Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ECC500 V600R001C01 User Manual 02

Caricato da

Mohamed SayedCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ECC500 V600R001C01 User Manual 02

Caricato da

Mohamed SayedCopyright:

Formati disponibili

ECC500

V600R001C01

User Manual

Issue 02

Date 2015-11-01

HUAWEI TECHNOLOGIES CO., LTD.

Copyright Huawei Technologies Co., Ltd. 2015. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://e.huawei.com

Issue 02 (2015-11-01) Huawei Proprietary and Confidential i

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual About This Document

About This Document

Purpose

This document describes the energy control center 500 (ECC500 for short) in terms of its

overview, configurations, ports, installation, commissioning, user interfaces, maintenance, and

troubleshooting, providing guidelines for onsite installation personnel and technical support

engineers.

Manufacturing, assembly, and factory maintenance commands are not provided in this

document. Certain advance commands for project implementation and error locating may

cause device exceptions or service interruptions if they are misused. These commands are not

provided in this document. If you need these commands, contact Huawei technical support.

The screen snapshots in this document are for reference only. The actual screen prevails.

Intended Audience

This document is intended for:

Marketing engineers

Technical support engineers

System engineers

Hardware installation engineers

Commissioning engineers

Data configuration engineers

Maintenance engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol Description

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential ii

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual About This Document

Symbol Description

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to

personal injury.

Calls attention to important information, best practices

and tips.

NOTE is used to address information not related to

personal injury, equipment damage, and environment

deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 02 (2015-11-01)

This issue is the second official release, which incorporates the following changes:

Updated the software WebUI.

Issue 01 (2015-04-26)

This issue is the first official release.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential iii

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual Contents

Contents

About This Document .................................................................................................................... ii

1 Overview......................................................................................................................................... 1

1.1 Positioning .................................................................................................................................................................... 1

1.2 Features ......................................................................................................................................................................... 1

1.3 Typical Application Scenarios ...................................................................................................................................... 2

2 Configurations and Port .............................................................................................................. 5

2.1 Configurations .............................................................................................................................................................. 5

2.2 Port ............................................................................................................................................................................... 8

2.2.1 Main Control Module ................................................................................................................................................ 8

2.2.2 Power Module .......................................................................................................................................................... 10

2.2.3 RS485 Communication Card ................................................................................................................................... 10

2.2.4 AI/DI Expansion Card ............................................................................................................................................. 13

2.2.5 GPRS Expansion Card ............................................................................................................................................. 15

2.2.6 AI/DI Module........................................................................................................................................................... 18

3 Installation and Commissioning.............................................................................................. 21

3.1 Installation and Commissioning Flowchart ................................................................................................................ 21

3.2 Installing Devices ....................................................................................................................................................... 21

3.2.1 Installing a Rack-mounted ECC500 ........................................................................................................................ 21

3.2.2 Installing a Wall-mounted ECC500 ......................................................................................................................... 23

3.2.3 (Optional) Installing a Rack-mounted AI/DI Module .............................................................................................. 23

3.2.4 (Optional) Installing a Wall-mounted AI/DI Module ............................................................................................... 24

3.3 Connecting Cables ...................................................................................................................................................... 25

3.3.1 Connecting Ground Cables ...................................................................................................................................... 25

3.3.2 Connecting to an IP Network ................................................................................................................................... 26

3.3.3 Connecting Monitoring Cables ................................................................................................................................ 26

3.3.4 Connecting Cables to Intelligent Equipment and Sensors ....................................................................................... 27

3.3.5 Connecting Power Cables ........................................................................................................................................ 28

3.3.6 Connecting the T/H Sensor Monitoring Cable......................................................................................................... 29

3.3.7 Connecting the UPS2000G-B Monitoring Cable ..................................................................................................... 30

3.3.8 Connecting the UPS2000G-A Monitoring Cable ..................................................................................................... 31

3.3.9 Connecting the UPS5000E Monitoring Cable ......................................................................................................... 31

3.3.10 Connecting the NetCol5000A Monitoring Cable ................................................................................................... 31

Issue 02 (2015-11-01) Huawei Proprietary and Confidential iv

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual Contents

3.3.11 Connecting the PDU8000 Monitoring Cable ......................................................................................................... 32

3.3.12 Connecting the ABB OTM ATS Monitoring Cable ............................................................................................... 32

3.3.13 Connecting the Fan Monitoring Cable ................................................................................................................... 33

3.4 Commissioning Devices ............................................................................................................................................. 33

3.4.1 Setting the T/H Sensor Device Address ................................................................................................................... 37

3.4.2 Setting the UPS2000G-A Device Address ............................................................................................................... 37

3.4.3 Setting the UPS2000G-B Device Address ............................................................................................................... 38

3.4.4 Setting the UPS5000E Device Address ................................................................................................................... 39

3.4.5 Setting the NetCol5000A Device Address ............................................................................................................... 40

3.4.6 Setting the PDU8000 Device Address ..................................................................................................................... 41

3.4.7 Setting the ABB OTM ATS Device Address ........................................................................................................... 42

4 UI Description ............................................................................................................................. 43

4.1 LCD ............................................................................................................................................................................ 43

4.1.1 LCD Menu Hierarchy .............................................................................................................................................. 43

4.1.2 LCD Operations ....................................................................................................................................................... 44

4.2 WebUI ......................................................................................................................................................................... 46

4.2.1 Commissioning Preparations ................................................................................................................................... 46

4.2.2 Adding a T/H Sensor................................................................................................................................................ 48

4.2.3 Adding Dry Contact Devices ................................................................................................................................... 50

4.2.3.1 Adding a Smoke Sensor ........................................................................................................................................ 50

4.2.3.2 Adding an SPD ..................................................................................................................................................... 51

4.2.3.3 Adding a Door Status Sensor ................................................................................................................................ 52

4.2.3.4 Adding a Water Sensor .......................................................................................................................................... 53

4.2.3.5 Adding a Device Connected to a DI Port on the GPRS Expansion Card .............................................................. 54

4.2.4 Adding UPSs ............................................................................................................................................................ 57

4.2.4.1 Adding a UPS2000G ............................................................................................................................................. 57

4.2.4.2 Adding a UPS5000E ............................................................................................................................................. 58

4.2.5 Adding a NetCol5000A ........................................................................................................................................... 60

4.2.6 Adding a PDU8000 .................................................................................................................................................. 61

4.2.7 Adding an ABB OTM ATS ...................................................................................................................................... 63

4.2.8 Adding a Networked Device .................................................................................................................................... 64

4.2.9 (Optional) Setting SMS Parameters ......................................................................................................................... 65

