Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FORTRON® 1140L4 - PPS - Glass Reinforced: Description

Caricato da

Adam GordonTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FORTRON® 1140L4 - PPS - Glass Reinforced: Description

Caricato da

Adam GordonCopyright:

Formati disponibili

FORTRON 1140L4 | PPS | Glass Reinforced

Description

Fortron 1140L4 is a 40% glass-reinforced grade that is the strongest and toughest product available. It exhibits excellent heat

and chemical resistance, good electrical properties and is inherently flame-retardant. The high hardness and rigidity at

elevated temperatures allows for good load bearing performance. This product has good weldability due to the modest filler

level. Applications made of this grade are electronical components (i.e. bobbins, lamp housings, brush holders) and various

other components requiring strength and resistance to aggressive chemicals (i.e. automotive heaters, pumps, valves, fuel

rails, microwave oven rings and distillartion column packings).

Physical properties Value Unit Test Standard

Density 1650 kg/m ISO 1183

Mold shrinkage - parallel 0.2 - 0.6 % ISO 294-4

Mold shrinkage - normal 0.4 - 0.6 % ISO 294-4

Water absorption (23C-sat) 0.02 % ISO 62

Mechanical properties Value Unit Test Standard

Tensile modulus (1mm/min) 14700 MPa ISO 527-2/1A

Tensile stress at break (5mm/min) 195 MPa ISO 527-2/1A

Tensile strain at break (5mm/min) 1.9 % ISO 527-2/1A

Flexural modulus (23C) 14500 MPa ISO 178

Flexural stress @ break 285 MPa ISO 178

Charpy impact strength @ 23C 53 kJ/m ISO 179/1eU

Charpy impact strength @ -30C 53 kJ/m ISO 179/1eU

Charpy notched impact strength @ 23C 10 kJ/m ISO 179/1eA

Charpy notched impact strength @ -30C 10 kJ/m ISO 179/1eA

Unnotched impact str (Izod) @ 23C 34 kJ/m ISO 180/1U

Notched impact strength (Izod) @ 23C 10 kJ/m ISO 180/1A

Notched impact strength (Izod) @-30C 10 kJ/m ISO 180/1A

Rockwell hardness 100 M-Scale ISO 2039-2

Thermal properties Value Unit Test Standard

Melting temperature (10C/min) 280 C ISO 11357-1,-2,-3

Glass transition temperature (10C/min) 90 C ISO 11357-1,-2,-3

DTUL @ 1.8 MPa 270 C ISO 75-1/-2

DTUL @ 8.0 MPa 215 C ISO 75-1/-2

Coeff.of linear therm. expansion (parallel) 0.26 E-4/C ISO 11359-2

Coeff.of linear therm. expansion (normal) 0.62 E-4/C ISO 11359-2

Limiting oxygen index (LOI) 47 % ISO 4589

Flammability @1.6mm nom. thickn. V-0 class UL94

thickness tested (1.6) 1.5 mm UL94

Flammability at thickness h V-0 class UL94

thickness tested (h) 0.38 mm UL94

Flammability 5V at thickness h 5VA class UL94

thickness tested (5V) 3 mm UL94

Electrical properties Value Unit Test Standard

Relative permittivity - 10kHz 4 - IEC 60250

Relative permittivity - 1 MHz 4.6 - IEC 60250

Dissipation factor - 10kHz 2 E-4 IEC 60250

Dissipation factor - 1 MHz 62 E-4 IEC 60250

Printed: 15. January 2007 Page: 1

Ticona - A business of Celanese

FORTRON 1140L4 | PPS | Glass Reinforced

Electrical properties Value Unit Test Standard

Volume resistivity >1E13 Ohm*m IEC 60093

Surface resistivity >1E15 Ohm IEC 60093

Electric strength 28 kV/mm IEC 60243-1

Comparative tracking index CTI 125 - IEC 60112

Test specimen production Value Unit Test Standard

Injection molding melt temperature 310 - 340 C ISO 294

Injection molding mold temperature 135 - 160 C ISO 294

Rheological Calculation properties Value Unit Test Standard

Specific heat capacity of melt 1500 J/(kg K) Internal

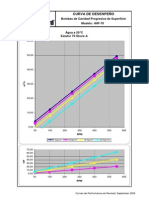

Dynamic Shear modulus-temperature Stress-strain

Printed: 15. January 2007 Page: 2

Ticona - A business of Celanese

FORTRON 1140L4 | PPS | Glass Reinforced

Secant modulus-strain Stress-strain (isochronous)

