Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ammonolysis Process Description (Revised)

Caricato da

Mika PelagioDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ammonolysis Process Description (Revised)

Caricato da

Mika PelagioCopyright:

Formati disponibili

In this process, a mixed-vapor feed of phenol and ammonia is pre-heated and passed over a fixed catalyst

bed reactor (R-101) at 370 C and 1.7 MPa using a Silica- Alumina catalyst. The two feed streams are

pumped to a pressure of 255 psia before they are mixed with their respective recycle streams (stream 6

and stream 17). Ammonia recycle (stream 6) has small amounts of hydrogen, nitrogen and water. The

phenol recycle consists of phenol, aniline and diphenylamine. The cooling of the reactor effluent begins

with the cross exchanger (E-100) which cools stream 10 by about 500 F. The purification of aniline begins

with the column D-100. The pressure at the top of the column is 220 psia and the pressure at the bottom is

222.5 psia. The distillate (stream 5) is composed of ammonia and water. The components lighter than

ammonia will also appear in the distillate. Therefore, all of the hydrogen and nitrogen will go to stream 5.

From the column D-100, stream 5 goes to a splitter. The splitter sends 98.9% of the stream to stream 6,

which is the ammonia recycle stream. The splitter also sends 1.1% of stream 5 to the gaseous purge,

stream 7. The purge is necessary to avoid any pressure build-up in the process. Stream 7 is a non-product

stream, but it is used as fuel for the heater. The bottoms stream (stream 8) is one of the feeds to the next

column. The second column in the purification section is the drying column (D-101). The pressure at the top

of the column is 15 psia, and the pressure at the bottom of the column stage is 21.25 psia. The key

components are water and phenol. However, some aniline is lost in the distillate because aniline is soluble

in water. The distillate contains 99.99% of the water, 6% of the phenol and 5% of the aniline fed to the

column. The distillate, stream 9, is cooled by E-103 to a temperature of 110 F with a pressure of 10 psia.

Stream 10 is then sent to a three-phase separator (V-100) to separate the aqueous product and the liquid

(organic) product. The organic product (stream 12) is recycled to the column. Stream 12 consists of 7% of

the ammonia, 3% of the water, 30.5% of the phenol and 86% of the aniline in stream 20. Because stream

12 is below the pressure of the top stage pressure, P-102 is used to bring the pressure in stream 23 up to

15 psia. The aqueous product (stream 11) from V-100 is a non-product output stream. This stream will be

sent through wastewater treatment and released off-site. The bottoms stream (stream 13) is the feed to the

next column.

The final column is the product column (D-102). The pressure at the top of the column is 2.707 psia, while

the pressure at the bottom of the column is 21.46 psia. Due to a high-boiling azeotrope between phenol

and aniline, the main component in the distillate (stream 14) is aniline. Stream 15 contains all of the water,

19.5% of the phenol and 92.3% of the aniline from stream 13. Stream 15 must be at least 99 wt% aniline

for industrial use. Because there is a 10 psia pressure drop for liquids in coolers, stream 14 needs to be

pumped up to a pressure of 12.71 psia by P-104. The resulting stream (stream 14) is cooled by E-104.

Stream 15, a product stream, emerges from the cooler at 90o F and 2.707 psia. The azeotrope between

phenol and aniline is recycled. This azeotrope (stream 17) contains 33 wt% phenol, 65 wt% aniline and 2

wt% diphenylamine. These weight percents account for 80% of the phenol, 7.7% of the aniline and 4.6% of

the diphenylamine in stream 13. Stream 17 is below the pressure of stream 2, therefore it is pumped to a

pressure of 255 psia by P-103. Stream 18 emerges at 373o F and 255 psia. The bottoms product (stream

16) consists of 5% of the phenol and 95.4% of the diphenylamine in stream 13. Stream 32 must be at least

95 wt% diphenylamine for industrial use. This stream is then cooled by E-105. Stream 16, a product

stream, emerges from E-105 at 130o F and 11.46 psia. This concludes the description of the aniline

process.

