaOH) to 100 cc of

distilled water. Do not allow pellets to stick to bottom of mixing container.

SOLUTION 6: Sulfuric Acid Solution.

Sulfuric Acid, reagent A.C.S., Sp. Gr. 1.84, CAS 7664-93-9, formula weight 98.08.

Appearance: oily liquid, colorless, very corrosive, battery acid.

25% sulfuric acid solution. Slowly add 25 cc of Sulfuric acid (H2SO4) to 75 cc of distilled water. Stir

during addition of acid.

SOLUTION 7: Silver Nitrate Solution.

Silver Nitrate Ag NO3. Crystals, Reagent, A.C.S., CAS 7761-88-8, formula weight 169.87.

Appearance: colorless transparent crystals.

Dissolve 0.002 pound (1 g) of silver nitrate in 100 cc of distilled water. To prevent degrading the

solution, wrap the reagent bottle with opaque tape. The shelf life of the solution is 6 months.

ECCN EAR99 14 DEC 2010 A-13

BHT-ALL-SRM

SOLUTION 8: Sodium Thiosulfate Solution.

Mix 0.035 pound (16 g) of anhydrous sodium thiosulfate (C-243) with 1000 cc of demineralized

water. However, this ratio does not account for the additional 5H2O content if the crystals form is

procured. Then, a concentration of 0.055 pound (25 g) per 1000 cc is recommended. A 0.1 Normal

Sodium Thiosulfate solution can be procured and mixed at 50% with demineralized water.

SOLUTION 9: Diluted Copper Sulfate Solution.

Dissolve 0.002 pound (1 g) of copper sulfate crystals (CuSO4 5H2O) in 25 cc of 1 Normal Sulfuric

Acid. Normal sulfuric acid (H2SO4) is used in chemical laboratories for analysis. Concentrated

98% sulfuric acid is 36 Normal.

A-3-1. IDENTIFYING MAGNETIC FROM NON-MAGNETIC MATERIAL

1.0 Approach part with a magnet. If an attraction force is felt, then part is magnetic. If no attraction force is felt, part

is non-magnetic. Some materials may only have a slight magnetic response.

A-3-2. IDENTIFYING MAGNETIC MATERIALS

1.0 Apply a droplet of copper sulfate solution (Solution 1) on metal surface; a reaction (red copper deposit)

indicates low carbon steel such as 4130, 4340, 8630 or 8730 steel. Copper sulfate will not react with chromium

nickel steel such as 17-4 PH or 17-7 PH steel.

A-3-3. IDENTIFYING NON-MAGNETIC MATERIALS

A-3-3-1. IDENTIFYING MAGNESIUM

1.0 Cut two or three small chips from edge of metal surface and drop chips on a clean glass surface.

2.0 Apply a droplet of hydrochloric acid solution (Solution 2) to chips; a violent reaction indicates magnesium.

Since hydrochloric acid will also react with aluminum, use silver nitrate solution (Solution 7) to differentiate

magnesium from aluminum.

3.0 Apply a droplet of silver nitrate solution (Solution 7) on a clean surface; a reaction (drop turns black and there

is a black deposit on part when reactant is absorbed on an absorbing media) indicates magnesium.

A-3-3-2. IDENTIFYING 7075 ALUMINUM ALLOY

1.0 Apply a droplet of cadmium sulfate solution (Solution 3) on metal surface; a reaction (black deposit), within

2 minutes, indicates bare or CLAD 7075 aluminum alloy. Cadmium sulfate solution will not react with other

material.

2.0 To identify if the 7075 is bare or CLAD, apply a droplet of scratch test solution (Solution 4) on cleaned surface;

a reaction (black deposit) indicates bare 7075 aluminum alloy. Scratch test solution will not react with CLAD

7075 aluminum alloy.

