Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CBD Type Z1 PDF

Caricato da

vtalexDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CBD Type Z1 PDF

Caricato da

vtalexCopyright:

Formati disponibili

CALCULATION REPORT

STRESS ANALYSIS OF

TYPICAL 'Z-FIX' ANCHOR FOR EXTERNAL

INSTALLATION

HORIZONTAL AND VERTICAL JOINT FIXING

TYPE Z1

FOR STONE SIZES:

4 x 61 x 150 cm

PROJECT:

COMMERCIAL BANK OF DOHA

CLIENT:

ANGMP LLC

FIXING SYSTEM SUPPLIER:

COMMERCIAL BANK OF DOHA

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 1/10

INDEX

1.0 CALCULATION STANDARTS:

2.0 VERIFICATION OF ALLOWABLE STRESSES:

2.1 MECHANICAL PROPERTIES FOR HOT ROLLED PLATE:

2.2 MECHANICAL PROPERTIES FOR COLD DRAWN RODS:

2.3 RECOMENDED STRUCTURAL LOADS FOR THROUGH BOLT:

3- VERIFICATION OF WIND & DEAD LOADS:

3.1 ANCHORAGE SYSTEM SKETCH:

3.2 VERIFY DEAD LOAD OF STONE PANEL:

3.3 VERIFY IMPACT LOAD OCCURRED ON STONE PANEL:

4- STATICAL CALCULATION OF TYPICAL Z-FIX-03 SERIES ANCHOR:

4.1 CHECK ON THE PIN:

4.2 CHECK ON THE EXTENSION ARM:

4.2.1 CHECK ON SECTION 1-1:

4.2.2 CHECK ON SECTION 2-2:

4.3 CHECK ON THE ANCHOR BODY:

4.3.1 CHECK ON SECTION 3-3:

4.3.2 CHECK ON SECTION 4-4:

5.0 CHECK OF THE PULL-OUT FOR THROUGH BOLT:

6.0 SKETCH & CHART FOR DIMENSIONAL VARIABLES:

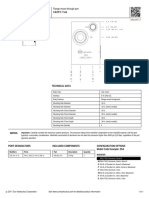

7.0 HILTI HSA-THROUGH BOLT ANCHOR TECHNICAL DATA :

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 2/10

2.0 VERIFICATION OF ALLOWABLE STRESSES:

FIXING MATERIALS:

ANCHOR BODIES, SERRATED WASHER:

AISI 316 AUSTENITIC STAINLESS STEEL HOT ROLLED PLATE

EXTENSION ARM, FIXING PIN, HEXAGONAL BOLT:

AISI 316 AUSTENITIC STAINLESS STEEL HOT ROLLED PLATE

2.1 MECHANICAL PROPERTIES FOR HOT ROLLED PLATE:

2

YIELD STRESS (Y): 316.00 N/mm

2

SHEAR STRESS (SS=ASx0.60): 189.60 N/mm

2.2 MECHANICAL PROPERTIES FOR COLD DRAWN RODS:

2

YIELD STRESS (Y): 609.00 N/mm

2

SHEAR STRESS (SS=ASx0.60): 365.40 N/mm

2.3 RECOMMENDED STRUCTURAL LOADS FOR THROUGH BOLT:

THROUGH BOLT: HILTI HSA M8X92 AISI 316

TYPE OF LOADING SAFE WORKING LOADS (N)

TENSILE 4800 N

SHEAR 4800 N

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 3/10

3- STRUCTURAL CALCULATION OF TYPICAL C-FIX SERIES ANCHOR:

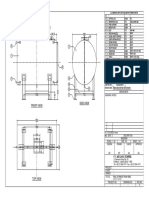

3.1 ANCHORAGE SYSTEM SKETCH

C

C1 C2

A

B5

A

HORIZONTAL FIXING SECTION A-A

1 S.S 316L Z-FIX ANCHOR BODY

1 2 S.S 316L NUT FOR ADJUSTABLE ARM

3 S.S 316L ADJUSTABLE ARM

4 S.S 316L FIXING PIN

2

5 S.S 316L SERRATED WASHER

3

6 S.S 316 THROUGH BOLT

4

Note: The oriantation of the above plate should be respected on the site

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 4/10

3- VERIFICATION OF WIND LOAD & DEAD LOADS:

