Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Palm Oil Boom in Indonesia

Caricato da

Hotib PerwiraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Palm Oil Boom in Indonesia

Caricato da

Hotib PerwiraCopyright:

Formati disponibili

Clean 2008, 36 (5 6), 453 465 S. J.

Santosa 453

Sri Juari Santosa1

Review

1

Department of Chemistry, Faculty of

Mathematics and Natural Sciences, Palm Oil Boom in Indonesia: From Plantation to

Gadjah Mada University, Yogyakarta,

Indonesia. Downstream Products and Biodiesel

Indonesia has been the biggest producer of palm oil (PO) in the world since 2005. The

total production in 2007 was 17.0 and 1.9 million tons of crude palm oil (CPO) and

crude palm kernel oil (CPKO), respectively. More than 70% of the CPO was exported

and 87% of the domestic consumption was used for food. The production and subse-

quent refining and fractionation of CPO and CPKO generated biomass by-products

that consists of trunk, frond, empty fruit bunch (EFB), fiber, shell, and palm kernel

meal (PKM), and discharged wastes of palm oil mill effluent (POME) as well as palm

fatty acid distillate (PFAD). The amount of by-products and wastes produced has been

growing very rapidly and efforts to diversify and improve their utilization are a great

challenge. As claimed in many research reports, the by-products and wastes could be

potentially utilized as sources of energy, animal feed, chemicals, paper pulp,

advanced materials, medicines and food ingredients. A more important role may be

played by PO as the Indonesian Government took further steps in 2006 to become the

world's largest producer of biodiesel. As a starting point, Presidential Instruction No.

1/2006 for the Production and Use of Biofuel as Alternative Fuel was issued in January

2006. Responding to this Presidential Instruction, at least 15 companies are planning

to establish new larger biodiesel refineries to enhance the currently produced 82.5

million L of biodiesel. It is planned to start production in 2008/2009 with two new

refineries that have a total capacity of ca. 1,600 million L/year.

Keywords: Biodiesel; Biofuel; Indonesia; Palm kernel oil; Palm oil;

Received: February 20, 2008; revised: March 27, 2008; accepted: April 15, 2008

DOI: 10.1002/clen.200800039

1 Introduction Elaeis guineensis was originally grown in the humid tropics of

Africa, mainly in the coastal belt between 108 N latitude and 108 S

Oil palm trees (Elaeis) belong to the Arecaceae family and comprise latitude. Elaeis oleifera (also known as Elaeis melanococca) is frequently

two species, i. e., Elaeis guineensis and Elaeis oleifera. The Elaeis guineensis found at riversides or in swampy areas of tropical Central and South

is native to West Africa while Elaeis oleifera is native to tropical Cen- America. The oil obtained from Elaeis oleifera is used locally for cook-

tral and South America. ing, soap manufacturing, and lamp fuel, but the plant has not been

cultivated on a commercial scale previously. For commercial pur-

poses, the tropical countries in Central and South America grew

Correspondence: Prof. S. J. Santosa, Department of Chemistry, Faculty of

Mathematics and Natural Sciences, Gadjah Mada University, Sekip Utara Elaeis guineensis, which was first introduced to Guatemala from

Kotak Pos Bls. 21, Yogyakarta, Indonesia. Sierra Leone in 1920, from Malaysia to Panama in 1926 and Hondu-

E-mail: sjuari@yahoo.com ras in 1927, and later other introductions were from Java (Indone-

sia) and Congo [1]. As a result, Elaeis guineensis is now spreading

Abbreviations: BPPT, Agency for Assessment and Application of Tech-

nology; CNO, coconut oil; CNOOC, China National Offshore Oil Corp.; throughout the tropical regions in the world with countries such as

COD, chemical oxygen demand; CPKO, crude palm kernel oil; CPO, Indonesia and Malaysia being the main producer of palm oil (PO)

crude palm oil; EFB, empty fruit bunch; EU, European Union; FFA, free from Elaeis guineensis. In addition to Indonesia and Malaysia, Thai-

fatty acid; FFB, fresh fruit bunches; HDL cholesterol, high-density lipo-

land and Papua New Guinea are the other important PO producers

protein cholesterol; LDL cholesterol, low-density lipoprotein cholester-

ol; Lemigas, Center for Oil and Gas Technology; MSG, monosodium glu- in Southeast Asia. Nigeria, Congo, The Ivory Coast, and Cameroon

tamate; NAD, Nanggroe Aceh Darussalam; NSP, non-starch polysaccharide; are important countries producing PO in Africa, while Colombia,

Pertamina, state-owned petroleum industry; PFAD, palm fatty acid dis- Ecuador, Honduras, and Costa Rica are the main PO producers in

tillate; PHA, polyhydroxyalkanoate; PIR, Perkebunan Inti Rakyat; PKM,

America.

palm kernel meal; PO, palm oil; POME, palm oil mill effluent; ppm, part

per million; PTP, PT Perkebunan; RBDP olein, refined, bleached, and deo- PO has been an important commodity for thousands of years. It

dorized palm olein; RBDP stearin, refined, bleached, and deodorized may have been traded in Egypt, since archaeological evidence indi-

palm stearin; RBDPK olein, refined, bleached, and deodorized palm ker- cated that PO was most likely available in ancient Egypt. The excava-

nel olein; RBDPK stearin, refined, bleached, and deodorized palm kernel

tion of an early tomb dated to 3000 B.C. at Abydos, revealed a mass

stearin; RBDPKO, refined, bleached, and deodorized palm kernel oil;

RBDPO, refined, bleached, and deodorized palm oil of several kg of palm oil in a vessel. Even before the first civilizations

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

454 S. J. Santosa Clean 2008, 36 (5 6), 453 465

appeared in Africa, PO was eaten by populations living along the

coast between Senegal, Angola and the Congo River basin. In

Europe, PO became more widely used during the Industrial Revolu-

tion and was utilized as grease and to produce soaps, candles and

lubricants. In addition, kernel husks recovered from the remaining

chaff of the palm fruit were used as cattle feed during the industrial

revolution [1].

2 Oil Palm Plantation

The oil palm was first introduced to Southeast Asia in 1848, when

four seedlings were brought from Nigeria by the Dutch and planted

in the botanical gardens at Buitenzorg (now Bogor, West Java). For

some years, this introduction did not lead to a plantation industry

but only involved ornamental purposes [2]. Later, four seedlings

from Bogor were cultivated in Deli (East Sumatera) and it was Figure 1. Expansion and annual growth of oil palm plantations in Indone-

noticed that the trees grew more quickly and bore a richer fruit sia from 1985 to 2007.

than their counterpart in West and Central Africa. This superiority

probably reflected the more optimal soils, rainfall, and sunshine

palm area after 1975 was a result of both the state-owned companies

conditions for the oil palm in Southeast Asia than in its original

and in addition, smallholders and private (both foreign and domes-

home.

tic) companies [6].

Malaysia was the world's biggest PO producer in the 1970s. In the

1980s, with the availability of much larger areas of land for oil palm

2.1 Plantation Area

plantation and a cheaper work force, Indonesia set a target to over-

The relatively high yields and low risks involved in planting oil take Malaysia as the main worldwide producer of PO. To achieve

palm in Deli inspired traders to commercially plant oil palm in this target, the government handed out vast areas of land to both

Southeast Asia. Using the seedlings from the Deli palms, the first foreign investors and domestic business groups for oil palm planta-

large-scale oil palm plantation was set up by the Dutch trader Hallet tions. These plantations were not only limited to the traditional

in Sumatra, which was followed by a plantation by his friend Fau- areas in Sumatera but also new areas in the eastern part of Indone-

connier in Malaya in the 1910s. By 1919 more than 6,000 ha had sia. As a result, the plantation area expanded from 176,408 ha in

been planted in Sumatra and this figure rose to 32,000 ha by 1925. 1979 to 630,000 ha in 1985. However, the target to supersede Malay-

Over the next five years, the coverage of oil palm plantations in sia as the leading PO producer was still not achieved until the

Sumatra was doubled [1]. PO produced in the 1930s to 1940s was 1990s.

restricted mainly for use as a lubricant [3]. Until recently there were The fact that the domestic and world demand for vegetable oil

three types of oil palm, namely dura, pisifera, and tenera planted in including PO grew rapidly, coupled with the need for biofuel as a

Indonesia [4]. Tenera is the most widely cultivated palm in the world substitute for fossil fuels with their decreasing reserves and produc-

because it gives the highest yield of oil per ha [5]. tion, has again accelerated the expansion of oil palm plantations in

After Indonesia proclaimed and gained its independence in 1945, Indonesia. From 630,000 ha in 1985, the plantation area had

the Dutch plantation system collapsed, and all of the colonial plan- increased to 1,117,000 ha in 1990, doubled again in 1991, and

tations were nationalized and placed under the control of Perusa- became three, four, five, six, seven and nine times larger in 1994,

haan Perkebunan Negara (the State Plantation Company) in 1957. 1997, 2000, 2002, 2004, and 2006, respectively, Fig. 1. In 2007, the

Until the end of the Orde Lama (Old Order) regime in 1967, the oil plantation area reached 6.65 million ha or more than ten times

palm plantations covered an area of no more than 106,000 ha, greater than that in 1985.

including 65,573 ha of state-owned plantations [3]. The annual growth of oil palm plantation area from 1986 to 1997