A-14 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

A-3-3-3. IDENTIFYING 2024 ALUMINUM ALLOY FROM 6013 ALUMINUM ALLOY

1.0 Apply a droplet of sodium hydroxide solution (Solution 5) on metal surface; a reaction (black deposit) indicates

bare 2024 aluminum alloy. If a white deposit appears, the following step 2.0 must be performed to differentiate

CLAD 2024 aluminum alloy from 6013 aluminum alloy. Sodium hydroxide solution will not react with other

material.

2.0 The following steps must be performed to differentiate CLAD 2024 aluminum alloy from 6013 aluminum alloy.

2.1 Sand material to remove cladding from surface (can be up to 5% of light gauge sheet thickness).

2.2 Apply a droplet of sodium hydroxide solution (Solution 5) on cleaned surface; a reaction (black

deposit) indicates CLAD 2024 aluminum alloy. A white deposit indicates 6013 aluminum alloy.

A-3-3-4. IDENTIFYING CORROSION RESISTANT STEEL (CRES)

1.0 Cut six to eight small shavings from edge of metal surface and drop shavings into a clean, 50 cc beaker.

2.0 Cover shavings with Sulfuric acid solution (Solution 6) then boil until shavings dissolves.

3.0 Add a drop of copper sulfate solution (Solution 1) to content of beaker; absence of coloration indicates

corrosion resistant steel such as 301 or 302 steel.

A-3-3-5. IDENTIFYING HASTALLOY X FROM CRES 321 OR N-155

1.0 Lightly abrade surface to be tested using abrasive pad (C-407) or 400 grit abrasive paper (C-423).

2.0 Apply a droplet of hydrochloric acid (Solution 2) on metal surface ensuring the test area is horizontal.

3.0 Apply a droplet of sodium thiosulfate solution (Solution 8) directly on top of the droplet of hydrochloric acid.

4.0 Allow to react between 2 to 5 minutes then check the color of the stain; a reaction (dark color stain) indicates

material is CRES 321 or N-155 while a reaction producing a milky white color stain or no reaction indicates

material is Hastalloy X.

A-3-3-6. IDENTIFYING CRES 321 FROM CRES N-155

1.0 Lightly abrade surface to be tested using abrasive pad (C-407) or 400 grit abrasive paper (C-423).

2.0 Apply a droplet of hydrochloric acid (Solution 2) on metal surface ensuring the test area is horizontal.

3.0 Allow to react between 2 to 5 minutes.

4.0 Apply a droplet of diluted copper sulfate solution (Solution 9) directly on top of droplet of hydrochloric acid; a

reaction (bright copper stain) indicates CRES 321. Copper sulfate solution will not react with CRES N-155.

ECCN EAR99 14 DEC 2010 A-15

BHT-ALL-SRM

A-4. MATERIAL SPECIFICATIONS

The following tables contain listings of the most common material specifications used at Bell Helicopter Textron.

Table A-10. Most Common Material Specifications

TEMPER OR AS

FORM MATERIAL ALLOY PURCHASED SPECIFICATION

CONDITION

O, T351, T4 AMS-QQ-A-225/6

2024

O, T3510, T3511, T4 AMS-QQ-A-200/3

O, T4, T6, T651 AMS-QQ-A-225/8

6061

Bar Aluminum O, T4, T6, T6510, T6511 AMS-QQ-A-200/8

O, T6, T651, T73, T7351 AMS-QQ-A-225/9

7075 O, T6, T6510, T6511, T73,

AMS-QQ-A-200/11

T73510, T73511

AMS-QQ-A-596, AMS-QQ-A-601,

356 T6

AMS 4217 or AMS 4260

Aluminum A356 T6 AMS-A-21180 or AMS 4218

Casting

A357 T6 AMS-A-21180 or AMS 4219

D357 T6 AMS 4241

Magnesium AZ91C T6 AMS-QQ-M-56

2024 O, T3510, T3511, T4 AMS-QQ-A-200/3

6061 O, T4, T6, T6510, T6511 AMS-QQ-A-200/8

Extrusion Aluminum

O, T6, T6510, T6511, T73,

7075 AMS-QQ-A-200/11

T73510, T73511

2014 T6 AMS-QQ-A-367 or MIL-A-22771

6061 T6 AMS-QQ-A-367 or MIL-A-22771

Forging Aluminum

7050 T7452 AMS 4108

7075 T6, T73 AMS-QQ-A-367 or MIL-A-22771

A-16 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

Table A-10. Most Common Material Specifications (Cont)

