Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Torque-Tension Chart For A307 Gr5 Gr8 Gr9 PDF

Caricato da

Stephanie ScottTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Torque-Tension Chart For A307 Gr5 Gr8 Gr9 PDF

Caricato da

Stephanie ScottCopyright:

Formati disponibili

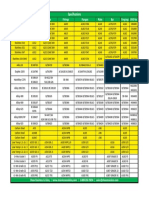

Torque-Tension Relationship for A307A, Grade 5, 8 & 9 Bolts

Tensile

Nominal threads

Stress ASTM A307 Grade A SAE J429 Grade 5 SAE J429 Grade 8 FNL Grade 9

Dia. per

Area Clamp Tightening Torque Clamp Tightening Torque Clamp Tightening Torque Clamp Tightening Torque

inch

Load Load Load Load

(in.) (sq. in.) (Lbs.) K = 0.15 K = 0.17 K = 0.20 (Lbs.) K = 0.15 K = 0.17 K = 0.20 (Lbs.) K = 0.15 K = 0.17 K = 0.20 (Lbs.) K = 0.15 K = 0.17 K = 0.20

Unified Coarse Thread Series

1/4 20 0.0318 859 32 in-lbs 37 in-lbs 43 in-lbs 2029 76 in-lbs 86 in-lbs 101 in-lbs 2864 107 in-lbs 122 in-lbs 143 in-lbs 3357 126 in-lbs 143 in-lbs 168 in-lbs

5/16 18 0.0524 1416 66 75 88 3342 157 178 209 4719 221 251 295 5531 259 294 346

3/8 16 0.0775 2092 10 ft-lbs 11 ft-lbs 13 ft-lbs 4940 23 ft-lbs 26 ft-lbs 31 ft-lbs 6974 33 ft-lbs 37 ft-lbs 44 ft-lbs 8174 38 ft-lbs 43 ft-lbs 51 ft-lbs

7/16 14 0.1063 2870 16 18 21 6777 37 42 49 9568 52 59 70 11214 61 70 82

1/2 13 0.1419 3831 24 27 32 9046 57 64 75 12771 80 90 106 14969 94 106 125

9/16 12 0.1819 4912 35 39 46 11599 82 92 109 16375 115 130 154 19193 135 153 180

5/8 11 0.2260 6102 48 54 64 14408 113 128 150 20340 159 180 212 23840 186 211 248

3/4 10 0.3345 9030 85 96 113 21322 200 227 267 30101 282 320 376 35281 331 375 441

7/8 9 0.4617 12467 136 155 182 29436 322 365 429 41556 455 515 606 48707 533 604 710

1 8 0.6057 16355 204 232 273 38616 483 547 644 54517 681 772 909 63899 799 905 1065

1 1/4 7 0.9691 26166 409 463 545 53786 840 952 1121 87220 1363 1545 1817 102229 1597 1810 2130

1 1/2 6 1.4053 37942 711 806 949 77991 1462 1657 1950 126473 2371 2688 3162 148237 2779 3150 3706

Fine Thread Series

1/4 28 0.0364 982 37 in-lbs 42 in-lbs 49 in-lbs 2319 87 in-lbs 99 in-lbs 116 in-lbs 3274 123 in-lbs 139 in-lbs 164 in-lbs 3837 144 in-lbs 163 in-lbs 192 in-lbs

5/16 24 0.0581 1568 73 83 98 3702 174 197 231 5226 245 278 327 6125 287 325 383

3/8 24 0.0878 2371 11 ft-lbs 13 ft-lbs 15 ft-lbs 5599 26 ft-lbs 30 ft-lbs 35 ft-lbs 7905 37 ft-lbs 42 ft-lbs 49 ft-lbs 9265 43 ft-lbs 49 ft-lbs 58 ft-lbs

7/16 20 0.1187 3205 18 20 23 7568 41 47 55 10684 58 66 78 12523 68 78 91

1/2 20 0.1600 4319 27 31 36 10197 64 72 85 14396 90 102 120 16873 105 120 141

9/16 18 0.2030 5480 39 44 51 12940 91 103 121 18268 128 146 171 21412 151 171 201

5/8 18 0.2560 6911 54 61 72 16317 127 144 170 23036 180 204 240 27000 211 239 281

3/4 16 0.3730 10070 94 107 126 23776 223 253 297 33566 315 357 420 39343 369 418 492

7/8 14 0.5095 13756 150 171 201 32479 355 403 474 45853 502 568 669 53743 588 666 784

1 14 0.6799 18357 229 260 306 43343 542 614 722 61190 765 867 1020 71720 896 1016 1195

1 1/4 12 1.0729 28970 453 513 604 59548 930 1055 1241 96565 1509 1710 2012 113182 1768 2004 2358

1 1/2 12 1.5810 42688 800 907 1067 87747 1645 1865 2194 142292 2668 3024 3557 166778 3127 3544 4169

The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength.

Clamp load calculated as 75% of the proof load when specified by the standard. ASTM A307 utilized 75% of 36,000 PSI.

