Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

0medida de Espesor Con Laser PDF

Caricato da

Viny Gavilanes0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni1 paginaThis document discusses using laser sensors to measure thickness in various industries such as woodworking, metalworking, textiles, and extrusion lines. It describes different thickness measurement methods including using two sensors on the top and bottom of an object to measure thickness, or using a single sensor and a fixed reference distance on the bottom. Multiple sensor systems can simultaneously measure thickness on items like profile plates. Differentiation measurement can also detect differences in height.

Descrizione originale:

Titolo originale

0medida_de_espesor_con_laser.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses using laser sensors to measure thickness in various industries such as woodworking, metalworking, textiles, and extrusion lines. It describes different thickness measurement methods including using two sensors on the top and bottom of an object to measure thickness, or using a single sensor and a fixed reference distance on the bottom. Multiple sensor systems can simultaneously measure thickness on items like profile plates. Differentiation measurement can also detect differences in height.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni1 pagina0medida de Espesor Con Laser PDF

Caricato da

Viny GavilanesThis document discusses using laser sensors to measure thickness in various industries such as woodworking, metalworking, textiles, and extrusion lines. It describes different thickness measurement methods including using two sensors on the top and bottom of an object to measure thickness, or using a single sensor and a fixed reference distance on the bottom. Multiple sensor systems can simultaneously measure thickness on items like profile plates. Differentiation measurement can also detect differences in height.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Thickness Measurement with LASER Sensors

MEL thickness measuring systems are used in many fields of application:

Woodworking and metal industry: thickness measurement of plates and bands

Products of extrusion lines and calenders

Materials like floorings, roofing, sealings etc.

Textiles

Control of material doubling to avoid tool or machine damage

and so on

Double-sided measuring method:

Two sensors measure on the upper and the lower side of

the object. The material thickness results from the addition

of the measuring signals.

Application: Detection of metal sheet doubling:

The thickness can also be measured with a one-sided sensor system: one or more sensors are measuring

onto one side, the reference distance will be the fixed underlayment of the object. The material thickness

results from the difference of reference and object distance.

Multiple measuring systems:

The signals of up to 4 thickness measuring systems can

be simultaneously evaluated with a MEL i-Control (e.g.

thickness measurement of profile plates).

A special application of the thickness measurement is the

differentiation measurement. With this method differences

in height can be detected.

Intelligente Sensoren

& Mess-Systeme

Digital Display MODIG 106:

The digital display MODIG 106 for

displaying all important values, indicators

and units is optionally available at MEL.

The device is operated via 5 buttons at

the front panel.

Cabling of thickness and differentiation

measurement system with one sensor pair

MIKROELEKTRONIK GmbH Tel. +49 89 / 327150-0 Fax +49 89 / 319 20 23 www.MELsensor.de

Potrebbero piacerti anche

- Nanoscale Calibration Standards and Methods: Dimensional and Related Measurements in the Micro and Nanometer RangeDa EverandNanoscale Calibration Standards and Methods: Dimensional and Related Measurements in the Micro and Nanometer RangeNessuna valutazione finora

- Dowel Scan Tie Bar Alignent BrochureDocumento2 pagineDowel Scan Tie Bar Alignent BrochureAjit P. SinghNessuna valutazione finora

- Keyence 3D MittausasemaDocumento28 pagineKeyence 3D Mittausasemabee140676Nessuna valutazione finora

- Aplicatii Keyence - Digitalizari - Masuratori 2020 PDFDocumento8 pagineAplicatii Keyence - Digitalizari - Masuratori 2020 PDFArjocan Emil DanNessuna valutazione finora

- Metrology Manual (2012)Documento46 pagineMetrology Manual (2012)Saibabu RollaNessuna valutazione finora

- Metrology and MeasurementsDocumento140 pagineMetrology and MeasurementsVivekanand SriramNessuna valutazione finora

- InfiniteFocus Combines 3D Measurement and Surface Finish AnalysisDocumento2 pagineInfiniteFocus Combines 3D Measurement and Surface Finish Analysistruejefs100% (1)

- Lecture 3-ArDocumento19 pagineLecture 3-ArSherif SaidNessuna valutazione finora

- Chapter 2 Metrology and InstrumentsDocumento15 pagineChapter 2 Metrology and InstrumentsHafizudin DaudNessuna valutazione finora

- VR-3200 BrochureDocumento32 pagineVR-3200 BrochureAndres Melendez HernandezNessuna valutazione finora

