Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ETS 0071 Am 1

Caricato da

AnthonyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ETS 0071 Am 1

Caricato da

AnthonyCopyright:

Formati disponibili

Document No: ETS 0071

Amendment No: 1

Equipment Technical Specification

Distribution fuses

IMPORTANT DISCLAIMER

As the information contained in this publication is subject to change from time to time, Endeavour

Energy gives no warranty that the information is correct or complete or is a definitive statement of

procedures. Endeavour Energy reserves the right to vary the content of this publication as and

when required. You should make independent inquiries to satisfy yourself as to correctness and

currency of the content. Endeavour Energy expressly disclaims all and any liability to any persons

whatsoever in respect of anything done or not done by any such person in reliance, whether in

whole or in part, on this document.

Copyright Endeavour Energy 2016

51 Huntingwood Drive Huntingwood NSW 2148 www.endeavourenergy.com.au

PO BOX 811 Seven Hills 1730

T: 131 081 F: 61 2 9853 6000

Equipment Technical Specification

Document No : ETS 0071

Amendment No : 1

ASSET STANDARDS AND DESIGN Approved By : GMAM

Approval Date : 03/05/16

Review Date : 03/05/21

ETS 0071 DISTRIBUTION FUSES

CONTENTS

1.0 PURPOSE............................................................................................................................ 4

2.0 SCOPE ................................................................................................................................ 4

3.0 REFERENCES ..................................................................................................................... 4

4.0 DEFINITIONS AND ABBREVIATIONS ................................................................................ 5

5.0 ACTIONS ............................................................................................................................. 7

5.1 General ............................................................................................................................ 7

5.1.1 General...................................................................................................................... 7

5.1.2 Service conditions and environment .......................................................................... 8

5.2 Padmount and indoor substation fuses ........................................................................ 8

5.2.1 High Voltage fuse for padmount and indoor substations ............................................ 8

5.2.2 Low voltage fuses for padmount and indoor substations ............................................ 9

5.2.3 Solid blade links ....................................................................................................... 10

5.2.4 J type fuse links - spare fuses for existing installations ............................................ 10

5.3 Pole substation fuses ................................................................................................... 11

5.3.1 Dropout fuses for pole substations and overhead HV distribution lines .................... 11

5.3.2 Low voltage fuse for pole substations ...................................................................... 12

5.4 Testing ........................................................................................................................... 14

5.4.1 General.................................................................................................................... 14

5.4.2 Testing laboratories ................................................................................................. 15

5.4.3 Type tests ................................................................................................................ 15

5.4.4 Routine tests............................................................................................................ 15

5.4.5 Thermocouple locations ........................................................................................... 15

5.4.6 List of type tests ....................................................................................................... 15

5.5 Quality assurance ......................................................................................................... 16

5.6 Approval process ......................................................................................................... 16

5.6.1 Product approval and audit form: ............................................................................. 16

5.7 Drawings ....................................................................................................................... 16

ETS 0071 Copyright Endeavour Energy 2016 Page 2 of 17

ETS 0071 Amendment No: 1

6.0 AUTHORITIES AND RESPONSIBILITIES......................................................................... 16

7.0 DOCUMENT CONTROL .................................................................................................... 17

ETS 0071 Copyright Endeavour Energy 2016 Page 3 of 17

1.0 PURPOSE

To set out in detail the minimum requirements for the design manufacture and testing of fuses

suitable for use in Endeavour Energy distribution network.

2.0 SCOPE

This specification covers the requirements, types, classifications and mechanical arrangements for

fuses to be used in Endeavour Energys distribution network. These fuses are used with

switchgear installed in indoor substations, padmount substations, pole mount substations and

mains pillars.

It is not the intention to specify the manufacturing, testing and material requirements in detail.

However, the fuses offered in response to this specification shall be manufactured and tested to

the standards with the year of publication listed below.

This specification does not cover the procedure for selection of fuses for Endeavour Energy

applications. Endeavour Energy procedures for the selection of fuses for different applications are

set out in MCI 0005 and MCI 0006.

This document does not cover the specification of the equipment on which the fuses are mounted,

such as switchgear, dropout fuse assemblies and fuse bases.

3.0 REFERENCES

Internal

Company Policy 9.2.2 (Network) Network Protection

Company Policy 9.2.5 (Network) Network Asset Design

Company Policy 9.7.1 (Network) Network Construction

Company Policy 9.8.3 (Network) Network Operations

Branch form PAE 1004 - Product approval process

Branch form FAE 3161 - Distribution fuses approval and audit form

Equipment Technical Specification ETS 0068 - Distribution indoor and padmount substation

12-24kV switchgear

Equipment Technical Specification ETS 0069 - Distribution indoor and padmount substation

low voltage switchgear

Mains Construction Instruction MCI 0005 - Overhead distribution construction standards

manual

Mains Construction Instruction MCI 0006-Underground distribution construction standard

manual

Equipment Technical Specification ETS 0083 12kV/24kV expulsion dropout fuse

specification

External

Code of Practice-Distribution Risk Management-NSW Department of Energy, Utilities and

Sustainability (DEUS) 1998

ENA-National Electricity Network Safety Code (NENS 01-2008)

AS 3000: SAA Wiring Rules Oct 2007

AS 1033.1:1990 - High voltage fuses (for rated voltages exceeding 1000V)-Expulsion Type

(including boric acid fuses)Similar to IEC 60282-2:2008

AS 1033.2:1988 - High voltage fuses (for rated voltages exceeding 1000V)-Current Limiting

(Powder filled Type)-- Similar to IEC 60282-1:2014

AS/NZS IEC 60947.1:2015 Low-voltage switchgear and controlgear Part 1: General rules

