Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Frangible Roof To Shell Joint

Caricato da

SAGARTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Frangible Roof To Shell Joint

Caricato da

SAGARCopyright:

Formati disponibili

Owner PETROLEUM DEVLOPMENT OMAN

AREA

EQUIP. FIRE WATER STORAGE TANK Doc No CL-1007-24135-001

TAG No. T-24135A/B Rev. 3

DESIGN CALCULATION FOR FIRE WATER STORAGE TANK Date 28-Feb-17

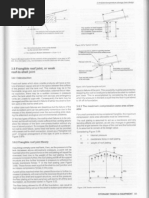

4) Compression Ring at Shell to Roof Joint (Frangible roof)

Minimum required curb angle

Used Curb Angle As per Fig. F2 Detail d = 100 x 100 x 10 API 650 APPENDIX F

Curb Angle Area (one leg) Aa = Le * ta

= 630 mm2 (Corroded Area)

Length of normal to roof from tank C.L. R2 = Rc / sin

R2 = 91,242 mm

Inside radius of tank, Rc = 15,000 mm

Max. width of participating roof Wh = 0.3 x (R2 x th) Ref: API 650 Fig F-2

Thickness of roof plate (corroded) th = 6.50 mm Detail d

Wh = 231.03 mm

Max. width of participating shell Wc = 0.6 x (Rc x ts)

Thickness of shell plate (corroded) tc = 7.00 mm

Wc = 186.42 mm

Participating area of roof (corroded) Ah = wh x th

= 1502 mm2

Participating area of shell (corroded) As = wc x tc

= 1305 mm2

Total Area Provided Aprov. = Ah + Aa + AS

Aprov. = 3437 mm2

Area resisting the compressive force A = DLS API 650 Sec.5.10.2.6(a)

2**FY*tan

Where,

Dead load od tank shell,shell attachments, DLS = 1579957 N

roof frame work supported by shell

Angle between roof & horizontal = 9.4623

lowest minimum specified yield strength FY = 250 Mpa

of material in roof to shell junction

A = 6038.29 mm2

Since, 3437 < 6038

Provided shell to roof junction is satisfactory for frangible roof.

Note: We designed frengible roof to shell joint so, roof to curb angle fillet weld size not more than 5mm.

no seal weld provided

Page 9

PDF created with pdfFactory trial version www.pdffactory.com

Potrebbero piacerti anche

- Storage Tank CALC Api 650Documento10 pagineStorage Tank CALC Api 650kuselanml100% (3)

- PIP VECV1001 Vessel Design Criteria ASME Code Section VIII Divisions 1 and 2Documento38 paginePIP VECV1001 Vessel Design Criteria ASME Code Section VIII Divisions 1 and 2Miguel A. GarciaNessuna valutazione finora

- 2012 Omix-Aida Master CatalogDocumento340 pagine2012 Omix-Aida Master Cataloglowtech4Nessuna valutazione finora

- Supported Cone Roof (CS) Add.4Documento21 pagineSupported Cone Roof (CS) Add.4skhurramq100% (2)

- Piles Design Calc PDFDocumento15 paginePiles Design Calc PDFMukhlish Akhatar100% (1)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersDa EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersValutazione: 3.5 su 5 stelle3.5/5 (19)

- TK-500MB - DB - Rev. 00Documento173 pagineTK-500MB - DB - Rev. 00Daniel GómezNessuna valutazione finora

- TorsionDocumento36 pagineTorsiondixn__Nessuna valutazione finora

- Design. Ref - Decuments: API 650, 11TH - ED M09Documento31 pagineDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNessuna valutazione finora

- Embraer Towing and Brake Riding OverviewDocumento20 pagineEmbraer Towing and Brake Riding Overviewrelaxation02Nessuna valutazione finora

- Self-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Documento29 pagineSelf-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)amokhta0% (1)

- API 2000 Venting1Documento5 pagineAPI 2000 Venting1aw_ae100% (1)

- Sample Calculation For Ammonia Tank - API 620 11th EdDocumento43 pagineSample Calculation For Ammonia Tank - API 620 11th EdAde FaruroziNessuna valutazione finora

- CompeTank-En EEMUA CourseDocumento6 pagineCompeTank-En EEMUA CoursebacabacabacaNessuna valutazione finora

- Tank Anchorage (Overturning Stability)Documento3 pagineTank Anchorage (Overturning Stability)robertantoreni100% (1)

- Tank 620 US 0002 API 620 Calculation ReportDocumento39 pagineTank 620 US 0002 API 620 Calculation ReportPhượng NguyễnNessuna valutazione finora