TEMPER OR AS

FORM MATERIAL ALLOY PURCHASED SPECIFICATION

CONDITION

2024 CLAD(1) O, T3, T351, T4 AMS-QQ-A-250/5

2024 O, T3, T351, T4 AMS-QQ-A-250/4

T4 AMS 4347

6013

Aluminum T6 AMS 4216

7050 T7451 AMS 4050

7075 CLAD(1) O, T6, T651 AMS-QQ-A-250/13

7075 O, T6, T651, T73 AMS-QQ-A-250/12

Sheet AMS 5901

Annealed

and (previously MIL-S-5059 Annealed)

Plate AMS 5517

1/4 Hard

(previously MIL-S-5059 1/4 Hard)

AMS 5518

Steel 301 CRES 1/2 Hard

(previously MIL-S-5059 1/2 Hard)

AMS 5902

3/4 Hard

(previously MIL-S-5059 3/4 Hard)

AMS 5519

Full Hard

(previously MIL-S-5059 Full Hard)

AMS-T-9046 or MIL-T-9046

Titanium Annealed

(See Table B-11 for more details)

O, T3 AMS-WW-T-700/3

2024

O, T3510, T3511, T4 AMS-QQ-A-200/3

Tubing Aluminum 5052 O AMS-WW-T-700/4

O, T4, T6 AMS-WW-T-700/6

6061

O, T4, T6, T6510, T6511 AMS-QQ-A-200/8

NOTE:

1. Bell Helicopter Textron has not used CLAD material since 1997. Non-CLAD repair material shall be used

instead.

ECCN EAR99 14 DEC 2010 A-17

BHT-ALL-SRM

Table A-11. Titanium Equivalencies

MIL-T-9046J

or MIL-T-9046H

AMS-T-9046

CP-3 Comp. A

CP-1 Commercially Pure Comp. B

CP-2 Type I Comp. C

CP-4 N/A

AB-1 Alpha-Beta (6Al-4V) Comp. C

AB-2 Type III Comp. D

A-5. BLIND RIVETS EQUIVALENCIES

The following table contains alternate part numbers for blind rivets.

Table A-12. Blind Rivet Alternate Part Numbers

Rivet Description Rivet Part Number or Specification

(Alcoa)

Sleeve Diameter Head Type M7885 Cherry Huck Allfast NAS

Material Aerospace

Rivets

Protruding M7885/2 CR3213 HC3213 AF3213 NAS9301B

Flush M7885/3 CR3212 HC3212 Not Approved NAS9302B

Nominal

Flush

Aluminum Shallow M7885/27 CR3214 HC3214 Not Approved NAS9303B

Head

Protruding M7885/6 CR3243 HC3243 AF3243 NAS9304B

Oversize

Flush M7885/7 CR3242 HC3242 Not Approved NAS9305B

M7885/4 CR3523 HR3523 AF3523 NAS9307M

Protruding

M7885/17 CR3523P HR3523P AF3523F NAS9307ML

M7885/5 CR3522 HR3522 Not Approved NAS9308M

Nominal Flush

M7885/18 CR3522P HR3522P Not Approved NAS9308ML

Flush M7885/19 CR3524 HR3524 Not Approved NAS9309M

Monel Shallow

Head M7885/20 CR3524P HR3524P Not Approved NAS9309ML

M7885/8 CR3553 HR3553 AF3553 NAS9310M

Protruding

M7885/21 CR3553P HR3553P AF3553F NAS9310ML

Oversize

M7885/9 CR3552 HR3552 Not Approved NAS9311M

Flush

M7885/23 CR3552P HR3552P Not Approved NAS9311ML

A-18 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

A-6. APPROVED FASTENERS FOR USE IN CARBON FIBER REINFORCED COMPOSITE

MATERIALS

Table A-13 contains a list of fasteners approved by Bell Helicopter Textron for joints involving parts made from

carbon fiber reinforced composite materials.

