Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Communications Site Installation: CSII/R56 Installer Version Competency Requirements

Caricato da

wiyah1610Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Communications Site Installation: CSII/R56 Installer Version Competency Requirements

Caricato da

wiyah1610Copyright:

Formati disponibili

Communications Site Installation

CSII/R56 Installer version

COMPETENCY REQUIREMENTS

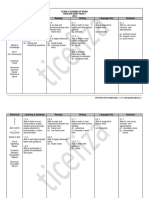

The following is a listing of each topic considered necessary to be included in a course of study towards

the education of technicians performing Communications Site Installation and Inspections. There are 7

major categories, 171 competencies, of training. This COMPETENCY listing is supplied to provide a detail

syllabus with an identification of each individual subject in which the technician must be knowledgeable and

skilled. These subjects are derived from material compiled from applicable Motorola and other

industry codes and standards.

Technicians seeking the ETA Communications Site Installation Inspector are required to have a

basic education in fundamental electronics. The basic electronics knowledge is to be assessed with the ETA

Associate CET examination. The Communications Site Installation Inspector certification is a Journeyman

level certification and counts towards the requirements for Master certification (CETma). Only Motorola

employees and affiliate technicians invited with Motorola Solutions authorization are eligible to attempt the

CSII.

The ETA Communications Site Installation R56 certification and is a non-Auditor certification, which

validates examinees knowledge of the core concepts required in the installation of a communications site,

based on the R56 industry codes and standards. It should be attempted by installation contractors, service

shops, project supervisors, project managers, site construction teams, and electrical contractors involved with

communications site installation and construction. . The R56 Installer is a stand-alone and does NOT require

the Associate CET certification. However, if the Associate CET is obtained before the R56 is earned, then the

R56 will be issued at the journeyman CET level.

Examinees must first complete a Motorola approved Communications Site Installer (R56) training course.

Both the CSII and the R56 are four year term certifications. To re-certify the current examination must be

taken and passed at the end of that four year term.