4.2.10 (Optional) Adding a Video Link ............................................................................................................................ 67

4.2.11 (Optional) Setting SNMP Monitoring Parameters ................................................................................................. 68

4.2.12 (Optional) Setting the Security Certificates for the ECC500 Collector and the Network Management System ... 71

4.2.13 (Optional) Exporting and Importing a Configuration File ..................................................................................... 73

4.2.14 (Optional) Viewing the Real-time Surveillance Screen, Active Alarms, Historical Alarms, and Historical Data . 75

5 Maintenance and Troubleshooting ......................................................................................... 76

5.1 Routine Maintenance .................................................................................................................................................. 76

5.2 Alarm Reference ......................................................................................................................................................... 76

5.2.1 Alarm Reference for the RS485 Expansion Card .................................................................................................... 77

Issue 02 (2015-11-01) Huawei Proprietary and Confidential v

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual Contents

5.2.1.1 MUS02A_Board Not Exist ................................................................................................................................... 77

5.2.1.2 MUS02A_COM4 Voltage Low Alarm.................................................................................................................. 77

5.2.2 Alarm Reference for the AI/DI Expansion Card ...................................................................................................... 78

5.2.2.1 MUE05A_Board Not Exist ................................................................................................................................... 78

5.2.2.2 MUE05A_AIDI_1 DI Alarm ................................................................................................................................ 79

5.2.2.3 MUE05A_AIDI_1 Sensor Fault ........................................................................................................................... 80

5.2.2.4 MUE05A_AIDI_1 Over Alarm ............................................................................................................................ 80

5.2.2.5 MUE05A_AIDI_1 Lower Alarm .......................................................................................................................... 81

5.2.2.6 MUE05A_AIDI_1 Voltage Low Alarm ................................................................................................................ 82

5.2.2.7 MUE05A_AIDI_1 Sensor Connection Error Alarm ............................................................................................. 83

5.2.3 Alarm Reference for the GPRS Expansion Card ..................................................................................................... 83

5.2.3.1 MUC01A Board Not Detected .............................................................................................................................. 83

5.2.3.2 MUC01A_DI_1 Alarm ......................................................................................................................................... 84

5.2.4 Alarm Reference for the AI/DI Module ................................................................................................................... 85

5.2.4.1 MUE06A_Board Not Exist ................................................................................................................................... 85

5.2.4.2 MUE06A_Power Voltage Low Alarm .................................................................................................................. 86

5.2.5 Comm Failed ........................................................................................................................................................... 86

5.2.6 Network Device Connect Fail .................................................................................................................................. 87

5.2.7 ECC500 Network Fault ........................................................................................................................................... 88

5.3 Troubleshooting .......................................................................................................................................................... 89

5.4 Parts Replacement ...................................................................................................................................................... 90

6 FAQ ................................................................................................................................................ 92

6.1 ECC500 Device Cascading Rules ............................................................................................................................... 92

6.2 What do I do if the ECC500 collector cannot be logged in on the WebUI?................................................................ 92

6.3 How Can I Install a Network Security Certificate? .................................................................................................... 93

6.4 How Can I Change the ECC500 IP Address on the LUI? ........................................................................................... 94

6.5 How Can I Change the ECC500 IP Address on the WebUI? ...................................................................................... 95

6.6 How Can I Change the ECC500 LUI Password? ....................................................................................................... 96

6.7 How Can I Change the ECC500 WebUI Password? ................................................................................................... 97

6.8 How Can I Create a User? .......................................................................................................................................... 99

6.9 How Can I Set the Date and Time? ........................................................................................................................... 101

6.10 How Can I Enable or Disable an Alarm and Set the Alarm Severity? .................................................................... 101

6.11 How Can I Handle Alarms? .................................................................................................................................... 102

6.12 How Can I Change the System Site Name? ............................................................................................................ 103

6.13 How Can I Change the UPS2000G Name and T/H Sensor Name? ........................................................................ 104

6.14 How Can I Set Temperature and Humidity Alarm Thresholds for a T/H Sensor? .................................................. 106

6.15 How Can I Change Fan Alarm Thresholds and Reset a Fan? ................................................................................. 107

6.16 How Can I Delete a Device Failing in Communication or Restart the ECC500? ................................................... 109

6.17 How Can I View Performance Data? ...................................................................................................................... 110

6.18 How Can I View Operation Logs? .......................................................................................................................... 111

6.19 How Can I View the ECC500 Version Information? .............................................................................................. 112

Issue 02 (2015-11-01) Huawei Proprietary and Confidential vi

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual Contents

6.20 How Can I Export Data? ......................................................................................................................................... 113

6.21 How Can I Export Fault Information? .................................................................................................................... 114

6.22 How Can I Restore Factory Settings? ..................................................................................................................... 115

A Technical Specifications ......................................................................................................... 117

B Devices Managed by the ECC500 .......................................................................................... 120

C Acronyms and Abbreviations ................................................................................................ 122

Issue 02 (2015-11-01) Huawei Proprietary and Confidential vii

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 1 Overview

1 Overview

1.1 Positioning

The ECC500 collector is a cross-platform monitoring product, in which a main control

module works with several expansion cards to receive, collect, process, and report signals.

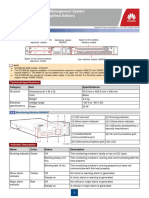

Figure 1-1 shows an ECC500.

Figure 1-1 Appearance

In the infrastructure management system of data centers, the ECC500 receives signals from

monitoring devices, collects, processes, and reports the signals to the NMS. In the IDS1000

and IDS2000 data centers, the ECC500 provides a complete solution for working environment

and security management. It collects, manages, and analyzes operating information of power

and environment monitoring devices, and reports alarms for them.

1.2 Features

Hardware Functions

The ECC500 supports AC inputs of 100 V to 240 V, 50 Hz or 60 Hz, and can be used

worldwide.

Ports for sensors and intelligent equipment support only RJ45 terminals, minimizing

cable types, simplifying delivery, and enabling fast deployment.

The RS485 expansion card can be connected to southbound intelligent equipment such

as uninterruptible power systems (UPSs), precision air conditioners, and power

distribution cabinets over the RS485 ports compatible with two-wire or four-wire cables.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 1

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 1 Overview

The AI/DI input channel can detect signals from multiple types of sensors, including

420 mA sensors, negative temperature coefficient (NTC) resistor-based temperature

sensors, current-based sensors, and devices with dry contacts.

The ECC500 supports the automatic assess of sensors such as water sensors and NTC

resistor-based temperature sensors, simplifying delivery and deployment.

The ECC500 provides the 12 V DC power supply to devices such as sensors and audible

and visual alarms. Additional power supply to these devices is not needed.