ECCN EAR99 14 DEC 2010 A-19

BHT-ALL-SRM

Table A-13. Approved Fasteners for Use in Fiber Reinforced Composite Parts

Near-Side Far-Side Fastener Head Type Material Finish Part Number

Material Material Type

Aluminum 110-223-( )

Protruding Titanium

Coating CR7771S-( )-( )

Aluminum 110-229-( )

Blind Bolt Flush 100 Titanium

Coating CR7770S-( )-( )EE

Aluminum 110-225-( )

Flush 130 Titanium

Coating CR7774S-( )-( )EE

Aluminum Carbon

Protruding, Aluminum 100-159-( )

Titanium

Shear Coating 30-296-( )W or 30-298-( )

Pin Flush 100, Aluminum 100-160-( )

Titanium

Collar Tension Coating 30-296-( )W or 30-297-( )W

Flush 130, Aluminum 100-158-( )

Titanium

Shear Coating 30-296-( )W or 30-298-( )

IVD NAS9310M-( )

Blind

Protruding Monel Aluminum

Rivet NAS9307M-( )

Coating

Aluminum

Protruding Titanium 110-223-( )

Coating

Aluminum

Blind Bolt Flush 100 Titanium 110-229-( )

Coating

Aluminum 110-225-( )

Flush 130 Titanium

Aluminum Coating CR7774S-( )-( )EE

Protruding, Aluminum 100-159-( )

Titanium

Shear Coating 30-295-( ) or 30-298-( )

Protruding, Aluminum 100-161-( )

Titanium

Pin Tension Coating 30-296-( )W or 30-297-( )W

Collar Flush 100, Aluminum 100-160-( )

Titanium

Tension Coating 30-296-( )W or 30-297-( )W

Flush 130, Aluminum 100-158-( )

Titanium

Shear Coating 30-295-( ) or 30-298-( )

Carbon Steel Blind A286

Flush 100 DFL 110-151-( )

1/4 Hard Rivet CRES

110-223-( )

Aluminum

Protruding Titanium 110-216-( )

Coating

CR7771S-( )-( )

Blind Bolt

110-225-( )

Aluminum

Flush 130 Titanium 110-220-( )

Coating

CR7774S-( )-( )EE

Solid Phosphate

Flush 100 Titanium CSR90433-( )F

Carbon Rivet Fluoride

Protruding, Aluminum 100-159-( )

Titanium

Shear Coating 30-296-( )W or 30-298-( )

Protruding, Aluminum 100-161-( )

Titanium

Pin Tension Coating 30-296-( )W or 30-297-( )W

Collar Flush 100, Aluminum 100-160-( )

Titanium

Tension Coating 30-296-( )W or 30-297-( )W

Flush 130, Aluminum 100-158-( )

Titanium

Shear Coating 30-296-( )W or 30-298-( )

A-20 14 DEC 2010 ECCN EAR99

BHT-ALL-SRM

A-7. MATERIALS COMPATIBILITY

This table shows the galvanic compatibilities of the following materials.

Silver and Noble Metals

Beryllium Alloys except

Nickel or Nickel Plated

Carbon or Alloy Steel

PH STainless Steel

Zinc or Zinc Plated

Aluminum Coating

Carbon (Graphite)