CSII/R56 INSTALLER COMPETENCIES

1.0 Communication Site Building Design and Installation

1.1 Describe the different site categories:

1.1.1 Modules within a single rack

1.1.2 Dedicated radio room within a new or existing building

1.1.3 Pre-fabricated equipment shelter of concrete/fiberglass construction

1.1.4 A shipping container

1.1.5 Renovation

1.1.6 A new green site on undeveloped land

1.2 Identify the differences between:

1.2.1 a building

1.2.2 a shelter

1.2.3 a vault

1.2.4 equipment cabinet/enclosure

1.2.5 rack

1.3 Determine ceiling height requirements with respect to an equipment cabinet or rack and a

cable runway system

1.4 Describe cable runway system installation requirements:

1.4.1 Design and safety

1.4.2 Placement with respect to smoke detectors and sprinkler heads

1.4.3 Minimum separation requirements

1.4.4 Support requirements

1.5 Describe floor loading and sealing requirements

1.6 List the different types of cable entry ports and explain how each is to be weather sealed

1.7 Explain adequate lighting requirements

1.7.1 Describe how illumination levels are to be measured

1.8 Describe how ambient temperature is to be measured

1.8.1 List the temperature and relative humidity requirements for the HVAC system

CSII/R56 Installer 1 Copyright 2016, ETA International, All Right Reserved

Communication Site Installer Competency

1.9 Explain the basic uses for exhaust fans and how the exterior opening needs to be protected

1.10 List the minimum fire suppression equipment requirements

1.10.1 Explain the installation requirements for a portable and a fixed total flood system

1.11 Define an approved first aid kit and relate where it needs to be located

1.12 List the personal protective safety equipment requirements for servicing batteries and identify

when this equipment is required at the site

1.13 Describe the types of on-site communication equipment that needs to be available at the site

1.14 Identify phone numbers of importance that need to be posted at the site

1.15 List minimum required signage that needs to be posted at the site and additional signage that

may be required

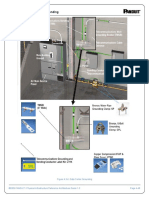

2.0 Grounding System Inspection Equipment

2.1 Describe the uses of a clamp-on ground resistance tester

2.2 Explain how the clamp-on ground resistance tester works

2.3 Identify the prerequisites for using a clamp-on ground resistance tester

2.4 Describe testing a single grounding electrode conductor

2.5 Describe testing multiple grounding electrode conductors connected to a single grounding

electrode

2.6 Explain the procedure for testing of multiple grounding electrode conductors connected to

parallel grounding electrodes

2.7 Explain where the correct location is for measuring the ground resistivity of a communication

site

2.8 Describe how to measure the ground resistivity of the communication site:

2.8.1 Before the AC utility is installed

2.8.2 When the AC utility is installed

2.9 Explain how the clamp-on ground resistance tester can check bonding continuity

2.10 Explain how to use a jumper wire to verify bonding continuity to a common grounding

electrode system

3.0 External Grounding and Bonding

3.1 Explain the purpose for external grounding

3.2 Describe common grounding

3.3 Identify the different grounding electrode system components that need to be bonded together

to form a common grounding electrode system

3.4 List the different ground resistance requirements between a Type A and Type B site

3.5 Define the Motorola recommended design goal for ground resistance at Type B sites

3.6 Explain what needs to be done if the ground resistance goals cannot be achieved at a Type

A or Type B site

3.7 Identify acceptable grounding electrodes and define their minimum requirements

3.8 Describe supplemental grounding

3.9 Explain sphere-of-influence for a grounding electrode and define minimum grounding electrode

spacing requirements

3.10 Determine if the grounding electrode system design meets the requirements appropriate for

the type of site

3.11 Explain the difference between grounding electrode conductors and grounding conductors and

identify their minimum sizing requirements

3.12 List conductor bending and routing requirements

3.13 List requirements for protecting and securing grounding conductors

3.14 Explain the causes for galvanic corrosion and methods to help reduce or prevent it from

occurring

3.15 Describe conductor bonding requirements for each item that needs to be bonded to the

external grounding system

3.15.1 Explain exothermic welding requirements

3.15.2 Explain irreversible high compression crimping requirements

3.15.3 State the appropriate type of conductive anti-oxidant compound to be applied to a

mechanical bonding connection

3.16 Describe and list the requirements for installing an external ground bus bar (EGB)

3.17 Describe the requirements for installing a tower ground bus bar (TGB)

CSII/R56 Installer 2 Copyright 2016, ETA International, All Right Reserved

Communication Site Installer Competency

3.18 Explain how grounding conductors must be connected to the EGB and TGB

3.19 Describe how to install grounding kits

3.19.1 Identify the minimum and recommended installation locations

3.20 Identify braided grounding conductors and explain why they are not be used in the grounding

system

3.21 Explain antenna structure grounding requirements for a:

3.21.1 Guyed tower

3.21.2 Self-supporting tower

3.21.3 Monopole tower

3.21.4 Rooftop tower

3.21.5 Rooftop or building side mounted antenna mast

3.21.6 Light pole

3.21.7 Wooden pole structure

3.22 Describe tower guy wire grounding requirements when the guy anchor locations are located on

the earth surface and on a building rooftop

3.23 Explain ice bridge or cable support grounding

3.24 Describe fence grounding requirements

3.25 Identify generator grounding requirements

3.26 List all other metallic items at the site that need to be bonded to the grounding system and

describe how they need to be bonded

3.27 Identify special grounding situations and explain grounding conductor sizing requirements

4.0 Internal Bonding and Grounding

4.1 Explain the purpose for internal grounding

4.2 List examples of common grounding within a building or equipment shelter

4.3 Identify the requirements for installing a master ground bus bar (MGB)

4.4 Identify the requirements for installing a sub system ground bus bar (SSGB)

4.5 List examples of how SSGBs can be utilized in different applications

4.6 Explain how conductors need to be connected to the MGB and SSGB

4.7 Explain the difference between a ground bus conductor and an equipment grounding

conductor

4.7.1 Identify their minimum sizing requirements

4.8 Describe conductor bending and routing requirements

4.9 Explain how equipment ground bus conductors, ground bus extensions and equipment

grounding conductors need to be bonded together

4.9.1 Explain how the bonding connections need to be insulated

4.10 Describe the installation requirements for an internal perimeter ground bus (IPGB) system and