The change of regime from Orde Lama to Orde Baru (New Order) tended to increase from 12 to 14%, see Fig. 1. The growth then fell to

also led to changes in the policies for the oil palm sector. The gov- 5% just after the Asian financial crisis in 1997 to 1998 and gradually

ernment in this New Order era actively expanded the oil palm plan- increased again during the Reformation Era which replaced the

tations, primarily in North Sumatera to reach 176,408 ha in 1979 Orde Baru in 1998. In the last two years, the growth has sharply

through direct investment via the state-owned company PT Perke- increased to 15 and 19% in 2006 and 2007, respectively. These sharp

bunan (PTP). When the price of PO in the international market was expansions in 2006 and 2007 were driven by the efforts of govern-

exceptionally high in 1974, efforts were made to increase the PO ment to accelerate the development of biofuel from PO after Indone-

production. For this purpose, the government established a scheme sia became a net oil importer in July 2004 [7].

known as Perkebunan Inti Rakyat (PIR) or Nucleus Estate and Small- The accelerated increase in oil palm plantation area also yielded

holder, where the state-owned companies provided seedlings, tech- an increase of mature oil palm plantation. From the financial crisis

nical assistance and finance to smallholders. Their crops were then to 2007, the mature oil palm area increased from 1.83 to 4.39 mil-

purchased by companies' mills [6]. With this PIR scheme, the oppor- lion ha, see Fig. 2. The mature plantation constituted 64% of the

tunity for smallholders (farmers) to possess their own mills was total plantation area in 1998 and reached 76% in 2005. Since 2005,

opened. As a result, more and more farmers and small companies the portion of mature oil palm to the total plantation has decreased

were attracted to cultivate oil palm, and therefore, the growth of oil because of the vast expansion of new oil palm plantations in 2006

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Clean 2008, 36 (5 6), 453 465 Palm Oil Boom in Indonesia 455

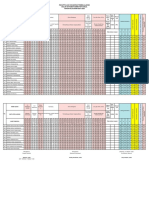

Table 1. Private estates involved in oil palm plantation projects in 2007.

No. Estate Area (103 ha)

1 Salim group 1155.6

2 China National Offshore Oil Corp. (CNOOC) 1000.0

3 Sinar Mas 320.5

4 PBB Oil Palm Bhd 274.8

5 Raja Garuda Mas 259.1

6 London Sumatera 245.6

7 Wilmar Holding 210.0

8 Astra Group 192.4

9 Sampoerna Agro 170.0

10 Surya Dumai Group 154.1

lion ha in 2020. The vast extension will be implemented in West

Kalimantan, Riau, and Papua Provinces with 5, 3, and 3 million ha,

respectively, followed by North Sumatera, Central Kalimantan,

South Sumatera, Jambi, and East Kalimantan Provinces with 1 mil-

lion ha each. Smaller extensions will also be implemented in West

Sumatera, South Kalimantan, Lampung, South Sulawesi, Bengkulu,

Figure 2. Mature oil palm area and its proportion of the total area under Nanggroe Aceh Darussalam (NAD), Central Sulawesi, South East

palm. Sulawesi, and Bangka Belitung Provinces. The only areas where

extension prospects are not available are Banten and West Java Prov-

and 2007, as shown in Fig. 1. From 2007 to 2012, the total area for inces. In summary, the order of oil palm plantation by province

oil palm will be enlarged from 6.65 to 8.90 million ha, and the from the largest to the smallest in 2012 will be West Kalimantan,

mature oil palm area is also estimated to increase significantly, see Riau, Papua, North Sumatera, Central Kalimantan, South Sumatera,

Fig. 2. Jambi, East Kalimantan, West Sumatera, South Kalimantan, Lamp-

ung, South Sulawesi, Bengkulu, NAD, Central Sulawesi, South East

Sulawesi, Bangka Belitung, Banten and West Java, see Fig. 3.

2.2 Plantation by Company

As described earlier, during the Orde Lama, the state-owned company 3 Production, Consumption and Export

dominated the oil palm plantation business. Privatization by small-

holders (farmers) occurred during the PIR scheme starting in 1975 Nigeria, Malaysia, and Indonesia are the countries that consecu-

and was conducted by the government in Orde Baru, and eventually, tively occupy the position as the biggest PO producer in the world.

the privatization of large estates was implemented predominantly Nigeria became the world's biggest PO producer in the 1960s. In

by later governments in the Reformation Era. From 5.6 million ha 1970, the PO production of Malaysia surpassed that of Nigeria, while

of oil palm plantations in 2006, the proportions of large private Indonesia was in third position. In that year, the production of PO

estates, smallholders, and state-owned company involvement were in these three countries was 598, 432, 248 thousand tons for Malay-

ca. 50, 33, and 17%, respectively [6]. The portion of large private sia, Nigeria, and Indonesia, respectively, see Fig. 4. Malaysia was

estates in 2007 was more than 50%, since from a total oil palm plan- able to maintain its leading position until 2004 before being over-

tation area of 6.65 million ha, 3.98 million ha was run by these taken by Indonesia in 2005. The proportion of PO production in

estates. The breakdown of private estates involved in oil palm plan- 2005 by the two countries was 15.0 million tons for Indonesia and

tation projects in 2007 is summarized in Tab. 1. The largest estates 14.8 million tons for Malaysia. The sharp increase of PO production

were the Salim Group and China National Offshore Oil Corp. in Indonesia began just after the financial crisis in the mid 1990s,

(CNOOC) with plantation areas of 1.16 and 1.00 million ha, respec- see Fig. 4. In 1998, the production of PO was 5.8 million tons and

tively. Other estates, i. e., Sinar Mas, PBB Oil Palm Bhd., Raja Garuda this has jumped to 17 million tons in 2007. This was caused by the

Mas, London Sumatera, Wilmar Holding, Astra Group, Sampoerna fact that in that period, the oil palm plantation area was expanded

Agro, and Surya Dumai Group are running plantation areas of 0.32, extensively and most of these palms (> 64%) had reached maturity

0.27, 0.26, 0.25, 0.21, 0.19, 0.17, and 0.15 million ha, respectively. to give a maximum production yield.

The latest news indicates that the Astra Group will expand its oil While Indonesia has cheaper labor and copious quantities of land

palm plantations in Sumatera, Kalimantan, and Sulawesi to give a compared to Malaysia, it still lacks the capital and technical know-

combined total of 0.26 million ha in 2008 [8], and a new player, i. e., how to maximize these advantages. This fact was proven by the fact

PT. Pupuk Kaltim will also enter the PO business by running 20,000 that nearly 25% of Indonesia's current crude palm oil (CPO) produc-

ha in 2008 [9]. tion is derived from Malaysian investment. Indonesian nationalists

As mentioned above, the ambition of the Indonesian government have long complained that Indonesia served as merely a source of

to be the world's largest PO producer was achieved in 2005, and now raw material and cheap labor for Malaysia's better-funded, more

their ambition is to become the world's largest biofuel producer. sophisticated and considerably more profitable operations [10].

Efforts to reach this ambition involve pursuing the further expan- From 1965 to 1977, the PO produced by Indonesia was mostly for

sion of the oil palm plantation area. This expansion that is planned export, Fig. 5. With the increasing demand for domestic consump-

to reach 8.90 million ha in 2012 will be extended again to 26.07 mil- tion, which has still not been accompanied by increased levels of

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

456 S. J. Santosa Clean 2008, 36 (5 6), 453 465

Figure 3. The existing and planned exten-

sion of oil palm plantation area by province in

Indonesia.

Figure 4. Palm oil production of Indonesia, Malaysia, Nigeria, and other Figure 5. Exported and domestic consumption of palm oil in Indonesia

countries. from 1965 to 2005.

production due to the oil palms that were newly planted, the fried foods. There are many varieties of fried foods in Indonesia, and

domestic consumption balanced the export requirements in the nearly all these foods need oil for their preparation.

period between 1977 and 1998. After 1998, with aggressive expan- India was the main CPO importer in the world in 2003/2004, fol-

sion of oil palm plantations and the dominance of mature planta- lowed by the European Union (EU), China, and Pakistan [12]. These

tions, exports once again significantly surpassed domestic con- countries were also the destination for Indonesian CPO export, see

sumption. The exported PO consists of crude and processed PO. The Fig. 6. With a total export of CPO worth 2.35 billion US$ in 2003, the

proportion of these products to the total exports from 2002 to 2005 export of CPO to India accounted for 37.7%, followed by that to

is listed in Tab. 2 [6]. It appears that the contribution of the proc- China (15.0%), The Netherlands (8.7%), Malaysia (7.5%), Singapore

essed PO to exports is higher than that of CPO. In addition to PO, (5.5%), and Pakistan (5.0%). The remaining CPO was exported to the

Indonesia also exports palm kernel oil (PKO). Unlike the PO, the USA, Germany, Italy, Egypt, Bangladesh, and Saudi Arabia. Total

crude palm kernel oil (CPKO) makes a greater contribution to the exports consisting of 2.35 billion US$ were achieved in 2003 from

total export than the processed oil. Europe typically buys 61% of 2.89 million ton of CPO, since the price of CPO at that time was US$

Indonesia's exports of PKO, primarily for use in cosmetics, and 87% 813/ton. Today, the price of CPO has climbed to US$ 915/ton, follow-

of Indonesia's exports of palm kernel meal (PKM), which is used in ing the price of petroleum, which has exceeded US$ 100/barrel [13].

animal feed [11]. The domestic consumption of PO is mostly for food The recent growth in consumption of edible oil in India, i. e.,

and more precisely, for frying oil. This accounts for 87% of total from 700 to 800 million tons, is twice that of its production growth

domestic consumption in 2005, while the domestic consumption capacity. Approximately 80% of CPO imports into India are origi-

for industry was only 11%. Indonesian people are accustomed to nally from Indonesia [13]. As a competitor of India in consuming

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Clean 2008, 36 (5 6), 453 465 Palm Oil Boom in Indonesia 457

Table 2. Export of palm and palm kernel oils from Indonesia for 2002 to 2005.