AS 62271.1:2012 High-voltage switchgear and controlgear. Part 1: Common specifications

ETS 0071 Copyright Endeavour Energy 2016 Page 4 of 17

DISTRIBUTION FUSES Amendment No: 1

IEC 60269.1:2014 Low-voltage fuses Part 1: General Requirements

IEC 60269.2:2014 Low-voltage fuses Part 2:Supplementary requirements for fuses for use

by authorized persons (fuses mainly for industrial application) Examples of standardised

systems of fuses A to K

IEC 60269.3:2014 Low-voltage fuses Part 3:Supplementary requirements for fuses for use

by unskilled persons (fuses mainly for household or similar application) Examples of

standardised systems of fuses A to F

4.0 DEFINITIONS AND ABBREVIATIONS

Current limiting fuse

Device that during and by its operation in a specified current range, limits the current to a

substantially lower value than the peak value of the prospective current.

General purpose fuse (G)

Current limiting fuse capable of breaking, under specified conditions of use and behaviour,

all currents from the rated breaking current down to the current that cause melting of the

fuse-element in one (1) hour.

Back-up fuse

Current limiting fuse capable of breaking, under special conditions of use and behaviour, all

current from the rated breaking current down to the rated minimum breaking current.

Backup fuses are generally associated with another switching device.

Full-Range fuse

Current-limiting fuse capable of breaking, under specified conditions of use and behaviour,

all currents that cause melting of the fuse element(s), up to its rated maximum breaking

current.

Distribution fuse

Switching device, used at voltages of 22 kV or less, that by the fusion of its element disconnects

the circuit in which it is installed. Fuses with voltage rating to 1000Vac. and 1500 Vdc are known as

low voltage fuses. Fuses with voltage ratings exceeding 1000 Vac are known as high voltage

fuses.

Dropout fuse or expulsion dropout fuse

A fuse which, when it operates, causes the fuse-carrier to drop to an open position that provides a

visible indication that it has operated. Expulsion fuses are fuses in which the arc is extinguished by

the expulsion effect of the gases produced by the arc.

ETS 0071 UNCONTROLLED IF PRINTED Page 5 of 17

DISTRIBUTION FUSES Amendment No: 1

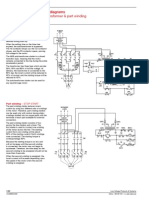

Dropout fuse components

Fuses are composed of the following parts:

Figure 1: Dropout fuse

Dropout fuse-base

Fuse-mount -the part of a fuse containing fixed contacts and terminals on an insulated

base.

Dropout fuse-carrier

The part of a fuse designed to hold the fuse-link. It contains contacts intended to engage

with the fuse-base contacts such that the carrier may be removed from the base.

Dropout fuse-link

The part of a fuse containing the fuse-element. The fuse-link must be replaced by a new

fuse-link after the operation of a fuse.

ENA

Energy Networks Association

ETS

Equipment Technical Specification

Fuse-element

The part of a fuse designed to melt when the current exceeds a given value for a sufficient time.

HRC

high rupturing capacity current limiting fuse

Indicator

Device designed to provide indication that a fuse has operated.

LV

Low voltage

MEN

Multiple Earthed Neutral

ETS 0071 UNCONTROLLED IF PRINTED Page 6 of 17

DISTRIBUTION FUSES Amendment No: 1

MCI

Mains Construction Instructions

MDI

Mains Design Instruction

NATA

National Association of Testing Authorities

SDI

Substation Design Instructions

Striker

Mechanical device that travels at a specified force and travels during the fuse operation. It may be

used as an indicator or to provide initiation to a tripping device.

Figure 2: Current limiting (powder-filled) fuse link with striker pin

SWER

Single Wire Earth Return

TCC

Time current curve

TRV

Transient recovery voltage

5.0 ACTIONS

5.1 General

5.1.1 General

The fuses shall comply with the specified standards and be suitable for use in the Endeavour

Energy distribution network.

All ferrous parts shall be treated to provide acceptable surface finish and protection from corrosion.

All component parts shall be supplied and tested in accordance with the specified standard. The

equipment shall include everything necessary or usually supplied for operation, whether directly

specified or not.

The manufacturer is required to provide all information requested in the FAE 3161 form and attach

specified test reports, time/current characteristics and the like where specified.

ETS 0071 UNCONTROLLED IF PRINTED Page 7 of 17

DISTRIBUTION FUSES Amendment No: 1

5.1.2 Service conditions and environment

Endeavour Energys LV network consists mainly of nominal 400V three- (3) phase system with an

extensive MEN system (TN-C-S earthing system).

The Endeavour Energy distribution network consists of 11kV distribution substations and 22kV

distribution substations. The number of 22kV substations is approximately 5% of the total

substations.

The equipment shall be suitable for use on Endeavour Energys 11kV and 22kV 3-phase 50Hz

system having the neutral point of the supply source effectively earthed. The highest continuous

system voltages are 12kV and 24kV RMS respectively.

Except for the LV fuses used for padmount and indoor substations, the service condition for all

other fuses are in accordance with the requirements of normal service conditions set out in clause

2.1 of AS 62271.1:2012.

Free-standing cubicles used for padmount substations are subjected to high levels of humidity and

temperature. Some padmount substations are located in a dusty and/or moist environment. The

air temperature inside the padmount substation cubicle may reach 80 deg. C which is a much

higher value than the highest ambient air temperature stated in clause 2.1 of AS 62271.1:2012.

This high temperature within the confined space of padmount substation is due to transformer

losses, the effects of solar radiation and heat contribution from the switchgear. Padmount

substation cubicles are not provided with forced ventilation. The fuses shall be suitable for use in

this type of environment, Endeavour Energy will provide some adjustments to the ratings

accordingly.