a Halo grounding system

4.11 Identify what can be bonded to the IPGB or Halo grounding systems

4.12 List ancillary support items and explain how they need to be bonded to the internal grounding

system

4.13 Describe how to bond each of the following to the internal grounding system:

4.13.1 Piping systems

4.13.2 Steel roof trusses

4.13.3 Exposed support beams

4.13.4 Drop ceiling grids

4.13.5 Raised flooring systems

4.13.6 Other exposed metallic building materials

4.14 Explain how to bond metallic surge protection housings to the internal grounding system

4.15 State how different types of separately derived AC electrical systems need to be bonded to the

internal grounding system

4.16 Describe how a DC power system needs to be bonded to the MGB

4.17 Explain what a primary surge protection device is and how it needs to be bonded to the

grounding system

4.18 Identify where RF surge protection devices need to be installed and describe the different

ways they can be bonded to the internal grounding system

4.19 Describe additional grounding requirements for primary and RF surge protection devices when

they are not located adjacent to the MGB

CSII/R56 Installer 3 Copyright 2016, ETA International, All Right Reserved

Communication Site Installer Competency

4.20 Relate how different cable runway configurations need to be bonded to the MGB or to a

separate equipment room SSGB

4.21 Explain when it is necessary to bond cable runway sections together

4.22 Describe how to bond separate cable runway sections and supporting hardware together

4.23 Describe how an equipment ground bus system needs to be installed and routed back to the

MGB or a separate equipment room SSGB in a building and an equipment shelter

4.24 Explain how equipment housings and equipment racks need to be bonded

4.25 Describe what a rack ground bus bar (RGB) is and how it needs to be installed and bonded to

the internal grounding system

4.26 Explain how to bond individual system component chassis equipment to the internal grounding

system

4.27 Describe where secondary surge protection devices need to be installed and how they need to

be bonded to the grounding system

4.28 Describe how to bond control center and dispatch network operator equipment

4.28.1 Explain equal potential bonding

4.28.2 Describe examples of how to establish equal potential bonding at the network

operator positions

4.28.3 List acceptable grounding conductor sizing requirements at the network operator

positions

5.0 Power Sources

5.1 Describe how distribution panel boards, circuit breakers and electrical receptacles need to be

marked for identification

5.2 Identify the clear working space requirements for electrical panels

5.3 Describe how power receptacles need to be securely mounted to the supporting structure

5.4 Explain the need for adequate service receptacle outlets

5.5 Describe why each piece of critical equipment needs to be powered by a dedicated branch

circuit

5.6 Explain why power receptacles need to be installed by the equipment and why extension cords

are not allowed in the final installation

5.7 Define what GFCI is and where this type protection needs to be installed

5.8 Explain why power strips need to be mounted off the floor and describe the requirements for

an approved power strip

5.9 Explain why UPS equipment needs to be installed with adequate clearance from other items

5.10 Identify the location where the main electrical service Neutral-to-Ground bonding connection

will be established

5.11 Define how a Neutral-to-Ground bonding connection can be established

5.12 Explain why only one Neutral-to-Ground bonding connection can be established at a location

unless a separately derived power source has been installed

5.13 Describe the locations where a Neutral-to-Ground bonding connection can be located when a

separately derived power source has been installed

5.14 Define an ACEG conductor and why this type conductor needs to be installed

5.15 Identify the location where ACEG conductor originates and explain how it needs to be routed

throughout the electrical distribution system

5.16 Identify the installation requirements for solar panels and wind generators

5.17 Describe the installation requirements for battery systems

5.18 Describe the installation requirements for generators and their fuel tanks

5.19 Identify the minimum adequate spacing requirement for safe serving of a generator

5.20 Identify the minimum recommended spacing requirements for a generator fuel tank and the

fence and between the tank and the shelter

5.21 Explain why a main disconnect may be needed in the feeder cable between the generator and

the transfer switch

5.22 Describe the minimum electrical panelboard ampacity rating for an electrical panel being

served by a generator

5.23 Define the minimum size circuit for communications equipment

CSII/R56 Installer 4 Copyright 2016, ETA International, All Right Reserved

Communication Site Installer Competency

6.0 Transient Voltage Surge Suppression

6.1 Explain the need for transient voltage surge protection

6.2 Identify transient voltage sources

6.3 List the four major points of entry into a communications site that must be protected

6.4 Identify the protection modules used in a Type 1 AC surge protection device (SPD)

6.5 Identify the protection modules used in a Type 2 AC surge protection device (SPD)

6.6 Describe the proper installation requirements and locations for the Type 1 and Type 2 AC SPDs

6.7 Define the difference between normal mode and common mode protection

6.8 Identify primary SPDs that are used for metallic telephone, control and data lines

6.9 Describe and indicate the proper installation requirements and locations for primary SPDs

6.10 Explain how to tell if the primary SPD meets the proper listing or marking requirements

6.11 Explain what needs to be done with unused cable conductors that are not protected by the

primary SPD

6.12 Explain how to identify secondary SPDs that are used for metallic telephone, control and

data lines

6.13 Describe and explain the proper installation requirements and locations for the secondary SPDs

6.14 Indicate if the secondary SPD meets the proper listing or marking requirements

6.15 Explain what needs to be done with unused conductors that are not extended through the

secondary SPD

6.16 Describe and explain the proper installation requirements and locations for RF SPDs

6.17 Explain what needs to be done with non-terminated or spare transmission lines entering the site

6.18 Describe and explain the proper installation requirements and locations for SPDs that are used

to protect tower top amplifier transmission lines and control cables

6.19 Identify the proper installation requirements and locations for tower lighting controllers and their

control cables

6.20 Describe and explain the proper installation requirements and locations for SPDs that are

required to protect the tower lighting controller power, control and alarm conductors