3.2 VERIFY DEAD LOAD OF STONE PANEL:

LARGEST STONE DIMENSIONS

HEIGHT (h): 150 cm

WIDTH (wd): 61 cm

THICKNESS (th): 4 cm

3

DENSITY OF STONE (d): 25000 N/m

DEAD WEIGHT OF STONE (FDL=h x wd x th / 1000000 x d): 915.00 N

EACH STONE PANEL WILL BE CARRIED BY TWO NOS Z-FIX. THE SAME Z-FIX WILL BE LOAD BEARING FOR THE UPPER STONE PANEL

AND RESTRAIN FOR THE BOTTOM STONE PANEL

DEAD WEIGHT OF STONE PER ANCHOR (FDLA=FDL/2): 457.50 N

DESIGN LOAD PER ANCHOR (FDWA=1.2 X FDLA): 549.00 N

3.3 VERIFY WIND LOAD OCCURRED ON STONE PANEL:

DESIGN WIND LOAD (FW = FP): 2550.00 N

PRESSURE PER ANCHOR (FWA= h x wd x FW / 2 x 1.2): 1399.95 N

PRESSURE PER PIN (FWP = FW / 4): 699.98 N

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 5/10

4- STATICAL CALCULATION OF TYPICAL Z-FIX-03 SERIES ANCHOR:

4.1 CHECK ON THE PIN:

j (between two stones)= 9 mm

g (impression area)= 5 mm

2

Pin Area (Ap = x (P1) / 4): 19.63 mm2

Shear Stress ( = (4 / 3) x FWP / Ap): 47.53 N/mm2 <all = 365.40 N/mm2

Moment on the Pin (Mp = FWP x g ) : 3499.88 Nmm

W = x (P1)3 / 32= 12.27 mm3

Tensile Stress ( = Mp / W): 285.20 N/mm2 <all = 609.00 N/mm2

Combined Stress (c= sqrt ( ()2 + 3 x 2): 296.84 N/mm 2

<all = 609.00 N/mm

3

Thus, the pin is safe under the given loading

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 6/10

4.2 CHECK ON THE EXTENSION ARM:

EXTENSION ARM:

E1 10 mm

E2 50 mm

E3 20 mm

E4 8 mm

FDW

E5 12 mm

E6 4 mm

E7 5 mm

E1min 9 mm

-

+ FWA ANCHOR BODY:

