Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bypassing of Protective Devices - A Need For Action by Standard-Ization Bodies?

Caricato da

Aaqib Nazir0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginagood

Titolo originale

Safety Devices

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentogood

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaBypassing of Protective Devices - A Need For Action by Standard-Ization Bodies?

Caricato da

Aaqib Nazirgood

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Bypassing of protective devices up of balanced concepts in conjunction with SPECIAL

a need for action by standard- manufacturers and operators.

A+A 2003

ization bodies? Following this stage, technical solutions

During plant visits, occupational health must be found by which bypassing can be

and safety experts frequently observe po- made more difficult. The working group has

sition switches on safety doors which therefore recommended that standard ISO

have been bypassed, resulting in machi- 14119/EN 1088, interlocking devices as-

nery being operated in an improper con- sociated with guards, be adapted. This ge-

dition. Bypassing of this kind has repeat- neric, type B standard is intended to offer

edly led to serious accidents, some of a range of solutions, including for location

which sadly have been fatal. Generally, of the switches, which can be selected for

the party which bypassed the function is the machinery-specific standards. This

considered responsible. In the view of would enable an appropriate level of pro-

many OH&S experts, however, this defini- tection to be laid down in consideration of

tion of responsibility does not go far the machine and situation concerned. The

enough. technical solutions are largely contained in

Section 5.7 of the existing version of the

Normally, a machine deactivates hazard- standard, concerning arrangements for the

ous areas when a safety door the position reduction of scope for bypassing (such as

of which is monitored is opened. Should the shrouded installation of the switches); the

position monitoring facility be bypassed, the structure should however be improved to

door can be opened without the fact being facilitate referencing, as the reference to

registered by the control system. It is of ISO 14119/EN 1088 contained in many

course prohibited for protective devices to type C standards in the past is too general.

be rendered inoperative. The responsible Bypassing safety

In its plenary session held at the beginning

parties in the plants and the manufacturers of October 2003, the responsible ISO/TC devices: getting to

should nevertheless give greater conside- 199, Safety of machinery, accepted the the root of the evil

ration to the underlying reasons why pro- German petition for an amendment to Sec-

tective devices are bypassed in the first tion 5.7 of the standard, to be drafted on

place. the basis of the proposals drawn up by KAN.

The reasons for bypassing may lie in the Although the responsibility shared by ope-

design of the machine itself. Possible rea- rators should not be diminished, it is crucial

sons include a poor view of the process, that the guidelines contained in the generic Werner Sterk

malfunctions leading to repeated interrup- standards describing the means by which Tel. + 49 2241-231- 3460

tion of production, and excessive delays bypassing is to be avoided and made more sterk@kan.de

before operation can be resumed. In some difficult are also observed by designers.

cases, operating modes are not provided One aspect of this is that the latter must in-

which are necessary for the completion of clude reasonably foreseeable misuse in

certain work required on the machine. their risk assessment in addition to intend-

Other factors may also be at work: switches ed use1. All work to be performed on the

may be freely accessible and easily removed, machine by an operator must also be pos-

even at critical points. In addition, employ- sible with the observance of an appropriate

ees may not have been adequately informed safety level. With regard to standardiza-

of possible risks, and bypassing may be tol- tion, this means that the existing type C

erated in the plant. Reckless use of substi- standards must be reviewed and if neces-

tute actuators for bypassing, whether fab- sary improved in consideration of practical

ricated by those concerned or obtained application with regard to their concepts for

commercially, has also become a wide- protection and operation and the technical

spread but incorrect practice. measures contained within them for the

In the light of this situation, KAN was ask- prevention of bypassing.

ed by the institution for statutory accident Werner Sterk, paper delivered at the A+A

insurance and prevention in the mechanical Congress 2003: Safe machinery

engineering and metalworking industry to

gather and summarize opinion on the issue

and to propose solutions within standards 1

See KANBRIEF 2/01, p.12

projects. A working group convened by KAN

has drawn up recommendations for stand-

ardization activity and OH&S research. KAN

considers the most important step towards

the avoidance of bypassing to be the appli-

cation of user-oriented and ergonomic con-

cepts for equipment operation and protec-

tion, beginning at the design stage; such

concepts should leave no incentive for by-

passing in later operation. OH&S institutions KANBRIEF 9

have a valuable role to play in the drawing NR 4/03

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- NOTICE TO PRINCIPAL IS NOTICE TO AGENT Right To Travel CasesDocumento6 pagineNOTICE TO PRINCIPAL IS NOTICE TO AGENT Right To Travel CasesNotarys To Go100% (1)

- BarricadeDocumento2 pagineBarricadeAaqib NazirNessuna valutazione finora

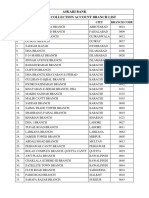

- Askari Bank BranchesDocumento1 paginaAskari Bank BranchesAaqib Nazir100% (1)

- Managing SafelyDocumento1 paginaManaging SafelyAaqib NazirNessuna valutazione finora