7.0 Equipment Installation

7.1 Explain the minimum spacing and aisle width requirements at an equipment shelter or building

7.2 Describe how you would determine if equipment is installed level, plumb and square with

surrounding equipment and walls

7.3 Explain how communications equipment and ancillary items needs to be braced and secured

in seismic 3 or greater rated areas

7.4 Explain how to determine if communications equipment cabinets and racks are properly

secured to the floor as required

7.5 Describe the appropriate cable group separation and routing requirements for RF lines, power

cables, ground conductors and control, data, telephone, alarm and reference cables

7.6 Describe the minimum bending radius requirements for all types of RF cables

7.7 Identify when plenum-rated cables are required at the site and explain how to determine if all

types of cabling meet the requirements

7.8 Explain how to determine that cables are sized to length and that excess cabling is not coiled up

7.9 Identify that cables have been adequately secured at the required intervals

7.9.1 Explain why communication cabling cannot be secured to the exterior of any

electrical conduit or electrical raceways

7.10 Describe why AC power conductors installed on a cable runway system should meet NFPA 70

requirements

7.11 List the standard identification requirements for communication cabling

7.12 Describe how distribution frame wiring would conform to the proper punch-down or wire-wrap

techniques

7.13 Identify that system network cabling meets all installation requirements

7.14 Describe how cabling routed under and through a raised flooring system would meet the

proper installation requirements

7.15 Explain how cabling shall be supported when it is routed above a suspended or drop ceiling

7.16 List the minimum electrostatic discharge practices that shall be observed for serving

communications equipment and storing static sensitive components

End of Communications Site Installer Competencies Listing

CSII/R56 Installer 5 Copyright 2016, ETA International, All Right Reserved

Communication Site Installer Competency

Find an ETA approved school and approved test site: http://www.eta-i.org/test_sites.html

Additional REQUIRED materials and resources:

Standards and Guidelines for Communication Sites (R56) Available from Motorola Parts (phone

number: 800-422-4210, part number: hard copy #68P81089E50-8 and CD # can be found on Motorola

Solutions: http://www.motorolasolutions.com/en_us/services/managed-support-services/training.html)

Motorola Solutions Certification Program: ETA Communication Site Installer (R56) Certification

Preparation Guide

NST925 / RTW050 Site Installation Practices Workshop (R56) for New to R56 certification or expired

past the 4 year term

NST925-5 R56 Standards Update 2016 Course for R56 re-certification at the 4 year term

Additional suggested study materials and resources:

NFPA 70: National Electrical Code (NEC ), (2017, 14 Ed.) ISBN available in August 2016

th

NFPA 70: National Electrical Code (NEC ) Handbook (2017) ISBN available in November 2016

NFPA 70E : Standard for Electrical Safety in the Workplace . (Softbound, Approx. 910 pp., 2017) -

NFPA 780 : Standard for the Installation of Lightning Protection Systems

2014 Understanding the National Electrical Code, Volume 1 Articles 90-480 ISBN 978-193268576-3

2014 Understanding the National Electrical Code, Volume 2 Articles 500-820 ISBN 978-193268574-9

Understanding Low-Voltage and Power Limited Systems ISBN 1932685200 (2005)

IEEE Recommended Practice for Grounding of Industrial and Commercial Power Systems (IEEE Std

142-1991) ISBN 1559371412

IEEE Recommended Practice for Powering and Grounding Electronic Equipment (IEEE Std 1100-

2005) ISBN 0738148806

Lighting Protection and Grounding Solutions for Communication Sites PolyPhaser

Lyncole Ground Test Methods Lyncole XIT Grounding

ETA certification programs are accredited through the ICAC,

complying with the ISO/IEC 17024 standard.

