Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

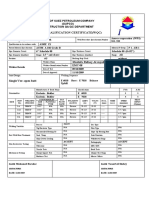

With Strainer, Piston Qap

Caricato da

ajmainDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

With Strainer, Piston Qap

Caricato da

ajmainCopyright:

Formati disponibili

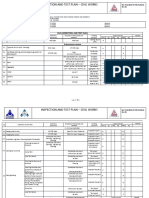

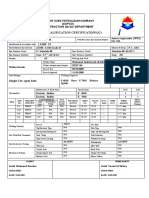

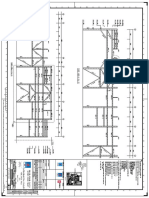

QUALITY ASSURANCE PLAN

PO No- LOI Dt-27/JULY/2010 O. A. No.110103151 & 110103147 Dt. 30/06/10

PROJECT NAME:

PROJECT NAME:BIO-FUEL

DUNGETHANOL PLANT IN NORTHEN

QUAT BIO-FUELS ETHNOLREGION

PLANT SPIRAX MARSHALL LTD. QAP No. :SQFT20M

MUMBAI-PUNE ROAD, PRODUCT : FT-20 C. S. WITH STRAINER, PISTON REV. No. : 00

spirax CLIENT: ALFA LAVAL(INDIA) LTD KASARWADI, P.B. 29 VALVE & FLANGE Module DATE : 26.02.10

PUNE 411 034 PAGE 1 OF 1

Sr. No. COMPONENT CHARACTER- CLASS TYPE OF QUANTUM REFERENCE ACCEPTANCE FORMAT OF AGENCY REMARKS

& ISTICS CHECK OF CHECK DOCUMENT NORM RECORD

OPERATION V S C 11

1 2 3 4 5 6 7 8 9 10

1a Base & Cover Material Critical Chemical/ One sample ASTM A 216 ASTM A 216 Foundry P R R

Casting (Ball float trap FT20 Physical per heat GR WCB Certificate

& Fig 14 strainer)

Surface Def. Major Visual 100% WI-PUR-408 WI-PUR-408 GIRS R R -

1b Base & Bonnet forgings Material Critical Chemical/ One sample ASTM A 105 ASTM A 105 Foundry P R R

(Piston Vlave) Physical per heat Certificate

Surface Def. Major Visual 100% WI-PUR-408 WI-PUR-408 GIRS R R -

1c Body & disc Material Critical Chemical/ One /Heat CF8M & CF3M CF8M & CF3M Foundry P R R

castings (DCV3) Physical ASTM A351 ASTM A351 Certificate

mech prop.

---DO--- Surface Defects Major Visual Sampling WI-PUR-408 WI-PUR-408 GIRS R R -

2a Body & cover Machining Dimensions Major Dimensional As per Approved Drawing Approved Drawing SIR - P -

(Ball float trap FT20 WI/MFG/509

& Fig 14 strainer)

2b. Body & Bonnet Machining Dimensions Major Dimensional As per Drawing Drawing SIR - P -

(Piston Valve) WI/MFG/509

2c. Body, Disc Dimensions Critical Dimensional As per Drawing Drawing SIR - P -

m/ced comp. (DCV3) WI/MFG/509

3 All other items Material, Critical Chemical/Physical One/batch Approved Drawing/ Approved Drawing Material T.C. P R R

Flange, Reducer,Pipe** Spec Spec

Dimensions Major Dimensional As per Approved Drawing Approved Drawing SIR - P R

WI/MFG/509

4 Weld-setUp Dimensional Major Dimensional 100% Approved Drawing/ Approved Drawing/ SIR - P R

Spec Spec

5 Welding Procedure Major ---------- 100% Approved Drawing/Spec Approved Drawing/ IR - P R

Spec - P R

6 Steam Functional Functioning of Critical Tested on steam at 100% PTS PTS PTS - P W @ 10% Max. Witness

Test Trap & leak 7 kg/sq.cm or

tightness below differtial - P R

pr. whichever

is less .

