Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bearing Reliability

Caricato da

Wayu100%(1)Il 100% ha trovato utile questo documento (1 voto)

75 visualizzazioni3 pagineBearing Reliability

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBearing Reliability

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

75 visualizzazioni3 pagineBearing Reliability

Caricato da

WayuBearing Reliability

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Introduction to Selection of bearing size:

System Approach and Bearing Reliability

SKF General Catalog 6000

Summary

Selection of bearing size is as simple or complex as desired by the user. Simple

approaches will give general idea of how long a bearing can be expected to last in an

application. Machine builders and reliability professionals with an interest in optimizing

reliability can use more sophisticated tools for bearing life prediction.

SKF @ptitude Exchange

SKF Reliability Systems GC6000-2-2

5271 Viewridge Court Joe Conyers

San Diego, CA 92123 3 Pages

United States Published November, 2008

tel. +1 858 496 3400

fax +1 858 496 3511

email: info@aptitudexchange.com

Internet: http://www.aptitudexchange.com

Introduction to Selection of bearing size: System Approach and Bearing Reliability

2009 SKF Group

Selection of bearing size is as simple or shock load, or simply applying a stationary

complex as desired by the user. Simple load, such as lifting an object with a crane

approaches will give general idea of how when the bearing is stationary.

long a bearing can be expected to last in

an application. Machine builders and The history of selecting bearing size using

reliability professionals with an interest in dynamic load ratings began about the

optimizing reliability can use more time of the industrial revolution: late

sophisticated tools for bearing life 1800s and early 1900s. Plain bearings

prediction. (without rolling elements) were in wide

use, but, as machines demanded faster

There are two fundamental application speeds, energy usage began to become a

differences that dominate bearing size factor. Rolling element bearings were a

selection: dynamic or static operation. logical development, displacing plain

Dynamic operation is more common, for bearings as soon technically practicable.

example, electric motors, pumps, At first, there was limited knowledge

gearboxes and conveyor systems. For about how to select the right size rolling

overhead cranes and other machines element bearing. Does the replacement

suffering shock loads, such as mining bearing need to be larger or smaller than

equipment, the static load carrying the equivalent plain bearing? There was

capacity should be used to determine the no good science to answer the question

minimum bearing size required. until Lundberg and Palmgren began their

work on Life theory for bearings in the

The main difference in the two calculation 1920s. The theories were developed

methods (dynamic versus static load mathematically and empirically using data

ratings) is in how a bearing might be collected at SKF laboratories since 1911.

expected to fail. In the dynamic load The first life law they discovered for

rating methods, bearings typically fail bearing life, called Basic Rating Life is

from the inside out. That is to say, the still widely used for initial estimates of

rolling elements repeatedly overrolling bearing life. Using this life prediction

and stressing the bearing material method gives a good starting point for

eventually cause a fatigue failure. This is sizing the bearing to an application. If

similar to bending a wire repeatedly until loads and speeds can be determined with

it breaks. some accuracy, the right size bearing can

be selected for the machine.

Static load carrying capacity is based

instead on the concept of permanent As our knowledge of bearing life

plastic deformation of the bearing developed, it became clear that lubrication

material, or simply put, a dent in the and materials played a strong role in

bearing that remains after the load is bearing life. Poor lubrication film

removed. This dent could occur from a thickness leads to reduced bearing life.

Introduction to Selection of bearing size: System Approach and Bearing Reliability

2009 SKF Group 2(3)

But how much lubricant is needed? And of together to achieve the ultimate service

what type mineral oil or some other life of the application. The life theories are

kind? Are heavy oils always better? useful if the bearing fails in a

predictable way, generally, from fatigue

Adjusted life theory was the result: users of the bearing materials.

could now make better decisions about

making changes to their lubricants (oil Some applications dont play by the rules:

viscosity and temperatures) and the fluid contamination, misalignment,

expected outcomes. Adjusted life theory operational deflection, extremes or

also explained how cleaner, stronger steel temperature and other conditions can

increases bearing life. Also added to the severely degrade service life in real-world

life calculation was a modification to help conditions. In these cases, SKF has a wide

choose the right bearing using different array of Knowledge Engineering resources

probabilities of failure. For example, ready to help. To assist with Bearing

safety-related aircraft applications require damage analysis, SKF provides literature

a lower probability of failure, and the (), Online tools (Bearing Detective) , Online

standard life calculation is modified as a and Live courses to help diagnose the

result. causes of bearing damage. Advanced

analysis tools such as the SKF Interactive

The new life theory established a Engineering Catalog, SKF Bearing

benchmark for sizing bearings, and was BEACON, BEAST and Orpheus (to be

accepted internationally after World War discussed in a future article) are essential