- Category of RadiographyDocumento9 pagineCategory of RadiographySAGARNessuna valutazione finora

- Valve Pit Wall DesignDocumento3 pagineValve Pit Wall DesignersivarajNessuna valutazione finora

- Technical Paper On API 650 Tank Roof DesignDocumento219 pagineTechnical Paper On API 650 Tank Roof Designskumar_krishnan100% (1)

- Ldo Storage Tank CalculationDocumento7 pagineLdo Storage Tank CalculationchetanmaleNessuna valutazione finora

- Eurocode 1: Actions On Structures: EN 1991, Part 1-4: Wind ActionsDocumento78 pagineEurocode 1: Actions On Structures: EN 1991, Part 1-4: Wind ActionsLeutrim AvdiuNessuna valutazione finora

- Process Industry Practices Structural: PIP STE01100 Constructability Design GuideDocumento22 pagineProcess Industry Practices Structural: PIP STE01100 Constructability Design Guideeng laythNessuna valutazione finora

- Larsen & Toubro Limited: ECC Division - EDRCDocumento4 pagineLarsen & Toubro Limited: ECC Division - EDRCOuseppachan AmbookenNessuna valutazione finora

- Tank Venting According API 2000Documento34 pagineTank Venting According API 2000Youssef Lagrini50% (2)

- Design of Flat Head For HydrotestDocumento12 pagineDesign of Flat Head For HydrotestSAGAR100% (1)

- Gek105060 File0060Documento12 pagineGek105060 File0060Mauricio GuanellaNessuna valutazione finora

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Documento9 pagineInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNessuna valutazione finora

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Documento9 pagineInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNessuna valutazione finora

- Mark Up Priority 5Documento11 pagineMark Up Priority 5SAGARNessuna valutazione finora

- Frangible Roof To Shell JointsDocumento2 pagineFrangible Roof To Shell JointsShane HancockNessuna valutazione finora

- Variable Design Point Method.Documento56 pagineVariable Design Point Method.jwochNessuna valutazione finora

- Final Bulk Storage CalculationDocumento2 pagineFinal Bulk Storage CalculationokahertaberNessuna valutazione finora

- AST - Fixed Roof DesignDocumento23 pagineAST - Fixed Roof DesignAntony Bruno Genewin100% (2)

- Mass-10 14 1 - May-2016Documento14 pagineMass-10 14 1 - May-2016ianfldNessuna valutazione finora

- Salary Increase ModelDocumento1 paginaSalary Increase ModelJasmineVeenaNessuna valutazione finora

- API 650 Tank Design 5Documento31 pagineAPI 650 Tank Design 5gon972001Nessuna valutazione finora

- Tank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Documento52 pagineTank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Tony Lozada Mahuen100% (1)

- VEFV3100Documento19 pagineVEFV3100adolfocienfuegosNessuna valutazione finora

- AWWA D100 Guide Specification PDFDocumento8 pagineAWWA D100 Guide Specification PDFDaniel Marín100% (1)

- Double DeckDocumento4 pagineDouble DeckJose CarlosNessuna valutazione finora

- Allowable Nozzle Load Calculation PDFDocumento5 pagineAllowable Nozzle Load Calculation PDFSAGARNessuna valutazione finora

- 114-F - OASE Solution Storage Tank - R0 PDFDocumento33 pagine114-F - OASE Solution Storage Tank - R0 PDFManish542Nessuna valutazione finora

- Company Introduction - Shinwoo ValveDocumento26 pagineCompany Introduction - Shinwoo ValveLe Cam NhanNessuna valutazione finora

- Ammonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesDocumento16 pagineAmmonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesVaanNessuna valutazione finora

- PC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineDocumento12 paginePC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineJohn MkCito KINessuna valutazione finora

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDa EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNessuna valutazione finora

- Anchor ChairDocumento3 pagineAnchor ChairrsubramaniNessuna valutazione finora

- API 650 Tank CalculationDocumento30 pagineAPI 650 Tank Calculationsachin8389100% (2)

- AST - Study GuideDocumento174 pagineAST - Study Guiderongweius100% (4)

- Floating Roof DesinDocumento5 pagineFloating Roof Desindimdaliak_985662241Nessuna valutazione finora

- Frangible RoofDocumento8 pagineFrangible RoofamevaluacionesNessuna valutazione finora

- Lug Support DesignDocumento3 pagineLug Support DesignSajal KulshresthaNessuna valutazione finora