Potrebbero piacerti anche

- Haematology Notes - 3rd EdDocumento100 pagineHaematology Notes - 3rd EdSally Brit100% (1)

- Right To HealthDocumento9 pagineRight To HealthPriya SharmaNessuna valutazione finora

- Titrations worksheet calculationsDocumento2 pagineTitrations worksheet calculationsHarsh bajajNessuna valutazione finora

- GCSDocumento20 pagineGCSnicole aligno100% (2)

- CIRCLES - Angles, ChordsDocumento158 pagineCIRCLES - Angles, ChordsMika Pelagio100% (2)

- Control of Hazardous EnergiesDocumento15 pagineControl of Hazardous EnergiesMika PelagioNessuna valutazione finora

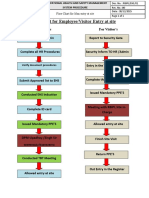

- fLOW CHART FOR WORKER'S ENTRYDocumento2 paginefLOW CHART FOR WORKER'S ENTRYshamshad ahamedNessuna valutazione finora

- Acrylonitrile by The Ammoxidation of PropaneDocumento10 pagineAcrylonitrile by The Ammoxidation of PropaneVincet Vega100% (1)

- Phenol PlantDocumento33 paginePhenol PlantrakeshNessuna valutazione finora

- Module A Specimen Questions January2020 PDFDocumento5 pagineModule A Specimen Questions January2020 PDFShashi Bhusan SinghNessuna valutazione finora

- Sigma monitor relayDocumento32 pagineSigma monitor relayEdwin Oria EspinozaNessuna valutazione finora

- SNAMPROGETTI UREA PROCESS STEPSDocumento23 pagineSNAMPROGETTI UREA PROCESS STEPSTu Hai50% (2)

- Auramo Oy spare parts listsDocumento12 pagineAuramo Oy spare parts listsYavuz ErcanliNessuna valutazione finora

- Production of PhenolDocumento65 pagineProduction of Phenolchaitanyavura67% (3)

- Production of AnilineDocumento16 pagineProduction of AnilineNaixt Cabudz100% (2)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresDa EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresValutazione: 5 su 5 stelle5/5 (1)

- Cipac MT 185Documento2 pagineCipac MT 185Chemist İnançNessuna valutazione finora

- Production of Formaldehyde From MethanolDocumento13 pagineProduction of Formaldehyde From MethanolAugusto Mohr Christmann100% (1)

- Phenol ProductionDocumento9 paginePhenol ProductionPlant Design100% (1)

- DWSIM Abstract PDFDocumento3 pagineDWSIM Abstract PDFredagalihNessuna valutazione finora

- CHE655 - Formalin Production DesignDocumento13 pagineCHE655 - Formalin Production DesignAhmed Ali100% (1)

- 8-Plant Design - Separation Units Part 4Documento189 pagine8-Plant Design - Separation Units Part 4MrHemFunNessuna valutazione finora

- Perfusion for Congenital Heart Surgery: Notes on Cardiopulmonary Bypass for a Complex Patient PopulationDa EverandPerfusion for Congenital Heart Surgery: Notes on Cardiopulmonary Bypass for a Complex Patient PopulationValutazione: 5 su 5 stelle5/5 (2)

- Project 1 StyreneDocumento11 pagineProject 1 StyreneAbigail MCabezasNessuna valutazione finora

- CHE655 - Plant Design Project #4 Summer 2011 Design of A Styrene Production ProcessDocumento11 pagineCHE655 - Plant Design Project #4 Summer 2011 Design of A Styrene Production ProcessAhmed Ali67% (3)

- RTG E-One - Manual de Manutenção 41300-41303 (EN)Documento328 pagineRTG E-One - Manual de Manutenção 41300-41303 (EN)Conrado Soares100% (1)

- Hydrodealkylation SimulationDocumento8 pagineHydrodealkylation SimulationLívia Lopes100% (2)