5.2 Padmount and indoor substation fuses

5.2.1 High Voltage fuse for padmount and indoor substations

Table 1 sets out the approved sizes of medium voltage fuses to be used with the switchgear

installed in padmount and indoor substations. In deciding the fuse sizes, consideration has been

given to the transformer capacity and grading with low voltage fuses and circuit breakers.

Table 1: Approved high voltage fuse sizes for padmount and indoor substations

12kV HRC Fuses 50A 63A 100A

24kV HRC Fuses 25A 32A 50A

The 12kV and 24kV current limiting fuse links shall be either back-up or full range, Type I, as in

Appendix D of AS 1033.2:1988 with the dimensions given in Figure 3, and striker type medium.

The fuse links must be suitable for use in Endeavour Energy substations and shall comply with AS

1033.2:1988. Fuses of 12kV with extenders are acceptable to use with 24kV switchgear when

24kV switchgear is used for 12kV application.

ETS 0071 UNCONTROLLED IF PRINTED Page 8 of 17

DISTRIBUTION FUSES Amendment No: 1

Figure 3: Type I fuse links

292mm for 12kV /442mm for 24kV

34mm 34mm

45mm

THE STRIKER SHALL BE ON THE CENTRELINE OF THE FUSE

LINK

Fuses used in new switchgear and in most existing switchgear installations are incorporated with

an active striker pin mechanism. Operation of the striker pin in any fuse switch combination unit

shall disconnect all three phases simultaneously.

Table 2: Maximum in- service temperatures for HV fuse contacts refer to Table 3 of AS 62271.1:2012

Maximum Maximum temperature rise at ambient air

Contacts Temperature temperature not exceeding 40 deg. C

deg. C K

i) Bare copper 75 35

ii) Tin-coated copper 90 50

iii) Silver or nickel-

105 65

coated copper

5.2.2 Low voltage fuses for padmount and indoor substations

Table 3 below sets out the approved sizes of low voltage fuses to be used with the various

category of switchgear used in padmount and indoor substations. In deciding the sizes,

consideration has been given to the transformer capacity, downstream fuses and circuit breakers.

Table 3: Approved LV blade contact fuse sizes for padmount and indoor substations

Blade contact (DIN) fuse for LV

250A 315A 400A

switchgear

Fuses shall be blade contact (called DIN fuses) size 2, as shown in figure 101 of IEC 60269-

2:2013. The utilisation category is gG (g-full range braking capacity, G-general application), rated

voltage 500V ac, maximum rated current 400 Amp, maximum rated power dissipation 34W, and

dead pin.

The fuse links must be suitable for use in Endeavour Energy substations and shall comply with IEC

60269.2:2013. The maximum in-service temperatures of the contacts specified in Table 5 must be

met.

ETS 0071 UNCONTROLLED IF PRINTED Page 9 of 17

DISTRIBUTION FUSES Amendment No: 1

Details of the fuse links are shown in Figure 4 and the dimensions are set out in Table 4.

Figure 4: Fuse links with blade contacts from Figure 101 of IEC 60269.2:2013

A Indicating device

B Contact

Table 4: Dimensions of blade contact fuses with maximum rated current 400A and voltage 500V-refer

figure 101 of IEC 60269-2:2013 for remaining dimensions

b1 f

Size a1 a2 a3 a4

min max

150 75 62 68

2 25 15

2.5 -10 2.5 2.5

Fuse size selection (A); 400, 315, 250,200,160,100,80. (Refer table 2 and table 9)

Table 5: Maximum in-service temperatures for LV fuse contacts refer to Table 2 of AS/NZS IEC

60947.1:2015

Maximum temperature rise from ambient temperature

Contacts

K

Bare copper 60

Bare brass 65

Tin-coated copper 65

Silver or nickel-coated copper 70

(Maximum external ambient temperature = 40 deg C)

5.2.3 Solid blade links

Solid blade links shall have a minimum current rating of 630 Amps and shall be fitted with insulated

tags, and be compatible with fuse base size 2 specified in Figure 102 of IEC 60269-2:2013.

5.2.4 J type fuse links - spare fuses for existing installations

J type fuse links are of 400 Vac, 400A maximum rated current with the details shown in figure 5

and the dimensions in Table 6. Except for the dimension variation, J type fuses must comply with

gU (g braking range and U utilisation category) fuse links with wedge tightening contact

ETS 0071 UNCONTROLLED IF PRINTED Page 10 of 17

DISTRIBUTION FUSES Amendment No: 1

specified in Fuse system I of IEC 60269-2:2013. The J type fuse link, size 400A, is approved for

use only in existing electrical installations.

Figure 5: J type fuse links

Table 6: Dimensions of J type fuse links

Max Max power A B C D F G K L M

rated dissipation (max/min)

current (max) (nom) (max) (max) (max) (nom) (nom) (nom)

A W mm mm mm mm mm mm mm mm mm

6.53

400 33 112 82 41 18 45 18 31 2.4

6.45

5.3 Pole substation fuses

5.3.1 Dropout fuses for pole substations and overhead HV distribution lines

Table 7 sets out the approved sizes of fuse links for dropout fuse assemblies. In deciding the fuse

sizes consideration has been given to the transformer sizes and grading with LV fuses and circuit

breakers.

Table 7: Approved dropout fuse sizes for pole substations and HV distribution lines

Expulsion dropout fuses for 12kV (maximum

3.15A 8A 16A 20A 40A 63A 80A 100A

8kA fault level)

Powder filled fuses(boric acid) 24kV (maximum

3A 8A 16A 20A 40A N/A N/A N/A

16.8kA fault level)

The boric acid fuses specified above are used in the following situations in the 11kV system:

Adjacent to zone substations where the fault level exceeds 8kA value.