B1 5 mm

B2 50 mm

B3 34 mm

B4 89 mm

B5 25 mm

FDW B6 30 mm

B7 25 mm

B8 10 mm

B9 20 mm

B10 9 mm

B12 10 mm

B13 7 mm

-

+ FWA

4.2.1 CHECK ON SECTION 1-1:

Section Area (AEA1 = E6 x E5)= 48.00 mm2

2

W EA1 = (1 / 6) x (E6) x E5 = 32.00 mm3

Moment on Section 1-1 (M1 = (FDWA) x E3): 10,980.00 Nmm

372.29 N/mm2 <all =

2

Tensile Stress ( = M1 / W EA1 + FWA / AEA1): 609.00 N/mm

2

Shear Stress (= (3 / 2) x (FDWA) / A): 14.30 N/mm <all = 365.40 N/mm2

Combined Stress (C = sqrt ( ()2 + 3 x 2): 373.11 N/mm2 <all = 609.00 N/mm

2

Thus, the extension arm is safe under the given loading

4.2.2 CHECK ON SECTION 2-2:

2

Section Area (AEA2 = x (E1min) / 4)= 56.75 mm2

3

W EA2 = x (E1min) / 32 = 60.29 mm3

Lmax1 = E2 - E4 - B1 = 37.00 mm

Moment on Section 2-2 (M2 = (FDWA) x Lmax1): 20,313.00 Nmm

Tensile Stress ( = M2 / W EA2 + FWA / AEA2): 361.58 N/mm2 <all = 609.00 N/mm2

2 2

Shear Stress (= (4 / 3) x (FDWA) / AEA2): 10.75 N/mm <all = 365.40 N/mm

2 2

Combined Stress (C = sqrt ( () + 3 x ): 362.06 N/mm 2

<all = 609.00 N/mm

2

Thus, the extension arm is safe under the given loading

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 7/10

4.3 CHECK ON THE ANCHOR BODY:

FDW

-

+ FWA

4.3.1 CHECK ON SECTION 3-3:

2

Section Area (AAB1 = (B2 - B12) x B1)= 200 mm

2

(W AB1 = (B1) x (B2-B12) / 6= 166.67 mm3

LMAX2 = E2 - E4 - ((B1)/2) = 39.5 mm

Moment on Section 3-3 (M3 = (FDWA) x LMAX2)= 21685.5 Nmm

Tensile Stress ( = M3 / W AB + FDW / AAB1)= 132.86 N/mm2 <all = 316.00 N/mm2

2

Shear Stress (= (3 / 2) x (FWA) / AAB1)= 10.50 N/mm <all = 189.60 N/mm2

2 2

Combined Stress (C = sqrt ( () + 3 x )= 134.10 N/mm 2

<all = 316.00 N/mm

2

Thus, the anchor body is safe under the given loading

4.3.2 CHECK ON SECTION 4-4:

Section Area (AAB2 = (B2 - B10) x( B1) + (S1 x S3 ) = 280 mm2

Gravity Center y: 2.94 mm

y= ((B2 - B10) x B1 x B1 /2 + (S1 - S4) x S3 x (B1 + S3 / 2)) / A

Moment Of Inertia I = 4235.42 mm4

y1 = B1 + S3 - y = 5.06 mm

y= 5.06

W AB2 = (1 / 6) x (B1+S3)2 x (B2-B10) = 437.33 mm3

LMAX3 = B4 - (B6 / 2) - B8 - (T1 / 2) - B13 = 53.5 mm

LMAX4 = LMAX2 + B5 - B1/2= 62.0 mm

Moment on Section 4-4 (M4 = (FDWA x LMAX4) + FWA x LMAX3 : 108935.33 Nmm

Tensile Stress ( = M4 / W AB2 + (FDWA) / AAB2): 250.72 N/mm2 <all = 316 N/mm2

2

Shear Stress (= (3 / 2) x FWA / AAB2): 7.50 N/mm <all = 189.6 N/mm2

2 2

Combined Stress (C = sqrt ( () + 3 x ): 251.06 N/mm 2

<all = 316 N/mm2

Thus, the anchor body is safe under the given loading

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 8/10

5.0 CHECK OF THE PULL-OUT FOR FOR THE THROUGH BOLT:

(SEE SKETCH)

FDW

FPO

-

+ FWA

PULL OUT FORCE AROUND MARKED ''A' POINT:

LMAX4 = E2 - E4 - B1 = 62.0 mm

LMAX5 = B4 - B8 - B9 + T1/2 = 63 mm

M=FDWA x LMAX4 = 34038.00 Nmm

FPO = M / LMAX5 = 540.29 Nmm

FPO= 540.29 N < 4800 N

Shear Force= 549.00 N < 4800 N

Thus, the bolt is safe under the given loading

BOLT AREA: 50.24 mm2

2 2

TENSILE STRESS = PULL OUT/AREA= 10.754 N/mm < 609.00 N/mm

Shear Force RVS = FDW = 549.00 N

SHEAR STRESS=SHEAR FORCE/AREA= 10.93 N < 365.40 N/mm2

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 9/10

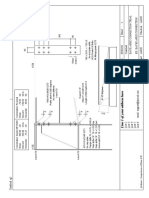

6.0 SKETCH & CHART FOR DIMENSIONAL VARIABLES:

ANCHOR BODY:

B1 5 mm

B2 50 mm

B3 34 mm

B4 89 mm

B5 25 mm

B6 30 mm

B7 25 mm

B8 10 mm

B9 20 mm

B10 9 mm

B12 10 mm

B13 7 mm

EXTENSION ARM:

E1 10 mm

E2 50 mm

E3 20 mm

E4 8 mm

E5 12 mm

E6 4 mm

E7 5.2 mm

E1min 8.5 mm

SERRATED WASHER:

S1 25 mm

S2 25 mm

S3 3.0 mm

S4 9 mm

FIXING PIN:

P1 5 mm

P2 50 mm

THROUGH BOLT

T1 8 mm

T2 92 mm

COMMERCIAL BANK OF DOHA

..SEL-FIX..