Copper Beryllium

Cadmium Plated

Copper or Brass

Inconel, Monel,

Stainless Steel

Stainless Steel

Material

Aluminum or

Cadmium or

or Hastalloy

Magnesium

400 Series

300 Series

Titanium

Magnesium * * * * * * * * * * * * * * X

Cadmium or

S S S S S/D D D D D D D X D *

Cadmium Plated

Zinc or Zinc Plated S S S S/D D D D D D D D D *

Aluminum or

S S S/D D D D D D D D D *

Aluminum Coating

Beryllium Alloys except

S S/D D D D D D D D D *

Copper Beryllium

Carbon or Alloy Steel S S/D S/D S/D D D D D D *

400 Series

S S/D S/D S/D S/D S/D S/D D *

Stainless Steel

Copper or Brass S S S/D S/D S/D S/D D *

Nickel or Nickel Plated S S S/D S/D S/D D *

300 Series

S S S S D *

Stainless Steel

PH Stainless Steel S S S D *

Inconel, Monel, or

S S D *

Hastalloy

Titanium S D(1) *

Silver and Noble Metals S *

Carbon (Graphite) *

NOTE:

1. Couple not permitted where temperature exceeds 350F (176.7C).

X = Combination not permitted.

Magnesium and carbon (graphite) are special cases.

* =

For additional information, please contact PSE.

S = Similar for interior and exterior faying surfaces.

D = Dissimilar for interior and exterior faying surfaces.

Similar for interior faying surfaces.

S/D =

Dissimilar for exterior faying surfaces.

Exterior surfaces: All surfaces that are normally exposed to the external environment during flight and while on

the ground, and all those inner surfaces that may be wetted with water when doors and access

panels have been closed, or those areas wetted during washing of helicopter.

Interior surfaces: All surfaces not considered to be exterior surfaces.

ECCN EAR99 14 DEC 2010 A-21/A-22

Potrebbero piacerti anche

- AS350B2VEMD Ang PMVA-RN4 9-16-RN3 EASA MasterDocumento78 pagineAS350B2VEMD Ang PMVA-RN4 9-16-RN3 EASA MasterRo LandNessuna valutazione finora

- 190 00587 00Documento116 pagine190 00587 00PREVISTONessuna valutazione finora

- Nas6703 NationalaerospacestandardDocumento8 pagineNas6703 NationalaerospacestandardSAPTONessuna valutazione finora

- All SRM Ch01Documento12 pagineAll SRM Ch01DiegoAlejandroBuitragoMartinezNessuna valutazione finora

- Bombardier Challenger 00 Flight ControlsDocumento39 pagineBombardier Challenger 00 Flight ControlsBill100% (1)

- SL Hartzell 2016Documento36 pagineSL Hartzell 2016Alexis KidemaNessuna valutazione finora

- Chapter 04 Airworthiness Limitations PDFDocumento12 pagineChapter 04 Airworthiness Limitations PDFSantiago TorresNessuna valutazione finora

- Bombardier Challenger 01 Flight ControlsDocumento23 pagineBombardier Challenger 01 Flight ControlsEmanøel AlvesNessuna valutazione finora

- 139 0000 ADocumento222 pagine139 0000 AgerardoferrandinoNessuna valutazione finora

- SE&P Relay Catalog PDFDocumento48 pagineSE&P Relay Catalog PDFMartinDiaz100% (1)

- 407 MM CH10Documento22 pagine407 MM CH10Bruno Alonso Pacheco0% (1)

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsDa EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNessuna valutazione finora

- Gualdoni 16Documento75 pagineGualdoni 16Leon Lella0% (1)

- Recognised Supplemental Type CertificatesDocumento23 pagineRecognised Supplemental Type CertificatesVignesh100% (1)

- Beech Starship AMMDocumento1.062 pagineBeech Starship AMMHeiriNessuna valutazione finora

- At575 234W TNCF 000 RG 29.5 NMDocumento3 pagineAt575 234W TNCF 000 RG 29.5 NMMarlene SalazarNessuna valutazione finora

- Saft Data Sheet and ManualDocumento61 pagineSaft Data Sheet and ManualDiegoEspinNessuna valutazione finora

- 429 Asb 15 19Documento4 pagine429 Asb 15 19Samir PeraltaNessuna valutazione finora

- 604 MmelDocumento219 pagine604 Mmelksmohsin100% (1)

- Adjustment - Check and Correction of Vertical Z and Horizontal Y Vibrations Main RotorDocumento19 pagineAdjustment - Check and Correction of Vertical Z and Horizontal Y Vibrations Main RotorFábio HenriqueNessuna valutazione finora