All boards, cards, and sensors are hot-swappable.

The ECC500 supports fault isolation. If a port is short-circuited or damaged, it is isolated

to ensure that other ports and boards are not affected.

The ECC500 features flexible extensibility. Boards or modules can be added or removed

to meet requirements of different scenarios.

The ECC500 can be mounted on a rack or wall.

The GPRS module can send alarm notifications to the mobile phones of maintenance

engineers through the short message service (SMS).

Software Functions

You can use a web browser to access the ECC500 for remote management.

You can upgrade the system, main control module, and other functional modules

remotely. The main control module rolls back to the source version if the upgrade fails.

You can re-upgrade functional modules if upgrades fail.

The ECC500 supports simple network management protocol (SNMP) northbound

interfaces that are compliant with SNMP v1, v2c, and v3.

The ECC500 allows you to download the management information base (MIB) files.

The ECC500 allows you to download or upload configuration files for system backup.

The ECC500 allows you to manage users and alarms. You can also download log files.

The ECC500 provides user-friendly interfaces, including the web user interface (WebUI)

and LCD user interface (LUI). You can remotely and locally maintain the ECC500 over

the WebUI and LUI respectively.

The ECC500 can automatically identify boards, cards, and sensor devices.

RS485 ports of the ECC500 support the transparent transmission mode, ensuring

real-time communication between the southbound equipment and the NMS.

The ECC500 locates abnormal sensor connections based on alarms, thereby facilitating

maintenance.

Northbound interface: connects to the upper-layer NMS or equipment for provisioning services and

reporting alarms and performance data.

Southbound interface: connects to the lower-layer NMS or equipment for provisioning services and

transmitting performance indicator data.

1.3 Typical Application Scenarios

The ECC500 can be used for transparent data transmission and local management.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 2

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 1 Overview

Transparent Data Transmission

If the ECC500 is used for transparent data transmission, the NMS such as the NetEco or

third-party NMS must be configured and the ECC500 works only as a data collector. The

ECC500 reports collected data to the NMS, where users manage devices.

Figure 1-2 shows the networking for transparent data transmission.

Figure 1-2 Networking for transparent data transmission

The ECC500 provides SNMP northbound interfaces for connecting to a third-party NMS to query

data and report alarms.

The ECC500 used for transparent data transmission can connect to diverse devices complying with

the Modbus protocol and providing dry contacts. For the devices that can be connected, see the

monitoring device list for the project.

Local Management

If the ECC500 is used for local management, there is no need to configure the NMS and the

ECC500 works as a data collector and manager. The ECC500 collects, analyzes, and

processes device data, while users manage the devices on the ECC500 WebUI.

Figure 1-3 shows the networking for local management.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 3

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 1 Overview

Figure 1-3 Networking for local management

For the devices that can be connected to and managed by the ECC500 used for local management, see B

Devices Managed by the ECC500.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 4

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

2 Configurations and Port

2.1 Configurations

The ECC500 consists of a power module, a main control module, a GPRS expansion card, an

RS485 expansion card, and an AI/DI expansion card. The detailed configuration rules are as

follows:

An ECC500 with standard configurations consists of a main control module, a power

module, an RS485 expansion card, and an AI/DI expansion card, as shown in Figure 2-1.

Depending on site requirements, a maximum of four RS485 expansion cards and AI/DI

expansion cards can be configured.

AI/DI modules can only be connected to COM4 and COM5 ports on RS485 expansion

cards in slots 3 and 4. A maximum of two AI/DI modules can be connected to each port,

and the AI/DI module addresses can only be 1 or 2.

If two RS485 expansion cards are configured, a maximum of eight AI/DI modules can be

configured.

Figure 2-1 ECC500

(1) Slot 0: main control module (2) Slot 1: GPRS expansion card (optional)

(3) Slot 3: RS485 expansion card (4) Slots 5 and 6: power modules

(5) Slot 4: AI/DI expansion card

Table 2-1 describes the functions of the ECC500 components.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 5

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Table 2-1 ECC500 component functions

Hardware Silk Screen Configuration Function

Main control SMU03A Mandatory (1 PCS) Provides an LCD to

module query, set, and

control local

parameters.

Provides an operating

status indicator and

alarm indicator.

Provides a fast

Ethernet (FE) port.

Records active alarms

and historical alarms.

Provides intelligent

unit management.

RS485 MUS02A Mandatory (1 PCS) Provides five

expansion card half-duplex RS485

communications

ports, among which

the COM4 and

COM5 ports provide

DC outputs of 12 V

(actual range:

12.815 V), 400 mA

to devices such as

AI/DI modules and

intelligent T/H

sensors.

The power supply

status indicators for

the power output

ports are steady green

when they provide

power outputs and

are off when they

supply no power.

AI/DI MUE05A Mandatory (1 PCS) Provides four AI/DI

expansion card ports with 12 V DC

outputs to sensors

such as smoke

sensors and water

sensors.

Provides one digital

output (DO) port for

remote control, and

one 12 V DC (< 300

mA) power supply

for controlling

devices such as the

audible and visual

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 6

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Hardware Silk Screen Configuration Function

alarm.

GPRS MUC01A or Optional (1 PCS) Provides GPRS

expansion card MUC02A out-of-band channels

(mutually for separate

exclusive) networking to

provide SMS alarm

notifications.

Provides six digital

input (DI) ports and

two dry contact

outputs.

AI/DI module MUE06A Optional Can be independently

installed in a 19-inch

rack or on a wall.

Provides eight AI/DI

ports that provide 12

V DC outputs to

sensors and offer

internal overcurrent

protection.

Provides eight AI/DI

ports compatible with

4 mA to 20 mA

current signals,

signals from

current-based smoke

sensors and water

sensors, dry contact

signals, and NTC

signals.

Configured with a

4-bit DIP switch.

Power module PAC75WA Mandatory (1 PCS) Converts the AC

input of 100 V to 240

V into two DC

outputs of 53.5 V and

15 V.

Provides the

overcurrent, output

overvoltage, and

overheat protection.

Supports natural

cooling of rectifiers.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 7

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

2.2 Port

2.2.1 Main Control Module

The main control module provides the LCD for querying, setting, and controlling local

parameters. Figure 2-2 shows ports on the front panel of the main control board.

Figure 2-2 Front panel of the main control module

(1) Indicators (2) LCD (3) Buttons (4) FE port

(5) RS485/RS232 port (6) COM1 port (7) COM2 port (8) USB port

Indicators

Table 2-2 describes indicators on the main control module.

Table 2-2 Indicator description

Silk Color Meaning Status Description

Screen

Green Run Off The main control module

indicator is faulty or has no DC

input.

