Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dos and Donts in Metallic Expansion Joints Installation

Caricato da

1339979Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dos and Donts in Metallic Expansion Joints Installation

Caricato da

1339979Copyright:

Formati disponibili

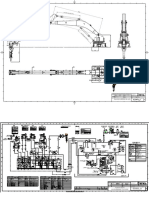

Dos and Donts in Metal

Expansion Joints Installation MACOGA

bkdfkbboba=bum^kpflk glfkqp

In order to ensure that the Expansion Joints work properly and in order to prolong their working life, it is

necessary to respect a series of precautions that make the Expansion Joints almost maintenance free

elements. In case of doubt we recommend that you contact MACOGA directly and inquire about your

specific question.

Dos= Donts=

Inspect for damage during shipment, i.e., dents, Do not lift the expansion joint by the shipping

broken hardware, water marks on carton, etc. bars.

Store in clean dry area where it will not be Do not lift the expansion joint by the hinges,

exposed to heavy traffic or damaging gimbals, tie rods or any other operative device.

environment.

Do not fix any chains or ropes to the bellows

Use only designated lifting lugs to lift the section. The bellows portion of the expansion

Expansion Joints. joint may be easily damaged and cannot usually

be repaired.

Expansion Joints must be fitted in the

appropriate longitude as laid out in the Do not remove any blocking/transport device

instructions supplied by MACOGA. (yellow marked and clearly identified) if available

until the Expansion Joint has been installed.

Install joint with arrow pointing in the direction

of flow. Do not stretch or compress the expansion joint

in order to absorb any defects along the length of

Install single van stone liners, pointing in the the pipe or to rectify any misalignments unless

direction of flow. Be sure to install a gasket this was taken into account during the initial

between the mating flange and liner. design and the manufacturing process.

With telescoping van stone liners, install the Do not allow weld splatter to hit unprotected

smallest I.D. liner pointing in the direction of bellows. Protect with an appropriate fire

flow. resistance insulation blanket or wet chloride-free

insulation.

Remove all shipping devices after the installation

is complete and before any pressure test of the Do not use cleaning agents that contain

fully installed system. chlorides.

Remove any foreign material that may have Do not use steel wool or wire brushes on bellows.

become lodged between the convolutions.

Do not force-rotate one end of an expansion joint

Protect the bellows with an appropriate fire for alignment of bolt holes. Ordinary bellows are

resistance insulation blanket during nearby not capable of absorbing rotation.

welding operations.

Do not hydrostatic pressure test or evacuate the

Refer to EJMA Standards for proper guide spacing system before installation of all guides and

and anchor recommendations. anchors. Pipe hangers are not adequate guides.

Do not exceed a pressure test 1- times the rated

working pressure of the expansion joint.

Do not use shipping bars to retain thrust if tested

prior to installation.

This document is FOR INFORMATION ONLY. and MACOGA does not accept any liability of the information contained herein. The

Purchaser shall be responsible for proper, storage, unpacking, handling and installation of the Expansion Joints and operating within

the design limits of the delivered unit(s).

j^`ld^=pK^K=

i~=LK=NRSUM=l=i~=`~I=p~=qW=HPQ=VUN=SU=MM=MM==

K~~K macoga@macoga.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Field Quality Control PlanDocumento59 pagineField Quality Control Plan1339979100% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento3 pagineAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- EXXI 080 50 00 PI DPS 0001 0(特殊管架与图纸)Documento103 pagineEXXI 080 50 00 PI DPS 0001 0(特殊管架与图纸)1339979Nessuna valutazione finora

- Piping Latest Aramco QuestionsDocumento2 paginePiping Latest Aramco Questionschandu666creator0% (1)

- RT ProcedureDocumento18 pagineRT Procedure1339979Nessuna valutazione finora

- Installation of T1501 PIPE ProcedureDocumento6 pagineInstallation of T1501 PIPE Procedure1339979Nessuna valutazione finora

- PDOC-476-CTRU-06 Rotating Equipment Installation ProcedureDocumento7 paginePDOC-476-CTRU-06 Rotating Equipment Installation Procedure1339979Nessuna valutazione finora

- Sample of Esr-FullDocumento6 pagineSample of Esr-Full1339979Nessuna valutazione finora

- Exxi 040 00 00 Pi Deg 0012Documento34 pagineExxi 040 00 00 Pi Deg 00121339979Nessuna valutazione finora

- DavonDocumento1.601 pagineDavonPalyyNessuna valutazione finora

- 《Pip Ineg1000美国的保温标准》Documento35 pagine《Pip Ineg1000美国的保温标准》1339979Nessuna valutazione finora

- Workshop On Fuel Cell Partnership: AgendaDocumento1 paginaWorkshop On Fuel Cell Partnership: Agenda1339979Nessuna valutazione finora

- Tu 2 3 3 PDFDocumento7 pagineTu 2 3 3 PDF1339979Nessuna valutazione finora

- Special Inspection Dsa 250Documento1 paginaSpecial Inspection Dsa 2501339979Nessuna valutazione finora

- A) Date and Location: Franklin TsuiDocumento2 pagineA) Date and Location: Franklin Tsui1339979Nessuna valutazione finora

- EXXI 003 00 00 PI LST 0002 - 2(供货清单)Documento2.692 pagineEXXI 003 00 00 PI LST 0002 - 2(供货清单)1339979Nessuna valutazione finora

- Lot 1 NB Support Lot 1 KG Support Total Lot 2 NB Support Lot 2 KG Support Total Material Purchased Material PurchasedDocumento13 pagineLot 1 NB Support Lot 1 KG Support Total Lot 2 NB Support Lot 2 KG Support Total Material Purchased Material Purchased1339979Nessuna valutazione finora