7 Hydro Porosity & Leakage Visual Dimensional Approved Drawing Approved Drawing - P W 10% Max. Witness

By TPI

8 Final Inspection Visual & Dimensions, Approved Drawing Approved Drawing - P W 10% Max. Witness

Surface, dim. identification & By TPI

marking

Note : SIR - Self Inspection Report GIRS - Goods Inspection Report Sheet

1. Hydro test for body can be shown only before P - Performed by V - VENDOR

assembly at 2 times the workig pressure . W - Witnessed by S - SPIRAX

PTS-Product Test Specification V -Varified by C - CUSTOMER

R - Review

AS PER INDIAN BOILER REGULATION ACT MATERIAL TEST CERTIFICATE FORM IIIA/IIIC SHALL BE PROVIDED

Prepared by ___________________ Checked & Authorized by _______________

PALLAVI PATIL PERCY KORKHAU

Potrebbero piacerti anche

- Steam Trap & Piston Valve Qap PDFDocumento1 paginaSteam Trap & Piston Valve Qap PDFajmainNessuna valutazione finora

- Barracuda and Caratinga Crude Oil Fields Production Facilities ProjectDocumento87 pagineBarracuda and Caratinga Crude Oil Fields Production Facilities ProjectneivaprojetosNessuna valutazione finora

- Mepl CPCLCBR Eil Qap&ds 001 2022 2023Documento7 pagineMepl CPCLCBR Eil Qap&ds 001 2022 2023Mathi Vinoth PillaiNessuna valutazione finora

- QAP For MS Pipes RevisedDocumento3 pagineQAP For MS Pipes RevisedAnuj PandeyNessuna valutazione finora

- New 2. Sfe-Dst-Pip-1402-4102 DST For Globe ValveDocumento4 pagineNew 2. Sfe-Dst-Pip-1402-4102 DST For Globe ValveSandeepNBabuNessuna valutazione finora

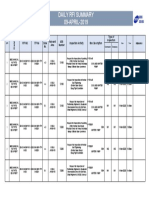

- Daily Rfi Summary 09-APRIL-2019: Project: United Eo/Eg-IiiDocumento1 paginaDaily Rfi Summary 09-APRIL-2019: Project: United Eo/Eg-IiiAbdul Muneeb MohammedNessuna valutazione finora

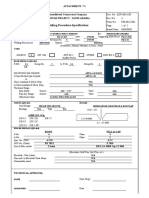

- FO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentDocumento1 paginaFO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentRico100% (1)

- Quality Assurance PlanDocumento1 paginaQuality Assurance PlanGuru Mishra100% (1)

- ITT - Sample of ITPDocumento3 pagineITT - Sample of ITPajiNessuna valutazione finora

- Mir Pipe NewDocumento11 pagineMir Pipe NewDimas agungNessuna valutazione finora

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocumento6 pagineAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNessuna valutazione finora

- 3685 Mir 006 PDFDocumento1 pagina3685 Mir 006 PDFashishpearlNessuna valutazione finora

- 3685 Mir 006Documento1 pagina3685 Mir 006ashishpearlNessuna valutazione finora

- 3685 Mir 006 PDFDocumento1 pagina3685 Mir 006 PDFashishpearlNessuna valutazione finora

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocumento3 pagineIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNessuna valutazione finora

- Aprroved QAP-1883-R01-15122022Documento1 paginaAprroved QAP-1883-R01-15122022Pavul RajNessuna valutazione finora

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDocumento1 paginaProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananNessuna valutazione finora

- Informe Radiografico para Piezas Moldeadas Radiographic Report For CastingDocumento2 pagineInforme Radiografico para Piezas Moldeadas Radiographic Report For CastingSathish JayaprakashNessuna valutazione finora

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Documento4 pagineInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNessuna valutazione finora

- Valves 9600 BOM Customer.4Documento2 pagineValves 9600 BOM Customer.4Al Gusto Tequeños y MasNessuna valutazione finora

- PPS WVFDocumento1 paginaPPS WVFmohammadNessuna valutazione finora

- RT Request: Hail Surface FacilitiesDocumento4 pagineRT Request: Hail Surface FacilitiesAnonymous AdofXEYAgENessuna valutazione finora

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Documento5 pagineWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNessuna valutazione finora

- Inspection Report: General InformationDocumento22 pagineInspection Report: General InformationShamsul AffendiNessuna valutazione finora

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocumento2 paginePolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Wagp-1-Par-9a-M-sas-99-0009 Lube and Seal Oil Sys 300 Ansi b4Documento4 pagineWagp-1-Par-9a-M-sas-99-0009 Lube and Seal Oil Sys 300 Ansi b4tope odumboniNessuna valutazione finora

- RT Request: Hail Surface FacilitiesDocumento4 pagineRT Request: Hail Surface FacilitiesAnonymous AdofXEYAgENessuna valutazione finora

- Quality RequirementsDocumento26 pagineQuality RequirementsDilip PatilNessuna valutazione finora