TYPE Z1 THE FIXING SYSTEM SPECIALIST

8/10/2014 REVISION 0 10/10

Potrebbero piacerti anche

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Calculation Report: Type Z1Documento10 pagineCalculation Report: Type Z1vtalexNessuna valutazione finora

- Catalogue CNA 50Hz Rev.1 Update 6-1Documento6 pagineCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNessuna valutazione finora

- Calculation Sheet: Yb For UB BeamDocumento2 pagineCalculation Sheet: Yb For UB BeamrammohanNessuna valutazione finora

- Double Regulating ValveDocumento24 pagineDouble Regulating ValveMohamed Rady33% (3)

- Fineadjust Applicator Specification Sheet Order No. 63900-0100Documento5 pagineFineadjust Applicator Specification Sheet Order No. 63900-0100Amine MaaouiNessuna valutazione finora

- Expansion Bellow SpecificationDocumento1 paginaExpansion Bellow SpecificationASHWINI BHOSALENessuna valutazione finora

- 8) Tss-Glycol Surge DrumDocumento1 pagina8) Tss-Glycol Surge DrumKiran KumarNessuna valutazione finora

- Co2 Cylinder Master Assembly: Data SheetDocumento19 pagineCo2 Cylinder Master Assembly: Data SheetLaxmanDungraniNessuna valutazione finora

- Block Shear Connection Design Checks PDFDocumento7 pagineBlock Shear Connection Design Checks PDF112160rbc100% (1)

- Brochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDocumento6 pagineBrochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDt BarusNessuna valutazione finora

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocumento6 pagineSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNessuna valutazione finora

- Brochure FSA, 60 HZDocumento6 pagineBrochure FSA, 60 HZIbrahim SanusiNessuna valutazione finora

- 7203-6311-MDC-030KL TankDocumento34 pagine7203-6311-MDC-030KL TankDarshJhaNessuna valutazione finora

- All Final DimensionDocumento6 pagineAll Final Dimensionshailesh deshmukhNessuna valutazione finora

- NV MedPress SMDocumento8 pagineNV MedPress SMElinton SarmientoNessuna valutazione finora

- Calcu Nozzle NeckDocumento15 pagineCalcu Nozzle Necksachmaya0% (1)

- VMS - 5Documento1 paginaVMS - 5ritoh8657Nessuna valutazione finora

- Hitungan Volume Pompa EbaraDocumento6 pagineHitungan Volume Pompa EbaraApriliyanto Rahadi PradanaNessuna valutazione finora

- Brosur EBARA - FSADocumento6 pagineBrosur EBARA - FSAdirumah AjaNessuna valutazione finora

- Hydrodynamic Cable Reels - Instruction Manual PDFDocumento24 pagineHydrodynamic Cable Reels - Instruction Manual PDFescupabloNessuna valutazione finora

- ER89-187-2 CL 9002 VacDocumento1 paginaER89-187-2 CL 9002 VacGabriel VejarNessuna valutazione finora

- Lifting CalcDocumento12 pagineLifting Calcwisnu_bayusaktiNessuna valutazione finora

- Valve Material Specification A1MDocumento9 pagineValve Material Specification A1Mchintan100% (1)

- Model Insert Style, Single Ball Shuttle Valve With Signal at Port 2Documento2 pagineModel Insert Style, Single Ball Shuttle Valve With Signal at Port 2snsnagarajanNessuna valutazione finora

- SMG Folder Emea EngDocumento4 pagineSMG Folder Emea EngsyNessuna valutazione finora

- CXDAXCN Full Es Metric A4Documento2 pagineCXDAXCN Full Es Metric A4Sara SaritaNessuna valutazione finora