II. Since that time, SKF has continued to in understanding advanced bearing

enhance and deepen our understanding of dynamics and operation. SKF also

bearing life. In the 1980s and 1990s SKF provides Engineering Consultancy

began work on New Life Theory, which Services to assist with selecting and sizing

was published and adopted as an ISO bearings properly. Contact the SKF

Standard. Additional modifications and Applications Engineering Service in your

amendments have led to the latest area for assistance.

version: ISO 281:2007, available from

www.iso.org. This latest version of life

theory takes into account the effects of Next in our series will be the SKF General

solid particle contamination. It also Catalogue: Principles of Bearing selection

explains why some lightly loaded bearings and Application: Selection of Bearing Size:

can achieve infinite life. Using the Life Equations: Load Ratings

and Life. Well dive deeper into the

Life theories are excellent for sizing methods used for sizing bearings.

bearings to fit a particular application.

Rolling element bearings can be thought

of as a system of many parts, working

Introduction to Selection of bearing size: System Approach and Bearing Reliability

2009 SKF Group 3(3)

Potrebbero piacerti anche

- Selection of Bearing SizeDocumento5 pagineSelection of Bearing SizeWayu100% (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsDa EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNessuna valutazione finora

- Assignment ClutchDocumento624 pagineAssignment ClutchSubhash KNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Rolling Contact Bearings - DMEDocumento28 pagineRolling Contact Bearings - DMESumitNessuna valutazione finora

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorDa EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNessuna valutazione finora

- Design and Analysis of Drive Shaft For Heavy Duty TruckDocumento6 pagineDesign and Analysis of Drive Shaft For Heavy Duty TruckesatjournalsNessuna valutazione finora

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationDa EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationValutazione: 4 su 5 stelle4/5 (1)

- Bearing ForceDocumento2 pagineBearing ForceJason BakerNessuna valutazione finora

- 2017 TRB CatalogDocumento760 pagine2017 TRB CatalogBrion Bara IndonesiaNessuna valutazione finora

- Guide to Load Analysis for Durability in Vehicle EngineeringDa EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonValutazione: 4 su 5 stelle4/5 (1)

- Power Units and TransmissionDocumento42 paginePower Units and TransmissionAmarjeet RaiNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Rockshox Suspension Theory PDFDocumento28 pagineRockshox Suspension Theory PDFJose Luis GutierrezNessuna valutazione finora

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Da EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNessuna valutazione finora

- A Bearing Is A Device To Permit Constrained Relative Motion Between Two Parts, Typically Rotation or Linear MovementDocumento18 pagineA Bearing Is A Device To Permit Constrained Relative Motion Between Two Parts, Typically Rotation or Linear MovementSreedhar Madhana100% (1)

- Additive Manufacturing A Complete Guide - 2020 EditionDa EverandAdditive Manufacturing A Complete Guide - 2020 EditionNessuna valutazione finora

- The Synthesis of Elliptical Gears Generated by Shaper-CuttersDocumento9 pagineThe Synthesis of Elliptical Gears Generated by Shaper-CuttersBen TearleNessuna valutazione finora

- General Engineering Science in SI Units: In Two VolumesDa EverandGeneral Engineering Science in SI Units: In Two VolumesNessuna valutazione finora

- A Study On Tribological & Statistical Investigation of PTFE, Tin Bronze and White MetalDocumento9 pagineA Study On Tribological & Statistical Investigation of PTFE, Tin Bronze and White MetalIJRASETPublicationsNessuna valutazione finora

- Laminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisDa EverandLaminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisNessuna valutazione finora

- Coupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, SeeDocumento24 pagineCoupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, Seerupesh8989Nessuna valutazione finora

- Basic Components of Power TrainDocumento24 pagineBasic Components of Power TrainAbdul Shukur100% (8)

- Bearing For Cement Industry - NDocumento20 pagineBearing For Cement Industry - NAjanta Bearing100% (1)

- 10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersDocumento10 pagine10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersĐen BáoNessuna valutazione finora

- Design and Analysis of An Epicyclic Gearbox For An Electric DrivetrainDocumento9 pagineDesign and Analysis of An Epicyclic Gearbox For An Electric DrivetrainNajrul IslamNessuna valutazione finora

- Lecture 1Documento8 pagineLecture 1Debabrat SaikiaNessuna valutazione finora

- Bhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429Documento51 pagineBhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429PreethamBAsaravalliMohanNessuna valutazione finora