Year Palm oil (106 ton) Palm kernel oil (103 ton)

Crude Processed Total Growth (%) Crude Processed Total Growth (%)

2002 2.81 3.53 6.34 595 143 738

2003 2.89 3.49 6.38 0.95 523 137 660 10.57

2004 3.82 4.84 8.66 35.52 706 198 904 36.97

2005 4.54 5.76 10.30 18.94 770 230 1000 10.62

Figure 6. Main exports (higher than 100

million US$) of Indonesian crude palm oil

(CPO) by country in 2003.

edible oil, China raised its import of CPO to 3.34 million tons during [14]. The empty bunches are then sent to the boiler station to be

the last nine months of 2007. This represents a 4.4% increase com- used as fuel, see Fig. 7. Before the oil palm fruits are extracted to

pared to the same period in 2006. The import of China's CPO is cur- yield their oil content, they are first reheated in a steam-heated ket-

rently mainly from Malaysia and Indonesia. tle to loosen the mesocarp. The extraction is typically performed by

pressing with a screw-type press to release the oil. The rate of oil

extraction averages between 21 and 23%. The extracted oil contains

water and impurities originating from the mesocrap and other veg-

4 Processing, Refinery and Product etable materials. The oil is then purified to remove the water and

Utilization impurities to produce CPO. The water and the impurities are first

removed by settling and centrifugation, and then the dissolved

Oil palm is harvested as fresh fruit bunches (FFB) throughout the water in the oil is removed by vacuum evaporation. Good clarifica-

year. The normally expected range of production varies between 20 tion should produce PO with a moisture content of 0.08% and

to 25 tons of FFB per hectare, depending on genetic characteristics impurities of 0.02%, which is then suitable for export [6].

and cultivation practices. The FFB is brought by trucks or other The cake produced as a residue of the oil extraction consists of

modes of transport to the PO mills. The oil palm fruit composes of nuts and fibers. It is transported by the screw-type cake breaker con-

mesocarp in the outer part, which contains PO, and kernel with veyor to a separating column and fiber cyclone where the nuts are

hard shell in the inner part, which contains PKO. separated. After sufficient drying, the nuts are fed into a nut cracker

and the mixture of kernels and shells exiting this nut cracker is sep-

arated by use of a winnower and hydro-cyclone. The kernels are

4.1 Processing then dried using steam so that the water content is reduced to 7%

The FFB have to be processed within 24 h or otherwise free fatty [6]. The fiber and shell by-products are used as fuel for the boiler sta-

acids will be built-up rapidly due to the action of fat splitting tion. Before 1980, oil palm in Indonesia was only processed to pro-

enzymes in the mesocarp. In order to avoid the action of the duce CPO and kernel, and by-products of empty bunch, fiber, and

enzymes, the FFB must be sterilized by steaming at a pressure 3 kg/ shell for use as fuels for the boiler stations. All CPO and kernel were

cm2 and then the fruits are separated from the bunch stalk [6]. This directly exported, since there was no kernel crushing plant or refin-

separation process following the sterilization is known as stripping ery plant for CPO and CPKO in Indonesia.

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

458 S. J. Santosa Clean 2008, 36 (5 6), 453 465

tralize free fatty acids that may develop a rancid taste due to their

reaction with oxygen in the air. Bleaching is used to remove color

and dissolved impurities. An adsorbent such as zeolite may be

employed for this purpose. Deodorizing is performed to remove any

smell and taste in the oil. This is achieved by blowing steam through

the heated oil and a vacuum draws off the steam along with the

smells and tastes [3].

Through neutralization, bleaching, and deodorizing, a refined,

bleached, and deodorized palm oil (RBDPO) is obtained from CPO

and palm fatty acid distillate (PFAD) is produced as a by-product.

RBDPO is a light yellow liquid or semi-solid at room temperature. It

is used for industrial frying oil, margarines, shortenings, ice cream,

condensed milk, soap, and other products [3]. In the case of PFAD, it

is a light brown solid at room temperature, which melts to a brown

liquid on heating. PFAD is used in the soap and animal feed indus-

tries as well as a raw material for oleochemical industries. Vitamin

E can be extracted from PFAD [15].

As with most other vegetable oils, POs in its original condition

have a limited application. Hence, their properties need to be modi-

fied in order to extend their range of utilization. Fractionation is

the most common secondary process undertaken in most oil refin-

eries. This means that the PO is cooled under controlled conditions,

separating the high melting point components in the oil from the

low ones. This separates a clear yellow liquid at room temperature,

named as a refined, bleached, and deodorized palm (RBDP) olein

from a white solid at room temperature named as RDBP stearin.

Figure 7. Current process operation and products of palm oil mills and RBDP olein and RBDP stearin are used for different end-products.

kernel crushing plants in Indonesia. RBDP olein for edible applications is sold as cooking oil, used in the

manufacture of margarines and shortenings, and in the industrial

frying of processed foods. RBDP stearin for edible uses is used for

4.2 Refinery and Product Utilization margarines and shortenings, a source for producing specialty fats

for coatings in confectionery, and for non-edible uses, in the soap

Kernel crushing plants as well as CPO and CPKO refineries were and oleochemical industries [3].

established in the 1980s. Since then, CPKO and palm kernel meal As for PO, the refining of CPKO firstly yields refined, bleached,

(PKM) have been domestically produced, see Fig. 7, and various and deodorized palm kernel oil (RBDPKO). A portion of the RBDPKO

downstream products of CPO and CPKO have also been generated, is fractionated into RBDPK olein as the liquid component and

see Fig. 8. While the average rate of oil extraction from mesocarp is RBDPK stearin as the solid component. RBDPKO is used in edible

between 21 and 23%, the average rate of extraction from kernel is applications, e. g., in the production of margarine and shortenings

only between 4.5 and 5.5%. PKM as a by-product of CPKO is currently and in non-edible areas, e. g., soaps, detergents, etc. RBDPK olein is

discarded due to its grittiness. In addition to PKM, palm oil mill commonly used as cooking and frying oil and as the base oil for the

effluent (POME) is generated as waste. To date, POME is only dis- manufacturing of margarine. The applications in non-edible fields

carded to ponds or used as landfill filler. include its use in the production of soaps, shampoos, detergents,

The refining of CPO and CPKO primarily consists of neutraliza- cosmetics, and lubricants [3]. RBDPK stearin is widely used to substi-

tion, bleaching, and deodorizing. Neutralization is required to neu- tute for the more expensive cocoa butter in many of its traditional

Figure 8. Downstream products obtained

from crude palm oil (CPO) and crude

palm kernel oil (CPKO).

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Clean 2008, 36 (5 6), 453 465 Palm Oil Boom in Indonesia 459

Table 3. Major chemical constituents of palm and palm kernel oils (compiled from [3, 5], www.chemblink.com, www.inchem.org/documents/icsc/icsc/

eics530.htm, http://palmoilis.mpob.gov.my/publications/pod35-pantzaris.pdf), www.sjlipid.com, http://en.wikipedia.org).

Constituent IUPAC* Name Molecular Physical Property Content

Formula (%)

Melting Boiling Density Palm Palm Ker-

point (8C) point (8C) (g/cm3) Oil nel Oil

Caproic acid Hexanoic acid CH3(CH2)4COOH 3 202 203 0.920 0.3

Caprylic acid Octanoic acid CH3(CH2)6COOH 16 17 237 0.910 4.2

Capric acid Decanoic acid CH3(CH2)8COOH 31 269 0.893 3.7

Lauric acid Dodecanoic acid CH3(CH2)10COOH 44 46 298 0.880 0.2 48.7

Myristic acid Tetradecanoic acid CH3(CH2)12COOH 58.8 326 0.862 1.1 15.6

Palmitic acid Hexadecanoic acid CH3(CH2)14COOH 63 64 351 352 0.853 44.1 7.5

Stearic acid Octadecanoic acid CH3(CH2)16COOH 69.6 383 0.847 4.4 1.8

Oleic acid (9Z)-octadec-9-enoic acid CH3(CH2)7CH=CH(CH2)7COOH 13 14 360 0.895 39.0 14.8

is-9-octadecenoic acid

Linoleic acid (Z)-9,12-octadecadienoic acid CH3(CH2)4CH=CH(CH2)CH=CH(CH2)7COOH 5 229 0.900 10.6 2.6

Cia,cis-9,12-octadecadienoic (16 mmHg)

acid

Others 0.8 0.1

* International Union of Pure and Applied Chemistry

applications. In some instances, RBDPK stearin exhibits perform- mainly of palmitic acid, (1) and glycerol, (2), as well as a mixture of

ance superior to that of cocoa butter. azelaic, (3) and pimelic acids, (4). The latter compounds are normal

For certain purposes such as in manufacturing margarines, short- oxidation products of fatty acids. As will be described later, palmitic

enings, fats, cocoa butter substitute, and other food ingredients for acid is the most dominant fatty acid in PO. Hence, the analyst con-

baking, chocolate, confectionery, ice cream, snacks, and biscuits, cluded that the original material was probably PO, partly hydro-

further processes such as hydrogenation and rearrangement (inter- lyzed and oxidized during its long storage [1].

esterification) are required. In hydrogenation, hydrogen is added to

unsaturated fatty acids to convert them to saturated fats, and hence,

to increase the oxidative stability and melting point of the oils.