- Especificaciones Compresor Centac C700Documento2 pagineEspecificaciones Compresor Centac C700Ascencio RubenNessuna valutazione finora

- The Analysis Will Be Carried Out in Accordance To AISC Design Guide 9Documento33 pagineThe Analysis Will Be Carried Out in Accordance To AISC Design Guide 9venkat27081995Nessuna valutazione finora

- M2-CV-RC-D-005 (Anchor Bolt Details)Documento19 pagineM2-CV-RC-D-005 (Anchor Bolt Details)neerajNessuna valutazione finora

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocumento1 paginaGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANessuna valutazione finora

- Standard Detail Drawings Storm and Sanitary SewersDocumento55 pagineStandard Detail Drawings Storm and Sanitary SewersAbdulsalamNessuna valutazione finora

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Documento370 pagineParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185Nessuna valutazione finora

- HousingDocumento58 pagineHousingDaniel Alam SubiruNessuna valutazione finora

- V-340 OutDocumento14 pagineV-340 OutSachin5586Nessuna valutazione finora

- FST001000LG Std-ModelDocumento1 paginaFST001000LG Std-ModelaryitoNessuna valutazione finora

- Sicca 150-600 GLC PDFDocumento4 pagineSicca 150-600 GLC PDFBrinto VargheseNessuna valutazione finora

- Sicca 150-600 GLC Ag PDFDocumento4 pagineSicca 150-600 GLC Ag PDFBrinto VargheseNessuna valutazione finora

- Ufm Flow MeterDocumento6 pagineUfm Flow MeterJaneth JqcNessuna valutazione finora

- Series 4030: SubmittalDocumento2 pagineSeries 4030: SubmittalPSC RFQNessuna valutazione finora

- Hoist CapacityDocumento10 pagineHoist CapacityDheeraj ThakurNessuna valutazione finora

- SankarDocumento49 pagineSankarRavikumara TNessuna valutazione finora

- FluidComponentsFullCatalog PDFDocumento502 pagineFluidComponentsFullCatalog PDFPablo MNessuna valutazione finora

- 4000 Series Cryogenic Valve: Bulletin 86.1:4000Documento8 pagine4000 Series Cryogenic Valve: Bulletin 86.1:4000Datt NguyenNessuna valutazione finora

- Railing Glass Detail Calculation-1.75 KpaDocumento7 pagineRailing Glass Detail Calculation-1.75 KpaSufiyan ShaikhNessuna valutazione finora

- Securedge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Documento2 pagineSecuredge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Constantin GubavuNessuna valutazione finora

- Model Flange Mount Through Port: Cavity: T-2ADocumento1 paginaModel Flange Mount Through Port: Cavity: T-2Acesar5984Nessuna valutazione finora

- Quick Release Snap Type CouplingDocumento1 paginaQuick Release Snap Type Couplingpeters petersNessuna valutazione finora

- Er89-196 MHF 50Documento1 paginaEr89-196 MHF 50Gabriel VejarNessuna valutazione finora

- Calculation Sheet 02Documento1 paginaCalculation Sheet 02kkgcNessuna valutazione finora

- KSB Sicca HP Cast Gate Valve PDFDocumento4 pagineKSB Sicca HP Cast Gate Valve PDFJamalNessuna valutazione finora

- Api 602 Forged Steel Valve PDFDocumento4 pagineApi 602 Forged Steel Valve PDFThomasFrenchNessuna valutazione finora

- CXHAXAN - Full - en - Metric - Letter BorbetDocumento2 pagineCXHAXAN - Full - en - Metric - Letter BorbetRonaldNessuna valutazione finora

- Wall Thickness: Piping SpecificationDocumento2 pagineWall Thickness: Piping SpecificationLynn AlgerNessuna valutazione finora

- 77e5-B005 (Hydraulic Cylinder)Documento4 pagine77e5-B005 (Hydraulic Cylinder)Sandeep JoshiNessuna valutazione finora

- Product CatalogueDocumento24 pagineProduct Cataloguerupa thakkarNessuna valutazione finora