- Chain Less BicycleDocumento46 pagineChain Less BicycleShubham PatilNessuna valutazione finora

- Industrial Gearbox Service ManualDocumento36 pagineIndustrial Gearbox Service ManualNovriansyah Brian100% (1)

- Gearboxes ClassDocumento35 pagineGearboxes ClassNaveen Vachipalli100% (1)

- A-313 - 98Documento7 pagineA-313 - 98José Ramón GutierrezNessuna valutazione finora

- Railway Bearings 8501-Ii PDFDocumento78 pagineRailway Bearings 8501-Ii PDFCarlo AguiluzNessuna valutazione finora

- Gear Ratio Calculations PDFDocumento4 pagineGear Ratio Calculations PDFrechingatuputamadreNessuna valutazione finora

- C Rollway PDFDocumento16 pagineC Rollway PDFoxonoerNessuna valutazione finora

- Bearing NotesDocumento6 pagineBearing NotesabhivpcoeNessuna valutazione finora

- Suspension Assembly of BAJA ATVDocumento4 pagineSuspension Assembly of BAJA ATVInfogain publicationNessuna valutazione finora

- GEARSDocumento25 pagineGEARSamitNessuna valutazione finora

- Exp - 3 (Ignition System) PDFDocumento10 pagineExp - 3 (Ignition System) PDFM SharmaNessuna valutazione finora

- PDFDocumento70 paginePDFvarunNessuna valutazione finora

- Design and Analysis of Composite Drive ShaftDocumento8 pagineDesign and Analysis of Composite Drive Shaftmesfin DemiseNessuna valutazione finora

- Design and Analysis of A Shock AbsorberDocumento15 pagineDesign and Analysis of A Shock AbsorberInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- Tech-03 Springs-Roll Stiffness-4 PDFDocumento9 pagineTech-03 Springs-Roll Stiffness-4 PDFMibsão EsdrasNessuna valutazione finora

- A Review of Structural and Thermal Analysis of Traction MotorsDocumento11 pagineA Review of Structural and Thermal Analysis of Traction MotorsGari PastranaNessuna valutazione finora

- Belt DriveDocumento16 pagineBelt DriveRuben Ruiperez Salas100% (1)

- Drive ShaftDocumento8 pagineDrive ShaftAkshat SharmaNessuna valutazione finora

- A Novel Power-Train Using Coaxial Magnetic GearDocumento6 pagineA Novel Power-Train Using Coaxial Magnetic GearHuynh Thanh AnhNessuna valutazione finora

- Bearing Design in Machinery - A. Harnoy (Marcel Dekker, 2003) WWDocumento640 pagineBearing Design in Machinery - A. Harnoy (Marcel Dekker, 2003) WWoptimist5Nessuna valutazione finora

- Design and Analysis of Composite Drive ShaftDocumento8 pagineDesign and Analysis of Composite Drive ShaftInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- E4201b PDFDocumento23 pagineE4201b PDFMuhammad JunaidNessuna valutazione finora

- ECOmove Powertrain SpecificationsDocumento6 pagineECOmove Powertrain SpecificationsjavierNessuna valutazione finora

- Gear Teeth: Clocks and ShipsDocumento16 pagineGear Teeth: Clocks and ShipsČika BrkoNessuna valutazione finora

- Lecture Slides: Shigley's Mechanical Engineering DesignDocumento108 pagineLecture Slides: Shigley's Mechanical Engineering DesignHamza SultanNessuna valutazione finora

- Moog-Ball Screws Planetary Roller Screws-DatasheetDocumento2 pagineMoog-Ball Screws Planetary Roller Screws-DatasheetvaneaNessuna valutazione finora

- Drive Shaft - WikipediaDocumento5 pagineDrive Shaft - WikipediaMohsen SharifNessuna valutazione finora

- Ball PistonDocumento13 pagineBall PistonpraneethreddyNessuna valutazione finora

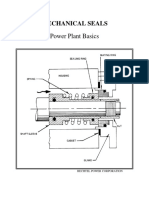

- Mechanical Seals: Power Plant BasicsDocumento26 pagineMechanical Seals: Power Plant BasicsService Port100% (1)

- Submitted By:: Sopal Gayatri Sanjay. - Coupling Types & ApplicationDocumento15 pagineSubmitted By:: Sopal Gayatri Sanjay. - Coupling Types & ApplicationB.AishwaryaNessuna valutazione finora

- Bearing ReliabilityDocumento3 pagineBearing ReliabilityWayu100% (1)