Depending on the extent of hydrogenation, the oils and fats can be (1)

modified to yield products of varying degrees of hardness, thus giv-

ing a wider range of utilization. Rearrangement (interesterification)

is a process that alters the distribution of fatty acids in the glycerol

moiety of the triglyceride, thus producing fats with different melt- (2)

ing and crystallisation characteristics compared to the non-interes-

terified fat [16].

5 Chemical Composition and Product (3)

Diversification

Oil palm is the most productive tree for producing oil. One hectare

of oil palm may yield 3.7 tons of CPO. This value is much higher

than that of rapeseed, sunflowers, soybeans [2], coconuts, jojoba,

peanuts, and sesame seeds [17].

(4)

5.1 Chemical Composition

As described before, the oils from oil palm can be extracted from In spite of the fact that PO and PKO only originate from different

the mesocarp and kernel. CPO is obtained from the mesocarp, while parts of the same fruit, but they are highly different in their major

CPKO is removed from the kernel. The by-products of oil extraction chemical composition, see Tab. 3. PO is rich in saturated palmitic

include EFB, fiber, shell, PKM, and POME. In the refinery plant, acid, followed by monounsaturated oleic acid and di-unsaturated

RBDPO, RBDPKO, RBDP olein, RBDPK olein, RBDP stearin, and linoleic acid. Since its proportion of unsaturated fatty acids is some-

RBDPK stearin are obtained with PFAD as the by-product. what higher than saturated ones, PO is relatively unstable towards

oxidation. On the other hand, PKO is richest in saturated lauric acid

5.1.1 Palm and Palm Kernel Oils (49%), followed by saturated myristic acid (16%) and monounsatu-

PO has likely been an important commodity even in the times of the rated oleic acid (15%). The domination of long chain saturated fatty

Pharaohs in ancient Egypt. A chemical analysis of a sample of the acids in PKO makes PKO stable towards oxidation and gives it sharp

tomb at Abydos, dated to 3000 B.C., found that the sample consisted melting properties. Since the long-chain saturated fatty acids are

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

460 S. J. Santosa Clean 2008, 36 (5 6), 453 465

solid at room temperature, the fractionation of PKO yields RBDPK

stearin as the major fraction. From the point of view of fatty acid

composition, PKO is very similar to coconut oil (CNO). Among the 17

major oils and fats in use for world trade, PKO and CNO are the only (7)

two vegetable oils enriched in lauric acid [18].

Saturated fatty acids such as lauric, myristic, and palmitic acids

had been claimed by the WHO in 2003 to have effects such as

increasing blood cholesterol and total to high-density lipoprotein

(HDL) cholesterol ratio levels, with a concomitant increase in the

risk of coronary heart disease [19]. This claim by the WHO was con-

tested by Chu-Sing [20] who cited many research outcomes showing

Squalene, (8), is a biochemical precursor to the entire family of

that PO intake increased the levels of HDL cholesterol (good choles-

steroids. Oxidation of its terminal double bond yields 2,3-squalene

terol) and reduced the levels of low-density lipoprotein (LDL) choles-

oxide which undergoes enzyme-catalyzed cyclization to produce

terol (bad cholesterol) in the blood.

lanosterol, followed by cholesterol and other steroids.

As mentioned above, in order to meet the desirable texture and

stability, unsaturated fatty acid dominated oil must be processed by

hydrogenation. Hydrogenation not only transforms unsaturated

(8)

fatty acids to saturated ones but also generates unnatural monoun-

saturated trans-fatty acids. It is claimed that the consumption of

mono trans-fatty acids increases harmful LDL cholesterol levels in

the blood.

The improvement of stability achieved for unsaturated fatty acids Vitamin A exists in several forms. The major form is an alcohol

is not so important for the saturated fatty acid dominated PKO. As a form of retinol, (9). It can also exist as an aldehyde (retinal) or as an

result, the risk of monounsaturated trans-fatty acid formation is acid (retinoic acid). Vitamin A is an essential human nutrient.

absent. Therefore, PKO may be heated without the risk of creating

harmful trans-fatty acids. This makes PKO more acceptable for use

in edible applications and justifies its generally higher price com-

pared with most other oils. In addition to fatty acids as the major (9)

component, PO also contains ca. 1% of minor substances such as

phospholipids, b-carotene, ubiquinone, squalene, vitamin A, and

vitamin E, etc. [21, 22]. As summarized from various sources by May

[23], the concentration of these minor components in CPO is typi-

cally in the range of tens to hundreds of parts per million (ppm).

Phospholipids, (5), function as antioxidant synergists and as a sur- Vitamin E is a series of compounds consisting of methylated phe-

face active agent to disperse impurities in oil. b-carotene, (6), is also nols. Natural vitamin E may exist in eight different forms, i. e., four

an anti-oxidant and can be used to sequence damaging free radicals tocopherols and four tocotrienols. All of them can donate a hydro-

in the body. It is the substance responsible for the reddish color of gen atom to reduce free radicals such that they are good anti-oxi-

PO. Unfortunately, this substance is unstable at elevated tempera- dants. Natural tocotrienols exist in four different isomers, i. e., a-, b-,

tures. c-, and d-tocotrienol, (10), and Tab. 4. Tocotrienols have also anti-can-

cer effects, especially against skin and breast cancers. The three ali-

phatic unsaturated bonds are responsible for this effect. In addition

to anti-oxidant and anti-cancer efficacy, many studies have demon-

(5) strated that tocotrienols have amazing beneficial health effects,

e. g., lowering of blood cholesterol levels, regression of atheroscler-

otic plaques in stroke patients, inhibition of the entry of white

blood cells into arterial walls to become devouring phagocytes,

Type of phospholipids where R1 and R2 are alkyl chains.

thereby preventing early plaque formation, inhibition of blood clot

formation in the bloodstream (anti-thrombotic effect), and protec-

tion of skin from damage by the ultra-violet rays of the sun [24].

(6)

Ubiquinone, (7), is a substance responsible for the production of

the body's own energy. This substance is also known as coenzyme Q

in which Q refers to the quinone chemical group. In each human (10)

cell, food energy is converted into energy in the mitochondria with

the aid of coenzyme Q. Therefore, high concentrations of coenzyme

Q are found in organs having high energy requirements, e. g., the

heart, liver, and lungs.

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Clean 2008, 36 (5 6), 453 465 Palm Oil Boom in Indonesia 461

Table 4. The structure of the four different isomers of tocotrienol with their 5.1.3 Refined, Bleached, and Deodorized Palm and Palm

associated R-groups. Kernel Oils

No Type R1 R2 R3 The major constituents of RBDPO and RBDPKO should be similar to

those of CPO and CPKO, respectively. Since the impurities are

1 a-tocotrienol CH3 CH3 CH3 removed during the refining of CPO and CPKO to RBDPO and

2 b-tocotrienol CH3 H CH3 RBDPKO, the proportion of fatty acids as the main component will

3 c-tocotrienol CH3 CH3 H

4 d-tocotrienol CH3 H H be somewhat enhanced in RBDPO and RBDPKO than their precur-

sors.

Unlike the major constituents, the proportion of minor constitu-

ents may be considerably changed after the refining. Minor compo-

Table 5. Ash and major elemental composition of empty fruit bunch

(EFB), fiber, and shell (dry basis). nents such as b-carotene, ubiquinone, squalene, vitamin A, and vita-

min E are generally sensitive to treatment such as bleaching. b-caro-

Element Contents (%) tene can be thermally degraded to hydrocarbons and removed by

the deodorization step in refining [21]. Hence, neutralization,

EFB Fiber Shell

bleaching, and deodorizing may affect the existence of minor com-

H 6.3 6.0 6.3 ponents in neutralized, bleached, and deodorized oils.