CSII/R56 Installer 6 Copyright 2016, ETA International, All Right Reserved

Potrebbero piacerti anche

- Communications Site Installation: CSII/R56 Installer Version Competency RequirementsDocumento6 pagineCommunications Site Installation: CSII/R56 Installer Version Competency Requirementswiyah1610Nessuna valutazione finora

- Spec CommunicationcablesDocumento12 pagineSpec CommunicationcablesDolyNessuna valutazione finora

- SECTION 16060 Grounding and BondingDocumento18 pagineSECTION 16060 Grounding and BondingMARIANNessuna valutazione finora

- Question Bank: Part-A Marks: 2 UNIT-1 Electrical Wiring and I.E RulesDocumento6 pagineQuestion Bank: Part-A Marks: 2 UNIT-1 Electrical Wiring and I.E RulesM Jaya Vignesh 1DS17EE051Nessuna valutazione finora

- Power and Control Cable SpecificationDocumento23 paginePower and Control Cable SpecificationJithuRajNessuna valutazione finora

- SECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDocumento8 pagineSECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDenyNessuna valutazione finora

- 12 Tmss 11 r0 HV Link BoxDocumento29 pagine12 Tmss 11 r0 HV Link BoxVijayan Thekke VeeduNessuna valutazione finora

- Terminal Connectors 66 132 220 400 KVDocumento9 pagineTerminal Connectors 66 132 220 400 KVVishnu ShankerNessuna valutazione finora

- 12-TMSS-04 R.0Documento19 pagine12-TMSS-04 R.0wastazoheb_700349353Nessuna valutazione finora

- 11 kV 12.5 kA Outdoor Switchgear SpecificationDocumento48 pagine11 kV 12.5 kA Outdoor Switchgear SpecificationMekonnen ShewaregaNessuna valutazione finora

- 33kV GIS Switchgear Technical SpecificationDocumento115 pagine33kV GIS Switchgear Technical SpecificationAhmed Al-BaghdadiNessuna valutazione finora

- LAS CompsDocumento5 pagineLAS CompsDelta VisionNessuna valutazione finora

- Electrical Requirements For InstallationsDocumento14 pagineElectrical Requirements For InstallationsFrancis OwusuNessuna valutazione finora

- Bechtel Limited: Engineering Guide Instruction 3DG-E23E-00100 D.C. Supply Units (Batteries & Battery Chargers)Documento11 pagineBechtel Limited: Engineering Guide Instruction 3DG-E23E-00100 D.C. Supply Units (Batteries & Battery Chargers)mohammadkassarNessuna valutazione finora

- Ufgs 33 82 00Documento36 pagineUfgs 33 82 00Miko GorospeNessuna valutazione finora

- ICTCBL2136B Install Maintain and Modify Customer Premises Communications Cabling ACMA Restricted Rule LR V1Documento225 pagineICTCBL2136B Install Maintain and Modify Customer Premises Communications Cabling ACMA Restricted Rule LR V1FfdsfdsNessuna valutazione finora

- DEWA Electrical Installation Regulations Section 1 OverviewDocumento123 pagineDEWA Electrical Installation Regulations Section 1 Overviewsiva_nagesh_280% (5)

- 3466 - Revised Solar PV Checklist - June 2017Documento8 pagine3466 - Revised Solar PV Checklist - June 2017Electricité & Instrumentation Gassi TouilNessuna valutazione finora

- 63-100 Kva Tf-Rural-907Documento91 pagine63-100 Kva Tf-Rural-907Ritesh DhawaleNessuna valutazione finora

- 31 TRF 07-07-2022Documento68 pagine31 TRF 07-07-2022abhi6784Nessuna valutazione finora

- APTRANSCO Connection CodeDocumento31 pagineAPTRANSCO Connection Codekrajeev2802Nessuna valutazione finora

- Ceia Tech 1Documento8 pagineCeia Tech 1B BorahNessuna valutazione finora

- Tech Specification of 33 KV 800amp Isolators With Without EB 17.06.19Documento46 pagineTech Specification of 33 KV 800amp Isolators With Without EB 17.06.19SE O&M Circle Wardha WardhaNessuna valutazione finora

- 3phase Blast WallDocumento39 pagine3phase Blast WallKaren-John Richard NelsonNessuna valutazione finora

- Spec - Earthing & BondingDocumento15 pagineSpec - Earthing & BondingcklconNessuna valutazione finora

- Specification of 11kv SF6 Insulated Ring Main UnitsDocumento8 pagineSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANNessuna valutazione finora

- Reliability Specification for Electronics in Indian Rail Rolling StockDocumento12 pagineReliability Specification for Electronics in Indian Rail Rolling Stockvikas katiyarNessuna valutazione finora

- SEC Transmission Grounding Transformer SpecificationDocumento29 pagineSEC Transmission Grounding Transformer SpecificationOrcun CalayNessuna valutazione finora