Blinking (1 second on The main control module

and 1 second off) runs properly and

communicates with the

web client properly.

Red Alarm Off No major or critical alarm

indicator is generated.

Steady on A critical or major alarm is

generated.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 8

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

LCD/Buttons

The LCD displays parameters for you to configure and query in real time by pressing the four

buttons on the panel. Table 2-3 describes the buttons.

Table 2-3 Button description

Button Name Description

Arrow button Allows you to view menu items and set the value of

or

a menu item.

Return button Returns to the previous menu without saving the

settings.

Confirm button Enters the main menu from the standby screen,

enters a submenu from the main menu, or changes

or saves the menu settings.

After a menu is displayed, the standby screen is displayed if no button is pressed within 1 minute.

After a menu is displayed, the LCD screen becomes dark if no button is pressed within 30 seconds.

Ports

Table 2-4 describes ports on the front panel of the main control module.

Table 2-4 Description of ports on the main control module

Silk Screen Port Description

FE Northbound Ethernet interface, which enables encrypted web-based

access through local or remote networks, provides the security

protection mechanism, and supports the third-party NMS and NetEco.

Pin definition:

1: TX+

2: TX-

3: RX+

6: RX-

RS485/RS232 RS485/RS232 port, reserved.

COM1 and RS485 ports. The baud rate for the COM2 port cannot be changed. The

COM2 COM2 port is a full-duplex communications port. It is recommended

that the ports be reserved.

Pin definition:

1: RX+

2: RX-

4: TX+

5: TX-

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 9

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Silk Screen Port Description

6: GND

USB Reserved. This port is protected by a security protection mechanism.

2.2.2 Power Module

Figure 2-3 shows the port on the front panel of the power module.

Figure 2-3 Front panel of the power module

Table 2-5 describes the performance specifications of the power module.

Table 2-5 Performance specifications of the power module

Parameter Description

Operating 100240 V AC

voltage range

Rated operating 110 V AC/220 V AC

voltage

Frequency 50 Hz/60 Hz

Rated output 53.5 V DC/15 V DC

voltage

Structure The subrack of the power module is less than 1 U high and occupies two

slots of the ECC500 subrack.

2.2.3 RS485 Communication Card

The RS485 communication card provides five half-duplex RS485 communication interfaces

that are compatible with two-wire and four-wire cables and connect to the southbound

intelligent equipment, AI/DI module, and intelligent ambient temperature and humidity sensor.

Figure 2-4 shows ports on the front panel of the RS485 communication card.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 10

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Figure 2-4 Front panel of the RS485 communication card

(1) COM1 port (2) COM2 port (3) COM3 port

(4) COM4/12V port (5) COM5/12V port (6) Indicators

Table 2-6 describes indicators on the front panel of the RS485 communication card.

Table 2-6 Description of indicators on the front panel of the RS485 communication card

Silk Screen Color Meaning Status Description

PWR Green Power indicator Steady on The power

supply is

normal.

Off The RS485

communication

card is faulty or

has no DC

input.

RUN Green Run indicator Blinking (1 The RS485

second on and 1 communication

second off) card is

communicating

with the main

control module

properly.

Blinking (0.125 The RS485

second on and communication

0.125 second card fails to

off) communicate

with the main

control module.

ALM Red Alarm indicator Off No alarm is

generated.

Steady on A board alarm

is generated.

COM4/12V Green Port power Steady on The port

output indicator properly

provides the 12

V DC output.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 11

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Silk Screen Color Meaning Status Description

COM5/12V Off The port

provides no 12

V DC output.

Table 2-7 describes ports on the front panel of the RS485 communication card.

Table 2-7 Description of ports on the front panel of the RS485 communication card

Silk Screen Port Description

COM1, COM2, Connect to intelligent equipment, such as the PDU8000, UPS, and

and COM3 temperature control equipment.

1: A

2: B

4: A

5: B

COM4/12V and Provide DC outputs of 12 V (actual range: 12.815 V), 400 mA to

COM5/12V equipment such as AI/DI module, intelligent ambient temperature and

humidity sensors, and electronic door locks.

1: A

2: B

3: 12 V DC power

4: A

5: B

8: GND

COM4/12V and COM5/12V ports: Pins 3 and 8 of these two ports provide 12 V DC power.

Therefore, before connecting equipment to the ports, check the equipment pin description to

ensure that pins of the equipment match those on the ports, preventing damage to ports or the

equipment.

The internal circuit design of the RS485 communication card allows its COM port to support

two-wire RS485 and four-wire RS422, eliminating the need to cascade cables, as shown in

Figure 2-5.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 12

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Figure 2-5 Compatibility of the RS485 interfaces

2.2.4 AI/DI Expansion Card

The AI/DI expansion card provides four AI/DI input ports to connect monitoring sensors and

provide the DO control function. Figure 2-6 shows ports on the front panel of the AI/DI

expansion card.

Figure 2-6 Front panel of the AI/DI expansion card

(1) DO control (2) AI/DI_1 (3) AI/DI_2

(4) AI/DI_3 (5) AI/DI_4 (6) Indicators

Table 2-8 describes indicators on the front panel of the AI/DI expansion card.

Table 2-8 Description of indicators on the front panel of the AI/DI expansion card

Silk Screen Color Meaning Status Description

PWR Green Power indicator Steady on The power

supply is

normal.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 13

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Silk Screen Color Meaning Status Description

Off The AI/DI

expansion card

is faulty or has

no DC input.

RUN Green Run indicator Blinking (1 The AI/DI

second on and 1 expansion card

second off) is

communicating

with the main

control module

properly.

Blinking (0.125 The AI/DI

second on and expansion card

0.125 second fails to

off) communicate

with the main

control module.

ALM Red Alarm indicator Off No alarm is

generated.

Steady on A board alarm

is generated.

Table 2-9 describes ports on the front panel of the AI/DI expansion card.

Table 2-9 Description of ports on the front panel of the AI/DI expansion card

Silk Screen Port Description

DO Provides the DO control function.

NO

COM

12V/0.3A Provides a 12 V DC output for supplying less than 300 mA power to

devices such as the audible and visual alarms.

12 V DC, 300 mA

GND

AI/DI_1, Provide 12 V DC outputs for sensors and are compatible with 4 mA to

AI/DI_2, 20 mA current signals, signals from current-based smoke sensors and

AI/DI_3, and water sensors, dry contact signals, and NTC signals.

AI/DI_4 Pin definition:

3: 12 V DC, 54 mA

6: D-

7: D+

8: GND

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 14

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Do not connect an active sensor to an AI/DI port. Otherwise, the port will be invalid.