- Super Cub PA - 18 / PA - 18A Serial No.:: Inspection ReportDocumento5 pagineSuper Cub PA - 18 / PA - 18A Serial No.:: Inspection ReportJoão MarcosNessuna valutazione finora

- 2012-05-09 Apache Maintenance ManualDocumento5 pagine2012-05-09 Apache Maintenance ManualScott McLainNessuna valutazione finora

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireDa EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireNessuna valutazione finora

- TM 11-5820-518-20Documento42 pagineTM 11-5820-518-20oosakataroNessuna valutazione finora

- Beechcraft DukeDocumento524 pagineBeechcraft Dukejamilahroslien35Nessuna valutazione finora

- TM 1-1500-204-23-1, Change 5Documento448 pagineTM 1-1500-204-23-1, Change 5"Rufus"Nessuna valutazione finora

- Service Instructions FOR Radar RDR 2000 With Moving Map Installation and Gns 530 (GPS) InstallationDocumento42 pagineService Instructions FOR Radar RDR 2000 With Moving Map Installation and Gns 530 (GPS) InstallationjohnnysNessuna valutazione finora

- Beech Kit Catalog April 2009Documento755 pagineBeech Kit Catalog April 2009Gerardo AltunaNessuna valutazione finora

- Bendix Generators - Overhaul InstructionsDocumento38 pagineBendix Generators - Overhaul InstructionsReydale Cacho100% (1)

- Illustrated Parts Catalog, Sa 4047-76C-4Documento18 pagineIllustrated Parts Catalog, Sa 4047-76C-4Ananda Fiqry AlkahfiNessuna valutazione finora

- M20C ManualDocumento46 pagineM20C ManualfasilpereiraNessuna valutazione finora

- Al 250Documento25 pagineAl 250EstevamNessuna valutazione finora

- Aero Supplies - Catalogue CHAPTER 6 (505-595) PDFDocumento91 pagineAero Supplies - Catalogue CHAPTER 6 (505-595) PDFJerome Cardenas TablacNessuna valutazione finora

- C47B OmmDocumento12 pagineC47B OmmturboshaftNessuna valutazione finora

- S-76 Barrier Filter PamphletDocumento20 pagineS-76 Barrier Filter PamphletJoness9Nessuna valutazione finora

- Bell 47G RFM Rev.04 (1958)Documento37 pagineBell 47G RFM Rev.04 (1958)mike nospamyNessuna valutazione finora

- O 320 H2AD Engine Valve ProblemDocumento5 pagineO 320 H2AD Engine Valve ProblemjdasfacNessuna valutazione finora

- Cessna 414 Updated Manual List As of June 2017Documento5 pagineCessna 414 Updated Manual List As of June 2017Elmer VillegasNessuna valutazione finora

- Asb 407-04-62Documento5 pagineAsb 407-04-62turboshaftNessuna valutazione finora

- Illustrated Parts Catalog: Aquila A211 / A212Documento440 pagineIllustrated Parts Catalog: Aquila A211 / A212KrasakKrusuk Si MaulNessuna valutazione finora

- (E-124) Betriebs-Und Einbauanweisung Operation and Installation ManualDocumento117 pagine(E-124) Betriebs-Und Einbauanweisung Operation and Installation ManualVincent LefeuvreNessuna valutazione finora

- Cover Static Port - FinalDocumento1 paginaCover Static Port - FinalMohammad NorouzzadehNessuna valutazione finora

- A700 Parts ManualDocumento162 pagineA700 Parts Manualmdhelicopters100% (1)

- Service Information: Model/Variant Title Description Pub Number Compliance Serial Number Publication TypeDocumento24 pagineService Information: Model/Variant Title Description Pub Number Compliance Serial Number Publication TypeMoshiurRahman100% (1)

- S65-5366 L-BandDocumento1 paginaS65-5366 L-Bandkkpatel87Nessuna valutazione finora

