Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

23x 30 PDF

Caricato da

reliableplacementTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

23x 30 PDF

Caricato da

reliableplacementCopyright:

Formati disponibili

Mechanical

pressure measurement

Bourdon tube pressure gauge

Stainless steel, safety version

Models 232.30, 233.30

WIKA data sheet PM 02.04

k

Applications

Increased safety requirements

With liquid-filled case for applications with high dynamic

pressure loads or vibrations 1)

For gaseous and liquid aggressive media that are

not highly viscous or crystallising, also in aggressive

ambience

Process industry: Chemical/petro-chemical, power

stations, mining, on- and offshore, environmental techno-

logy, machine building and general plant construction

Special features

Safety pressure gauge with solid baffle wall designed

in compliance with operational safety requirements of

EN837-1

Excellent load-cycle stability and shock resistance

All stainless steel construction

Scale ranges up to 0 1,600 bar Bourdon tube pressure gauge model 232.30

Description Pressure limitation

NS 63: Steady: 3/4 x full scale value

Design Fluctuating: 2/3 x full scale value

EN 837-1 Short time: Full scale value

Nominal size in mm NS 100, 160: Steady: Full scale value

63, 100, 160 Fluctuating: 0.9 x full scale value

Short time: 1.3 x full scale value

Accuracy class

Permissible temperature

NS 63: 1.6

Ambient: -40 ... +60 C without liquid filling

NS 100, 160: 1.0

-20 ... +60 C gauges with glycerine filling 1)

Scale ranges Medium: +200 C maximum without liquid filling

NS 63: 0 ... 1 to 0 ... 1,000 bar +100 C maximum with liquid filling 1)

NS 100: 0 ... 0.6 to 0 ... 1,000 bar

Temperature effect

NS 160: 0 ... 0.6 to 0 ... 1,600 bar

When the temperature of the measuring system deviates

or all other equivalent vacuum or combined pressure and

from the reference temperature (+20 C):

vacuum ranges

max. 0.4 %/10 K of full scale value

Ingress protection

IP 65 per EN 60529 / lEC 529

1) Model 233.30 (gauges with back mount: IP 55)

WIKA data sheet PM 02.04 06/2012 Page 1 of 2

Data sheets showing similar products:

Stainless steel version; model 232.50; see data sheet PM 02.02

High pressure version; model 222.30; see data sheet PM 02.09

For UHP applications, safety pressure gauges; model 232.35; see data sheet PM 02.11

Standard version Options

Process connection Other process connection

Stainless steel 316L (NS 63: 1.4571), Sealings (model 910.17, see data sheet AC 09.08)

lower mount (LM) or lower back mount (LBM) 1) Assembly on diaphragm seals see product review DS

NS 63: G B (male), 14 mm flats Measuring system Monel (model 262.30)

NS 100, 160: G B (male), 22 mm flats (NS 160 only lower Measuring system stainless steel 1.4571

mount) Panel mounting flange, stainl. steel or polished stainl. steel

Surface mounting lugs on the back, stainless steel

Pressure element Ambient temperatures -40 C: Silicone oil filling

Stainless steel 316L Ingress protection IP 66, IP 67

< 100 bar: C-type Pressure gauge with switch contacts, see model

100 bar: Helical type PGS23.1x0, data sheet PV 22.02 or see model

232.30.063, data sheet PV 22.03

Movement Pressure gauge with electrical output signal, see model

Stainless steel PGT23.1x0, data sheet PV 12.04

Version per ATEX Ex II 2 GD c TX

Dial DVGW conformity certificate for building services and

Aluminium, white, black lettering, systems engineering

NS 63 with pointer stop pin

Standard version

Pointer Lower mount (LM)

16 bar with compensating valve

Aluminium, black

1034588.02

> 16 bar without compensating valve

Case

Stainless steel, case with solid baffle wall and blow-out back,

scale ranges 0 ... 16bar (lower mount) with compensating

valve to vent case

Window

Laminated safety glass (NS 63: Polcarbonate)

Bezel ring

Cam ring (bayonet type), stainless steel

Lower back mount (LBM) 1)

Filling liquid (for model 233.30)