- 52TMSS01R0Documento29 pagine52TMSS01R0Orcun CalayNessuna valutazione finora

- E16406Documento11 pagineE16406HOFFERNessuna valutazione finora

- Grounding StandardDocumento85 pagineGrounding Standardflake03Nessuna valutazione finora

- 11and-22-Kv - LA 0307 Correctn FinalDocumento14 pagine11and-22-Kv - LA 0307 Correctn FinalSE O&M Circle Wardha WardhaNessuna valutazione finora

- 33.11kv Substation For LNPDocumento54 pagine33.11kv Substation For LNPnegiboyz80% (5)

- Reference Architecture Design Guide Part 3,0 PDFDocumento100 pagineReference Architecture Design Guide Part 3,0 PDFdexterNessuna valutazione finora

- Commercial Checklist-Print - 2008 Nec - 08-28-08Documento23 pagineCommercial Checklist-Print - 2008 Nec - 08-28-08akiferindrariskyNessuna valutazione finora

- FOI CompsDocumento6 pagineFOI Compsericomoura100% (1)

- Volume - Iv: Madhya Pradesh Power Transmission Co. LTDDocumento36 pagineVolume - Iv: Madhya Pradesh Power Transmission Co. LTDRamphani NunnaNessuna valutazione finora

- Circuit Breaker Technical SpecificationsDocumento24 pagineCircuit Breaker Technical SpecificationssanjayNessuna valutazione finora

- Certified Fiber Optics Designer (FOD) : Competency RequirementsDocumento9 pagineCertified Fiber Optics Designer (FOD) : Competency Requirementsasifusmani19Nessuna valutazione finora

- Inspection Checklist Guide For PV Systems in One-And Two - Family DwellingsDocumento7 pagineInspection Checklist Guide For PV Systems in One-And Two - Family DwellingsElectricité & Instrumentation Gassi TouilNessuna valutazione finora

- Dry Type Transformer Spec in Word FormatDocumento25 pagineDry Type Transformer Spec in Word Formatarulraj1971Nessuna valutazione finora

- bs7671 Iee On Site GuideDocumento184 paginebs7671 Iee On Site Guidemigzx95% (19)

- 12SDMS01Documento14 pagine12SDMS01hafezasadNessuna valutazione finora

- 87meg 01Documento6 pagine87meg 01DEVI PRASAD GREENSECURENessuna valutazione finora

- Current Transformer of Different RatioDocumento12 pagineCurrent Transformer of Different RatioPawan Kumar SahaNessuna valutazione finora

- COP 101 Version 12 Document (Text) June 2012Documento45 pagineCOP 101 Version 12 Document (Text) June 2012DFNessuna valutazione finora

- Fundamentals of Fault Current and Grounding in Electrical SystemsDa EverandFundamentals of Fault Current and Grounding in Electrical SystemsValutazione: 4 su 5 stelle4/5 (3)

- The IEE Wiring Regulations Explained and IllustratedDa EverandThe IEE Wiring Regulations Explained and IllustratedValutazione: 4 su 5 stelle4/5 (14)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Substation Automation Systems: Design and ImplementationDa EverandSubstation Automation Systems: Design and ImplementationValutazione: 4.5 su 5 stelle4.5/5 (3)

- 5G Explained: Security and Deployment of Advanced Mobile CommunicationsDa Everand5G Explained: Security and Deployment of Advanced Mobile CommunicationsNessuna valutazione finora

- The Internet of Things: Key Applications and ProtocolsDa EverandThe Internet of Things: Key Applications and ProtocolsValutazione: 5 su 5 stelle5/5 (1)

- CompTIA Network+ CertMike: Prepare. Practice. Pass the Test! Get Certified!: Exam N10-008Da EverandCompTIA Network+ CertMike: Prepare. Practice. Pass the Test! Get Certified!: Exam N10-008Nessuna valutazione finora

- Indoor Radio Planning: A Practical Guide for 2G, 3G and 4GDa EverandIndoor Radio Planning: A Practical Guide for 2G, 3G and 4GValutazione: 5 su 5 stelle5/5 (1)

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Da EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Valutazione: 5 su 5 stelle5/5 (2)

- Towards 5G: Applications, Requirements and Candidate TechnologiesDa EverandTowards 5G: Applications, Requirements and Candidate TechnologiesRath VannithambyNessuna valutazione finora

- Wireless Sensor Systems for Extreme Environments: Space, Underwater, Underground, and IndustrialDa EverandWireless Sensor Systems for Extreme Environments: Space, Underwater, Underground, and IndustrialNessuna valutazione finora