- DM5E Corrosion Thickness Gauge Product BrochureDocumento8 pagineDM5E Corrosion Thickness Gauge Product BrochureClaudio UNessuna valutazione finora

- Nota MetroDocumento1 paginaNota Metrolienna77-1Nessuna valutazione finora

- Engineering Metrology and Measurements PDFDocumento35 pagineEngineering Metrology and Measurements PDFhansleyNessuna valutazione finora

- UT1M With 2 MHZ ProbeDocumento2 pagineUT1M With 2 MHZ ProbeEko FajarNessuna valutazione finora

- Metrology Lab Review)Documento27 pagineMetrology Lab Review)papugowdaNessuna valutazione finora

- Comparison Corrosion Mapping Solutions Using PDFDocumento10 pagineComparison Corrosion Mapping Solutions Using PDFfabian barraganNessuna valutazione finora

- Comparison Corrosion Mapping Solutions Using Phased Array, Conventional UT and 3D ScannersDocumento10 pagineComparison Corrosion Mapping Solutions Using Phased Array, Conventional UT and 3D ScannersSooraj RajanNessuna valutazione finora

- Measurement and InspectionDocumento33 pagineMeasurement and InspectionSri RNessuna valutazione finora

- Abstraction: The Language of MeasurementDocumento5 pagineAbstraction: The Language of MeasurementCicel LucenoNessuna valutazione finora

- Metrology FundamentalsDocumento51 pagineMetrology FundamentalsRahul PathakNessuna valutazione finora

- SameerDocumento5 pagineSameerKhushi SalgaonkarNessuna valutazione finora

- Development of A Special CMM For Dimensional MetroDocumento9 pagineDevelopment of A Special CMM For Dimensional MetroDiana Alejandra Bermudez FajardoNessuna valutazione finora

- Huang 21Documento15 pagineHuang 21Istavay Orbegoso SalasNessuna valutazione finora

- Method InclinometerDocumento10 pagineMethod InclinometerKTMONessuna valutazione finora

- Lecture 1 MeasurementDocumento30 pagineLecture 1 Measurementakash258456Nessuna valutazione finora

- Cat ThermoMETER InfraredDocumento56 pagineCat ThermoMETER InfraredspyrosNessuna valutazione finora

- OBJECTIVEDocumento7 pagineOBJECTIVEDILEEPNessuna valutazione finora

- PMD 3D Sensor Brochure UKDocumento6 paginePMD 3D Sensor Brochure UKifm electronicNessuna valutazione finora

- Objectives Introduction (Metro 2) UpdateDocumento14 pagineObjectives Introduction (Metro 2) UpdateFazrul SyafiqNessuna valutazione finora

- Geosense CatalogueDocumento48 pagineGeosense CataloguenikalmillateguiNessuna valutazione finora

- Friction Control in Positioning by AE DetectionDocumento6 pagineFriction Control in Positioning by AE Detection채근병Nessuna valutazione finora

- SMR1302Documento286 pagineSMR1302Mr. RAVI KUMAR INessuna valutazione finora

- Metrology BasicsDocumento113 pagineMetrology Basicsavutu_kunduru100% (1)

- Rightrax System: Sensing & Inspection TechnologiesDocumento5 pagineRightrax System: Sensing & Inspection TechnologiesTechnical A-Star Testing & Inspection MalaysiaNessuna valutazione finora

- A Collection Of: Industry ExamplesDocumento15 pagineA Collection Of: Industry Exampleslil10zinNessuna valutazione finora

- Measurement and MetrologyDocumento84 pagineMeasurement and Metrologyjalim yadavNessuna valutazione finora

- Met - 1Documento132 pagineMet - 1Ashwani KaninaNessuna valutazione finora

- 2018, DasDocumento23 pagine2018, DasAlexander Bolaños DiazNessuna valutazione finora

- CHAPTER 1 Measurement and InstrumentationDocumento38 pagineCHAPTER 1 Measurement and InstrumentationAsif Bin SyedNessuna valutazione finora

- METROLOGY FUNDAMENTALSDocumento37 pagineMETROLOGY FUNDAMENTALSBriaydon TawandaNessuna valutazione finora

- Measure Temperature with InstrumentationDocumento3 pagineMeasure Temperature with InstrumentationgregNessuna valutazione finora

- Engineering Metrology and MeasurementsDocumento128 pagineEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Why Measure Properly With MetrologyDocumento6 pagineWhy Measure Properly With MetrologyericksetiyawanNessuna valutazione finora