- Coatings Non-ITAR Product and Specification GuideDocumento16 pagineCoatings Non-ITAR Product and Specification GuideCarlos Alberto Rozo R.Nessuna valutazione finora

- V-2158-101-A-884 - 3 Inspection and Test Procedure For PumpsDocumento80 pagineV-2158-101-A-884 - 3 Inspection and Test Procedure For PumpsMessaoud Goutas100% (1)

- AEPCOM-QAP-3281-58548 Rev 1Documento3 pagineAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINessuna valutazione finora

- MR For Pipeline Bulk Materials, Rev.ADocumento31 pagineMR For Pipeline Bulk Materials, Rev.ASandeepNBabuNessuna valutazione finora

- Checklist Fire StopDocumento9 pagineChecklist Fire StopAnonymous DMdGdsOENessuna valutazione finora

- Barhi Plant Grid-13 Cold FormDocumento6 pagineBarhi Plant Grid-13 Cold FormRakesh SharmaNessuna valutazione finora

- SVDN-CPP-I-0023-D01-0003-Rev.02-General Arrangement Drawing Isolation Valve Instrusive SignalerDocumento6 pagineSVDN-CPP-I-0023-D01-0003-Rev.02-General Arrangement Drawing Isolation Valve Instrusive SignalerjfdlksaNessuna valutazione finora

- RFI-WP2-SPT-STL-CN-00 - RFI - FIT UP (AutoRecovered)Documento3 pagineRFI-WP2-SPT-STL-CN-00 - RFI - FIT UP (AutoRecovered)daniNessuna valutazione finora

- Civil Inspection and Test PlanDocumento5 pagineCivil Inspection and Test PlanWalid AmdouniNessuna valutazione finora

- New 4. Sfe-Dst-Pip-1402-4104 DST For Check ValveDocumento4 pagineNew 4. Sfe-Dst-Pip-1402-4104 DST For Check ValveSandeepNBabuNessuna valutazione finora

- 200.000 Ton/Year Fractional Destillation Zone in Indonesia (Div.2)Documento3 pagine200.000 Ton/Year Fractional Destillation Zone in Indonesia (Div.2)Idil FitriNessuna valutazione finora

- QAP - ITP - Steel Girder ApproachDocumento21 pagineQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- Inspection and Test Plan: Enclosed Ground Flare (EGF)Documento17 pagineInspection and Test Plan: Enclosed Ground Flare (EGF)vincent100% (1)

- WPS 684 CS 012Documento3 pagineWPS 684 CS 012siva8000100% (1)

- Drawing (p15 Ace 857)Documento14 pagineDrawing (p15 Ace 857)ritoh8657Nessuna valutazione finora

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocumento1 paginaWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNessuna valutazione finora

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocumento1 paginaWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNessuna valutazione finora

- 12 Valves SpecificationsDocumento19 pagine12 Valves Specificationsshaliq28100% (1)

- Plate - ADocumento9 paginePlate - ASumit SinghNessuna valutazione finora

- U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ADocumento14 pagineU2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ATommy ArjanggiNessuna valutazione finora

- Tubacex-Prakash 10650T1 QapDocumento3 pagineTubacex-Prakash 10650T1 Qaprabiprasad.iispl.comletedNessuna valutazione finora

- DPR - 18-06-2023Documento1 paginaDPR - 18-06-2023Muhammad AftabNessuna valutazione finora

- TRAINING PVE Hari 4 PDFDocumento13 pagineTRAINING PVE Hari 4 PDFDheska AgungNessuna valutazione finora

- MRR - Ru-367Documento1 paginaMRR - Ru-367Abdullah alnajmNessuna valutazione finora

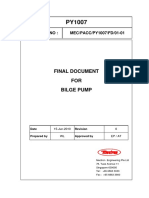

- Data Book de BombaDocumento7 pagineData Book de BombaSharon Botiny100% (1)

- Item 1 Bilge Pump - 803-101.10 BDocumento91 pagineItem 1 Bilge Pump - 803-101.10 BИгорь КлимовNessuna valutazione finora

- Datasheets For Bucket Type StrainerDocumento2 pagineDatasheets For Bucket Type StrainerbecpavanNessuna valutazione finora

- Tdi 50000 Tpy, GNFCDocumento6 pagineTdi 50000 Tpy, GNFCkrunal panchalNessuna valutazione finora