1034596.02

Glycerine 99.7 %

1) Connection location back mount only for

gauges NS 63 and 100 without liquid filling

Dimensions in mm

NS Dimensions in mm Weight in kg

a b b1 b2 D1 D2 e f G h 1 SW Model 232.30 Model 233.30

63 17.5 42 42 61 63 63 14.5 18.5 GB 54 14 0.20 0.26

100 25 59.5 59.5 93 101 100 17 30 GB 87 22 0.65 1.08

160 27 2) 65 3) - - 161 159 17.5 - GB 118 22 1.30 2.34

Process connection per EN 837-1 / 7.3 2) With scale ranges 100 bar: 41.5 mm

3) With scale ranges 100 bar: 79 mm

Ordering information

Model / Nominal size / Scale range / Connection size / Connection location / Options

2003 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

Page 2 of 2 WIKA data sheet PM 02.04 06/2012

06/2012 GB

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Strae 30

63911 Klingenberg/Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-mail info@wika.de

www.wika.de

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- NCSC Cyber Security Risk Management ExecutiveDocumento8 pagineNCSC Cyber Security Risk Management ExecutivereliableplacementNessuna valutazione finora

- Exercise 23 - Sulfur OintmentDocumento4 pagineExercise 23 - Sulfur OintmentmaimaiNessuna valutazione finora

- Electrical Estimate Template PDFDocumento1 paginaElectrical Estimate Template PDFMEGAWATT CONTRACTING AND ELECTRICITY COMPANYNessuna valutazione finora

- Chapter Two Complexity AnalysisDocumento40 pagineChapter Two Complexity AnalysisSoressa HassenNessuna valutazione finora

- QIPP-MPN013-M00-2303 Utility Requirements Rev A PDFDocumento18 pagineQIPP-MPN013-M00-2303 Utility Requirements Rev A PDFreliableplacementNessuna valutazione finora

- Capsule Research ProposalDocumento4 pagineCapsule Research ProposalAilyn Ursal80% (5)

- Bill Swad's Wealth Building Strategies - SwadDocumento87 pagineBill Swad's Wealth Building Strategies - Swadjovetzky50% (2)

- Binder 1Documento107 pagineBinder 1Ana Maria Gálvez Velasquez0% (1)

- Field JB's Specification (FF.17001) ORIGNALDocumento2 pagineField JB's Specification (FF.17001) ORIGNALreliableplacementNessuna valutazione finora

- YSLY-JZ DatasheetDocumento6 pagineYSLY-JZ DatasheetreliableplacementNessuna valutazione finora

- Pneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionDocumento4 paginePneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionreliableplacementNessuna valutazione finora

- CalculusDocumento2 pagineCalculusreliableplacement100% (1)

- Mobile Services: Your Account SummaryDocumento10 pagineMobile Services: Your Account SummaryreliableplacementNessuna valutazione finora

- Block 1 PDFDocumento50 pagineBlock 1 PDFreliableplacementNessuna valutazione finora

- Hyderabad Bhopal: DJNGHZ CompleteDocumento4 pagineHyderabad Bhopal: DJNGHZ CompletereliableplacementNessuna valutazione finora

- Management Programme Term-End Examination June, 2019: Ms-004: Accounting and Finance For ManagersDocumento4 pagineManagement Programme Term-End Examination June, 2019: Ms-004: Accounting and Finance For ManagersreliableplacementNessuna valutazione finora

- Good Work by UNDocumento4 pagineGood Work by UNreliableplacementNessuna valutazione finora

- AS ND S: Unit 2 Pects A IS UESDocumento13 pagineAS ND S: Unit 2 Pects A IS UESreliableplacementNessuna valutazione finora

- Unit 1 Basic Concepts: TroductioDocumento12 pagineUnit 1 Basic Concepts: TroductioreliableplacementNessuna valutazione finora

- Data Sheet: W-Series WDU 2.5Documento5 pagineData Sheet: W-Series WDU 2.5reliableplacementNessuna valutazione finora

- Management Programme Term-End Examination: December, 2017 Ms-004: Accounting and Finance For ManagersDocumento3 pagineManagement Programme Term-End Examination: December, 2017 Ms-004: Accounting and Finance For ManagersreliableplacementNessuna valutazione finora