- Xv-Ha5 RRV3217Documento110 pagineXv-Ha5 RRV3217WayuNessuna valutazione finora

- PrecisionBrgs e 244Documento8 paginePrecisionBrgs e 244WayuNessuna valutazione finora

- 3dcs Variation Analyst MC PDFDocumento2 pagine3dcs Variation Analyst MC PDFWayuNessuna valutazione finora

- Flow AnalysisDocumento16 pagineFlow AnalysisWayuNessuna valutazione finora

- Tpi 193 de enDocumento20 pagineTpi 193 de enWayuNessuna valutazione finora

- Uddeholm Steel For CWTDocumento28 pagineUddeholm Steel For CWTWayuNessuna valutazione finora

- Uddeholm Steel For CWTDocumento28 pagineUddeholm Steel For CWTWayuNessuna valutazione finora

- Tpi 213 de enDocumento24 pagineTpi 213 de enWayuNessuna valutazione finora

- Tpi 221 de en PDFDocumento8 pagineTpi 221 de en PDFWayuNessuna valutazione finora

- Parker Fluid Power Seal Design Guide 5370Documento300 pagineParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- SKF 4781 - e BDocumento40 pagineSKF 4781 - e BWayuNessuna valutazione finora

- Tpi 165 de en PDFDocumento18 pagineTpi 165 de en PDFWayuNessuna valutazione finora

- Uddeholm Steel For CWTDocumento28 pagineUddeholm Steel For CWTWayuNessuna valutazione finora

- Bangkok Rail Transportation PDFDocumento1 paginaBangkok Rail Transportation PDFWayuNessuna valutazione finora

- Axial BearingDocumento16 pagineAxial BearingWayuNessuna valutazione finora

- Bearing TypesDocumento5 pagineBearing TypesWayuNessuna valutazione finora

- Axial BearingDocumento16 pagineAxial BearingWayuNessuna valutazione finora

- CSTR Oring Catalog Or2009Documento48 pagineCSTR Oring Catalog Or2009roccandradoNessuna valutazione finora

- OchureDocumento13 pagineOchureWayuNessuna valutazione finora

- 5918 Machine Tool Catalog 1Documento240 pagine5918 Machine Tool Catalog 1AlvaroNessuna valutazione finora

- MolexDocumento1 paginaMolexWayuNessuna valutazione finora

- Parker Fluid Power Seal Design Guide 5370Documento300 pagineParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- Materials For Rolling Bearing TechnologyDocumento29 pagineMaterials For Rolling Bearing TechnologyWayuNessuna valutazione finora

- Werkstoffe E PDFDocumento12 pagineWerkstoffe E PDFirajfarji2481Nessuna valutazione finora

- Barbed FittingDocumento22 pagineBarbed FittingWayuNessuna valutazione finora

- Lubrication Oils For Enclosed Gear DrivesDocumento20 pagineLubrication Oils For Enclosed Gear DrivesWayu100% (1)

- SB Ibl P CBL Submersible Power CableDocumento23 pagineSB Ibl P CBL Submersible Power CableMuhammad ShahrukhNessuna valutazione finora

- Energizer 522: Product DatasheetDocumento1 paginaEnergizer 522: Product DatasheetAli AbdullahNessuna valutazione finora

- VP01-VP10 d900Documento6 pagineVP01-VP10 d900Constantin294Nessuna valutazione finora

- Three Phase Semi Controlled RectifierDocumento12 pagineThree Phase Semi Controlled RectifierSvk NareshNessuna valutazione finora

- 4.0 User Manual For TBS Sensors v6Documento18 pagine4.0 User Manual For TBS Sensors v6Alexandre MandettaNessuna valutazione finora

- WEG CFW700 Quick Parameter Reference PDFDocumento76 pagineWEG CFW700 Quick Parameter Reference PDFEdson Luiz ValandroNessuna valutazione finora

- What Is Geothermal Energy?: Mary H. Dickson and Mario FanelliDocumento61 pagineWhat Is Geothermal Energy?: Mary H. Dickson and Mario FanelliVikkiSandyNessuna valutazione finora

- 7 - DirectionvalvesDocumento48 pagine7 - DirectionvalvesMohamed ZahranNessuna valutazione finora

- M.A.N - B&W Diesel: Service LetterDocumento5 pagineM.A.N - B&W Diesel: Service LetterAleksandar Sasa SeferovicNessuna valutazione finora

- Power-Xformer Upto 420 KV-CM List Updated On 22.02.2017Documento11 paginePower-Xformer Upto 420 KV-CM List Updated On 22.02.2017KeshavNessuna valutazione finora