Sensors including 4 mA to 20 mA sensors, door status sensors, water sensors, and smoke sensors

provide data for the ports.

The power supply of each AI/DI port can be separately controlled. Each port provides a maximum of

14.6 V, 54 mA output power.

2.2.5 GPRS Expansion Card

Two models of GPRS expansion cards are available, including MUC01A and MUC02A

expansion cards. Table 2-10 describes the differences between the two models.

Table 2-10 GPRS expansion card differences

Expansion Card Model Number of SIM Card Slots

MUC01A 1

MUC02A 2

MUC01A

Figure 2-7 shows the front panel of the MUC01A expansion card.

Figure 2-7 Front panel of the MUC01A expansion card

(1) DO_1 (2) DO_2 (3) DI_1 (4) DI_2

(5) DI_3 (6) DI_4 (7) DI_5 (8) DI_6

(9) ANT (10) Indicators

Figure 2-8 shows the SIM card slot on the MUC01A expansion card.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 15

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Figure 2-8 SIM card slot on the MUC01A expansion card

MUC02A

Figure 2-9 shows the front panel of the MUC02A expansion card.

Figure 2-9 Front panel of the MUC02A expansion card

(1) DO_1 (2) DO_2 (3) DI_1 (4) DI_2

(5) DI_3 (6) DI_4 (7) DI_5 (8) DI_6

(9) ANT (10) Indicators

Figure 2-10 shows the SIM card slot on the MUC02A expansion card.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 16

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Figure 2-10 SIM card slot on the MUC02A expansion card

Indicators

Table 2-11 describes the indicators on the front panel of the GPRS expansion card.

Table 2-11 Indicator description

Silk Screen Color Status Description

PWR1 Yellow Steady on The GPRS board has

normal power

supply.

Off The power supply is

faulty or there is no

DC power input.

PWR2 Yellow Steady on The GPRS

expansion card in

the GPRS board is

working properly.

Off The GPRS

expansion card in

the GPRS board is

faulty or has no DC

power input.

GPRS Green Off The GPRS

expansion card in

the GPRS board is

not powered on.

Steady on A GPRS call is in

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 17

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Silk Screen Color Status Description

progress.

Blinking (on for GPRS data

0.1s, then off for transmission is in

0.025s) progress.

Blinking (on for The GPRS card has

0.1s, then off for registered with a

2.9s) network but is idle.

Blinking (on for No SIM card is

0.1s, then off for installed, the PIN is

0.9s) not decoded, or

network search is in

progress.

Ports

Table 2-12 describes the ports on the GPRS expansion card.

Table 2-12 Ports on the front panel of the GPRS expansion card

Silk Screen Port

DO_1 Dry contact output.

DO_2 Reserved.

DI_1 Dry contact input.

DI_2 Default setting:

Open: normal

DI_3 Closed: alarm

DI_4

DI_5

DI_6

ANT Used to connect the GPRS antenna.

2.2.6 AI/DI Module

When the AI/DI expansion card installed in the ECC500 has insufficient space for AI/DI data

collection, you can connect an AI/DI module to the AI/DI expansion card using an RS485 bus.

The eight AI/DI input ports on the module can collect more AI/DI signals. The AI/DI module

can be mounted in a 19-inch rack or on a wall. Figure 2-11 shows ports on its front panel.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 18

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Figure 2-11 Front panel of the AI/DI module

(1) DC 15 V power input port (2) Indicators (3) DIP switch

(4) Cascading ports (5) AI/DI_1 to AI/DI_8 (6) Ground point

Table 2-13 describes indicators on the front panel of the AI/DI module.

Table 2-13 Description of indicators on the front panel of the AI/DI module

Silk Screen Color Meaning Status Description

PWR Green Power indicator Steady on The power

supply is

normal.

Off The AI/DI

expansion card

is faulty or has

no DC input.

RUN Green Run indicator Blinking (1 The AI/DI

second on and 1 module is

second off) communicating

with the main

control module

properly.

Blinking (0.125 The AI/DI

second on and module fails to

0.125 second communicate

off) with the main

control module.

ALM Red Alarm indicator Off No alarm is

generated.

Steady on A board alarm

is generated.

Table 2-14 describes ports on the front panel of the AI/DI module.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 19

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 2 Configurations and Port

Table 2-14 Description of ports on the front panel of the AI/DI module

Silk Screen Port Description

COM_IN Cascading ports. COM_IN connects to the RS485 expansion card, and

COM_OUT COM_OUT connects another AI/DI module.

Pin definitions of the ports are the same as those of the COM4 port on

the communication card.

AI/DI_1 to Provide 12 V DC outputs for sensors and are compatible with 4 mA to

AI/DI_8 20 mA current signals, signals from current-based smoke sensors and

water sensors, dry contact signals, and NTC signals.

Pin definition:

3: 12 V DC, 54 mA

6: D-

7: D+

8: GND

The AI/DI module is configured with a 4-bit DIP switch. Set toggle switches 1 to 3 to

configure the address of the AI/DI module, and set toggle switch 4 to enable or disable the

resistance for the RS485 port. Table 2-15 describes the mapping between the AI/DI module

address and the DIP switch settings.

Table 2-15 Mapping between the AI/DI module address and the DIP switch settings

Address SW1 SW2 SW3

1 OFF ON ON

2 ON OFF ON

If the signal quality is poor due to signal reflection, set toggle switch 4 to ON for the farthermost AI/DI

module. After the DIP switch settings are modified, power off and restart the AI/DI module for the new

settings to take effect.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 20

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

3 Installation and Commissioning

3.1 Installation and Commissioning Flowchart

Figure 3-1 shows the flowchart for installing and commissioning the ECC500.

Figure 3-1 ECC500 installation and commissioning flowchart

3.2 Installing Devices

3.2.1 Installing a Rack-mounted ECC500

Prerequisites

The installation position has been determined.

The following tools are available: Phillips screwdriver, flat-head screwdriver, and rubber

mallet.

Context

A flat-head screwdriver can be used as a floating nut mounting bar.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 21

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Procedure

Step 1 Use a floating nut mounting bar to install floating nuts (one on each site) into the mounting

holes in the posts of the rack, as shown in Figure 3-2.

Figure 3-2 Installing a floating nut

Ensure that the floating nuts on both sides are on the same horizontal line.

Step 2 Place the ECC500 on the correct guide rails in the cabinet.

Step 3 Secure the ECC500 in the cabinet by tightening the M6 screws clockwise on the right and left

mounting ears, as shown by (2) in Figure 3-3.

Figure 3-3 Installing the ECC500

----End

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 22

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

3.2.2 Installing a Wall-mounted ECC500

Prerequisites

The installation position on the wall has been determined.