- RFI-R-KS2-PI-14180 Flange Joint Verification 331-HRSGB-SA-0001Documento6 pagineRFI-R-KS2-PI-14180 Flange Joint Verification 331-HRSGB-SA-0001serli meilaniNessuna valutazione finora

- Cable Connection List - Power & Control Cables-Ammonia Storage Plant # 90Documento18 pagineCable Connection List - Power & Control Cables-Ammonia Storage Plant # 90Sandeep GuptaNessuna valutazione finora

- Datahseet For Strainer With Air EliminatorDocumento4 pagineDatahseet For Strainer With Air Eliminatorvinoj chandranNessuna valutazione finora

- Longwall Mining at Shallow Depth of Cover in IndiaDa EverandLongwall Mining at Shallow Depth of Cover in IndiaNessuna valutazione finora

- SD 08Documento1 paginaSD 08ajmainNessuna valutazione finora

- 85Documento1 pagina85ajmainNessuna valutazione finora

- Steel Supports ListDocumento4 pagineSteel Supports ListajmainNessuna valutazione finora

- 86Documento1 pagina86ajmainNessuna valutazione finora

- L L L L: Section Section SectionDocumento1 paginaL L L L: Section Section SectionajmainNessuna valutazione finora

- SD.24 Handrial PDFDocumento1 paginaSD.24 Handrial PDFajmainNessuna valutazione finora

- SD.20 Structural Concrete Standards Anchor Bolt DetailsDocumento1 paginaSD.20 Structural Concrete Standards Anchor Bolt DetailsajmainNessuna valutazione finora

- Piping General Arrangement Cooling Tower Water System AreaDocumento1 paginaPiping General Arrangement Cooling Tower Water System AreaajmainNessuna valutazione finora

- D 90 1331 203 RevADocumento1 paginaD 90 1331 203 RevAajmainNessuna valutazione finora

- STDocumento23 pagineSTajmainNessuna valutazione finora

- Method of MeasurmentDocumento3 pagineMethod of MeasurmentajmainNessuna valutazione finora

- SPEDocumento15 pagineSPEajmainNessuna valutazione finora

- SD.23 Standard Ladder (Safety Gate)Documento1 paginaSD.23 Standard Ladder (Safety Gate)ajmainNessuna valutazione finora

- (B.O.Q) Supply & Install 2Documento2 pagine(B.O.Q) Supply & Install 2ajmainNessuna valutazione finora

- Free Issue MaterialDocumento1 paginaFree Issue MaterialajmainNessuna valutazione finora

- For Construction: Bio-Fuel Ethanol Plant in Northern Region ProjectDocumento24 pagineFor Construction: Bio-Fuel Ethanol Plant in Northern Region ProjectajmainNessuna valutazione finora

- S-00-1390-001 Rev 0 (Hot Insulation Specifications For BOP)Documento20 pagineS-00-1390-001 Rev 0 (Hot Insulation Specifications For BOP)ajmain100% (1)

- D 90 1331 208 RevADocumento1 paginaD 90 1331 208 RevAajmainNessuna valutazione finora

- D 90 1331 202 RevA PDFDocumento1 paginaD 90 1331 202 RevA PDFajmainNessuna valutazione finora

- D 90 1331 201 RevADocumento1 paginaD 90 1331 201 RevAajmainNessuna valutazione finora

- D 90 1331 205 RevADocumento1 paginaD 90 1331 205 RevAajmainNessuna valutazione finora

- D 90 1331 211 RevADocumento1 paginaD 90 1331 211 RevAajmainNessuna valutazione finora

- D 90 1331 202 RevADocumento1 paginaD 90 1331 202 RevAajmainNessuna valutazione finora

- C-90-1323-010 - Rev 0Documento46 pagineC-90-1323-010 - Rev 0ajmain100% (1)

- C-90-1323-009 - Rev 0Documento21 pagineC-90-1323-009 - Rev 0ajmainNessuna valutazione finora

- D-90-1331-210 - Rev 0 - Sheet 1 of 2Documento1 paginaD-90-1331-210 - Rev 0 - Sheet 1 of 2ajmainNessuna valutazione finora

- D 90 1331 200 RevADocumento1 paginaD 90 1331 200 RevAajmainNessuna valutazione finora

- C-90-1331-200 - Rev 0Documento114 pagineC-90-1331-200 - Rev 0ajmainNessuna valutazione finora

- C-90-1323-011 - Rev 0Documento20 pagineC-90-1323-011 - Rev 0ajmainNessuna valutazione finora

- C-90-1323-008 - Rev 0Documento25 pagineC-90-1323-008 - Rev 0ajmainNessuna valutazione finora