- PC Basic ShortcutsDocumento1 paginaPC Basic ShortcutsAaqib NazirNessuna valutazione finora

- Motion To Compel Responses To Defendant's DiscoveryDocumento4 pagineMotion To Compel Responses To Defendant's DiscoveryMarciaQuarle100% (2)

- CGRF Greater NOIDA Finds Builders Overcharging For ElectricityDocumento12 pagineCGRF Greater NOIDA Finds Builders Overcharging For ElectricitydeegaliaNessuna valutazione finora

- Martha Washington Based On A 1757 Portrait By: John WollastonDocumento1 paginaMartha Washington Based On A 1757 Portrait By: John WollastonroyjaydeyNessuna valutazione finora

- ( (Sig1 Es :signer1:signature) )Documento8 pagine( (Sig1 Es :signer1:signature) )SUNNY SINGHNessuna valutazione finora

- Family LawDocumento15 pagineFamily LawCyril K TomNessuna valutazione finora

- PR 2-2 A Group 1Documento8 paginePR 2-2 A Group 1Achmad ArdanuNessuna valutazione finora

- National Law University Odisha: Labour Law Project On A Critical Note On Banglore Water Supply CaseDocumento19 pagineNational Law University Odisha: Labour Law Project On A Critical Note On Banglore Water Supply CaseSarthak AroraNessuna valutazione finora

- 016 Magtajas v. Pryce Properties - 234 SCRA 255Documento13 pagine016 Magtajas v. Pryce Properties - 234 SCRA 255JNessuna valutazione finora

- Sample Answer For California Credit Card LitigationDocumento3 pagineSample Answer For California Credit Card LitigationStan Burman100% (1)

- ACC1ILV - Chapter 1 Solutions PDFDocumento3 pagineACC1ILV - Chapter 1 Solutions PDFMegan Joye McFaddenNessuna valutazione finora

- Teachers Service Commission: Tender Document For Procurement of ServicesDocumento56 pagineTeachers Service Commission: Tender Document For Procurement of ServicesinyasiNessuna valutazione finora

- PLT-04547 A.0 - FARGO C50 Windows Printer Driver 5.4.0.1 Release NotesDocumento4 paginePLT-04547 A.0 - FARGO C50 Windows Printer Driver 5.4.0.1 Release NotesWSN TVNessuna valutazione finora

- GR 199539 2023Documento28 pagineGR 199539 2023Gela TemporalNessuna valutazione finora

- Munro, Victoria - Hate Crime in The MediaDocumento260 pagineMunro, Victoria - Hate Crime in The MediaMallatNessuna valutazione finora

- PIChE Code of Ethics and Code of Good Governance Alignment MatrixDocumento10 paginePIChE Code of Ethics and Code of Good Governance Alignment MatrixBabeejay2Nessuna valutazione finora

- Shareholding Pattern of Force MotorsDocumento5 pagineShareholding Pattern of Force MotorsImran KhanNessuna valutazione finora

- Denied and The Case Is Dismissed Without PrejudiceDocumento4 pagineDenied and The Case Is Dismissed Without PrejudiceJustia.comNessuna valutazione finora

- Twitter Thread By: History of RajputanaDocumento12 pagineTwitter Thread By: History of Rajputanafreetrial dontbanNessuna valutazione finora

- Douglas County School District Board of Education Meeting Safety and Security ProtocolsDocumento4 pagineDouglas County School District Board of Education Meeting Safety and Security ProtocolsMichael_Roberts2019Nessuna valutazione finora

- Chemical Bonding & Molecular Structure QuestionsDocumento5 pagineChemical Bonding & Molecular Structure QuestionssingamroopaNessuna valutazione finora

- Vistar - The Rural InitiativeDocumento14 pagineVistar - The Rural InitiativePRAPTI TIWARINessuna valutazione finora

- CV Aristo VitoDocumento3 pagineCV Aristo VitoAristo VitoNessuna valutazione finora

- Titp-17 March 2022Documento7 pagineTitp-17 March 2022Ariel BahianNessuna valutazione finora

- MetDocumento2 pagineMetTiff DizonNessuna valutazione finora

- DiscountList2018 07 06Documento2 pagineDiscountList2018 07 06UtsavNessuna valutazione finora

- Pengaruh Paham Liberalisme Dan Neoliberalisme Terhadap Pendidikan Islam Di Indonesia PDFDocumento26 paginePengaruh Paham Liberalisme Dan Neoliberalisme Terhadap Pendidikan Islam Di Indonesia PDFAndi Muhammad Safwan RaisNessuna valutazione finora

- Isu Assessment Form 04152024Documento1 paginaIsu Assessment Form 04152024yun48814Nessuna valutazione finora

- The Role of Nusantara'S (Indonesian) IN: Legal Thoughts & Practices Globalization of LawDocumento175 pagineThe Role of Nusantara'S (Indonesian) IN: Legal Thoughts & Practices Globalization of LawLoraSintaNessuna valutazione finora

- NSTP - National Security NSS2018Documento8 pagineNSTP - National Security NSS2018vener magpayoNessuna valutazione finora