Low fault level and high soil resistivity locations generally with transformers up to 50kVA.

The fuse links must be suitable for use in the Endeavour Energy distribution network and shall

comply with AS 1033.1:1990.

Fire chokes are not to be fitted with dropout fuses.

The expulsion dropout fuse links must be spark class A, speed of operation Class K, and TRV

capability Class 1, as set out in section 3.1 of AS 1033-1:1990.

ETS 0071 UNCONTROLLED IF PRINTED Page 11 of 17

DISTRIBUTION FUSES Amendment No: 1

5.3.2 Low voltage fuse for pole substations

Table 10 sets out the approved sizes of low voltage fuses for different types of switchgear used in

pole substations. In deciding the fuse sizes, consideration has been given to transformer capacity,

downstream capacity, grading and sensitivity.

5.3.2.1 Cylindrical fuse links (service fuses or barrel fuses)

Cylindrical fuse links must be suitable for use with a typical fuse carrier and base shown in figure

301 of IEC 60269-3:2013. The service fuse sizes 22mm and 30mm given in Table 8 must be

suitable for outdoor use and shall comply with the referred standards.

Figure 6: Service fuse size IIa (22mm) and IIb (30mm) - refer to Figure 301 of IEC 60269-3:2013

Table 8: Details of cylindrical fuse links to comply with IEC 60269-3:2013

Fuse size (I)

Maximum (L) (D)

selection Maximum power Length of

Size rated current Length Diameter of

(A) dissipation (W) endcap

(A) (mm) endcap (mm)

(mm)

63 63 5.0 571.0 160.5 22.230.1

IIa

80 80 6.0 571.0 160.5 22.230.1

IIb 100 100,80,63 6.0 571.0 160.5 30.160.1

5.3.2.2 Bolted fuse links

Bolted type fuse links must be size B as stated in Figure 501 of IEC 60269-2:2013, utilisation

category gG (g-full range braking capacity, G-general application), 400Vac maximum rated current

400 Amp with maximum power dissipation 40W with the dimensions stated in Table 9.

Bolted fuse links must be suitable to use with outdoor crossarm mounted LV Line Isolating switch

fuse (crossarm mount) assembly and shall comply with IEC 60269-2:2013.

ETS 0071 UNCONTROLLED IF PRINTED Page 12 of 17

DISTRIBUTION FUSES Amendment No: 1

Figure 7: Bolted fuse links size B (refer to Figure 501 of IEC 60269-2:2013)

Table 9: Dimensions of bolted fuse links

Max

Fuse size Max power a b d e f g h j m

rated

Size selection dissipation (max) (max) (max) (max) (max) (max) (nom) (min) (max)

current

A W mm mm mm mm mm mm mm mm mm

A

B1 100 100,80 9.1 70 37 138 20 4 111 8.7 11 82

B2 200 200,160 17 77 42 138 20 4 111 8.7 11 82

B3 315 315,250 32 77 61 138 26 4.8 111 8.7 11 82

B4 400 400 40 83 66 138 26 6.6 111 8.7 11 89

5.3.2.3 Bolted solid links

Bolted solid links shall have a minimum current rating of 600A, and are suitable for use with

crossarm mount LV isolating switches. The solid links must be compatible with size B fuses

specified in IEC 60269-2:2013.

5.3.2.4 Blade contact fuse links (DIN fuses)

Blade contact size 2 fuses are also used in padmount and indoor substations. Specifications for

the fuse links are provided in clause 5.2.2. The fuse links must be suitable for use with outdoor

pole mounted LV ABC switches. Refer Table 10 for approved sizes.

5.3.2.5 Blade contact solid links

Blade contact solid links are specified in clause 5.2.4. The blade contact solid links must be

suitable for use with outdoor pole mounted LV ABC switches.

Table 10: Approved LV fuse categories and sizes for pole substations (outdoor use)

Fuse category Fuse size (Amp) Used with

Cylindrical fuse links Fuse holder-pole mount - two (2) sizes to fit

(service fuse) 22mm 63 either 22mm or 30mm fuse links

ETS 0071 UNCONTROLLED IF PRINTED Page 13 of 17

DISTRIBUTION FUSES Amendment No: 1

Fuse category Fuse size (Amp) Used with

dia. (refer Figure 6

and Table 8) 80

Cylindrical fuse links 63

(service fuse) 30mm

dia. (refer Figure 6

and Table 7) 80

100

.

Bolted, type B (refer 80 LV line isolating switch fuse - crossarm mount

Figure 7 and 100

Table 9) 160

200

250

315

400

LV line isolating switch solid links - crossarm

mount

600 (solid link)

Blade (DIN) fuse type ABC switch - pole mount

02 (refer Figure 4

and Table 4)

80

5.4 Testing

5.4.1 General

The manufacturer must provide two (2) copies of certified test reports for all type, routine and

special tests that are applied, to respective standard, to the various components during and on

completion of manufacture. Depending on the tests that are specifies in relevant standards,

Endeavour Energy may require additional tests to be conducted.

At any time during the supply of the equipment, Endeavour Energy may consider it necessary to

confirm any test results. These tests will initially be carried out at Endeavour Energys expense,

however, where it can be demonstrated that the equipment does not meet with the provided test

results, tests will be repeated in the presence of a suppliers representative. This and subsequent

tests will be at the suppliers expense.

ETS 0071 UNCONTROLLED IF PRINTED Page 14 of 17

DISTRIBUTION FUSES Amendment No: 1

Depending on the extent of these non-conformances, Endeavour Energy may remove or rectify

equipment already in service. In these cases, all costs will be at the suppliers expense.