- Fielders PurlinsGirts ManualDocumento104 pagineFielders PurlinsGirts ManualthailanNessuna valutazione finora

- Hydrostatic Test Procedure: Project No: 14481Documento6 pagineHydrostatic Test Procedure: Project No: 14481Ahmad MohammadNessuna valutazione finora

- Puc 6004 BuyDocumento16 paginePuc 6004 BuyJuanNessuna valutazione finora

- 360 SERIES Engineering CodebookDocumento23 pagine360 SERIES Engineering CodebookROI MADE SASNessuna valutazione finora

- Illlffl FDocumento26 pagineIlllffl FosamaNessuna valutazione finora

- Vertical Vessel AISCDocumento9 pagineVertical Vessel AISCRajveer SinghNessuna valutazione finora

- Beam Reactions (And Their Calculation)Documento20 pagineBeam Reactions (And Their Calculation)Sanghaar BhuttoNessuna valutazione finora

- 48th Floor Initial Punchlist For Other ContractorDocumento16 pagine48th Floor Initial Punchlist For Other ContractorBenhur CasasNessuna valutazione finora

- The Philippine Green Building Code V3Documento32 pagineThe Philippine Green Building Code V3itsmebridgethNessuna valutazione finora

- Specification Steel WorksDocumento59 pagineSpecification Steel WorksasadqhseNessuna valutazione finora

- Reducing Tee Table Carbon Steel FittingDocumento8 pagineReducing Tee Table Carbon Steel FittingAlmario SagunNessuna valutazione finora

- V20920 Bx220imDocumento32 pagineV20920 Bx220imjajsjxbxcbcbxNessuna valutazione finora

- Cheat Sheet of The GodsDocumento2 pagineCheat Sheet of The GodsAnonymous r1xl1wHlNessuna valutazione finora

- Seminar Topic EditedDocumento2 pagineSeminar Topic Editedhitheshds1999Nessuna valutazione finora

- Epcc-2 Package (RFCC Unit) ) For Petrochemical and Lube Integration Project "Lupech" (J-18)Documento8 pagineEpcc-2 Package (RFCC Unit) ) For Petrochemical and Lube Integration Project "Lupech" (J-18)phanikrishnabNessuna valutazione finora

- Er298links PDFDocumento85 pagineEr298links PDFMehrdokht MhjrnNessuna valutazione finora

- ST5015 Design of Bridges: Dr.A.M.VasumathiDocumento31 pagineST5015 Design of Bridges: Dr.A.M.VasumathiVasumathi100% (1)

- Structural SpecificationsDocumento71 pagineStructural SpecificationsFatima EberoNessuna valutazione finora

- NiraliDocumento13 pagineNiraliNIYATI PANDYANessuna valutazione finora

- Cmaa 74 Deflection Criteria: Most Asked Action Alerts MHIDocumento3 pagineCmaa 74 Deflection Criteria: Most Asked Action Alerts MHIboringNessuna valutazione finora

- Saga PVC Conduit and AccessoriesDocumento16 pagineSaga PVC Conduit and Accessoriesmy companyNessuna valutazione finora

- Uniform Plumbing Code For ReferenceDocumento98 pagineUniform Plumbing Code For ReferenceAlter EmailNessuna valutazione finora

- TOR For Dilapidation SurveyDocumento3 pagineTOR For Dilapidation Surveysayuti_yusofNessuna valutazione finora

- CH 12Documento64 pagineCH 12LeonardoMadeira11Nessuna valutazione finora

- Steel Girder Fabrication - Part 2 (Steel Bridge)Documento10 pagineSteel Girder Fabrication - Part 2 (Steel Bridge)AlsonChinNessuna valutazione finora

- Design and Develop Safety PolicyDocumento1 paginaDesign and Develop Safety PolicyJericFuentesNessuna valutazione finora

- Method Statement Sheet PilingDocumento9 pagineMethod Statement Sheet PilingAMA MUTTAHIZI AHADAN AUHAN100% (1)

- PSOW2 - MS For Waterproofing Dated 04.11.2023Documento5 paginePSOW2 - MS For Waterproofing Dated 04.11.2023projectsNessuna valutazione finora

- Repair, Retrofitting, Rehabiliation of StructuresDocumento57 pagineRepair, Retrofitting, Rehabiliation of Structures29-GouravNessuna valutazione finora

- Installation of Chain Link FenceDocumento10 pagineInstallation of Chain Link FencevitamkupaNessuna valutazione finora