- Cheemi SBWZ Temperature Transmitter PDFDocumento2 pagineCheemi SBWZ Temperature Transmitter PDFNguyen SonNessuna valutazione finora

- Book Abstracts Book RedDocumento207 pagineBook Abstracts Book Redankabe100% (1)

- Enerpac CLL & CAT Series CatalogDocumento4 pagineEnerpac CLL & CAT Series CatalogTitanplyNessuna valutazione finora

- FSD101eng FSG Seals Catalog A4Documento64 pagineFSD101eng FSG Seals Catalog A4ASHOKNessuna valutazione finora

- Nuclear Physics Interview Questions and Answers 830 PDFDocumento7 pagineNuclear Physics Interview Questions and Answers 830 PDFpeterjo raveloNessuna valutazione finora

- WIMES LCC Model 03 PD Pumps Issue 1 Guidance NotesDocumento10 pagineWIMES LCC Model 03 PD Pumps Issue 1 Guidance Notesawhk2006Nessuna valutazione finora

- Doseuro Ficha TécnicaDocumento8 pagineDoseuro Ficha TécnicaAdiel EnriquezNessuna valutazione finora

- JBL Sub140p ManualDocumento5 pagineJBL Sub140p ManualDiff DonNessuna valutazione finora

- New Chapter 6 Areva Transformer Differential ProtectionDocumento54 pagineNew Chapter 6 Areva Transformer Differential ProtectionTaha Mohammed83% (6)

- 4016TAG2A 1500 RPM ElectropaK PN2181Documento5 pagine4016TAG2A 1500 RPM ElectropaK PN2181Mohammed HamzaNessuna valutazione finora

- Form Rumusan Makalah Seminar InternasionalDocumento3 pagineForm Rumusan Makalah Seminar InternasionalMiedson miedsonNessuna valutazione finora

- LC1044 LRP14 3PH QRG 0823Documento2 pagineLC1044 LRP14 3PH QRG 0823FlakooNessuna valutazione finora

- Physics Past Paper (June 2005)Documento11 paginePhysics Past Paper (June 2005)Jotham Omoregie80% (5)

- Operating Instructions and Owner'S Manual Mr. Heater HeatstarDocumento8 pagineOperating Instructions and Owner'S Manual Mr. Heater HeatstarcjmNessuna valutazione finora

- Grid1 - Untitled - gr1S - CompleteRapportDocumento3 pagineGrid1 - Untitled - gr1S - CompleteRapportKhaoula BenNessuna valutazione finora

- SOLA HD. 63-23-125-4: MCR Hardwired Series - Power Line Conditioning With Voltage RegulationDocumento4 pagineSOLA HD. 63-23-125-4: MCR Hardwired Series - Power Line Conditioning With Voltage RegulationluisnirvanaNessuna valutazione finora

- 4098 9733Documento4 pagine4098 9733Sergio Sergio100% (1)

- Production of Biodiesel From Hybrid Oil Dairy Waste Scum and Karanja and Characterization and Study of Its Performance On Diesel Engine IJERTV3IS070674 PDFDocumento5 pagineProduction of Biodiesel From Hybrid Oil Dairy Waste Scum and Karanja and Characterization and Study of Its Performance On Diesel Engine IJERTV3IS070674 PDFManish PatilNessuna valutazione finora

- Paints IndustryDocumento43 paginePaints IndustryprachiNessuna valutazione finora

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDa EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchValutazione: 4 su 5 stelle4/5 (10)

- Beginning AutoCAD® 2020 Exercise WorkbookDa EverandBeginning AutoCAD® 2020 Exercise WorkbookValutazione: 2.5 su 5 stelle2.5/5 (3)

- Practical Reservoir Engineering and CharacterizationDa EverandPractical Reservoir Engineering and CharacterizationValutazione: 4.5 su 5 stelle4.5/5 (3)

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyDa EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyValutazione: 1.5 su 5 stelle1.5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Da EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Nessuna valutazione finora

- Certified Solidworks Professional Advanced Weldments Exam PreparationDa EverandCertified Solidworks Professional Advanced Weldments Exam PreparationValutazione: 5 su 5 stelle5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsDa EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsValutazione: 5 su 5 stelle5/5 (1)

- AutoCAD 2023 : Beginners And Intermediate user GuideDa EverandAutoCAD 2023 : Beginners And Intermediate user GuideNessuna valutazione finora

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Da EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Valutazione: 5 su 5 stelle5/5 (2)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersDa EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNessuna valutazione finora

- Up and Running with AutoCAD 2020: 2D Drafting and DesignDa EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignNessuna valutazione finora