5.4.2 Testing laboratories

The technical schedules and guarantees (together with a copy of each of the tests) shall be

completed and submitted to Endeavour Energy for evaluation.

All type tests shall be carried out by a testing authority holding accreditation:

by NATA Australia; or,

by an accreditation authority recognised by NATA Australia.

Tests from other testing authorities may be accepted at the discretion of the Manager Asset

Standards & Design

5.4.3 Type tests

Type tests to be conducted upon completion of the design, or following a change that affects the

performance. Required type tests for each category of fuses are listed in clause 5.4.6.

5.4.4 Routine tests

Routine tests will not usually be required; however it is the manufacturers responsibility to confirm

that all fuses supplied consistently meet the requirements of the relevant standards and this

specification.

5.4.5 Thermocouple locations

Where relevant, the thermocouple positions shall be:

All fuse contacts.

All fuse tags.

All accessible switch contacts.

All cable termination palms.

All external bolted connections (including transformer terminations).

With prior approval, thermocouples can be restricted to the switchgear components where the

temperature rise is expected to be most critical.

5.4.6 List of type tests

5.4.6.1 List of type tests for LV fuses

All tests specified are set out in clause 8.1.1 of IEC 60269-1:2014. The tests listed are the

minimum required.

General tests (to IEC 60269-1:2014)

Dimensions to comply with clause 8.1.4

Testing of fuse links to comply with clause 8.1.5.1 and as stated in table 7A

Verification of insulating properties to comply with clause 8.2

Verification of temperature rise and power dissipation at specified rated voltage and rated

current to comply with clause 8.3

Verification of operation to comply with clause 8.4

Additional tests for blade contact fuses (to IEC 60269-2:2013)

Impact resistance of gripping lugs to comply with clause 8.11.1.8

Verification of resistance to heat to comply with clause 8.9

ETS 0071 UNCONTROLLED IF PRINTED Page 15 of 17

DISTRIBUTION FUSES Amendment No: 1

5.4.6.2 List of type tests for HV fuses

Drop out fuses

The minimum tests required (to AS1033.1-1990):

Tests for time/current characteristics to comply with clause 5.7

Verification of spark production class (class A required) to comply with clause 3.1.4

Verification of speed class (class K required) to comply with clause 3.1.3

Verification of TRV rating (class 1 required) to comply with clause 3.1.2.

Breaking tests to comply with clause 5.6

If test results are available for verification of breaking capacity for combinations of the

manufacturers element with other manufacturers carriers, or vice versa, these must be supplied.

An indication should be provided of the suitability of the manufacturers elements for use with other

manufacturers carriers, or vice versa, along with a statement or guidelines on the mixing of the

manufacturers components with those of other manufacturers.

Powder filled - current limiting fuses

The minimum tests required (to AS 1033.2-1988):

Dielectric test to comply with clause 4.4

Temperature rise and power dissipation tests to comply with clause 4.5.

Breaking tests to comply with clause 4.6

Tests for time/current characteristics to comply with clause 4.7

Test of strikers to comply with clause 4.9

5.5 Quality assurance

Quality assurance certification is required to certify the manufacturers ability to design and

consistently manufacture fuses to this specification. The supplier and all its contractors shall have

a quality system which complies with the requirements of AS/NZS ISO 9001 or other comparable

Australian or International equivalent.

5.6 Approval process

5.6.1 Product approval and audit form:

In addition to all technical data, complete information on items shall be provided on Branch form

FAE 3161.

Product approval process:

Endeavour Energy will approve the equipment for use on the network. The product shall be

evaluated under the product approval process set out in PAE 1004.

5.7 Drawings

No drawings have been created for this specification.

6.0 AUTHORITIES AND RESPONSIBILITIES

General Manager Asset Management has the authority and responsibility for:

approving technical specifications, including any variations;

making all decisions concerning compliance in respect to this specification;

approving nominations of Endeavour Energy representative/s; and

ETS 0071 UNCONTROLLED IF PRINTED Page 16 of 17

DISTRIBUTION FUSES Amendment No: 1

delegating any of these authorities and responsibilities to the Manager Asset Standards &

Design.

Manager Asset Standards & Design has the authority and responsibility for:

reviewing this specification and making recommendations to the General Manager Asset

Management;

making recommendations concerning compliance in respect to this specification; and

making nominations of Endeavour Energy representative/s.

Network Substations Manager has the authority and responsibility for:

reviewing all test reports submitted and making recommendations to the Manager Asset

Standards & Design; and

clarifying all technical aspects of this specification to the stakeholders;

Protection Manager has authority and responsibility for reviewing power system protection

parameters and making recommendations to Manager Asset Standards & Design.

7.0 DOCUMENT CONTROL

Documentation content coordinator: Network Substations Manager

Documentation process coordinator: Branch Process Coordinator

ETS 0071 UNCONTROLLED IF PRINTED Page 17 of 17

Potrebbero piacerti anche

- EHV Catalogue PDFDocumento29 pagineEHV Catalogue PDFvineets058Nessuna valutazione finora

- 1959-Sag-Tension Calculation Program For Digital Computer by PickensDocumento8 pagine1959-Sag-Tension Calculation Program For Digital Computer by PickenscustomerxNessuna valutazione finora

- NS220Documento267 pagineNS220Victor IkeNessuna valutazione finora

- Sag Tension Report - 4pm 15th MayDocumento12 pagineSag Tension Report - 4pm 15th MayRakshit KumarNessuna valutazione finora