- Lug Support DesignDocumento3 pagineLug Support DesignSajal KulshresthaNessuna valutazione finora

- Lug Support DesignDocumento3 pagineLug Support DesignSajal KulshresthaNessuna valutazione finora

- For Buildings and Other Structures For Wind LoadsDocumento28 pagineFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- Calculo Venteo API 2000Documento3 pagineCalculo Venteo API 2000Produccion Vegetal100% (1)

- API 650 Tank Nozzle Loads - Can Not Use WRC For Tank Nozzle CheckDocumento3 pagineAPI 650 Tank Nozzle Loads - Can Not Use WRC For Tank Nozzle CheckDam Vo100% (1)

- ASME Venting Calculation FB-2007 - PDFDocumento3 pagineASME Venting Calculation FB-2007 - PDFjaganNessuna valutazione finora

- Storage Tank Alumnuim Roof - LatestDocumento22 pagineStorage Tank Alumnuim Roof - LatesthgagNessuna valutazione finora

- Tank Jet MixersDocumento2 pagineTank Jet MixersGabriela Axinte100% (1)

- Crue Oil 7500bbl API 650 DatasheetDocumento16 pagineCrue Oil 7500bbl API 650 DatasheetrobertantoreniNessuna valutazione finora

- Report On Artificial Gas Lift 1Documento60 pagineReport On Artificial Gas Lift 1Abhilash Baranwal100% (1)

- Inbreathing Outbreathing of TanksDocumento30 pagineInbreathing Outbreathing of Tanksomesh2008Nessuna valutazione finora

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocumento39 pagineVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNessuna valutazione finora

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocumento39 pagineVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNessuna valutazione finora

- Corbel CalculationDocumento1 paginaCorbel CalculationQuangKhảiNessuna valutazione finora

- Atmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)Documento18 pagineAtmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)ganeshdhageNessuna valutazione finora

- Atm Sto Tanks Venting Req API2000 2009 Rev1 - TESTDocumento18 pagineAtm Sto Tanks Venting Req API2000 2009 Rev1 - TESTRanjit PaulNessuna valutazione finora

- ID DCU ApplicationGuideDocumento27 pagineID DCU ApplicationGuideMarco Pilaguano LogañaNessuna valutazione finora

- Pile Head Stress CalculationsDocumento2 paginePile Head Stress Calculationssivapathamuthu100% (1)

- Frangible Roof Joint, or Weak PDFDocumento5 pagineFrangible Roof Joint, or Weak PDFseth_shelby007Nessuna valutazione finora

- Api Iso Equivalent Standards PDFDocumento8 pagineApi Iso Equivalent Standards PDFSantiago IsazaNessuna valutazione finora

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Documento1 paginaAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Mohammed AttiaNessuna valutazione finora

- 3191-CS-01 Rev A-009-011Documento3 pagine3191-CS-01 Rev A-009-011Syed Zain AliNessuna valutazione finora

- Tank Normal Venting (API)Documento1 paginaTank Normal Venting (API)ام يمنى ايمنNessuna valutazione finora

- 39-29computational Buckling Analysis of Wind Loaded5-1-PBDocumento9 pagine39-29computational Buckling Analysis of Wind Loaded5-1-PBzaneliuNessuna valutazione finora

- Spherical Tank PDFDocumento1 paginaSpherical Tank PDFevrim77Nessuna valutazione finora

- Rectangular Tank CalculationDocumento6 pagineRectangular Tank Calculationprince kumarNessuna valutazione finora

- Astm F436.04 PDFDocumento6 pagineAstm F436.04 PDFWelington Volpatto MoraisNessuna valutazione finora

- Significant Changes in AWWA D100-11Documento6 pagineSignificant Changes in AWWA D100-11Leslie Scott100% (4)

- Hemispherical HeadDocumento5 pagineHemispherical HeadPuRuiSen HelathchemicalNessuna valutazione finora

- Top Slab Design SheetDocumento3 pagineTop Slab Design SheetersivarajNessuna valutazione finora

- 1.0 Diesel Tank SupportsDocumento3 pagine1.0 Diesel Tank SupportsKushan Dhanushka NanayakkaraNessuna valutazione finora

- Valve Pit DesignDocumento3 pagineValve Pit DesignersivarajNessuna valutazione finora

- Japanese H Sections PDFDocumento2 pagineJapanese H Sections PDFSAGARNessuna valutazione finora

- Past Perfect TenseDocumento3 paginePast Perfect Tensepura2030Nessuna valutazione finora