- Series 2700 Maintenance ManualDocumento12 pagineSeries 2700 Maintenance ManualLuciusNessuna valutazione finora

- Advances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967Da EverandAdvances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967S. A. TobiasValutazione: 4 su 5 stelle4/5 (1)

- Finkster-Python CheatsheetDocumento11 pagineFinkster-Python CheatsheetvtalexNessuna valutazione finora

- DM04 04 PDFDocumento16 pagineDM04 04 PDFvtalexNessuna valutazione finora

- Kec Metro ReactionsDocumento157 pagineKec Metro ReactionsvtalexNessuna valutazione finora

- Interpolation - MathDocumento1 paginaInterpolation - MathvtalexNessuna valutazione finora

- Scia Engineer - Load Generators en 2Documento3 pagineScia Engineer - Load Generators en 2vtalexNessuna valutazione finora

- Fixed Base Plate ExampleDocumento5 pagineFixed Base Plate ExamplevtalexNessuna valutazione finora

- Commentary: Standards Secondary and Structural Girts Practices DesignDocumento2 pagineCommentary: Standards Secondary and Structural Girts Practices DesignvtalexNessuna valutazione finora

- Pinned Base PlateDocumento7 paginePinned Base PlatevtalexNessuna valutazione finora

- Purlin Bracing CriteriaDocumento19 paginePurlin Bracing CriteriavtalexNessuna valutazione finora

- Pinned Base Plate DesignDocumento12 paginePinned Base Plate DesignvtalexNessuna valutazione finora

- Aluminum CurtainwallDocumento8 pagineAluminum CurtainwallvtalexNessuna valutazione finora

- Calculation Headline: Roof GeometryDocumento2 pagineCalculation Headline: Roof GeometryvtalexNessuna valutazione finora

- Purlin Bracing CriteriaDocumento19 paginePurlin Bracing CriteriavtalexNessuna valutazione finora

- TNEB Online Payment ReceiptDocumento1 paginaTNEB Online Payment Receiptvtalex0% (1)

- Quikjoint - Eaves Haunch Calculations PDFDocumento9 pagineQuikjoint - Eaves Haunch Calculations PDFvtalexNessuna valutazione finora

- Quikjoint - ResultsDocumento15 pagineQuikjoint - ResultsvtalexNessuna valutazione finora

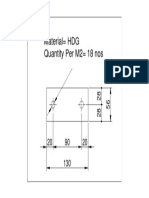

- Material HDG Quantity Per M2 18 NosDocumento1 paginaMaterial HDG Quantity Per M2 18 NosvtalexNessuna valutazione finora

- Quick Dashboard in Excel: Service Level Quality ScoreDocumento3 pagineQuick Dashboard in Excel: Service Level Quality ScorevtalexNessuna valutazione finora

- Doha Festival CIty Aug 16 Rev. 1Documento6 pagineDoha Festival CIty Aug 16 Rev. 1vtalexNessuna valutazione finora

- A1 60 Stone CladdingDocumento1 paginaA1 60 Stone CladdingvtalexNessuna valutazione finora

- Hilti - Pull Out Test Report-SampleDocumento3 pagineHilti - Pull Out Test Report-SamplevtalexNessuna valutazione finora

- Kiswel K-309LTDocumento1 paginaKiswel K-309LTOmer IkhlasNessuna valutazione finora

- Aci-211.2 (1998) PDFDocumento18 pagineAci-211.2 (1998) PDFFernando HerediaNessuna valutazione finora

- 2010 CBC Standard Partition Wall DetailsDocumento28 pagine2010 CBC Standard Partition Wall Detailspazz0Nessuna valutazione finora

- Supplementary Cementitious MaterialsDocumento2 pagineSupplementary Cementitious MaterialsaaNessuna valutazione finora

- BVD 2121 GBDocumento4 pagineBVD 2121 GBanon_487899699Nessuna valutazione finora

- Lightweight Roofing Solutions: Africa's Leading Roofing SolutionDocumento6 pagineLightweight Roofing Solutions: Africa's Leading Roofing SolutionMukomaNessuna valutazione finora

- Frequently Asked QuestionsDocumento6 pagineFrequently Asked QuestionsChimmy GonzalezNessuna valutazione finora