- ACSR Thermal Mechanical White PaperDocumento9 pagineACSR Thermal Mechanical White PaperleonardonaiteNessuna valutazione finora

- CIGRE 2008 A3-207 Int ArcDocumento10 pagineCIGRE 2008 A3-207 Int Arcdes1982Nessuna valutazione finora

- The Indian Electricity RulesDocumento2 pagineThe Indian Electricity Rulesdipakpani0550% (4)

- Ansi Tia 607 C 2015Documento92 pagineAnsi Tia 607 C 2015DamiánNessuna valutazione finora

- ManualDocumento56 pagineManualam02Nessuna valutazione finora

- Cable TerminationDocumento2 pagineCable TerminationElectrical RadicalNessuna valutazione finora

- DCB Disconnecting Circuit Breakers ABB Buyers and Application GuideDocumento48 pagineDCB Disconnecting Circuit Breakers ABB Buyers and Application GuideAnu Sun100% (1)

- REF Fuse Application GuideDocumento17 pagineREF Fuse Application GuidemuskanumeedNessuna valutazione finora

- RegthDocumento15 pagineRegthMohammedNessuna valutazione finora

- 24 - 400 - 220 - KV - SS HW PDFDocumento28 pagine24 - 400 - 220 - KV - SS HW PDFgaurang1111Nessuna valutazione finora

- Aster Tower Presentation V6Documento29 pagineAster Tower Presentation V6Shahir Ibrahimi100% (1)

- Code: Indian Electricity Rules / Central Electricity AuthorityDocumento5 pagineCode: Indian Electricity Rules / Central Electricity AuthorityAravindNessuna valutazione finora

- Transpowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-StrandedDocumento18 pagineTranspowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-Strandedravi474Nessuna valutazione finora

- Cross-Arms, Pins, and Pole Line HardwareDocumento20 pagineCross-Arms, Pins, and Pole Line HardwareIvan BolañosNessuna valutazione finora

- Transformer Losses AbbDocumento56 pagineTransformer Losses AbbJosé Ponce HuillcaNessuna valutazione finora

- Surge ArresterDocumento17 pagineSurge ArrestermoosuhaibNessuna valutazione finora

- Electric Power TransmissionDocumento42 pagineElectric Power TransmissionEarl Jay UayanNessuna valutazione finora

- Conductor Sag and Tension CalculatorDocumento11 pagineConductor Sag and Tension CalculatorSanjeev KumarNessuna valutazione finora

- Sag-Tension Calculation Program For Wood Pole Overhead LinesDocumento7 pagineSag-Tension Calculation Program For Wood Pole Overhead LinesTurinto MarjonoNessuna valutazione finora

- TransPowr ACSS Bare Overhead ConductorDocumento5 pagineTransPowr ACSS Bare Overhead ConductorHyrNessuna valutazione finora

- Why Is My Structure FailingDocumento14 pagineWhy Is My Structure Failingpakbilal1Nessuna valutazione finora

- 07 TT 01 Eskom Protection-SchemeDocumento3 pagine07 TT 01 Eskom Protection-Schemeakm-ntpcNessuna valutazione finora

- ACSR PAnether Stringing Upto 350 MtrsDocumento61 pagineACSR PAnether Stringing Upto 350 Mtrspsvsridhar100% (1)

- SBB Field Drawings - NEA (175008) PDFDocumento32 pagineSBB Field Drawings - NEA (175008) PDFOo Pen Dra100% (1)

- Support Structures: Substation Design InstructionDocumento9 pagineSupport Structures: Substation Design InstructionTony PedaNessuna valutazione finora

- Dist Distribution Substation EarthingDocumento15 pagineDist Distribution Substation Earthinglovedeep161Nessuna valutazione finora

- UniGear ZS3.2 Brochure Rev. B EN PDFDocumento8 pagineUniGear ZS3.2 Brochure Rev. B EN PDFbpchimeraNessuna valutazione finora

- 6 Pfisterer - General Product CatalogueDocumento7 pagine6 Pfisterer - General Product CatalogueSharafat AliNessuna valutazione finora

- Porcelain Long Rod Insulator Specification-WBSETCLDocumento13 paginePorcelain Long Rod Insulator Specification-WBSETCLSutirtha ChakrabortyNessuna valutazione finora

- Trench Shenyang TCVT 40.5-550 - ManualDocumento27 pagineTrench Shenyang TCVT 40.5-550 - ManualLong TranNessuna valutazione finora

- Temperature, Low-Sag (HTLS) ConductorsDocumento3 pagineTemperature, Low-Sag (HTLS) ConductorsApoorv TalatiNessuna valutazione finora

- Technical SpecificationDocumento14 pagineTechnical SpecificationbinodeNessuna valutazione finora

- Sie91093-T1000 PlusDocumento37 pagineSie91093-T1000 PlusRoyyan Hasmi FadhillahNessuna valutazione finora

- 3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPDocumento24 pagine3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPAnonymous 4kYNmixNessuna valutazione finora

- Hubbell - Connector Theory - Failure Modes & Practical ApplicationsDocumento30 pagineHubbell - Connector Theory - Failure Modes & Practical Applicationssulemankhalid100% (1)

- Requirements Transmission SystemDocumento20 pagineRequirements Transmission Systemgerrzen64Nessuna valutazione finora

- High Voltage Motors EN-1 PDFDocumento24 pagineHigh Voltage Motors EN-1 PDFRajiv VyasNessuna valutazione finora

- CAG14Documento8 pagineCAG14aja295Nessuna valutazione finora

- LA Condition MonitoringDocumento20 pagineLA Condition MonitoringPET MADAKKATHARANessuna valutazione finora

- Circuit BreakersDocumento48 pagineCircuit BreakerspitambervermaNessuna valutazione finora