- Tactile Sensing With Scalable Capacitive SensorDocumento15 pagineTactile Sensing With Scalable Capacitive Sensorhello worldNessuna valutazione finora

- Engineering Metrology and Measurements Unit 1 2Documento82 pagineEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- Wireless Sensor Network Approach to Large Scale Dimensional MetrologyDocumento14 pagineWireless Sensor Network Approach to Large Scale Dimensional MetrologyvromikoNessuna valutazione finora

- Dewinter Software CatalogueDocumento6 pagineDewinter Software CatalogueShivraman ThapliyalNessuna valutazione finora

- Tbe 233 234 296 333 433Documento4 pagineTbe 233 234 296 333 433Anonymous 8rb48tZSNessuna valutazione finora

- Dimensional Measurement Using Digital Height GaugeDocumento4 pagineDimensional Measurement Using Digital Height GaugeDheeraj KumarNessuna valutazione finora

- Metrology and MeasurementsDocumento140 pagineMetrology and MeasurementsVallik Tad0% (1)

- TM 3000 CatalogDocumento12 pagineTM 3000 CatalogblgndllNessuna valutazione finora

- By T.Karthik IT (3 / 4), Narsaraopeta Engineering College, Narsaraopeta, Guntur DistDocumento8 pagineBy T.Karthik IT (3 / 4), Narsaraopeta Engineering College, Narsaraopeta, Guntur DistmycatalystsNessuna valutazione finora

- Original Standard - DIN 32876-1-198604Documento6 pagineOriginal Standard - DIN 32876-1-198604TereNessuna valutazione finora

- Advantages and Limitations of Confocal Chromatic SensorsDocumento13 pagineAdvantages and Limitations of Confocal Chromatic SensorsGilmar A. NogueiraNessuna valutazione finora

- Engineering MetrologyDocumento34 pagineEngineering MetrologyMatthew CurmiNessuna valutazione finora

- DSPIC-based impedance measurement systemDocumento6 pagineDSPIC-based impedance measurement systemppedro07Nessuna valutazione finora

- Fidelica Microsystems' Unique Fingerprint Authentication TechnologyDocumento8 pagineFidelica Microsystems' Unique Fingerprint Authentication Technologypradeep2182Nessuna valutazione finora

- Cat thermoMETER Infrared enDocumento56 pagineCat thermoMETER Infrared ensrinathgudur11Nessuna valutazione finora

- PBL Ac-2Documento6 paginePBL Ac-2014EE048 S PRUDHVINessuna valutazione finora

- As 117014 TG 601061 WW GB 2021 1Documento12 pagineAs 117014 TG 601061 WW GB 2021 1Srivatsava RajagopalanNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Sure Step Manuals PDocumento70 pagineSure Step Manuals PjondeividNessuna valutazione finora

- EnglishDocumento1 paginaEnglishViny GavilanesNessuna valutazione finora

- Hult Prize 2019 ChallengeDocumento24 pagineHult Prize 2019 ChallengeManar HosnyNessuna valutazione finora

- drv8825 PDFDocumento32 paginedrv8825 PDFGerson FelipeNessuna valutazione finora

- Wonderware Intouch 10.1 Curso BasicoDocumento141 pagineWonderware Intouch 10.1 Curso BasicoViny GavilanesNessuna valutazione finora

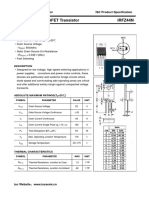

- Irfz44n PDFDocumento2 pagineIrfz44n PDFDenilson Gonzales VilchezNessuna valutazione finora

- Hult Prize 2019 ChallengeDocumento24 pagineHult Prize 2019 ChallengeManar HosnyNessuna valutazione finora

- Nombre de La Asignatura: Parcial de Estudio:: English III - Iv First PeriodDocumento4 pagineNombre de La Asignatura: Parcial de Estudio:: English III - Iv First PeriodAbbey LinkNessuna valutazione finora

- Links For Self-Study - English v-VIDocumento7 pagineLinks For Self-Study - English v-VIViny GavilanesNessuna valutazione finora

- Nombre de La Asignatura:: English I - IIDocumento7 pagineNombre de La Asignatura:: English I - IIViny GavilanesNessuna valutazione finora

- Links For Self-Study - English v-VIDocumento7 pagineLinks For Self-Study - English v-VIViny GavilanesNessuna valutazione finora

- Links For Self-Study - English V - VIDocumento8 pagineLinks For Self-Study - English V - VIFranklin Bravo ChufelizNessuna valutazione finora