The following tools are available: Phillips screwdriver, flat-head screwdriver, hammer

drill (10 bit), socket wrench, marker, and rubber mallet.

Procedure

Step 1 Install mounting ears on the ECC500 in the position and direction shown in Figure 3-4.

Step 2 Place the ECC500 at the installation position on the wall and mark the mounting ear hole

positions using a marker.

Step 3 Drill holes at the marked installation position (hole spacing: 52 mm x 472 mm) on the wall

using a hammer drill, and install four M8 expansion bolts into the holes.

Step 4 Install the ECC500 at the expansion bolts on the wall and ensure that the rear panel of the

ECC500 is flush with the wall.

Step 5 Tighten the four expansion bolts for the ECC500 using a socket wrench, as shown in Figure

3-4.

Figure 3-4 Wall-mounted ECC500

----End

3.2.3 (Optional) Installing a Rack-mounted AI/DI Module

Prerequisites

The installation position in the rack has been determined.

The following tools are available: Phillips screwdriver, flat-head screwdriver, and rubber

mallet.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 23

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Context

When installing a rack-mounted AI/DI module, choose appropriate long mounting ears

delivered with the AI/DI module.

A flat-head screwdriver can be used as a floating nut mounting bar.

Procedure

Step 1 Use a floating nut mounting bar to install floating nuts (one on each site) into the mounting

holes in the posts of the rack, as shown in Figure 3-5.

Figure 3-5 Installing floating nuts

Ensure that the floating nuts on both sides are on the same horizontal line.

Step 2 Install long mounting ears on the AI/DI module.

Step 3 Secure the AI/DI module in the cabinet by tightening the M6 screws clockwise on the right

and left mounting ears, as shown in Figure 3-6.

Figure 3-6 Installing a rack-mounted AI/DI module

----End

3.2.4 (Optional) Installing a Wall-mounted AI/DI Module

Prerequisites

The installation position on the wall has been determined.

The following tools are available: Phillips screwdriver, flat-head screwdriver, hammer

drill (10 bit), socket wrench, marker, and rubber mallet.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 24

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Procedure

Step 1 Install mounting ears on the AI/DI module in the position and direction shown in Figure 3-7.

Step 2 Place the AI/DI module at the installation position on the wall and mark the mounting ear

hole positions using a marker.

Step 3 Drill holes at the marked installation position (hole spacing: 52 mm x 205 mm) on the wall

using a hammer drill, and install four M8 expansion bolts into the holes.

Step 4 Install the AI/DI module at the expansion bolts on the wall and ensure that the rear panel of

the module is flush with the wall.

Step 5 Tighten the four expansion bolts for the AI/DI module using a socket wrench, as shown in

Figure 3-7.

Figure 3-7 Wall-mounted AI/DI module

----End

3.3 Connecting Cables

3.3.1 Connecting Ground Cables

After an ECC500 or an AI/DI module is installed, connect a ground cable to it and connect the

other end of the ground cable to the cabinet or site ground point. Figure 3-8 shows the ground

cable connections for the ECC500 and AI/DI module.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 25

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-8 Connecting ground cables

3.3.2 Connecting to an IP Network

Figure 3-9 shows the cable connection between the ECC500 and an IP network.

Figure 3-9 Connecting to an IP network

3.3.3 Connecting Monitoring Cables

All AI/DI and RS485 ports on expansion cards of the ECC500 are connected to monitoring

components using standard Ethernet cables with RJ45 connectors, as shown in Figure 3-10.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 26

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-10 Connecting monitoring cables

Connect an audible and visual alarm to the ECC500 using the delivered adapter.

3.3.4 Connecting Cables to Intelligent Equipment and Sensors

For details about how to connect cables to intelligent equipment through RS485 ports, see

Table 2-7.

Figure 3-11 shows how to connect cables between the ECC500 and sensors.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 27

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-11 Connecting cables to sensors

3.3.5 Connecting Power Cables

The power module of the ECC500 is connected to the external power supply using a power

cable. Figure 3-12 shows the cable connection.

Figure 3-12 Connecting a power cable

(1) ECC500 power port

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 28

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

3.3.6 Connecting the T/H Sensor Monitoring Cable

Context

When connecting a T/H sensor to the ECC500, perform the following steps to prepare a

special monitoring cable.

The cable connection method described in the section applies to cable connections from

the ports of the RS485 expansion card in the ECC500 to devices.

Procedure

Step 1 Prepare an RJ45 connector on one end of a network cable, as shown in Figure 3-13.

Figure 3-13 Preparing an RJ45 connector (unit: mm)

Step 2 Prepare an RJ12 connector on the other end of the cable, as shown in Figure 3-14.

Figure 3-14 Preparing an RJ12 connector (unit: mm)

Step 3 Plug the RJ45 connector to an RS485 port with 12 V power supply in the ECC500 and the

RJ12 connector to the RS485 port in the T/H sensor.

----End

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 29

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

3.3.7 Connecting the UPS2000G-B Monitoring Cable

Context

When connecting a UPS2000G-B to the ECC500, perform the following steps to prepare

a special monitoring cable.

The cable connection method described in the section applies to cable connections from

the ports of the RS485 expansion card in the ECC500 to devices.

UPS2000G-B V200R001 is used and equipped with an LCD screen, as shown in Figure

3-15.

Figure 3-15 LCD screen display

Procedure

Step 1 Prepare an RJ45 connector on one end of a network cable, as shown in Figure 3-13.

Step 2 Prepare a special RJ45 connector (exchange No. 4 and 5 wires) on the other end of the cable,

as shown in Figure 3-16.

Figure 3-16 Preparing a special RJ45 connector (unit: mm)

Step 3 Plug the common RJ45 connector to an RS485 port in the ECC500 and the special one to the

RS485 port in the UPS2000G-B.

----End

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 30

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

3.3.8 Connecting the UPS2000G-A Monitoring Cable

Context

The cable connection method described in the section applies to cable connections from

the ports of the RS485 expansion card in the ECC500 to devices.

UPS2000G-A V100R001 is used and equipped with an LCD screen, as shown in Figure

3-17.

Figure 3-17 LCD screen display

Procedure

Step 1 Prepare RJ45 connectors on both ends of a network cable, as shown in Figure 3-13.

Step 2 Plug one RJ45 connector to an RS485 port in the ECC500 and the other one to the RS485 port

in the UPS2000G-A.

----End

3.3.9 Connecting the UPS5000E Monitoring Cable

Context

The cable connection method described in the section applies to cable connections from the

ports of the RS485 expansion card in the ECC500 to devices.