Creep modulus-time Stress-strain (isochronous)

Printed: 15. January 2007 Page: 3

Ticona - A business of Celanese

FORTRON 1140L4 | PPS | Glass Reinforced

Creep modulus-time Stress-strain (isochronous)

Creep modulus-time Stress-strain (isochronous)

Printed: 15. January 2007 Page: 4

Ticona - A business of Celanese

FORTRON 1140L4 | PPS | Glass Reinforced

Creep modulus-time

Typical injection moulding processing conditions

Maximum residual moisture content: 0.0200%

Processing Temperatures:

Cavity Melt Hot Runner Die 4 3 2 1 Feeding Hopper

min (C) 140 330 330 310 330 330 310 290 60 20

max (C) 160 340 340 330 340 340 320 300 80 30

Processing Pressures:

Injection Pressure Holding Pressure Back Pressure

min (bar) 500 300 0

max (bar) 1000 700 30

Injection speed: fast

Screw speed:

Printed: 15. January 2007 Page: 5

Ticona - A business of Celanese

FORTRON 1140L4 | PPS | Glass Reinforced

Screw diameter (mm) 25 40 55

Screw speed (rpm) 120 75 50

Pre-drying conditions:

FORTRON should in principle be predried. Because of the necessary low maximum residual moisture content the use of dry

air dryers is recommended. The dew point should be =< - 30 C. The time between drying and processing should be as short

as possible.

For subsequent storage the material should be stored dry in the dryer until processed (<= 60 h).

Drying time: 3 - 4 h

Drying temperature: 130 - 140 C

Special information:

No special information available.

Injection Molding

On injection molding machines with 15-25 D long three-section screws, are usual in the trade, the unreinforced FORTRON is

processable. A shut-off nozzle is preferred to a free-flow nozzle.

Melt temperature 320-340 degC

Mold wall temperature at least 140 degC

A medium injection rate is normally preferred. All mold cavities must be effectively vented.

Contact Information

Americas Europe

Ticona Ticona GmbH

Product Information Service Information Service

8040 Dixie Highway Tel.: +49 (0) 180-5842662 (Germany)*

Florence, KY 41042 +49 (0) 69-30516299 (Europe)

USA Fax: +49 (0) 180-2021202 (Germany & Europe)**

Tel.: +1-800-833-4882 email: infoservice@ticona.de

Tel.: +1-859-372-3244 Internet: www.ticona.com

email: prodinfo@ticona.com

Ticona on the web: www.ticona.com *starting 01.01.2007 0,14/minute + local landline rates

**0,06/Call + local landline rates

Customer Service

Tel.: +1-800-526-4960

Tel.: +1-859-372-3214

Fax: +1-859-372-3125

Printed: 15. January 2007 Page: 6

Ticona - A business of Celanese

FORTRON 1140L4 | PPS | Glass Reinforced

General Disclaimer

NOTICE TO USERS: Values shown are based on testing of laboratory test specimens and represent data that fall within the standard range

of properties for natural material. These values alone do not represent a sufficient basis for any part design and are not intended for use in

establishing maximum, minimum, or ranges of values for specification purposes. Colorants or other additives may cause significant variations

in data values.

Properties of molded parts can be influenced by a wide variety of factors including, but not limited to, material selection, additives, part

design, processing conditions and environmental exposure. Any determination of the suitability of a particular material and part design for any

use contemplated by the users and the manner of such use is the sole responsibility of the users, who must assure themselves that the

material as subsequently processed meets the needs of their particular product or use.

To the best of our knowledge, the information contained in this publication is accurate; however, we do not assume any liability whatsoever for

the accuracy and completeness of such information. The information contained in this publication should not be construed as a promise or

guarantee of specific properties of our products. It is the sole responsibility of the users to investigate whether any existing patents are

infringed by the use of the materials mentioned in this publication.

Moreover, there is a need to reduce human exposure to many materials to the lowest practical limits in view of possible adverse effects. To

the extent that any hazards may have been mentioned in this publication, we neither suggest nor guarantee that such hazards are the only

ones that exist. We recommend that persons intending to rely on any recommendation or to use any equipment, processing technique or

material mentioned in this publication should satisfy themselves that they can meet all applicable safety and health standards.