- Insula at I On CoordinationDocumento72 pagineInsula at I On CoordinationKarthikeyan KNessuna valutazione finora

- Nxplus CDocumento172 pagineNxplus Cmurad musslumNessuna valutazione finora

- Transmission OPGW Fittings ClosuresDocumento20 pagineTransmission OPGW Fittings ClosuresARCC2030Nessuna valutazione finora

- Electrical Safety ClearanceDocumento6 pagineElectrical Safety Clearanceswanujay12Nessuna valutazione finora

- Breaker Failure Protection GuideDocumento40 pagineBreaker Failure Protection GuidesrinivasaphanikiranNessuna valutazione finora

- Abb Lightning Portection SystemDocumento52 pagineAbb Lightning Portection SystemMuddassir NiazNessuna valutazione finora

- Topraklama TestleriDocumento25 pagineTopraklama TestleriZiya KartalNessuna valutazione finora

- As NZS 5000.1 Standard For Earthing CableDocumento20 pagineAs NZS 5000.1 Standard For Earthing CableKamlesh VaishnavNessuna valutazione finora

- Auxiliary AC Supplies and Switchgear: Substation Design InstructionDocumento17 pagineAuxiliary AC Supplies and Switchgear: Substation Design InstructionJohan VargasNessuna valutazione finora

- Kbic ManualDocumento28 pagineKbic Manualsetyo wibowoNessuna valutazione finora

- ETS12-02-01 - LV Fuse LinksDocumento29 pagineETS12-02-01 - LV Fuse LinksTerex14253Nessuna valutazione finora

- Operation and Maintenance Manual For The 7200 Antenna Control SystemDocumento250 pagineOperation and Maintenance Manual For The 7200 Antenna Control SystemIrancell TellNessuna valutazione finora

- Piping and Equipment InsulationDocumento22 paginePiping and Equipment InsulationRampal Rahul Rampal RahulNessuna valutazione finora

- Manual SK 700EDocumento128 pagineManual SK 700EPruetikul WatanachaikulNessuna valutazione finora

- NPS - 002 - 022 Tech Specs For 66kV Power CablesDocumento14 pagineNPS - 002 - 022 Tech Specs For 66kV Power CablesandcrisdanmatNessuna valutazione finora

- KSS Catalog-EDocumento236 pagineKSS Catalog-EAnthonyNessuna valutazione finora

- Catalog Terminal Block JINHDocumento56 pagineCatalog Terminal Block JINHAnthonyNessuna valutazione finora

- PLC Industrial Control Board FX1N 20MRDocumento9 paginePLC Industrial Control Board FX1N 20MRAnthonyNessuna valutazione finora

- TeSys Deca Contactors - LC1D098GDDocumento3 pagineTeSys Deca Contactors - LC1D098GDAnthonyNessuna valutazione finora

- Catalog Connector JINHDocumento32 pagineCatalog Connector JINHAnthonyNessuna valutazione finora

- LC1E40M5: Lembar Data ProdukDocumento3 pagineLC1E40M5: Lembar Data ProdukAnthonyNessuna valutazione finora

- Catalog Cable Accessories JINHDocumento32 pagineCatalog Cable Accessories JINHAnthonyNessuna valutazione finora

- Steven: The Best Film DirectorDocumento2 pagineSteven: The Best Film DirectorAnthonyNessuna valutazione finora

- EasyPact TVS Contactors - LC1E1801M7Documento3 pagineEasyPact TVS Contactors - LC1E1801M7AnthonyNessuna valutazione finora

- L011283 - MT4414TE Spec SheetDocumento2 pagineL011283 - MT4414TE Spec SheetAnthonyNessuna valutazione finora

- EasyPact TVS Thermal Overload Relay - LRE35Documento3 pagineEasyPact TVS Thermal Overload Relay - LRE35AnthonyNessuna valutazione finora

- 0154 Introduction To Visual Studio and Csharp TutorialDocumento49 pagine0154 Introduction To Visual Studio and Csharp TutorialAnthonyNessuna valutazione finora

- Kalkulasi Creepage DistanceDocumento1 paginaKalkulasi Creepage DistanceAnthonyNessuna valutazione finora

- T Tahun Trend Forcasting Actual RatioDocumento1 paginaT Tahun Trend Forcasting Actual RatioAnthonyNessuna valutazione finora

- C50 1/16-Din Process Controller: Concise Product Manual - Im/C50Documento2 pagineC50 1/16-Din Process Controller: Concise Product Manual - Im/C50AnthonyNessuna valutazione finora

- NMi-11200858-01-CT Class 1 & 0.5S or B & C-1Documento76 pagineNMi-11200858-01-CT Class 1 & 0.5S or B & C-1AnthonyNessuna valutazione finora

- ABB ContactorDocumento226 pagineABB ContactorAnthonyNessuna valutazione finora

- Brochure Rockwool TOMBO Board 2015Documento8 pagineBrochure Rockwool TOMBO Board 2015AnthonyNessuna valutazione finora

- Is - Iec.60529.2001 IpDocumento15 pagineIs - Iec.60529.2001 IpAnthony0% (1)

- 4-PM - NH Fuse PDFDocumento2 pagine4-PM - NH Fuse PDFAnthonyNessuna valutazione finora

- 2017-033 - Silicone RubberDocumento1 pagina2017-033 - Silicone RubberAnthonyNessuna valutazione finora

- Production Flow ChartDocumento1 paginaProduction Flow ChartAnthony0% (1)

- Aksesoris Cold Shrink-1Documento1 paginaAksesoris Cold Shrink-1AnthonyNessuna valutazione finora