- BHT 412 SPM Chapter 02 Torque PDFDocumento30 pagineBHT 412 SPM Chapter 02 Torque PDFMARKPNessuna valutazione finora

- Eje/F: Chapter 28 - Fuel SystemDocumento46 pagineEje/F: Chapter 28 - Fuel SystemJose danielNessuna valutazione finora

- Airworthiness Limitations ManualDocumento12 pagineAirworthiness Limitations Manualahmed.19.77.4.5Nessuna valutazione finora

- 1 Aerodynamics Flight ControlsDocumento87 pagine1 Aerodynamics Flight ControlsAnonymous OZxPZgFcNessuna valutazione finora

- 412 MM CH06Documento8 pagine412 MM CH06Sebastian GarciaNessuna valutazione finora

- ICAO Noise MeasurementDocumento32 pagineICAO Noise MeasurementMuralidharan ShanmugamNessuna valutazione finora

- TIO-540-AJ1A Parts Catalog PC-TIO-540-AJ1ADocumento102 pagineTIO-540-AJ1A Parts Catalog PC-TIO-540-AJ1AGilberto Tarque Vivero100% (1)

- Continued Aiirworthiness - Model 200 SériesDocumento129 pagineContinued Aiirworthiness - Model 200 SériesGabriel vieiraNessuna valutazione finora

- CAMP Status CessnaDocumento95 pagineCAMP Status CessnaKritz FritzNessuna valutazione finora

- Week 5Documento116 pagineWeek 5Arief SambestNessuna valutazione finora

- Rolls - Royce: 250 - C47B Operation and MaintenanceDocumento23 pagineRolls - Royce: 250 - C47B Operation and MaintenanceSerafin MoralesNessuna valutazione finora

- InsertsDocumento10 pagineInsertsEagle1968Nessuna valutazione finora

- Sb1000 Rev BDocumento4 pagineSb1000 Rev BmycopteraviationNessuna valutazione finora

- 072 90 00 EngineAcessoryDocumento30 pagine072 90 00 EngineAcessoryblackhawkNessuna valutazione finora

- Global Warming IN AERONAUTICAL iNDUSTRYDocumento4 pagineGlobal Warming IN AERONAUTICAL iNDUSTRYLiney Jharitza Escobar BonillaNessuna valutazione finora

- Gebreab Kidanu PDFDocumento112 pagineGebreab Kidanu PDFLiney Jharitza Escobar BonillaNessuna valutazione finora

- Gebreab Kidanu PDFDocumento112 pagineGebreab Kidanu PDFLiney Jharitza Escobar BonillaNessuna valutazione finora

- Distance Measuring EquipmentDocumento4 pagineDistance Measuring EquipmentLiney Jharitza Escobar BonillaNessuna valutazione finora

- Comm SatDocumento23 pagineComm SatLiney Jharitza Escobar BonillaNessuna valutazione finora

- Comm SatDocumento23 pagineComm SatLiney Jharitza Escobar BonillaNessuna valutazione finora

- Satellite Link Design: A Tutorial: Aderemi A. Atayero, Matthew K. Luka and Adeyemi A. AlatisheDocumento6 pagineSatellite Link Design: A Tutorial: Aderemi A. Atayero, Matthew K. Luka and Adeyemi A. AlatishecloudtelNessuna valutazione finora

- Avionics Navigation Systems PDFDocumento25 pagineAvionics Navigation Systems PDFXingfang Cai0% (1)

- Lift Stability AnalysisDocumento23 pagineLift Stability Analysisaiyubi2Nessuna valutazione finora

- Biophy-Lec (Mod1 - The-Basics) PDFDocumento18 pagineBiophy-Lec (Mod1 - The-Basics) PDFShekinah LeynesNessuna valutazione finora

- Biography: Aryabhata (IAST: Āryabhaṭa; Sanskrit: आयरभटः) (476-550 CE) was the first in theDocumento7 pagineBiography: Aryabhata (IAST: Āryabhaṭa; Sanskrit: आयरभटः) (476-550 CE) was the first in theshabaan786Nessuna valutazione finora