- 10 - Ravichandran Et AlDocumento13 pagine10 - Ravichandran Et AlAdam Al AufaNessuna valutazione finora

- CorrosionDocumento19 pagineCorrosiongopal singhNessuna valutazione finora

- Comparative Study On RCC Beam With and Without Carbon Fibre Reinforced Polymer Using Ansys SoftwareDocumento5 pagineComparative Study On RCC Beam With and Without Carbon Fibre Reinforced Polymer Using Ansys SoftwareEditor IJTSRDNessuna valutazione finora

- ANSI IEEE 135.30 Amerian National Standar For Zinc Coated For Overhead or Underground Line ConstructionDocumento4 pagineANSI IEEE 135.30 Amerian National Standar For Zinc Coated For Overhead or Underground Line ConstructionLuis MartinezNessuna valutazione finora

- Cryogenic Globe Valves: Model BSDocumento4 pagineCryogenic Globe Valves: Model BSkresimir.mikoc9765Nessuna valutazione finora

- Emergency Showers G1691: Guardian EquipmentDocumento2 pagineEmergency Showers G1691: Guardian Equipmenteisenbarger5607Nessuna valutazione finora

- Greater London Council - 1961 - Code of Practice For Means of Escape in The.. Roof EscapeDocumento12 pagineGreater London Council - 1961 - Code of Practice For Means of Escape in The.. Roof EscapeJitesh NichaniNessuna valutazione finora

- Total Lactuca Metal Çalışma YağıDocumento1 paginaTotal Lactuca Metal Çalışma YağıahmetNessuna valutazione finora

- British StardardDocumento9 pagineBritish StardardSagubar SathikaliNessuna valutazione finora

- Water Distribution SystemsDocumento49 pagineWater Distribution SystemsAnonymous fE2l3Dzl100% (1)

- Utilization of Waste Plastic in Manufacturing of Paver BlocksDocumento4 pagineUtilization of Waste Plastic in Manufacturing of Paver BlocksAragorn RingsNessuna valutazione finora

- Airbus A380: A Double Deck, Wide-Body, Four-Engine Airliner Manufactured by The European Corporation AirbusDocumento19 pagineAirbus A380: A Double Deck, Wide-Body, Four-Engine Airliner Manufactured by The European Corporation Airbuspseudonomous actualityNessuna valutazione finora

- Electrical Layout: Side Elevation Back ElevationDocumento1 paginaElectrical Layout: Side Elevation Back ElevationanzaniNessuna valutazione finora

- Assignment 2: Construction Materials & MethodsDocumento6 pagineAssignment 2: Construction Materials & MethodsYeasfi ArafNessuna valutazione finora

- Ch23 Cutting Tools WileyDocumento45 pagineCh23 Cutting Tools WileyPrateek SaxenaNessuna valutazione finora

- Adwea Standard Quality Control Plan (SQCP) : For Ductile Iron FittingsDocumento17 pagineAdwea Standard Quality Control Plan (SQCP) : For Ductile Iron FittingsAmro HarasisNessuna valutazione finora

- EN# EN Name SAE UNS DIN Carbon SteelsDocumento4 pagineEN# EN Name SAE UNS DIN Carbon Steels'viki ArtNessuna valutazione finora

- Tle 2023Documento3 pagineTle 2023Md Bulbul AhmedNessuna valutazione finora

- Construction % Surfacing of Parking Areas 2Documento8 pagineConstruction % Surfacing of Parking Areas 2John DoughNessuna valutazione finora

- Di Pipes Rate AnalysisDocumento32 pagineDi Pipes Rate AnalysisDeepthy VasavanNessuna valutazione finora

- FMW7753 FoamerDocumento1 paginaFMW7753 FoamerfructoraNessuna valutazione finora

- Astm A148Documento4 pagineAstm A148Leo AislanNessuna valutazione finora

- Study On Partial Replacement of Coarse Aggregate With Steel SlagDocumento9 pagineStudy On Partial Replacement of Coarse Aggregate With Steel SlagIJRASETPublicationsNessuna valutazione finora