- No Te'::': ': "I :' :: " Jl,'il, I I,, "I",,' J, L,!J'JL C A RR YDocumento6 pagineNo Te'::': ': "I :' :: " Jl,'il, I I,, "I",,' J, L,!J'JL C A RR YreliableplacementNessuna valutazione finora

- Management Programme Term-End Examination December, 2018 Ms-004: Accounting and Finance For ManagersDocumento3 pagineManagement Programme Term-End Examination December, 2018 Ms-004: Accounting and Finance For ManagersreliableplacementNessuna valutazione finora

- AssignmentDocumento2 pagineAssignmentreliableplacementNessuna valutazione finora

- CO Mapping With PODocumento1 paginaCO Mapping With POreliableplacementNessuna valutazione finora

- VRP-B-CH ManualDocumento21 pagineVRP-B-CH ManualreliableplacementNessuna valutazione finora

- LNG Compatibility Document Full PDFDocumento28 pagineLNG Compatibility Document Full PDFreliableplacementNessuna valutazione finora

- Mobile Services: Your Account SummaryDocumento11 pagineMobile Services: Your Account SummaryreliableplacementNessuna valutazione finora

- 09 - Chapters 1-6Documento226 pagine09 - Chapters 1-6reliableplacementNessuna valutazione finora

- Oxygen BarrierDocumento20 pagineOxygen BarrierKarina ArdizziNessuna valutazione finora

- HP Sustainability Impact Report 2018Documento147 pagineHP Sustainability Impact Report 2018Rinaldo loboNessuna valutazione finora

- Fletcher Theophilus Ato CVDocumento7 pagineFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- Admissibility of Whatsapp Messages in Court For Family MattersDocumento3 pagineAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliNessuna valutazione finora

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Documento12 pagineTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewNessuna valutazione finora

- Small Signal Analysis Section 5 6Documento104 pagineSmall Signal Analysis Section 5 6fayazNessuna valutazione finora

- Heat Exchanger Designing Using Aspen PlusDocumento6 pagineHeat Exchanger Designing Using Aspen PlusMeethiPotterNessuna valutazione finora

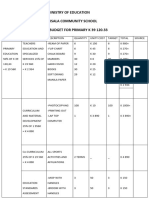

- Ministry of Education Musala SCHDocumento5 pagineMinistry of Education Musala SCHlaonimosesNessuna valutazione finora

- CEA 4.0 2022 - Current Draft AgendaDocumento10 pagineCEA 4.0 2022 - Current Draft AgendaThi TranNessuna valutazione finora

- Projects: Term ProjectDocumento2 pagineProjects: Term ProjectCoursePinNessuna valutazione finora

- Class 11 Accountancy NCERT Textbook Chapter 4 Recording of Transactions-IIDocumento66 pagineClass 11 Accountancy NCERT Textbook Chapter 4 Recording of Transactions-IIPathan KausarNessuna valutazione finora

- Bismillah SpeechDocumento2 pagineBismillah SpeechanggiNessuna valutazione finora

- Science News Explores-June July 2023Documento36 pagineScience News Explores-June July 2023Tobei AchimNessuna valutazione finora

- Lecture 1Documento11 pagineLecture 1Taniah Mahmuda Tinni100% (1)

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocumento3 pagineSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesNessuna valutazione finora

- Unit 5 Andhra Pradesh.Documento18 pagineUnit 5 Andhra Pradesh.Charu ModiNessuna valutazione finora

- ACM2002D (Display 20x2)Documento12 pagineACM2002D (Display 20x2)Marcelo ArtolaNessuna valutazione finora

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDocumento10 pagineA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungNessuna valutazione finora

- PHP IntroductionDocumento113 paginePHP Introductionds0909@gmailNessuna valutazione finora

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocumento2 pagineBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNessuna valutazione finora

- Mpi Model QuestionsDocumento4 pagineMpi Model QuestionshemanthnagNessuna valutazione finora

- Surface CareDocumento18 pagineSurface CareChristi ThomasNessuna valutazione finora

- Historical DocumentsDocumento82 pagineHistorical Documentsmanavjha29Nessuna valutazione finora

- WHO Partograph Study Lancet 1994Documento6 pagineWHO Partograph Study Lancet 1994Dewi PradnyaNessuna valutazione finora