- How To Learn, by Simon Oxenham, 15 Feb. 2013: Learning MethodsDocumento5 pagineHow To Learn, by Simon Oxenham, 15 Feb. 2013: Learning MethodsAnonymous Z1NYxC6hgYNessuna valutazione finora

- Unit I - Force Analysis (9) : Systems and Tribology ConceptDocumento82 pagineUnit I - Force Analysis (9) : Systems and Tribology ConceptSaranNessuna valutazione finora

- Hot and Dry Climate SolarPassiveHostelDocumento4 pagineHot and Dry Climate SolarPassiveHostelMohammed BakhlahNessuna valutazione finora

- Lighting ModuleDocumento133 pagineLighting ModulePrashanth KochuveetilNessuna valutazione finora

- Moving Charges and Magnetism 2Documento43 pagineMoving Charges and Magnetism 2Mavn LoginNessuna valutazione finora

- Automation and Robotic Lec 2Documento9 pagineAutomation and Robotic Lec 2Josh Sam Rindai MhlangaNessuna valutazione finora

- Bearing Basics For Gas-Industry Screw CompressorsDocumento5 pagineBearing Basics For Gas-Industry Screw CompressorsDayo IdowuNessuna valutazione finora

- National Institute of Technology Durgapur: Department of Chemical EngineeringDocumento2 pagineNational Institute of Technology Durgapur: Department of Chemical Engineeringpiyush dwivediNessuna valutazione finora

- Trial Mix Design Report PDFDocumento38 pagineTrial Mix Design Report PDFTimothy HughesNessuna valutazione finora

- Frac To GraphyDocumento639 pagineFrac To GraphyBHARANINessuna valutazione finora

- Scientech 2502Documento2 pagineScientech 2502Rishi KeshNessuna valutazione finora

- Nikuradse's ExperimentDocumento50 pagineNikuradse's ExperimentAli BahuNessuna valutazione finora

- Rigaku Journal 33-2-26-28Documento3 pagineRigaku Journal 33-2-26-28Eduardo ArdilesNessuna valutazione finora

- Heatcraft BN PDFDocumento44 pagineHeatcraft BN PDFDavid GironNessuna valutazione finora

- Chirimuuta. Outside ColorDocumento262 pagineChirimuuta. Outside Colorcrazijoe100% (2)

- Olympic 2018 - Tien Giang 11Documento17 pagineOlympic 2018 - Tien Giang 11Trần Quốc ToảnNessuna valutazione finora

- Case Studies in Engineering Failure Analysis: K. Gurumoorthy, Bradley D. Faye, Arindam GhoshDocumento8 pagineCase Studies in Engineering Failure Analysis: K. Gurumoorthy, Bradley D. Faye, Arindam GhoshRif SenyoNessuna valutazione finora

- ThermodynamicsDocumento8 pagineThermodynamicsBasu SbNessuna valutazione finora

- Thickening Agent - Wikipedia, The Free EncyclopediaDocumento5 pagineThickening Agent - Wikipedia, The Free EncyclopediaJohnNessuna valutazione finora

- Lab Report On AdsorptionDocumento12 pagineLab Report On AdsorptionElizabeth Polancos BruaNessuna valutazione finora

- Flint-2 5Documento671 pagineFlint-2 5GNZLNessuna valutazione finora

- SilverThin Slewing Rings and Pinions CatalogDocumento16 pagineSilverThin Slewing Rings and Pinions CatalogGanesh LohakareNessuna valutazione finora

- WSDOT FOP For AASHTO T 106Documento14 pagineWSDOT FOP For AASHTO T 106malaya tripathyNessuna valutazione finora

- ThermometryDocumento29 pagineThermometryaelle00Nessuna valutazione finora

- Fluid Mechanics Unit1Documento100 pagineFluid Mechanics Unit1anjuNessuna valutazione finora

- F80 Press ReleaseDocumento2 pagineF80 Press Releasespscribd1Nessuna valutazione finora