- Vibration Proof Fasteners - Welding, Bonding & Fastener Engineering - Eng-TipsDocumento8 pagineVibration Proof Fasteners - Welding, Bonding & Fastener Engineering - Eng-Tips1339979Nessuna valutazione finora

- DBBV PDFDocumento16 pagineDBBV PDF1339979Nessuna valutazione finora

- Ut - Q by B R MeghwalDocumento31 pagineUt - Q by B R Meghwal1339979100% (1)

- Strip Cladding: Technical HandbookDocumento20 pagineStrip Cladding: Technical Handbook1339979Nessuna valutazione finora

- GP 06-25 - Design For The PrevDocumento24 pagineGP 06-25 - Design For The Prev1339979Nessuna valutazione finora

- Qualification of Painters and Sand-BlastDocumento3 pagineQualification of Painters and Sand-Blast1339979Nessuna valutazione finora

- Brief Introduction For Piping ComponentDocumento60 pagineBrief Introduction For Piping Component1339979Nessuna valutazione finora

- Sprinkler Valve Inspection FormDocumento1 paginaSprinkler Valve Inspection Form1339979Nessuna valutazione finora

- Gasket Installation TrainingDocumento10 pagineGasket Installation Training1339979Nessuna valutazione finora

- Grain Diameter (MM) Strength (Mpa) : 0.015 170 Mpa 0.025 158 Mpa 0.035 151 Mpa 0.050 145 MpaDocumento1 paginaGrain Diameter (MM) Strength (Mpa) : 0.015 170 Mpa 0.025 158 Mpa 0.035 151 Mpa 0.050 145 MpaTEBATSONessuna valutazione finora

- H 012200 Barame Sho Man 2Documento2 pagineH 012200 Barame Sho Man 2Obande OrinyaNessuna valutazione finora

- Is 13134Documento14 pagineIs 13134Sowjanya ChNessuna valutazione finora

- 0108E - Report of Welders-OperatorsDocumento6 pagine0108E - Report of Welders-OperatorsErick AlvarezNessuna valutazione finora

- br604 PDFDocumento5 paginebr604 PDFmartinpellsNessuna valutazione finora

- QA QC: ApproachDocumento3 pagineQA QC: ApproachSherif EltoukhiNessuna valutazione finora

- Telescoping Guide Rhs and Chs Aug13 sj0510-1Documento2 pagineTelescoping Guide Rhs and Chs Aug13 sj0510-1Richard GrahamNessuna valutazione finora

- Carrier SelectionDocumento13 pagineCarrier SelectionRanesh SinglaNessuna valutazione finora

- MetamterialsDocumento3 pagineMetamterialsdhruba88Nessuna valutazione finora

- Xerox Workcentre 6400: System Administrator Guide Guide de L'Administrateur SystèmeDocumento184 pagineXerox Workcentre 6400: System Administrator Guide Guide de L'Administrateur SystèmeЃорѓи Поп-ЃорѓиевNessuna valutazione finora

- HAWE - FormulasDocumento6 pagineHAWE - FormulasDeeDee BossNessuna valutazione finora

- Reference Jica-Chodai Scouring Manual in ThailandDocumento175 pagineReference Jica-Chodai Scouring Manual in ThailandSeptinurriandianiNessuna valutazione finora

- Non-Segregated Phase Bus Duct BR en 6 2012Documento8 pagineNon-Segregated Phase Bus Duct BR en 6 2012Aziddin GadingNessuna valutazione finora

- Automobile Manufacturing Process (17403) : Chapter 1. ForgingDocumento87 pagineAutomobile Manufacturing Process (17403) : Chapter 1. ForgingPramod DhaigudeNessuna valutazione finora

- Python ScriptingDocumento2 paginePython ScriptingRavikumar TumuluriNessuna valutazione finora

- 1531 Colibasi H Th1 en Rev 2Documento35 pagine1531 Colibasi H Th1 en Rev 2iahim87Nessuna valutazione finora

- M3 Hull Plate Nesting - SP1Documento50 pagineM3 Hull Plate Nesting - SP1Bùi Công Lộc100% (1)

- 02 21 23 VBNC Drill Rig Filter ChartDocumento2 pagine02 21 23 VBNC Drill Rig Filter Chartvoisey warehouse foracoNessuna valutazione finora

- Lect-6 - Economics of Chemical PlantsDocumento36 pagineLect-6 - Economics of Chemical Plantsmaged1998Nessuna valutazione finora

- Specification For Piping MaterialDocumento9 pagineSpecification For Piping MaterialAgus SupriadiNessuna valutazione finora

- Index of Revisions Rev. Description And/Or Revised SheetsDocumento17 pagineIndex of Revisions Rev. Description And/Or Revised Sheetsfabio.henriqueNessuna valutazione finora

- Hangzhou Chenrui Air Separator Installation Manufacture CO., LTDDocumento10 pagineHangzhou Chenrui Air Separator Installation Manufacture CO., LTDTonyNessuna valutazione finora

- s7 1500 Compare Table en MnemoDocumento88 pagines7 1500 Compare Table en MnemoPeli JorroNessuna valutazione finora

- TRM34 Preparation of Calculations Rev5Documento5 pagineTRM34 Preparation of Calculations Rev5TuanNessuna valutazione finora

- SI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53Documento2 pagineSI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53strexxNessuna valutazione finora

- Int. J. Miner. Process.: Emin Cafer CilekDocumento10 pagineInt. J. Miner. Process.: Emin Cafer CilekJose Patricio VelardeNessuna valutazione finora

- KinematicsDocumento33 pagineKinematicsErik MagnoNessuna valutazione finora