C 48.8 47.2 52.4 Fractionation, on the other hand, modifies the major compo-

S 0.2 0.3 0.2 nents of RBDPO and RBDPKO. The olein fraction contains more low

N 0.2 1.4 0.6 melting point components such as oleic and linoleic acids, while

O 36.7 36.7 37.3 the stearin fraction has more high melting components such as

Ash 7.3 8.4 3.2

stearic, palmitic, myristic, and lauric acids. As an example, RBDPO

olein produced by the Daabon Group, Columbia contains oleic acid

(42.5%), which is ca. 3% higher than the amount in PO, while the

RBDPO stearin produced contains palmitic acid levels that are 12%

5.1.2 Empty Fruit Bunch, Fiber, Shell, Palm Kernel Meal, and higher than the original content in PO [31].

Palm Oil Mill Effluent

EFB, fiber, and shell have similar major elemental composition with

carbon as the most abundant element, see Tab. 5 [14]. As a conse- 5.1.4 Palm Fatty Acid Distillate

quence, these materials are basically suitable for use as good fuel As a by-product of CPO and CPKO refining, PFAD contains a variety

sources. The similarity is also observed in their major chemical com- of different compounds such as free fatty acids (FFA), glycerols, phy-

positions. Holocellulose is the dominant compound with an abun- tosterols, linoleic acid, squalene, and tocopherol. FFA is the main

dance of ca. 80% in EFB [25], 60% in fiber [26], and 75% in shell [27]. component with a proportion of ca. 84%, glycerols (monoacyl,

Lignin is the most common other compound in these three materi- diacyl, and triacylglycerols) compose ca. 13% [32], and phytosterols

als. According to Koba and Ishizaki [26], fiber also contains lipids (0.6%) [33]. Monoacyl glycerols are substances where one H on OH

(1.9%), proteins (3.6%), and other compounds (0.8%). group of the glycerol is replaced by a fatty acid radical. Similarly,

PKM is useful as a source of protein in compounding animal feed diacyl and triacylglicerols are substances with two and three H on

and has favorable calcium to phosphorus ratio. PKM typically con- OH groups of glycerol that are replaced by fatty acid radicals. The

tains carbohydrates (48.0%), crude protein (9.70%), fiber (13.0%), oil phytosterols contained in PFAD was mainly in the form of b-sitos-

(5.0%), and ash (4.0%). Many essential amino acids in the concentra- terol (58%), (11), and the remainder are campesterol (26%), (12), and

tion range of 0.27 to 2.20% can also be found, see Tab. 6 [28]. stigmasterol (16%), (13) [33].

POME is composed of water (96%) with a typical chemical oxygen Several studies have demonstrated that the consumption of phy-

demand (COD) of more than 40,000 ppm and total solids level of 4% tosterols reduced the cholesterol absorption and lowered total

[29]. The solid has a high nutrient content, and may be used directly serum and LDL cholesterol levels in animals and humans [34, 35].

as fertilizer [30]. The solid in PKM, i. e., palm oil sludge, the material Phytosterols present themselves as compounds having anti-cancer

that remains after decanting the POME, also contains many kinds of and cholesterol-lowering properties, and thus, they are finding

essential amino acids. The content of essential amino acids in palm wide applications in nutraceuticals and functional foods. The use of

oil sludge is typically smaller than that in PKM, see Tab. 6. phytosterols, its hydrogenated forms (phytostanols), and their

Table 6. Composition of essential amino acids in palm kernel meal (PKM) and palm oil sludge (POS).

Amino acid Content (%) Amino acid Content (%)

PKM POS PKM POS

Arginine 2.20 0.19 Methionine & cystine 1.98 0.28

Histidine 0.27 0.14 Phenylalanine & tyrosine 1.28 0.77

Isoleucine 0.63 0.35 Threonine 0.54 0.34

Leucine 1.05 0.60 Tryptophan 0.17 0.12

Lysine 0.56 0.21 Valine 0.90 0.36

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

462 S. J. Santosa Clean 2008, 36 (5 6), 453 465

esters in functional food formulations as a cholesterol lowering

agent has now been well-accepted by consumers.

(11)

(12)

(13)

Figure 9. The effect of mass distribution on the production of palm and

palm kernel oils.

5.2 Product Diversification

As happens for EFB, trunk and fronds are also just stored or

Expanding very rapidly in size and number, the PO industry repre- burned on the farms to give organic and inorganic nutrients for use

sents another opportunity for improved utilization of its by-prod- on the fields. These trunks and fronds can actually be used as fuel

ucts and wastes. In 2007, Indonesia had ca. 6.65 million ha of total for power production, especially in the off season when fiber, shell,

oil palm plantations with 4.39 million ha of it being mature oil and EFB are not available.

palm plantation, see Fig. 2. The plantations in 2007 produced 70.8 POME may be utilized to produce gas energy. It is technologically

million tons of FFB and ca. 64 million tons of biomass in the form of possible to harvest biogas from anaerobic digestion of effluent

trunk (6.1 million tons) and frond (57.9 million tons). From 70.8 mil- ponds of POME. It is estimated that ca. 20,000 m3 of biogas could be

lion tons of FFB, 17 million tons of PO and 1.9 million tons of PKO obtained per day from a 60 ton FFB mill operating for 20 h.

were obtained as the main products and 16.3, 8.5, 5.1, 2.3, and 47.5

million tons of EFB, fiber, shell, PKM, and POME, respectively, were

generated as the by-products and wastes Fig. 9. 5.2.2 Animal Feed

The palm industry produces PKM as a by-product, which is a valua-

ble source for animal feed. According to Sundu et al. [36], PKM has

5.2.1 Energy Sources no anti-nutritional properties, and thus, its inclusion is safe up to

The biomass generated at the PO mills such as EFB, fiber and kernel levels of at least 40% in the diet. The addition of PKM in the chicken

shell can be used to produce energy. A mixture of fiber and shell is diet reduces the feed digestibility due to he high dietary fiber of

the main solid fuel used by PO mills to produce the steam used to PKM but increases the feed intake. Mannan is the main component

process the FFB. The ratio between fiber and shell in the fuel mix- of palm kernel meal non-starch polysaccharide (NSP). Both mannose

ture is determined by the type of boiler used. The most commonly and manno-oligosaccharides have been reported to act as prebiotics.

used boiler type is the low pressure water tube boiler. The inclusion of PKM in the diet improves the immune system of

While the fiber and shells are currently being used entirely as birds, reduces pathogenic bacteria and increases the population of

fuel for the boilers, another waste, i. e., EFB, is usually burned in non-pathogenic bacteria in the intestine. PKM and PFAD can be used

incinerators at the PO mills with no heat recovery or just burned on in animal diets with some beneficial effects. Wing-Keong et al. [37]

the farms. Alternatively, EFB is disposed of on the farms as a source claimed that PFAD in catfish diets could offer protection against

of organic matter after its decomposition. The burning of EFB pro- lipid peroxidation in muscles that would translate to longer shelf-

vides beneficial ash as fertilizer to the palm fields but generates air life for seafood products.

pollution. It has been proposed that EFB could be used as a supple- It is possible that fibrous by-products such as EFB and fiber could

mentary fuel to ensure sufficient supplies of solid fuel for boiler be used as a feedstuff for ruminant animals. Ruminant animals

consumption [14]. such as dairy and beef cattle require two types of feeds, namely

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Clean 2008, 36 (5 6), 453 465 Palm Oil Boom in Indonesia 463

roughage (high fiber but low protein) and concentrates (high pro- by blending EFB with many types of materials such as polypropy-

tein and low fiber). Both types of feeds are in high demand espe- lene [40].

cially as the availability of grazing land is now becoming extremely

limited. 5.2.6 Medicine and Food Ingredients

The condensate from POME is another possible source of animal Oil palm trunk fiber has shown potential as a functional food ingre-

feed. The solid concentrate of POME is rich in essential amino acids dient and may help manage and lower the risk of diabetes, colon

and inorganic nutrients such as sodium, potassium, calcium, mag- cancer, heart disease and obesity. Another finding stated that oil

nesium, manganese, and iron [29]. However, the moisture content palm fiber extracted from the trunk has been shown to be an excel-

of this material is likely to be too high to render it an economical lent antioxidant and is thought to promote glucose metabolism

source of feed. and manage healthy cholesterol levels in sufferers of diabetes [41].

5.2.7 Biofuels

5.2.3 Chemicals

PO is a good raw material for liquid fuel. The biggest potential is in

Oil palm biomass may be a potential feedstock raw material for

respect to the conversion of PO into methyl esters (biodiesel). The

chemical industries. The cellulose component can be hydrolyzed to

process of conversion of PO into biodiesel involves transesterifica-

yield glucose from which ethanol, citric acid, and butanal can be

tion of the triglyceride to fatty acid alkyl esters, see reaction (14).

obtained through chemical transformation. Hemicelluloses, also

Transesterification involves taking a triglyceride molecule or a com-

present in the biomass can yield pentoses especially xylose, which

plex fatty acid, neutralizing the free fatty acids, creating fatty acid

upon hydrolysis, can be converted to xytitol, furfural, furan, resins

alkyl esters, and removing the glycerol by-product. Many types of

and furfuryl alcohol. The lignin fraction of oil palm biomass is a

alcohol such as methanol and ethanol can be used in creating the

potential source of phenolic resins.

fatty acid alkyl esters. If methanol is used, the resulting biodiesel is

Small molecule fatty acids and pure cellulose were successfully

fatty acid methyl ester which has suitable viscosity, boiling point

recovered from oil palm shell by using a new method combining a

and a high cetane number for use as a fuel.

hot water treatment and a two-stage liquid phase oxidation [38]. As

described previously, PFAD contains various valuable different com-

pounds such as FFA, glycerols, phytosterols, linoleic acid, squalene,

and tocopherol. The recovery of these compounds from PFAD is big

concern and is the subject of intensive research. Condensates from (14)

the PFAD have also been examined as substrates for fermentation

processes to produce ethanol, alcohols, monosodium glutamate

(MSG), vitamins, and other possible products.

5.2.4 Paper Pulp Due to the increase of fossil oil price and the depletion of its

reserves, biodiesel has shown potential as a substitute for fossil fuel.