- Japanese BeamDocumento2 pagineJapanese BeamSAGARNessuna valutazione finora

- JD - Engineer Mechanical Design - 1409Documento1 paginaJD - Engineer Mechanical Design - 1409SAGARNessuna valutazione finora

- Tenses TableDocumento5 pagineTenses Tableapi-314670535Nessuna valutazione finora

- Memorator MatematicaDocumento1 paginaMemorator MatematicaȘtefan LefterNessuna valutazione finora

- FMS - Materials (1008,1009)Documento157 pagineFMS - Materials (1008,1009)SAGARNessuna valutazione finora

- Leave Report of Sakir PDFDocumento1 paginaLeave Report of Sakir PDFSAGARNessuna valutazione finora

- Tenses TableDocumento5 pagineTenses Tableapi-314670535Nessuna valutazione finora

- Leave Report of Sakir PDFDocumento1 paginaLeave Report of Sakir PDFSAGARNessuna valutazione finora

- Comparison of API-650 To AWWA D-100Documento1 paginaComparison of API-650 To AWWA D-100SAGARNessuna valutazione finora

- Reducer Spool PDFDocumento13 pagineReducer Spool PDFSAGARNessuna valutazione finora

- Anchore Bolt Root AreaDocumento1 paginaAnchore Bolt Root AreaSAGARNessuna valutazione finora

- 13 Venting Requirements PDFDocumento4 pagine13 Venting Requirements PDFAngel LugoNessuna valutazione finora

- Reducer Spool PDFDocumento13 pagineReducer Spool PDFSAGARNessuna valutazione finora

- Ac446 Acceptance Criteria For Headed Cast-In Specialty Inserts in ConcreteDocumento44 pagineAc446 Acceptance Criteria For Headed Cast-In Specialty Inserts in ConcreteDianna Lambert100% (1)

- Wireless Polling Method Using RFDocumento101 pagineWireless Polling Method Using RFSravani SravzNessuna valutazione finora

- 17-Oil Centrifuge PDFDocumento89 pagine17-Oil Centrifuge PDFUmangtarangNessuna valutazione finora

- Writing Process Poster and ChecklistDocumento4 pagineWriting Process Poster and ChecklistNur FarahinNessuna valutazione finora

- REMU Big FloatDocumento2 pagineREMU Big FloatForomaquinasNessuna valutazione finora

- Ab Brass IveDocumento4 pagineAb Brass IvejengandxbNessuna valutazione finora

- 3RD Time Table-25-07-2011Documento33 pagine3RD Time Table-25-07-2011Abhi9777354837Nessuna valutazione finora

- Module 2 Planning 3 Lecture Fundamentals Urban Planning PDF LECTUREDocumento44 pagineModule 2 Planning 3 Lecture Fundamentals Urban Planning PDF LECTUREGrace PabicoNessuna valutazione finora

- SHC AluminiumDocumento2 pagineSHC Aluminiumsylent gohNessuna valutazione finora

- ASCE 7-10 - Tabla4-1 - Minimum Uniformly Distributed Live Loads PDFDocumento4 pagineASCE 7-10 - Tabla4-1 - Minimum Uniformly Distributed Live Loads PDFAlvaro Jaen Kravarovic100% (1)

- Aura-FX Operation Manual V2.0Documento27 pagineAura-FX Operation Manual V2.0Micha LoRuNessuna valutazione finora

- Foreword 2007 Ludwig S Applied Process Design For Chemical and PetrochemicalDocumento1 paginaForeword 2007 Ludwig S Applied Process Design For Chemical and PetrochemicalKemal Faza HastadiNessuna valutazione finora

- Technical Manual Index (Engine Manuals)Documento8 pagineTechnical Manual Index (Engine Manuals)NikooNessuna valutazione finora

- Saic Q 1015Documento2 pagineSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Zhang2016 PDFDocumento14 pagineZhang2016 PDFHéctor Jorge Bravo PastorNessuna valutazione finora

- Service Bulletin Copier: SubjectDocumento9 pagineService Bulletin Copier: Subjectoleg-spbNessuna valutazione finora

- Maco 6 Element Beam ManualDocumento8 pagineMaco 6 Element Beam Manualw8ddw100% (1)

- Base CourseDocumento5 pagineBase Coursephemmy jibadeNessuna valutazione finora

- FYP2 Poster Presentation11Documento22 pagineFYP2 Poster Presentation11Anonymous PyFkX4jYVWNessuna valutazione finora

- Tam Anulus Casing PackersDocumento20 pagineTam Anulus Casing Packersallan_lennoxNessuna valutazione finora