We strongly recommend that users seek and adhere to the manufacturers current instructions for handling each material they use, and

entrust the handling of such material to adequately trained personnel only. Please call the telephone numbers listed (+49 (0) 69 30516299 for

Europe and +1 859-372-3244 for the Americas) for additional technical information. Call Customer Services for the appropriate Materials

Safety Data Sheets (MSDS) before attempting to process our products.

The products mentioned herein are not intended for use in medical or dental implants.

Copyright 2007, Ticona, all rights reserved. (Pub. 02-Jan-2007)

Printed: 15. January 2007 Page: 7

Ticona - A business of Celanese

Potrebbero piacerti anche

- Cadenas RR-C-271F PDFDocumento45 pagineCadenas RR-C-271F PDFAdam GordonNessuna valutazione finora

- Din 580Documento1 paginaDin 580safaozhanNessuna valutazione finora

- Steam Calculators - Steam Turbine Calculator2Documento2 pagineSteam Calculators - Steam Turbine Calculator2Adam GordonNessuna valutazione finora

- Gems LS1900 PN35676 FLOTANTEDocumento1 paginaGems LS1900 PN35676 FLOTANTEAdam GordonNessuna valutazione finora

- Polymer LectureDocumento12 paginePolymer LectureAdam GordonNessuna valutazione finora

- Standard For Wood Containers 2012Documento51 pagineStandard For Wood Containers 2012Cristina Garcia100% (1)

- Ansi Icwm 2012Documento65 pagineAnsi Icwm 2012Adam GordonNessuna valutazione finora

- Sae J1397-1992 PDFDocumento11 pagineSae J1397-1992 PDFAdam GordonNessuna valutazione finora

- Ansi C3752Documento17 pagineAnsi C3752Adam GordonNessuna valutazione finora

- Tabale de ParafusoDocumento54 pagineTabale de ParafusoSilas MendesNessuna valutazione finora

- IDENTIFYING CAP SCREW GRADESDocumento2 pagineIDENTIFYING CAP SCREW GRADESAdam GordonNessuna valutazione finora

- Steel PipesDocumento16 pagineSteel PipesAdam GordonNessuna valutazione finora

- ONE-WAY CLUTCH BEARINGS—CSK SeriesDocumento3 pagineONE-WAY CLUTCH BEARINGS—CSK SeriesAdam GordonNessuna valutazione finora

- Cadenas RR-C-271F PDFDocumento45 pagineCadenas RR-C-271F PDFAdam GordonNessuna valutazione finora

- Dimensiones y Acotaciones PDFDocumento34 pagineDimensiones y Acotaciones PDFAdam GordonNessuna valutazione finora

- Industrial rivets according to DIN standardsDocumento10 pagineIndustrial rivets according to DIN standards'Verness'NotoBudyoNessuna valutazione finora

- Chtmultiregionfoam4regiontutorial 140818030511 Phpapp01Documento24 pagineChtmultiregionfoam4regiontutorial 140818030511 Phpapp01Adam GordonNessuna valutazione finora

- Sae j429 Vs Astm A354 BDDocumento2 pagineSae j429 Vs Astm A354 BDAdam GordonNessuna valutazione finora

- Parker O-Ring Handbook: Approximate Service Temperature Ranges For Commonly Used Basic Polymer TypesDocumento53 pagineParker O-Ring Handbook: Approximate Service Temperature Ranges For Commonly Used Basic Polymer Typesvadim.isheevNessuna valutazione finora

- CFD with OpenSource softwareDocumento31 pagineCFD with OpenSource softwareAdam GordonNessuna valutazione finora

- Naca Report 1368Documento86 pagineNaca Report 1368Adam GordonNessuna valutazione finora

- SW11Documento6 pagineSW11Adam GordonNessuna valutazione finora

- CSK..P, CSK..PP CSK..P-2RS: Combined Bearing/FreewheelDocumento2 pagineCSK..P, CSK..PP CSK..P-2RS: Combined Bearing/FreewheelAdam GordonNessuna valutazione finora

- API - 6D - Plant 3 - 2015Documento1 paginaAPI - 6D - Plant 3 - 2015Adam GordonNessuna valutazione finora

- Curva 4HF 70LDocumento1 paginaCurva 4HF 70LAdam GordonNessuna valutazione finora

- GlossaryDocumento17 pagineGlossaryPRASAD326100% (1)

- Norris Maximum Torque Values For PCP ApplicationsDocumento2 pagineNorris Maximum Torque Values For PCP ApplicationsJorgeArraizNessuna valutazione finora