- Process 2Documento5 pagineProcess 2Mika PelagioNessuna valutazione finora

- Alternative 1Documento8 pagineAlternative 1JeanNessuna valutazione finora

- Energy Balances and Numerical Methods Design ProjectDocumento8 pagineEnergy Balances and Numerical Methods Design ProjectoptimisteveNessuna valutazione finora

- PDescDocumento1 paginaPDescMaria Mikaela PelagioNessuna valutazione finora

- Production of CumeneDocumento5 pagineProduction of CumeneMohit YaduwanshiNessuna valutazione finora

- Urea Plant Process: Raw Materials to Final ProductDocumento9 pagineUrea Plant Process: Raw Materials to Final ProductSaad KhanNessuna valutazione finora

- 402 18 Simexam TakehomeDocumento3 pagine402 18 Simexam TakehomeSSNessuna valutazione finora

- US1586732 - Collumn StillDocumento4 pagineUS1586732 - Collumn StilletyseNessuna valutazione finora

- ImmediatelyDocumento17 pagineImmediatelyJomhel CalluengNessuna valutazione finora

- AMMONIA PROCESS SIMULATIONDocumento8 pagineAMMONIA PROCESS SIMULATIONChecoCastilloNessuna valutazione finora

- Allyl BDocumento9 pagineAllyl BDemet AcargilNessuna valutazione finora

- TareaDocumento3 pagineTareaAydee GarciaNessuna valutazione finora

- Project 1 Acetone PDFDocumento13 pagineProject 1 Acetone PDFvanesaNessuna valutazione finora

- From The Distilation Zone, Condensing The Vaporized Water and Methanol and Maintaining A Reflux Ratio of About 1.5 To 1 Thereby Maintaining TheDocumento3 pagineFrom The Distilation Zone, Condensing The Vaporized Water and Methanol and Maintaining A Reflux Ratio of About 1.5 To 1 Thereby Maintaining TheannissaNessuna valutazione finora

- 1.0 1.1 Overview of TPADocumento8 pagine1.0 1.1 Overview of TPAlilyNessuna valutazione finora

- Hindustan Organic Chemicals Ltd. Implant Training Report Propylene Recovery Unit (PRU) and Effluent Treatment Plant (ETPDocumento7 pagineHindustan Organic Chemicals Ltd. Implant Training Report Propylene Recovery Unit (PRU) and Effluent Treatment Plant (ETPajin k bobanNessuna valutazione finora

- Edz 1Documento14 pagineEdz 1Joshua Peter Evangelista CadoyNessuna valutazione finora

- Practice Problems in Chemical Engineering CalculationsDocumento1 paginaPractice Problems in Chemical Engineering CalculationsTheresa TuliaoNessuna valutazione finora

- Process DescriptionDocumento1 paginaProcess Descriptionamirul ashrafNessuna valutazione finora

- Crude Distillation Unit - OdtDocumento32 pagineCrude Distillation Unit - OdtfaresNessuna valutazione finora

- Ethanolamine Production Process DescriptionDocumento2 pagineEthanolamine Production Process DescriptionSanjay KumarNessuna valutazione finora

- Reactions: Phenol Production From CumeneDocumento2 pagineReactions: Phenol Production From CumeneAhmed Hassan RashedNessuna valutazione finora

- Mass Balance AssignmentDocumento2 pagineMass Balance AssignmentSiti Hajar Mohd PodziNessuna valutazione finora

- TolueneDocumento1 paginaTolueneAlliah Mae LumanogNessuna valutazione finora

- CH656 Aspen Plus Simulation ProblemsDocumento3 pagineCH656 Aspen Plus Simulation Problemsankit singhNessuna valutazione finora

- Urea Synthesis ProcessDocumento5 pagineUrea Synthesis ProcessrajmaneamitNessuna valutazione finora

- Produce Acetone from Isopropyl AlcoholDocumento13 pagineProduce Acetone from Isopropyl AlcoholGustavo Vasquez100% (1)

- FormalinDocumento5 pagineFormalinDipankar KalitaNessuna valutazione finora

- Acrylic Acid Production Process DescriptionDocumento3 pagineAcrylic Acid Production Process DescriptionMauliduni M. AuniNessuna valutazione finora