It appears that paper pulp may be potentially one of the most impor- It is more efficient, renewable, and environmentally cleaner (clean

tant uses of EFB in the future. Some preliminary research has shown burning and does not produce net CO2 emission). It has been hailed

that the paper pulp quality obtained from EFB is favorable. How- as an essential part of the overall fight against global warming. It

ever, the technology and economics of this particular application can replace fossil fuels in transportation and the plants from which

are not yet clear. A combined research group from Japan, Malaysia, the biodiesel is produced absorb CO2 as they grow.

and Indonesia has successfully obtained high quality pulp from EFB The Indonesian government is preparing plans to make Indonesia

using both acetosolv- and ethanosolv-processes [38]. a major player in the global biofuel industry. For years, the govern-

More advance research has also been conducted for frond. Fiber ment has backed research into biofuel that was initially pioneered

strands from the frond of oil palm were examined relative to their by the Center for Oil and Gas Technology (Lemigas) and the state-

physical and chemical characteristics and their response to chemi- owned petroleum industry, Pertamina, in 1996 [42]. Similar

cal pulping such as sulfite, soda-sulfite and soda processes. Morpho- research is now extending to many research institutes, universities,

logically, the frond fibers are comparable to those of hardwood. and the state-run Agency for Assessment and Application of Tech-

They contain a high content of holocellulose but are low in lignin. nology (BPPT).

Chemical pulps of 45 to 50% yield produced either by soda-sulfite or After becoming the world's biggest PO producer in 2005, Indone-

soda process exhibit acceptable papermaking properties compara- sia took further steps in 2006 to become the world's largest pro-

ble to those of hardwood kraft pulps. The study showed that frond ducer of biodiesel. As a start, in January 2006, the President of Indo-

pulp might be used as a reinforcement component in newsprint nesia issued Presidential Instruction No. 1/2006 for the Production

production by using softwood thermomechanical fibers [39]. and Use of Biofuel as Alternative Fuel, giving instruction to various

ministries, including the Ministry of Energy and Mineral Resources

5.2.5 Advanced Materials and the Ministry of Agriculture, to speed up the production and use

The production of a polyhydroxyalkanoate (PHA) bio-degradable of biofuel as alternative fuel [43]. Since then, different national and

polymer through a freeze concentration pretreatment of POME and private banks and credit institutes have financed the opening of

subsequent cultivation using bacteria such as Rhodobacter has been new oil palm and jatropha plantations. The government has also

conducted [38]. Miura et al. [38] also pointed out that a molecular been putting greater effort into attracting foreign investors. On Jan-

sieving carbon could be obtained from kernel shell after impregna- uary 9, 2007, a memorandum of understanding (MoUs) was signed

tion with ZnCl2 and subsequent pyrolysis. Various composites with by a total 59 energy firms and institutions for their commitment to

excellent physical and chemical properties have also been afforded invest US$ 12.4 billion in biofuel in Indonesia. The major investors

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

464 S. J. Santosa Clean 2008, 36 (5 6), 453 465

Table 7. Investors proposing the large-scale production of biodiesel in Indonesia by 2007.

No Investor Plantation Prod. capacity

(106 L/year)

Location Area (105 ha)

1 Wilmar Group Sumatera, Kalimantan 180 1000

2 Bakrie, Indofood Asianagro Sumiasih Sumatera, Java - 600

3 Sweden Bioenergy East Nusa Tenggara 100 350

4 Multing Group Merauke (Papua) 290

5 BP Indonesia East Nusa Tenggara, Papua, Kalimantan 100

6 Aprobi Group Kalimantan 100

7 PT. Pupuk Kaltim Kalimantan 20

were Hong Kong Energy, CNOOC, and Genting Energy. Hong Kong obtained from oil palm. Extraction of these oils from the palm fruit

Energy and CNOOC committed to investing 5.5 billon US$, while also yields the biomass by-products of EFB, fiber, shell, PKM, and

Genting Energy made a commitment of 3 billion US$ [44]. wastes of POME as well as trunk and frond biomass generated in oil

Indonesia has already possesses some smaller biodiesel refineries palm plantation. The refining of CPO and CPKO and subsequent

where the capacity of each refinery is smaller than 70 million L/ fractionation produces RBDP olein, RBDPK olein, RBDP stearin, and

year. The total production capacity in 2006 was 82.5 million L. The RBDPK stearin, and PFAD by-product.

total production in the next five years (2007 to 2011) will be Indonesia is now the largest PO producer in the world. With a pro-

increased to reach 2,000 million L [45]. duction of 15.0 million tons, Indonesia replaced Malaysia as the

Although the effort to become the largest biodiesel producer in world's biggest PO producer in 2005. Production reached 17.0 mil-

the world has been enthusiastically programmed, it has not been lion tons in 2007, while the production of Malaysia increased from

accompanied by strategic plan to utilize the main by-product, i. e., 14.8 million tons in 2005 to 15.4 million tons in 2007. This 17.0 mil-

glycerol. The portion of glycerol co-produced during the production lion tons of PO was obtained from 6.65 million ha of total oil palm

of biodiesel is typically 10%. With the total production of biodiesel plantation where 4.39 million ha of it was mature oil palm planta-

projected to reach 2,000 million L in the next five years, this means tion. The sharp increase of PO production in Indonesia began just

that there will be ca. 200 million L of glycerol produced. The most after the Asian financial crisis in 1998. The production in 2007 was

common utilization of glycerol in Indonesia to date is in the oleo- ca. three times higher compared to 1998. More than 70% of the PO

chemical industry as raw material for soap. Unfortunately, due to produced in 2007 was exported, while 87% of the domestic con-

the high investment costs coupled with the low awareness of envi- sumption was for food.

ronmental care for the common Indonesian, the oleochemical The products of oil palm are multifunctional materials with their

industry in Indonesia has expanded very slowly. The total produc- uses varying from cooking oil to soap, from lubricants to raw mate-

tion of all oleochemical industries only increased from 712,000 rial sources for the oleochemical industry, etc. The biomass by-prod-

tons in 2001 [3] to 950,000 tons in 2007 [46]. Instead of involving ucts, i. e., fiber, shell, EFB, trunk, and frond, are traditionally used as

industrial scale use, a research collaboration for the utilization of a fuel for boilers of palm oil mills or just stored and/or burned on

glycerol has been initiated between BPPT and the Fraunhofer Insti- farms. These biomass by-products, along with PKM, PFAD, and

tute, Germany, for three years from 2007 [47]. POME, are now becoming the subject of intensive research for their

At least fifteen companies are planning new biodiesel refineries valuable utilization. Various research findings show that they can

and the Indonesian government is also intending to create eight potentially be diversified into sources of energy, animal feed, chem-

additional small refineries. Among them, the most important com- icals, paper pulp, advanced materials, medicine, and food ingre-

panies are Wilmar Group, Bakrie Indofood Asianagro Sumiasih, dients. Efforts to utilize and diversify the function of palm oil by-

Sweden Bioenergy, Multing Group, BP Indonesia, Aprobi Group, products and wastes are urgently required in Indonesia. Approxi-

and PT. Pupuk Kaltim. The planting concessions and planned pro- mately 64 million tons of biomass in the form of trunk (6.1 million

duction capacities of the companies are summarized in Tab. 7. The tons) and frond (57.9 million tons) as well as 16.3, 8.5, 5.1, 2.3, and

first two refineries built by the Wilmar and Bakrie Groups are 47.5 million tons of EFB, fiber, shell, PKM, and POME, respectively,

expected to start production in 2008/2009 [45]. were generated by the palm oil mills in Indonesia in 2007.

Domestic biodiesel retail sales in Indonesia are now estimated at More recently PO has played an important role in the develop-

one ton per day. Retailers are allowed to blend up to 10% biodiesel ment of alternative fuel sources. Studies on the conversion of PO to

to their mixes. The state-owned oil company, Pertamina sells 2.5% biodiesel and its blending to fossil diesel were initiated by Lemigas

of biodiesel-type in 210 fuel stations and 2.5% of bio-premium type and Pertamina in 1996. After becoming the world's largest PO pro-

in one fuel station in Jakarta. The total biodiesel and biopremium ducer in 2005, Indonesia made further steps in 2006 to become the

sold by Pertamina in 2006 was 215,730 and 1,700 million L, respec- world's largest producer of biodiesel. As a start, in January 2006 the

tively [45]. President of Indonesia issued Presidential Instruction No. 1/2006 for

the Production and Use of Biofuel as Alternative Fuel. The instruc-

tion ordered various ministries including the Ministry of Energy

6 Summary

and Mineral Resources and the Ministry of Agriculture, to speed up

Oil palm is a tropical plant which has become extremely important the production and use of biofuel as an alternative fuel.

in today's life. It is the world's leading raw material supply of edible Currently, Indonesia has only small biodiesel refineries and the

oils and fats. Along with CPKO, CPO is the main upstream product total production capacity in 2006 was 82.5 million L. At least fifteen

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Clean 2008, 36 (5 6), 453 465 Palm Oil Boom in Indonesia 465

companies are planning to establish new larger biodiesel refineries. [25] H. D. Rozman, K. R. A. Hiline, A. Abubakar, Polyurethane composites

Two of them with a total capacity of about 1,600 million L/year are based on oil palm empty fruit bunches: effect of isocyanate/hydroxyl

planning to start production in 2008/2009. ratio and chemical modification of empty fruit bunches with tol-

uene diisocyanate and hexamethylene diisocyanate on mechanical

Domestic biodiesel retailers in Indonesia are allowed to blend up properties, J. Appl. Polym. Sci. 2006, 106 (4), 2290.

to 10% biodiesel to their mixes for transportation fuel. In fact, the

[26] Y. Koba, A. Ishizaki, Chemical composition of palm fiber and its fea-

state-owned oil industry, Pertamina, only sells 2.5% biodiesel type. sibility as cellulosic raw material for sugar production, Agric. Biol.