- Tool Kit Termination Termination Joint Joint Complete 3-Core 1-Core 3-Core 1-CoreDocumento1 paginaTool Kit Termination Termination Joint Joint Complete 3-Core 1-Core 3-Core 1-CoreAnthonyNessuna valutazione finora

- PTW-06 Electrical Work PermitDocumento3 paginePTW-06 Electrical Work PermitjayNessuna valutazione finora

- Workscope For The Installation of The 60MVA TransformerDocumento8 pagineWorkscope For The Installation of The 60MVA TransformerokemmaNessuna valutazione finora

- 1000v Solar Array Box Data Sheet 20161115Documento2 pagine1000v Solar Array Box Data Sheet 20161115Juan AdrianzenNessuna valutazione finora

- Unitronic Li2ycy TPDocumento2 pagineUnitronic Li2ycy TPSani PoulouNessuna valutazione finora

- How To Make A 50 Watt Small Homemade InverterDocumento111 pagineHow To Make A 50 Watt Small Homemade InverterMuhammad SalahuddinNessuna valutazione finora

- Pioneer Vsa-Ax10i-S rrv2689Documento30 paginePioneer Vsa-Ax10i-S rrv2689AUDIO DesignerNessuna valutazione finora

- Collage Plano Electrico YyzDocumento54 pagineCollage Plano Electrico YyzAlex Consuegra MedinaNessuna valutazione finora

- Sharp r-1874Documento20 pagineSharp r-1874Andre VPNessuna valutazione finora

- MB35 TrainingDocumento33 pagineMB35 TrainingNicu LiviuNessuna valutazione finora

- NTE7163 Intergrated Circut 4 X 40W Quad Bridge Car Radio AmplifierDocumento3 pagineNTE7163 Intergrated Circut 4 X 40W Quad Bridge Car Radio AmplifierdaneloNessuna valutazione finora

- SARS01Documento6 pagineSARS01Pablo AllosiaNessuna valutazione finora

- Components of Power GenerationDocumento3 pagineComponents of Power GenerationWyndellRioNessuna valutazione finora

- Invers or ChinaDocumento67 pagineInvers or Chinaand25skyNessuna valutazione finora

- Omron H3CA Timer DatasheetDocumento16 pagineOmron H3CA Timer DatasheetpumperNXNessuna valutazione finora

- MCQ in Vacuum Tubes Part 2 AnswerDocumento4 pagineMCQ in Vacuum Tubes Part 2 AnswerRolando CelesteNessuna valutazione finora

- Fauji Meat Limited: Breaker Size, Cable Size and Voltage Drop CalculationDocumento2 pagineFauji Meat Limited: Breaker Size, Cable Size and Voltage Drop CalculationAbdul RafaeNessuna valutazione finora

- EC2201 - Electrical EngineeringDocumento5 pagineEC2201 - Electrical EngineeringrgramachandranNessuna valutazione finora

- 200w Power SupplyDocumento4 pagine200w Power SupplySungyong SohnNessuna valutazione finora

- Circuit Diagrams Reduced Voltage StarterDocumento2 pagineCircuit Diagrams Reduced Voltage StarterRicky Ocktavi RizkyNessuna valutazione finora

- Top 12 Hex Inverter ICs - All You Should KnowDocumento13 pagineTop 12 Hex Inverter ICs - All You Should KnowjackNessuna valutazione finora

- Oscillator Test AnswersDocumento5 pagineOscillator Test AnswersNikhil Pratap GargNessuna valutazione finora

- Electrical Engineering Safety Final ExamDocumento2 pagineElectrical Engineering Safety Final ExamMarielle LopezNessuna valutazione finora

- Nec 250 Part X GroundingDocumento23 pagineNec 250 Part X Groundingvladimir rosas ayalaNessuna valutazione finora

- whirpool-MT 244-1-Black - Microondas PDFDocumento8 paginewhirpool-MT 244-1-Black - Microondas PDFjosenicolas12000Nessuna valutazione finora

- Bobcat 743 - Engine Electrical Circuitry (S - N 501914085 & Above) - 743Documento4 pagineBobcat 743 - Engine Electrical Circuitry (S - N 501914085 & Above) - 743CsabaNessuna valutazione finora

- SW1070 Installation ManualDocumento40 pagineSW1070 Installation ManualGabi RusNessuna valutazione finora

- 2 Datasheet Detector Tactil de Teclado TTP223Documento9 pagine2 Datasheet Detector Tactil de Teclado TTP223Carlos Roman ZarzaNessuna valutazione finora

- Transistor DatasheetDocumento4 pagineTransistor DatasheetpepiNessuna valutazione finora

- 2020 - Chapter-5 Loss Less Lines - ON LINE - A - 2 - No AudioDocumento28 pagine2020 - Chapter-5 Loss Less Lines - ON LINE - A - 2 - No AudioSherry KhanNessuna valutazione finora

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDa EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNessuna valutazione finora

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDa EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsValutazione: 4.5 su 5 stelle4.5/5 (12)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Solar Energy: Survive Easily on Solar Power Off the GridDa EverandSolar Energy: Survive Easily on Solar Power Off the GridNessuna valutazione finora

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDa EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNessuna valutazione finora

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningDa EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningValutazione: 5 su 5 stelle5/5 (4)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Global Landscape of Renewable Energy FinanceDa EverandGlobal Landscape of Renewable Energy FinanceNessuna valutazione finora

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadDa EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadValutazione: 4.5 su 5 stelle4.5/5 (10)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDa EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNessuna valutazione finora

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Thermal Power Plant: Design and OperationDa EverandThermal Power Plant: Design and OperationValutazione: 4.5 su 5 stelle4.5/5 (23)