- CP1E CPU Unit Hardware Users ManualDocumento246 pagineCP1E CPU Unit Hardware Users Manualwiyah1610Nessuna valutazione finora

- Readme (English)Documento1 paginaReadme (English)wiyah1610Nessuna valutazione finora

- Kod Dan Nama ProgramDocumento1 paginaKod Dan Nama Programwiyah1610Nessuna valutazione finora

- Test Table of Specification Primary School English JSUDocumento1 paginaTest Table of Specification Primary School English JSUSylviaJonathanNessuna valutazione finora

- GL Vi-7-2 e PDFDocumento32 pagineGL Vi-7-2 e PDFwiyah1610Nessuna valutazione finora

- RPT Tingkatan 5 2014 Subjek Bahasa InggerisDocumento6 pagineRPT Tingkatan 5 2014 Subjek Bahasa InggerisAzma ZiehaNessuna valutazione finora

- 120 Maintenance CCTV Surveillance Systems CopDocumento16 pagine120 Maintenance CCTV Surveillance Systems CopAdrian Dalida AgawinNessuna valutazione finora

- RPH Bahasa Inggeris Tahun 1 KSSRDocumento21 pagineRPH Bahasa Inggeris Tahun 1 KSSRsyazalina8392% (13)

- Communications Site Installation: CSII/R56 Installer Version Competency RequirementsDocumento6 pagineCommunications Site Installation: CSII/R56 Installer Version Competency Requirementswiyah1610Nessuna valutazione finora

- 120 Maintenance CCTV Surveillance Systems CopDocumento16 pagine120 Maintenance CCTV Surveillance Systems Copwiyah1610Nessuna valutazione finora

- Yearly Scheme of Work English KSSR Year 4 2015 Week/Unit Listening & Speaking Reading Writing Language Arts GrammarDocumento18 pagineYearly Scheme of Work English KSSR Year 4 2015 Week/Unit Listening & Speaking Reading Writing Language Arts Grammarwiyah1610Nessuna valutazione finora

- Guideline AA Form v3Documento53 pagineGuideline AA Form v3Eszeree RimieNessuna valutazione finora

- GL Vi-7-2 e PDFDocumento32 pagineGL Vi-7-2 e PDFwiyah1610Nessuna valutazione finora

- Jsu Bi Paper 1 T4Documento2 pagineJsu Bi Paper 1 T4Ahmad Sazli ZainalNessuna valutazione finora

- Application Form Amateur Service v2009Documento7 pagineApplication Form Amateur Service v2009hasirin76Nessuna valutazione finora

- RPH KSSR Bahasa Inggeris BI Tahun 4 PDFDocumento27 pagineRPH KSSR Bahasa Inggeris BI Tahun 4 PDFwiyah1610Nessuna valutazione finora

- Kod Dan Nama ProgramDocumento1 paginaKod Dan Nama Programwiyah1610Nessuna valutazione finora

- Answer Bi t4Documento2 pagineAnswer Bi t4Blancoz Zamani BoeNessuna valutazione finora

- T2 Answer BI Kertas 2Documento1 paginaT2 Answer BI Kertas 2Ct R MienaNessuna valutazione finora

- Spo Exchange Scrap Notification FormDocumento1 paginaSpo Exchange Scrap Notification Formwiyah1610100% (1)

- BAHASA INGGERIS Kertas 1, Tahun 2Documento13 pagineBAHASA INGGERIS Kertas 1, Tahun 2Siti Noorazah Jamil100% (1)

- Spo Exchange Scrap Notification Form: 1 86100-63048-79-0812-03111 Pad Lifted at R215 Unable To Rework Remain To ScrapDocumento1 paginaSpo Exchange Scrap Notification Form: 1 86100-63048-79-0812-03111 Pad Lifted at R215 Unable To Rework Remain To Scrapwiyah1610Nessuna valutazione finora

- Form 2 English Scheme of Work With PPPM 2015Documento14 pagineForm 2 English Scheme of Work With PPPM 2015bhuvana ruebenNessuna valutazione finora

- Q & I TemplateDocumento1 paginaQ & I Templatewiyah1610Nessuna valutazione finora

- RPT Tingkatan 5 2014 Subjek Bahasa InggerisDocumento6 pagineRPT Tingkatan 5 2014 Subjek Bahasa InggerisAzma ZiehaNessuna valutazione finora

- Part Failure FormDocumento5 paginePart Failure Formwiyah1610Nessuna valutazione finora