The total amount of 2.5% biodiesel type sold by the Pertamina from Chem. 1990, 54 (5), 1183.

its 210 fuel stations in Jakarta in 2006 was 215,730 million L. [27] National Institute of Advanced Industrial Science and Technology (AIST),

2007. www.aist.go.jp.

[28] J. F. Perez, A. G. Gernat, J. G. Murillo, The effect of different levels of

palm kernel meal in layer diets, Poultry Sci. 2000, 79 (1), 77.

References [29] E. Maksum, Liquid Waste Utilization (POME) of Palm Oil Factory (PKS), PT

Agricinal, Bengkulu Utara, Indonesia 2006.

[1] K. G. Berger, S. M. Martin, Palm Oil, The Cambridge World History of Food

(Eds: K. F. Kiple, K. C. Ornelas), Cambridge University Press, Cam- [30] Z. Z. Zakaria, H. Khalid, A. B. Hamdan, Guidelines on Land Applica-

bridge 2000. tion of Palm Oil Mill Effluent (POME), PORIM Bull. Palm Oil Res. Inst.

Malaysia 1994, 28.

[2] The Oil Palm Worldwide, 2007. http://fedepalma.org/world.htm.

[31] Organic Palm Oil, Daabon Group, Columbia 2007. www.daabonorga-

[3] J. W. van Gelder, Greasy Palms: European Buyers of Indonesian Palm Oil,

nic.com.

Friends of the Earth, The Netherlands 2004.

[32] C. S. L. Chua, B. S. Baharin, Y. B. C. Man, C. P. Tan, Separation of Squa-

[4] Palm Oil, National Agency for Trade Export Development, Ministry of

lene from Palm Fatty Acid Distillate using Adsorption Chromatogra-

Trade Republic of Indonesia, Jakarta 2007.

phy, Eur. J. Lipid Sci. Technol. 2007, 109, 1083.

[5] T. P. Pantzaris, M. J. Ahmad, Properties and Utilization of Kernel

[33] A. G. M. Top, M. Sulong, R. M. Soom, Production of Phytosterols from Palm

Meal in Layer Diets, Poultry Sci. 2002, 79 (1), 77.

Fatty Acid Distillate, MPOB Information Series, 2007. http://palmoi-

[6] D. Bangun, Indonesian Palm Oil Industry, National Institute of Oilseed lis.mpob.gov.my

Products Annual Convention, Arizona 2006.

[34] P. J. H. Jones, F. Y. Ntanios, M. Raeini-Sarjaz, C. A. Vanstone, Choles-

[7] Selected Indicators Social-Economics of Indonesia, Directorate of Statistical terol-lowering efficacy of a sitosteryl-containing phytosterol mix-

Dissemination, Jakarta 2006. ture with a prudent diet in hyperlipidemic men, Am. J. Clin. Nutr.

[8] Y. W. Jati, A. Muhibbuddin, Astra Agro Ekspansi Lahan 30.000 ha, Bis- 1998, 69, 1144.

nis Indonesia, November 28, 2007. [35] J. Plat, D. A. Kerckhoffs, R. P. Mensink, 2000, Therapeutic potential of

[9] F. Achmad, BNI Siapkan Rp 1 Triliun untuk PKT, Bisnis Indonesia, plant sterols and stanols. Curr. Opin. Lipidol. 2000, 11, 571.

November 28, 2007.. [36] B. Sundu, A. Kumar, J. Dingle, Palm kernel meal in diets: Effect on

[10] B. Guerin, Jakarta Eyes Palm Oil for Fuel, Asia Times, Hong Kong 2006. chicken performance and health, World Poultry Sci. J. 2006, 62, 316.

[11] Palm Oil and the Rainforest, 2007. www.mongabay.com/external/ foe_- [37] Ng. Wing-Keong, Y. Wang, P. Ketchimenin, K.-H. Yuen, Replacement

palm_oil.htm. of dietary fish oil with fatty acid distillate elevates tocopherol and

[12] World Palm Oil Import, United States Department of Agriculture, 2007. tocotrienol concentrations and increases oxidative stability in the

www.fas.usda.gov/oilseed/circular/2003/03-11/Novcov.pdf. muscle of African catfish, Clarias gariepinus. Aquaculture 2004, 233 (1

4), 423.

[13] B. Elisabeth, Areal Pertanian Kedelai AS Melorot. Bisnis Indonesia,

November 27, 2007. [38] K. Miura et al., Efficient Use of Oil Palm Wastes as Renewable Resource for

Energy & Chemicals, 2007. www.nedo.go.jp/itd/grant-e/list/energy/

[14] T. M. I. Mahlia, M. Z. Abdulmuin, T. M. I. Alamsyah, D. Mukhlishien,

98ef1-e.html.

An Alternative Energy Source from Palm Wastes Industry for Malay-

sia and Indonesia, Energy Conversion Manage 2001, 42, 2109. [39] W. D. Wan Rosli, Z. Zainuddin, K. N. Law, R. Asro, Pulp from oil palm

fronds by chemical processes. Ind. Crops Prod. 2007, 25 (1), 89.

[15] Palm Oil, Kuala Lumpur Kepong Berhard, 2007. www.klk.com.my.

[40] B. Wiryosentono, P. Guritno, I. Hanafi, Oil palm empty fruit bunch

[16] E. M. Goh, Application and Uses of Palm and Palm Kernel Oils in Specialty filled polypropylene composites, Int. J. Polymeric Materials 2004, 53 (4),

Products, MOSTA Short Course 8, Genting Highlands, Malaysia, April 295.

2002.

[41] Nutra Ingedients, 2007. www.nutraingedients.com.

[17] R. A. Butler, Environmental Concerns Mount as Palm Oil Production Surges,

[42] E. H. Legowo, Present Status of Biomass Development in Indonesia, Bio-

Key Points on the Environmental Impact of Palm Oil, 2007. http://news.-

mass-Asia Workshop, Tokyo, Japan, 2005. www.biomass-asia-work-

mongabay.com.

shop.jp/ 01workshop/program.html.

[18] Oil World Annual, ISTA Mielke GmbH., Hamburg, Germany 2000.

[43] B. Setyogroho, Indonesia Follows Suit in Production of Biofuels, Price

[19] Diet, Nutrition and the Prevention of Chronic Diseases, WHO Techni- Water House and Coopers, 2007. www.pwc.com.

cal Report Series 916, Geneva, 2003.

[44] 59 Energy Firms and Institutions to Invest $ 12.4b in Biofuel. The

[20] K. Chu-Sing, Comment on Draft Document: Diet, Nutrition and the Preven- Jakarta Post, January 10, 2007.

tion of Chronic Diseases, 2007. www.who.int/dietphysicalactivity/

[45] R. Ariffianto, Proyek Biofuel Serap US$ 17 Miliar, Bisnis Indonesia, July

media/en/ gsfao_cmo_068.pdf.

24, 2007.

[21] S. H. Goh, Y. M. Choo, S. H. Ong, Minor constituents of palm oil, J. Am.

[46] Y. H. Simanjuntak, M. Sembiring, 13 Perusahaan Ekspansi ke Bisnis

Oil Chem. Soc. 2007, 62 (2), 237.

Oleokimia, Bisnis Indonesia, October 4, 2007.

[22] Palm Oil, 2007. http://en.wikipedia.org/wiki/Palm_oil.

[47] W. Sumaryono, Indonesia-Jerman Jalin Kerjasama Olah Limbah CPO

[23] C. Y. May, Palm Oil Carotenoids, Food Nutr. Bull. 1994, 15 (2), 34. Jadi Gliserol, Radio Republik Indonesia, 2008. www.rri-online.com/

[24] Malaysian Palm Oil Promotion Council (MPOPC), 2007. www.mpoc.org.my. module.php?name= Artikel&sid=28954.

i 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.clean-journal.com

Potrebbero piacerti anche

- Insights Reg PlantationsDocumento69 pagineInsights Reg PlantationsNasya YenitaNessuna valutazione finora

- thomas-mielke-OIL WORLD 2017 PDFDocumento42 paginethomas-mielke-OIL WORLD 2017 PDFDestonkNessuna valutazione finora

- Malaysia and Indonesia Palm Oil Exports, Prices, Duties ComparedDocumento11 pagineMalaysia and Indonesia Palm Oil Exports, Prices, Duties ComparedystongNessuna valutazione finora

- Palm Oil Plantation 2012Documento12 paginePalm Oil Plantation 20122oooveeeNessuna valutazione finora

- Competitor Analysis: No. Name Address Website/Platform Social Media Portfolios Official Partner CommoditiesDocumento9 pagineCompetitor Analysis: No. Name Address Website/Platform Social Media Portfolios Official Partner CommoditiesFlo CartNessuna valutazione finora

- Palm Oil MarketDocumento7 paginePalm Oil MarketGopalNessuna valutazione finora

- Palm Oil Report 2012Documento152 paginePalm Oil Report 2012S J100% (1)

- The Foreign Exchange MarketDocumento40 pagineThe Foreign Exchange Marketdragosvoinea96Nessuna valutazione finora