- CT-308 Phenol Production-2023Documento22 pagineCT-308 Phenol Production-2023Divyansh NagarNessuna valutazione finora

- Unit 3Documento29 pagineUnit 3ASHISH K.K.Nessuna valutazione finora

- Chapter 2 (Blueprint)Documento4 pagineChapter 2 (Blueprint)John Patrick Sanay NunezNessuna valutazione finora

- Dee CDocumento15 pagineDee CAnderson David ValenciaNessuna valutazione finora

- Distillation 2Documento3 pagineDistillation 2roxetteNessuna valutazione finora

- Production of Specialty Chemicals From A Coal Gasification Acid Gas Waste StreamDocumento26 pagineProduction of Specialty Chemicals From A Coal Gasification Acid Gas Waste StreamAbubakar Ahmed MagzoubNessuna valutazione finora

- Air PDFDocumento10 pagineAir PDFAbednego ZanoNessuna valutazione finora

- Flowsheeting Sheet (1) 21/2/2015: Ag-CatalystDocumento5 pagineFlowsheeting Sheet (1) 21/2/2015: Ag-CatalystAhmed Hamdy Khattab100% (1)

- PPDDocumento79 paginePPDEddie ChangNessuna valutazione finora

- Extractive Distillation Process Design and AnalysisDocumento2 pagineExtractive Distillation Process Design and AnalysisstephenbwogoraNessuna valutazione finora

- English Report 1Documento9 pagineEnglish Report 1Mika PelagioNessuna valutazione finora

- MATH 6 - Problem Set 2 - Q3Documento1 paginaMATH 6 - Problem Set 2 - Q3Mika PelagioNessuna valutazione finora

- SLG CHEM2 LG 5.2 Galvanic CellsDocumento7 pagineSLG CHEM2 LG 5.2 Galvanic CellsMika PelagioNessuna valutazione finora

- 5 Principles of CalibrationDocumento46 pagine5 Principles of CalibrationMika PelagioNessuna valutazione finora

- SanhibungaDocumento1 paginaSanhibungaMika PelagioNessuna valutazione finora

- Maria Rafaela V. Pelagio 9-Alpha Biology Ms. Fabon Aug. 7, 2018Documento3 pagineMaria Rafaela V. Pelagio 9-Alpha Biology Ms. Fabon Aug. 7, 2018Mika PelagioNessuna valutazione finora

- BibliographyDocumento1 paginaBibliographyMika PelagioNessuna valutazione finora

- Vessel Data SheetDocumento2 pagineVessel Data SheetMika PelagioNessuna valutazione finora

- TableDocumento1 paginaTableMika PelagioNessuna valutazione finora

- CounterDocumento1 paginaCounterMika PelagioNessuna valutazione finora

- Distillation: Different Boiling Points Into The Gas PhaseDocumento2 pagineDistillation: Different Boiling Points Into The Gas PhaseMika PelagioNessuna valutazione finora

- Che BoardsDocumento1 paginaChe BoardsMika PelagioNessuna valutazione finora

- History of PlasticsDocumento42 pagineHistory of PlasticsMika PelagioNessuna valutazione finora

- Liquid-Liquid Extraction ExamplesDocumento31 pagineLiquid-Liquid Extraction ExamplesJeffersonPalaciosNessuna valutazione finora

- Process Description Ni AnilineDocumento1 paginaProcess Description Ni AnilineMika PelagioNessuna valutazione finora

- DESIGNDocumento14 pagineDESIGNMika PelagioNessuna valutazione finora

- PFD Process2 v2Documento1 paginaPFD Process2 v2Mika Pelagio100% (1)

- Styrene Butadiene PolymerDocumento4 pagineStyrene Butadiene PolymerMika PelagioNessuna valutazione finora

- Rrl-Nitrobenzene & Hydrogen Gas To AnilineDocumento3 pagineRrl-Nitrobenzene & Hydrogen Gas To AnilineDianne AlarconNessuna valutazione finora