Procedure

Step 1 Prepare RJ45 connectors on both ends of a network cable, as shown in Figure 3-13.

Step 2 Plug one RJ45 connector to an RS485 port in the ECC500 and the other one to the RS485 port

in the UPS5000E.

----End

3.3.10 Connecting the NetCol5000A Monitoring Cable

Context

The cable connection method described in the section applies to cable connections from the

ports of the RS485 expansion card in the ECC500 to devices.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 31

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Procedure

Step 1 Prepare RJ45 connectors on both ends of a network cable, as shown in Figure 3-13.

Step 2 Plug one RJ45 connector to an RS485 port in the ECC500 and the other one to the RS485 port

in the NetCol5000A.

----End

3.3.11 Connecting the PDU8000 Monitoring Cable

Context

The cable connection method described in the section applies to cable connections from the

ports of the RS485 expansion card in the ECC500 to devices.

Procedure

Step 1 Prepare RJ45 connectors on both ends of a network cable, as shown in Figure 3-13.

Step 2 Plug one RJ45 connector to an RS485 port in the ECC500 and the other one to the RS485 port

in the PDU8000.

----End

3.3.12 Connecting the ABB OTM ATS Monitoring Cable

Context

Before the PDU8000 configured with an ABB OTM ATS is delivered, the wiring terminal

block in the PDU8000 is connected to the RS485 port on the rear of the ABB OTM ATS. You

only need to connect the monitoring cable to the wiring terminal block in the PDU8000.

Locate the RS485 port on the wiring terminal block by using either of the following methods:

Obtain the number of the RS485 port on the wiring terminal block from the delivered

conceptual diagram.

Locate the RS485 port on the rear of the ATS and the cable connected to the port. The

port to which the other end of the cable is connected is the RS485 port on the wiring

terminal block.

The cable connection method described in the section applies to cable connections from the

ports of the RS485 expansion card in the ECC500 to devices.

Procedure

Step 1 Prepare an RJ45 connector on one end of a network cable, as shown in Figure 3-13.

Step 2 Connect the orange-white wires on the other end of the cable to the RS485+ wiring terminal

in the PDU8000. Connect the orange wires to the RS485- wiring terminal in the PDU8000.

In the example shown in Figure 3-18, PDU8000 wiring terminal 1 is RS485+ and wiring

terminal 2 is RS485-.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 32

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-18 PDU8000 wiring terminal

Step 3 Plug the RJ45 connector to an RS485 port in the ECC500.

----End

3.3.13 Connecting the Fan Monitoring Cable

Context

The fan can be connected only to the COM1 port of the main control module in the ECC500.

Procedure

Step 1 Prepare RJ45 connectors on both ends of a network cable, as shown in Figure 3-13.

Step 2 Plug one RJ45 connector to the COM1 port on the main control module of the ECC500 and

the other one to the COM_OUT port on the fan.

----End

3.4 Commissioning Devices

Checking Cable Connections and Powering On the ECC500

Check that power cables, ground cables, RS485 communications cables, and AI/DI signal

cables are connected to the main control module, RS485 expansion card, AI/DI expansion

card, and AI/DI module in the manner specified in 3.3 Connecting Cables. Connect the

external power supply to the power module to power on the ECC500.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 33

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Checking Indicator Status

Check the indicators on the main control module, RS485 expansion card, AI/DI expansion

card, and AI/DI module. Table 3-1 describes their normal status.

Table 3-1 Indicator description

Module Normal Indicator Status

Main control The run indicator blinks (on for 1s and then off for 1s).

module The alarm indicator is off.

RS485 expansion The PWR indicator is steady on.

card, AI/DI The RUN indicator blinks (on for 1s and then off for 1s).

expansion card, and

The ALM indicator is off.

AI/DI module

Setting ECC500 Communications Parameters (LCD)

Table 3-2 lists the communications parameters that can be set over the LCD.

Table 3-2 Communications parameters

Parameter Description

IP address Set to 192.168.1.168 by default but can be adjusted according to the

network plan.

Subnet mask Set to 255.255.255.0 by default but can be adjusted according to the

network plan.

Gateway Set to 192.168.1.1 by default but can be adjusted according to the

network plan.

Figure 3-19 shows the procedure for setting these communications parameters.

Change the password after your first login.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 34

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-19 Setting communications parameters

Querying Information (LCD)

You can view active alarms over the LCD, as shown in Figure 3-20.

Figure 3-20 Viewing active alarms

Basic Settings (LCD)

For details about how to set the language, date, and time over the LCD, see 4.1.2 LCD

Operations.

Figure 3-21 shows how to set the LCD contrast.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 35

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-21 Setting the LCD contrast

Figure 3-22 shows how to change the LCD login password.

Figure 3-22 Changing the password

Figure 3-23 shows how to restore ECC500 factory settings over the LCD.

Restoring factory settings will restore the ECC500 parameters to their factory settings.

Perform this operation with caution.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 36

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-23 Restoring factory settings

3.4.1 Setting the T/H Sensor Device Address

Procedure

Step 1 Operate the DIP switch on the T/H sensor to set the device address for the sensor.

Toggles 1 to 6 of the DIP switch specify the device address in binary mode. ON indicates 1,

and OFF indicates 0. Table 3-3 shows an example of the switch settings.

Table 3-3 Mapping between T/H sensor device addresses and DIP switch settings

Device Toggle Toggle Toggle Toggle Toggle Toggle Toggle Toggle

Addre Switch Switch Switch Switch Switch Switch Switch Switch

ss 1 2 3 4 5 6 7 8

1 ON OFF OFF OFF OFF OFF OFF OFF

2 OFF ON OFF OFF OFF OFF OFF OFF

3 ON ON OFF OFF OFF OFF OFF OFF

4 OFF OFF ON OFF OFF OFF OFF OFF

----End

3.4.2 Setting the UPS2000G-A Device Address

Context

UPS2000G-A V100R001 is used and equipped with an LCD screen, as shown in Figure 3-24.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 37

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-24 LCD screen display

Procedure

Step 1 Operate the DIP switch S2 on the optional Modbus card to set the UPS2000G-A device

address.

Toggles 1 to 8 of DIP switch S2 specify the device address in binary mode. ON indicates 0,

and OFF indicates 1. Table 3-4 shows an example of the switch settings.