- BOOKLET - Profile of Palm Cooking Oil Industry1 PDFDocumento40 pagineBOOKLET - Profile of Palm Cooking Oil Industry1 PDFAndina VeronicaNessuna valutazione finora

- Samsung Quant Portfolio: Quantitative IssueDocumento26 pagineSamsung Quant Portfolio: Quantitative IssueashmiljNessuna valutazione finora

- Global Food SecurityDocumento25 pagineGlobal Food SecurityMelanie JulianesNessuna valutazione finora

- PG Palm Oils Mill List FINALDocumento57 paginePG Palm Oils Mill List FINALUnlimited KaokaoNessuna valutazione finora

- Mini Case: Mrs. Watanabe and The Japanese Yen Carry TradeDocumento11 pagineMini Case: Mrs. Watanabe and The Japanese Yen Carry Tradedragosvoinea96Nessuna valutazione finora

- Telecom Game TheoryDocumento24 pagineTelecom Game TheoryIliyas Ahmad Khan100% (2)

- Salvatore Study-Guide ch01 PDFDocumento5 pagineSalvatore Study-Guide ch01 PDFEconomics LabNessuna valutazione finora

- Case Study Report: Palm Oil in IndonesiaDocumento59 pagineCase Study Report: Palm Oil in IndonesiaHamid Jahangir100% (1)

- Investment Management PDFDocumento15 pagineInvestment Management PDFMelissa MillerNessuna valutazione finora

- Evolution of Banking SectorDocumento16 pagineEvolution of Banking SectorNaishrati SoniNessuna valutazione finora

- Balance of PaymentsDocumento14 pagineBalance of Paymentsনীল রহমানNessuna valutazione finora

- A New Commodity Supercycle - Oct 2020Documento35 pagineA New Commodity Supercycle - Oct 2020Variant Perception ResearchNessuna valutazione finora

- Industrial Transformation 2050Documento208 pagineIndustrial Transformation 2050y9903061100% (1)

- EPS-bank profit linkDocumento10 pagineEPS-bank profit linkchudamaniNessuna valutazione finora

- Foreign Banks' Impacts on Emerging Markets: A Host Country PerspectiveDocumento29 pagineForeign Banks' Impacts on Emerging Markets: A Host Country PerspectiveH.m. HasanNessuna valutazione finora

- Damodaran's Optimal Capital StructureDocumento17 pagineDamodaran's Optimal Capital StructureRajaram IyengarNessuna valutazione finora

- MILLS LISTDocumento38 pagineMILLS LISTVedant KapoorNessuna valutazione finora

- An Economic History of SingaporeDocumento10 pagineAn Economic History of SingaporeLilian Lim100% (1)

- KCP (Repaired)Documento61 pagineKCP (Repaired)keerthiNessuna valutazione finora

- Elton Gruber Ch#16Documento7 pagineElton Gruber Ch#16Sarjeel Ahsan NiloyNessuna valutazione finora

- CFA Equity Research Challenge 2011 - Team 9Documento15 pagineCFA Equity Research Challenge 2011 - Team 9Rohit KadamNessuna valutazione finora

- Chapt08 Krugman 46657 09 IE C08 FDocumento63 pagineChapt08 Krugman 46657 09 IE C08 FMihai StoicaNessuna valutazione finora

- From Convergence to Crisis: Labor Markets and the Instability of the EuroDa EverandFrom Convergence to Crisis: Labor Markets and the Instability of the EuroNessuna valutazione finora

- Money and BankingDocumento57 pagineMoney and BankingMohammed RaihanNessuna valutazione finora

- Baye's BookDocumento6 pagineBaye's BookGatraErgaYudhantoNessuna valutazione finora

- Sharpening The Arithmetic of Active Management - AQR 2016Documento14 pagineSharpening The Arithmetic of Active Management - AQR 2016Guido 125 LavespaNessuna valutazione finora

- Chapter 11-12 QuestionsDocumento6 pagineChapter 11-12 QuestionsFreeBooksandMaterialNessuna valutazione finora

- Intra Industry Trade TheoryDocumento2 pagineIntra Industry Trade TheoryGalibur Rahman100% (1)

- Carbon Program Introduction: January 2022Documento14 pagineCarbon Program Introduction: January 2022Rahim DavisNessuna valutazione finora

- Equity Cheat Sheet GuideDocumento2 pagineEquity Cheat Sheet GuidewleongtNessuna valutazione finora

- What The Great Fama-Shiller Debate Has Taught Us - Justin Fox - Harvard Business Review PDFDocumento2 pagineWhat The Great Fama-Shiller Debate Has Taught Us - Justin Fox - Harvard Business Review PDFppateNessuna valutazione finora

- Capital Flows To Emerging Market EconomiesDocumento20 pagineCapital Flows To Emerging Market EconomiesRaghavendra MandavilliNessuna valutazione finora

- Time Value of Money Summary SheetDocumento4 pagineTime Value of Money Summary SheetnaliniymtNessuna valutazione finora

- Dairy Industry Indonesia 2011Documento59 pagineDairy Industry Indonesia 2011anantowardonoNessuna valutazione finora

- Report On Company ValuationDocumento23 pagineReport On Company ValuationFarzana Fariha Lima100% (1)

- 2020-01, Ambit Capital - When Accounting PredictedDocumento62 pagine2020-01, Ambit Capital - When Accounting PredictedKarthikNessuna valutazione finora

- Developing The International Manager WalMarts Cross Cultural Management in GermanyDocumento22 pagineDeveloping The International Manager WalMarts Cross Cultural Management in GermanyTâm NhưNessuna valutazione finora

- IPO Underpricing Explained in 40 CharactersDocumento13 pagineIPO Underpricing Explained in 40 Charactersshivams18Nessuna valutazione finora

- Case Study For HRBBBDocumento3 pagineCase Study For HRBBBSumit Kumar JhaNessuna valutazione finora

- BBA 2011 - Historical link between inflation and unemploymentDocumento35 pagineBBA 2011 - Historical link between inflation and unemploymentluvpriyaNessuna valutazione finora

- CH04Documento29 pagineCH04Z pristinNessuna valutazione finora

- BLK Risk Factor Investing Revealed PDFDocumento8 pagineBLK Risk Factor Investing Revealed PDFShaun RodriguezNessuna valutazione finora

- A Value Chain Analysis of The Meat Sector in PakistanDocumento53 pagineA Value Chain Analysis of The Meat Sector in Pakistanmazamniazi80% (5)

- IS-LM Curve Model ExplainedDocumento28 pagineIS-LM Curve Model ExplainedabhishekNessuna valutazione finora

- AnomaliesDocumento3 pagineAnomalieskaedelarosaNessuna valutazione finora

- Cerulli Report - Targeting The Affluent and The Emerging AffluentDocumento25 pagineCerulli Report - Targeting The Affluent and The Emerging AffluentJoin RiotNessuna valutazione finora

- Stock Exchanges - Investments and Derivatives - Questions and Answers PDFDocumento120 pagineStock Exchanges - Investments and Derivatives - Questions and Answers PDFkaran sanwalNessuna valutazione finora

- Property-Type Diversification and REIT PerformanceDocumento27 pagineProperty-Type Diversification and REIT PerformanceUNLV234Nessuna valutazione finora

- Beyond Crisis: The Financial Performance of India's Power SectorDa EverandBeyond Crisis: The Financial Performance of India's Power SectorNessuna valutazione finora

- Oil palm cultivation in India: past, present and future scenarioDocumento12 pagineOil palm cultivation in India: past, present and future scenarioChaitanya KumarNessuna valutazione finora

- Oil Palm Breeding 100 Years JOPRZulkiflyetal 2017Documento17 pagineOil Palm Breeding 100 Years JOPRZulkiflyetal 2017adhi widyawan liongNessuna valutazione finora

- A Comparative Study of Chemical Analysis of Palm Kernel OilDocumento41 pagineA Comparative Study of Chemical Analysis of Palm Kernel OilAhmad Jaelani ManurungNessuna valutazione finora

- Energy balance on chemical reactorsDocumento41 pagineEnergy balance on chemical reactorsHotib PerwiraNessuna valutazione finora

- Chapter 8Documento80 pagineChapter 8Hotib PerwiraNessuna valutazione finora

- Solubility and Complexation EquilibriaDocumento14 pagineSolubility and Complexation EquilibriaHotib PerwiraNessuna valutazione finora

- Chapter 4Documento27 pagineChapter 4Hotib PerwiraNessuna valutazione finora

- Chapter 5Documento11 pagineChapter 5Hotib PerwiraNessuna valutazione finora

- Chapter 6.1Documento10 pagineChapter 6.1Hotib PerwiraNessuna valutazione finora

- Balances On Plug Flow Packed Bed Reactor (PFPBR)Documento11 pagineBalances On Plug Flow Packed Bed Reactor (PFPBR)Hotib PerwiraNessuna valutazione finora

- Chapter 1Documento30 pagineChapter 1Hotib PerwiraNessuna valutazione finora

- English VersionDocumento193 pagineEnglish VersionHotib PerwiraNessuna valutazione finora

- Energy balance on chemical reactorsDocumento41 pagineEnergy balance on chemical reactorsHotib PerwiraNessuna valutazione finora

- Chapter 3Documento16 pagineChapter 3Hotib PerwiraNessuna valutazione finora