- Links For Self-Study - English V - VIDocumento8 pagineLinks For Self-Study - English V - VIFranklin Bravo ChufelizNessuna valutazione finora

- CAD For IC Design Handout 2018-2019Documento2 pagineCAD For IC Design Handout 2018-2019bkgp1994Nessuna valutazione finora

- Clock Wizard PDFDocumento58 pagineClock Wizard PDFRaja Narendra Kumar SayiNessuna valutazione finora

- Lab ManDocumento33 pagineLab Manapi-3693527Nessuna valutazione finora

- Rhinoceros 3D TutorialDocumento68 pagineRhinoceros 3D TutorialsilikondioksidaNessuna valutazione finora

- 08-3471 Walker 2080 Mk2 PDFDocumento2 pagine08-3471 Walker 2080 Mk2 PDFAbdelouahab BendahmaneNessuna valutazione finora

- Multi Circuit Range SF6 RMUEnglishDocumento2 pagineMulti Circuit Range SF6 RMUEnglishdip461Nessuna valutazione finora

- Computerized Livestock Information Management SystemDocumento47 pagineComputerized Livestock Information Management SystemMajesty89% (9)

- FusionServer 2288H V7 Server Technical White PaperDocumento173 pagineFusionServer 2288H V7 Server Technical White PaperOnur TemizsoyluNessuna valutazione finora

- HG240641Documento1 paginaHG240641sdk00Nessuna valutazione finora

- Megz790godlike enDocumento88 pagineMegz790godlike encernadasgabriel0Nessuna valutazione finora

- Hotel Management SystemDocumento20 pagineHotel Management SystemRohit100% (1)

- Jatin Mer CVDocumento7 pagineJatin Mer CVsumitNessuna valutazione finora

- 1999-09 The Computer Paper - BC EditionDocumento154 pagine1999-09 The Computer Paper - BC EditionthecomputerpaperNessuna valutazione finora

- Main Specifications of FOMA 905i SeriesDocumento5 pagineMain Specifications of FOMA 905i SeriesAditya R. AchitoNessuna valutazione finora

- SID97-3C ADJUSTMENT of Continental Fuel InjectionDocumento41 pagineSID97-3C ADJUSTMENT of Continental Fuel InjectionTito Teixeira100% (1)

- Dt47mg User ManualDocumento32 pagineDt47mg User ManualRanko LazicNessuna valutazione finora

- Intel Performance Maximizer V1.0.3 User GuideDocumento26 pagineIntel Performance Maximizer V1.0.3 User GuidezerotacetNessuna valutazione finora

- Epiqa Demo Manual Version 2.2.1 FinalDocumento68 pagineEpiqa Demo Manual Version 2.2.1 FinalBenfredj KhalilNessuna valutazione finora

- Gulfstream G650Er: Maintenance ManualDocumento20 pagineGulfstream G650Er: Maintenance ManualLena BatboldNessuna valutazione finora

- Accutorr V Service ManualDocumento125 pagineAccutorr V Service ManualMiguel IralaNessuna valutazione finora

- 1.0 Data Representation SlidesDocumento137 pagine1.0 Data Representation SlidesAbdu AbdoulayeNessuna valutazione finora

- Weighing Systems For The Heavy Industries ABBDocumento12 pagineWeighing Systems For The Heavy Industries ABBEJECUTIVO_10% (1)

- Ensure Data Meets Criteria for Useful InformationDocumento4 pagineEnsure Data Meets Criteria for Useful InformationmikkomartinezNessuna valutazione finora

- Edge Adaptive Image Steganography Based On LSB Matching Revisited CodeDocumento24 pagineEdge Adaptive Image Steganography Based On LSB Matching Revisited Codegangang1988Nessuna valutazione finora

- MSP CatalogDocumento128 pagineMSP CatalogsanthoshNessuna valutazione finora

- Sensor ComparisonDocumento8 pagineSensor ComparisongiasnavyhsrNessuna valutazione finora

- 2009 7Documento29 pagine2009 7Yang YiNessuna valutazione finora

- Satellite L850: A Class Act, Inside and OutDocumento2 pagineSatellite L850: A Class Act, Inside and OutessameldinNessuna valutazione finora

- SIMATIC - S7-200 To S7-1200 Migration Overview V3Documento6 pagineSIMATIC - S7-200 To S7-1200 Migration Overview V3Jorge_Andril_5370Nessuna valutazione finora

- Selecting Criteria of A MotherboardDocumento3 pagineSelecting Criteria of A MotherboardDa NishNessuna valutazione finora