- Reedswitch HYR-2003Documento2 pagineReedswitch HYR-2003Adam GordonNessuna valutazione finora

- Contracción ElastomerosDocumento2 pagineContracción ElastomerosAdam GordonNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Excel Data AnalysisDocumento30 pagineExcel Data AnalysisРоман УдовичкоNessuna valutazione finora

- Seminar - Review 2 FinalDocumento12 pagineSeminar - Review 2 FinalBhaskaruni Sai TarunNessuna valutazione finora

- Stage TwoDocumento34 pagineStage TwoThar LattNessuna valutazione finora

- Proposed - TIA - 1392 - NFPA - 221Documento2 pagineProposed - TIA - 1392 - NFPA - 221Junior TorrejónNessuna valutazione finora

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Documento24 pagine3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2Nessuna valutazione finora

- Subject and Content NotesDocumento52 pagineSubject and Content NotesJoe Carl CastilloNessuna valutazione finora

- Managerial Performance Evaluation ProceduresDocumento3 pagineManagerial Performance Evaluation Procedures1robcortesNessuna valutazione finora

- Advanced Scan I21no2Documento29 pagineAdvanced Scan I21no2Jaiber SosaNessuna valutazione finora

- CEILING BOARDING GUIDEDocumento5 pagineCEILING BOARDING GUIDEahahNessuna valutazione finora

- 5 Tests of Significance SeemaDocumento8 pagine5 Tests of Significance SeemaFinance dmsrdeNessuna valutazione finora

- Fort St. John - Tender Awards - RCMP Building ConstructionDocumento35 pagineFort St. John - Tender Awards - RCMP Building ConstructionAlaskaHighwayNewsNessuna valutazione finora

- Course-PM SSY135 Wireless Communications 21-22Documento7 pagineCourse-PM SSY135 Wireless Communications 21-22Amirhossein MohsenianNessuna valutazione finora

- ERC12864-12 DemoCode 4wire SPI 2Documento18 pagineERC12864-12 DemoCode 4wire SPI 2DVTNessuna valutazione finora

- TCBE - Conversation Skills TemplateDocumento10 pagineTCBE - Conversation Skills TemplateAryoma GoswamiNessuna valutazione finora

- 3000 Most Common Words in EnglishDocumento85 pagine3000 Most Common Words in Englishapi-575590272100% (1)

- Documentation For UStarDocumento26 pagineDocumentation For UStarthunder77Nessuna valutazione finora

- The Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12Documento313 pagineThe Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12justice hayfordNessuna valutazione finora

- DC CheatsheetDocumento2 pagineDC CheatsheetRashi SinghNessuna valutazione finora

- Movement Joints (NHBC)Documento5 pagineMovement Joints (NHBC)hemendraengNessuna valutazione finora

- Feasibility of Traditional Milk DeliveryDocumento21 pagineFeasibility of Traditional Milk DeliverySumit TomarNessuna valutazione finora

- Sci9 Q4 Mod8.2Documento24 pagineSci9 Q4 Mod8.2John Christian RamosNessuna valutazione finora

- Ethanol: Safety Data SheetDocumento19 pagineEthanol: Safety Data SheetNitika SinhaNessuna valutazione finora

- 6 Main Rotor Config DesignDocumento44 pagine6 Main Rotor Config DesignDeepak Paul TirkeyNessuna valutazione finora

- Catalogue: Product Offering 51Documento56 pagineCatalogue: Product Offering 51Bruno MartinsNessuna valutazione finora

- Pop-Up SystemDocumento4 paginePop-Up Systemkothat82Nessuna valutazione finora

- The Effects of Self-Esteem On Makeup InvolvementDocumento9 pagineThe Effects of Self-Esteem On Makeup InvolvementMichelle Nicole Tagupa SerranoNessuna valutazione finora

- SEW Motor Brake BMGDocumento52 pagineSEW Motor Brake BMGPruthvi ModiNessuna valutazione finora

- Materials Technical Specification.: Stainless SteelDocumento6 pagineMaterials Technical Specification.: Stainless SteelMario TirabassiNessuna valutazione finora

- Packing, Transportation and Marketing of Ornamental FishesDocumento16 paginePacking, Transportation and Marketing of Ornamental Fishesraj kiranNessuna valutazione finora

- Timothy Prehn CV 021209Documento4 pagineTimothy Prehn CV 021209Jason GomezNessuna valutazione finora