- PFD and PDDocumento3 paginePFD and PDMika Pelagio0% (1)

- PFD and PDDocumento3 paginePFD and PDMika PelagioNessuna valutazione finora

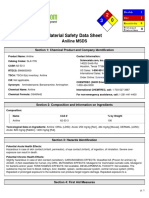

- Msds Aniline PDFDocumento6 pagineMsds Aniline PDFMika PelagioNessuna valutazione finora

- DISTI 1 Enbal - MikaDocumento4 pagineDISTI 1 Enbal - MikaMika PelagioNessuna valutazione finora

- DISTI 1 Enbal - MikaDocumento4 pagineDISTI 1 Enbal - MikaMika PelagioNessuna valutazione finora

- Styrene Butadiene PolymerDocumento4 pagineStyrene Butadiene PolymerMika PelagioNessuna valutazione finora

- ABSCESSDocumento35 pagineABSCESSlax prajapatiNessuna valutazione finora

- Impact of Covid-19 On Audit Quality: Presented byDocumento13 pagineImpact of Covid-19 On Audit Quality: Presented byMST. SADIYA SULTANANessuna valutazione finora

- Bs8161 - Chemistry Laboratory Syllabus: Course ObjectivesDocumento47 pagineBs8161 - Chemistry Laboratory Syllabus: Course ObjectiveslevisNessuna valutazione finora

- Introduction To Animal Science For Plant ScienceDocumento63 pagineIntroduction To Animal Science For Plant ScienceJack OlanoNessuna valutazione finora

- Consumer Behaviour: Group ProjectDocumento5 pagineConsumer Behaviour: Group ProjectAanchal MahajanNessuna valutazione finora

- CERADocumento10 pagineCERAKeren Margarette AlcantaraNessuna valutazione finora

- NLOG GS PUB 1580 VGEXP-INT3-GG-RPT-0001.00 P11-06 Geological FWRDocumento296 pagineNLOG GS PUB 1580 VGEXP-INT3-GG-RPT-0001.00 P11-06 Geological FWRAhmed GharbiNessuna valutazione finora

- Hotel Housekeeping EQUIPMENTDocumento3 pagineHotel Housekeeping EQUIPMENTsamahjaafNessuna valutazione finora

- 2 English Course BDocumento8 pagine2 English Course BAnjana27Nessuna valutazione finora

- Dimensional Data: For Valves and ActuatorsDocumento52 pagineDimensional Data: For Valves and ActuatorsPaulNessuna valutazione finora

- Analisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiDocumento10 pagineAnalisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiSYIFA ABIYU SAGITA 08211840000099Nessuna valutazione finora

- Akshaya Trust NgoDocumento24 pagineAkshaya Trust NgodushyantNessuna valutazione finora

- Nursing Diagnosis TemplateDocumento6 pagineNursing Diagnosis Templatesdk6972Nessuna valutazione finora

- DVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in ElectronicsDocumento1 paginaDVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in Electronicsdinple sharmaNessuna valutazione finora

- Treatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Documento5 pagineTreatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Victoria LeahNessuna valutazione finora

- Hydrogeological Characterization of Karst Areas in NW VietnamDocumento152 pagineHydrogeological Characterization of Karst Areas in NW VietnamCae Martins100% (1)

- Design and Built-A4Documento2 pagineDesign and Built-A4farahazuraNessuna valutazione finora

- Biology (Paper I)Documento6 pagineBiology (Paper I)AH 78Nessuna valutazione finora

- TS4-F - Fire SafetyDocumento2 pagineTS4-F - Fire SafetyDominic SantiagoNessuna valutazione finora

- Fluid Mechanics Sessional: Dhaka University of Engineering & Technology, GazipurDocumento17 pagineFluid Mechanics Sessional: Dhaka University of Engineering & Technology, GazipurMd saydul islamNessuna valutazione finora

- To The OneDocumento8 pagineTo The OnePizzaCowNessuna valutazione finora