Table 3-4 Mapping between device addresses and Modbus card DIP switch settings

Device Toggle Toggle Toggle Toggle Toggle Toggle Toggle Toggle

Addre Switch Switch Switch Switch Switch Switch Switch Switch

ss 1 2 3 4 5 6 7 8

1 OFF ON ON ON ON ON ON ON

2 ON OFF ON ON ON ON ON ON

3 OFF OFF ON ON ON ON ON ON

4 ON ON OFF ON ON ON ON ON

----End

3.4.3 Setting the UPS2000G-B Device Address

Context

UPS2000G-B V200R001 is used and equipped with an LCD screen, as shown in Figure 3-25.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 38

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Figure 3-25 LCD screen display

Procedure

Step 1 Operate the DIP switch S1 on the optional Modbus card to set the UPS2000G-B device

address.

Toggles 1 to 8 of DIP switch S1 specify the device address in binary mode. ON indicates 1,

and OFF indicates 0. Table 3-5 shows an example of the switch settings.

Table 3-5 Mapping between device addresses and Modbus card DIP switch settings

Device Toggle Toggle Toggle Toggle Toggle Toggle Toggle Toggle

Addre Switch Switch Switch Switch Switch Switch Switch Switch

ss 1 2 3 4 5 6 7 8

1 ON OFF OFF OFF OFF OFF OFF OFF

2 OFF ON OFF OFF OFF OFF OFF OFF

3 ON ON OFF OFF OFF OFF OFF OFF

4 OFF OFF ON OFF OFF OFF OFF OFF

----End

3.4.4 Setting the UPS5000E Device Address

Prerequisites

You have obtained the device address assigned to the UPS5000E.

The UPS5000E has been powered on.

Procedure

Step 1 Tap Settings on the UPS5000E home screen.

Step 2 Enter the administrator user name and password and tap on the screen.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 39

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

The preset user name and password for the UPS5000E are respectively Admin and 000001. To ensure

access security, change the password upon first use.

Step 3 Tap Communication.

Step 4 Set RS485 baud rate and RS485 address.

Table 3-6 Parameter description

Parameter Setting

RS485 address Indicates the device address assigned to the

UPS5000E. The addresses of devices

connected to a same port must be unique.

When creating a UPS5000E on the ECC500

WebUI, enter this value in Equipment

Address.

RS485 baud rate Retain the default value 9600.

The DataBit, StopBit, and Parity for the UPS5000E cannot be set on the WebUI. Their

default values are 8, 1, and None respectively.

----End

3.4.5 Setting the NetCol5000A Device Address

Prerequisites

You have obtained the device address assigned to the NetCol5000A.

The NetCol5000A has been powered on.

Procedure

Step 1 Tap Settings on the NetCol5000A home screen.

Step 2 Enter the administrator user name and password and tap on the screen.

The preset user name and password for the NetCol5000A are respectively Admin and 000001. To ensure

access security, change the password upon first use.

Step 3 Tap Com Settings.

Step 4 Set Baud Rate and Com address.

Table 3-7 Parameter description

Parameter Setting

Com address Indicates the device address planned for the

NetCol5000A. The addresses of devices

connected to the same collector port must be

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 40

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

Parameter Setting

unique. When creating a NetCol5000A on

the ECC500 WebUI, enter the value in

Equipment Address.

Baud Rate Retain the default value 9600.

The DataBit, StopBit, and Parity for the NetCol5000A cannot be set on the WebUI. Their

default values are 8, 1, and None respectively.

----End

3.4.6 Setting the PDU8000 Device Address

Prerequisites

You have obtained the device address assigned to the PDU8000.

The PDU8000 has been powered on.

Procedure

Step 1 Tap Settings on the PDU8000 home screen.

Step 2 Enter the PDU8000 password and tap on the screen.

The preset user name and password for the PDU8000 are respectively admin and 000001. To ensure

access security, change the password upon first use.

Step 3 Tap Communication.

Set Serial port baud rate and Serial port address.

Table 3-8 Parameter description

Parameter Setting

Serial port baud rate Retain the default value 9600.

Serial port address Indicates the device address assigned to the

PDU8000. The addresses of devices

connected to a same port must be unique.

When creating a PDU8000 on the ECC500

WebUI, enter this value in Equipment

Address.

The DataBit, StopBit, and Parity for the PDU8000 cannot be set on the WebUI. Their default

values are 8, 1, and None respectively.

----End

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 41

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 3 Installation and Commissioning

3.4.7 Setting the ABB OTM ATS Device Address

Prerequisites

You have obtained the device address assigned to the ABB OTM ATS.

The ABB OTM ATS has been powered on.

Procedure

Step 1 On the display panel of the ABB OTM ATS, press .

Step 2 Press to move the cursor to Device Configuration.

Step 3 Press .

Step 4 Enter the password and press .

The preset password is 0001. To ensure access security, change the password upon first use.

Step 5 Press to move the cursor to Modbus.

Step 6 Press . On the Modbus parameter setting screen, set communications parameters.

Set the device address for the ABB OTM ATS. The addresses of devices connected to a same

port must be unique. When creating an ABB OTM ATS on the ECC500 WebUI, enter this

value in Equipment Address.

Step 7 Press ESC to return to the home screen.

----End

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 42

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 4 UI Description

4 UI Description

4.1 LCD

The LCD of the ECC500 is located on the front panel of the main control module. It allows

you to:

View active alarms.

View the running status of the system.

Set system parameters, select a language, and set communications parameters.

Set basic parameters, such as the date, time, and LCD contrast.

Change the password.

Restore factory settings.

4.1.1 LCD Menu Hierarchy

Figure 4-1 shows the LCD main menu hierarchy.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 43

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 4 UI Description

Figure 4-1 LCD menu hierarchy

A password is required for access to Running Control and Basic Settings.

4.1.2 LCD Operations

This section uses language selection and parameter setting as examples to illustrate how

to operate the LCD. For details about buttons on the front panel of the main control

module, see LCD/Buttons.

The figure is for reference only.

Selecting a Language

After powering on the ECC500, select English by pressing or on the LCD, as

shown in Figure 4-2. Then press to enter the default system information screen.

Figure 4-2 Screen for selecting a language

After accessing the system, you can change the display language by performing the steps

shown in Figure 4-3.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 44

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 4 UI Description

Figure 4-3 Setting the language

Setting the Date and Time

Figure 4-4 uses the date and time setting as an example to show how to set parameters quickly

over the LCD.

Figure 4-4 Setting the date and time

Viewing Information

Figure 4-5 uses equipment status viewing as an example to show how to view information

over the LCD.

Issue 02 (2015-11-01) Huawei Proprietary and Confidential 45

Copyright Huawei Technologies Co., Ltd.

ECC500

User Manual 4 UI Description

Figure 4-5 Viewing information

4.2 WebUI

To ensure secure data transmission, the ECC500 transmits encrypted data over the Secure

Sockets Layer (SSL) protocol to the WebUI, which allows you to:

View system status and current alarm information.