- Template of Business Letter 1Documento1 paginaTemplate of Business Letter 1wiyah1610Nessuna valutazione finora

- EducationDocumento31 pagineEducationwiyah1610Nessuna valutazione finora

- SasDocumento6 pagineSasసతీష్ పసులNessuna valutazione finora

- Matrix of Proposed Revisions To RA No 9173Documento25 pagineMatrix of Proposed Revisions To RA No 9173Ray Andrew del Rosario80% (5)

- CRA GuideDocumento42 pagineCRA Guidevspkumar100% (1)

- FAQ - CPA Programming Essentials in C++ (August 25, 2016)Documento8 pagineFAQ - CPA Programming Essentials in C++ (August 25, 2016)Mohammad HassanNessuna valutazione finora

- Metrobank Foundation and Fluor Inc. Engineering Scholarship ProgramDocumento5 pagineMetrobank Foundation and Fluor Inc. Engineering Scholarship Programayagi erisNessuna valutazione finora

- ASP Complete GuideDocumento32 pagineASP Complete GuideAmmar Hussain67% (3)

- Iso31000 LRM p4 EnglishDocumento3 pagineIso31000 LRM p4 Englishapi-357147824Nessuna valutazione finora

- Cert Handbook CTS-DDocumento56 pagineCert Handbook CTS-DIra Beyer100% (1)

- CCP Exam Prep Workshops Saudi 2014Documento3 pagineCCP Exam Prep Workshops Saudi 2014Waqas AhmedNessuna valutazione finora

- ISACA to Update CISA Exam in 2019Documento2 pagineISACA to Update CISA Exam in 2019freakyneo0% (1)

- Css RequirementDocumento56 pagineCss Requirementcv7022963Nessuna valutazione finora

- Ankit Roy: Curriculum - VitaeDocumento2 pagineAnkit Roy: Curriculum - VitaesupriyaNessuna valutazione finora

- 2020 Sustainable Agriculture Standard - Farm Requirements - Rainforest Alliance PDFDocumento83 pagine2020 Sustainable Agriculture Standard - Farm Requirements - Rainforest Alliance PDFLuis LanzasNessuna valutazione finora

- SHS Implementation Updates For R7Documento141 pagineSHS Implementation Updates For R7tumasitoeNessuna valutazione finora

- 200-310 Cisco Real Exam QuestionsDocumento20 pagine200-310 Cisco Real Exam Questions100-101100% (1)

- Autodesk Maya 2015 Certification Roadmap PDFDocumento2 pagineAutodesk Maya 2015 Certification Roadmap PDFHandriToarPangkeregoNessuna valutazione finora

- Regulation of Research Analyst Draft Guidlines SebiDocumento33 pagineRegulation of Research Analyst Draft Guidlines SebidelhiceerNessuna valutazione finora

- Customs Clearing Agents RegulationDocumento5 pagineCustoms Clearing Agents RegulationTSEDEKENessuna valutazione finora

- Cii Qualifications BrochureDocumento38 pagineCii Qualifications BrochureNoor MahmoodNessuna valutazione finora

- Teachers' Guide To Serving in The NYC Public SchoolsDocumento80 pagineTeachers' Guide To Serving in The NYC Public SchoolsBronx ProfessoraNessuna valutazione finora

- Iiba Cpoa Certification HandbookDocumento7 pagineIiba Cpoa Certification HandbookDerrickKeithNessuna valutazione finora

- Autodesk Inventor 2015 Certification RoadmapDocumento2 pagineAutodesk Inventor 2015 Certification RoadmapNugroho Adhi SaputroNessuna valutazione finora

- SQF Quality Code Ed 8.1Documento49 pagineSQF Quality Code Ed 8.1Luis GallegosNessuna valutazione finora

- ISO 17024-2016 - How To Develop Squemes For The Certification of Persons - PublDocumento24 pagineISO 17024-2016 - How To Develop Squemes For The Certification of Persons - Publgmitsuta100% (1)

- Leadership Portfolio Component DetailsDocumento4 pagineLeadership Portfolio Component DetailssurfingbananaNessuna valutazione finora

- ICMAP New Reshuffled Courses Schedule 2012Documento3 pagineICMAP New Reshuffled Courses Schedule 2012KhAliq KHanNessuna valutazione finora

- Insol Dossier (20022019)Documento26 pagineInsol Dossier (20022019)Anthony Charles ANessuna valutazione finora

- Gini Aintp Guidebook MinDocumento15 pagineGini Aintp Guidebook MinMohamed ShteawiNessuna valutazione finora