Torque values for 1/4 and 5/16-in series are in inch-pounds. All other torque values are in foot-pounds.

Torque values calculated from formula T=KDF, where

K = 0.15 for "lubricated" conditions

K = 0.17 for zinc plated and dry conditions; we have also found various forms of customer applied thread lockers to have a similar K value.

K = 0.20 for plain and dry conditions

D = Nominal Diameter

F = Clamp Load

Note: When using Zinc Plated (lubricated with wax) Top Lock Nuts, the K value can vary between 0.12-0.16

Caution: All material included in this chart is advisory only, and its use by anyone is voluntary. In developing this information, Fastenal has made a determined effort to present its contents accurately.

Extreme caution should be used when using a formula for torque/tension relationships. Torque is only an indirect indication of tension. Under/over tightening of fasteners can result in costly equipment

failure or personal injury.

Rev 3-6-09

Potrebbero piacerti anche

- Tips - For - Designers AISC Design Guide VibrationDocumento5 pagineTips - For - Designers AISC Design Guide VibrationRicardo Argentton FicanhaNessuna valutazione finora

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocumento14 pagineMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottNessuna valutazione finora

- Plate RectangularDocumento8 paginePlate RectangularRUBEN BARTOLOME GARCIANessuna valutazione finora

- Torque-Tension Chart For Metric Fasteners PDFDocumento1 paginaTorque-Tension Chart For Metric Fasteners PDFmhd abdouNessuna valutazione finora

- Reinterpreting Vernacular Architecture Through Contemporary.Documento27 pagineReinterpreting Vernacular Architecture Through Contemporary.kansha23010% (1)

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDocumento17 pagineAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarNessuna valutazione finora

- Bored Pile - FS 2.0 PDFDocumento2 pagineBored Pile - FS 2.0 PDFDương TrầnNessuna valutazione finora

- Compress CalculationDocumento106 pagineCompress CalculationKrupal Patel100% (1)

- TR 5075eDocumento324 pagineTR 5075eLeandro Ribeiro100% (1)

- ContentDocumento23 pagineContentajay katrojNessuna valutazione finora

- Boilers and Condensers YuanDocumento77 pagineBoilers and Condensers YuanDaniel SetyadiNessuna valutazione finora

- Experimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersDocumento9 pagineExperimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersKartikAgrawalNessuna valutazione finora

- ACI 445R-99: Reported by Joint ACI-ASCE Committee 445Documento55 pagineACI 445R-99: Reported by Joint ACI-ASCE Committee 445Jimmy Tien TrinhNessuna valutazione finora

- Torque-Tension Relationship For ASTM A193 B7 Bolts and StudsDocumento1 paginaTorque-Tension Relationship For ASTM A193 B7 Bolts and StudsSiva Krishna ChaudharyNessuna valutazione finora

- Yale & Sentry 2010 Closure Catalog - R&MDocumento16 pagineYale & Sentry 2010 Closure Catalog - R&MAlfredo OrellanaNessuna valutazione finora

- 1 - Volumen 1 - Fittings PDFDocumento168 pagine1 - Volumen 1 - Fittings PDFjuan_octoberNessuna valutazione finora

- JIS G3101 SS 400 Steel Plate StandardDocumento6 pagineJIS G3101 SS 400 Steel Plate StandardArun kumarNessuna valutazione finora

- Concepts of Basement Construction MethodsDocumento9 pagineConcepts of Basement Construction Methodssreejit77100% (4)

- Nozzle Load CheckDocumento4 pagineNozzle Load CheckpipestressNessuna valutazione finora

- Cause and Effect Table PDFDocumento3 pagineCause and Effect Table PDFKamal DeshapriyaNessuna valutazione finora

- Internal Pipe Distributor Design ProcedureDocumento5 pagineInternal Pipe Distributor Design Proceduresenthil kumarNessuna valutazione finora

- Excel FFTDocumento5 pagineExcel FFTKunal MasaniaNessuna valutazione finora

- Carbon & Stainless Steel Pipe DimensionsDocumento4 pagineCarbon & Stainless Steel Pipe DimensionsM Zahran KhairyNessuna valutazione finora

- Manhole. API 650-2021Documento3 pagineManhole. API 650-2021jose luisNessuna valutazione finora

- Pipe Thickness & RF Pad Calculations As Per Asme b313Documento3 paginePipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNessuna valutazione finora

- Applied Thermal Engineering: F.J. Gutiérrez OrtizDocumento16 pagineApplied Thermal Engineering: F.J. Gutiérrez OrtizXamir Suarez AlejandroNessuna valutazione finora

- 37 Pecb Whitepaper Iso37001 2016 Anti Bribery Management SystemsDocumento18 pagine37 Pecb Whitepaper Iso37001 2016 Anti Bribery Management SystemsSoe LwinNessuna valutazione finora

- Pressure Vessel Design Software and ChartsDocumento8 paginePressure Vessel Design Software and ChartsniginpNessuna valutazione finora

- Control of Crack WidthsDocumento55 pagineControl of Crack WidthsMahmood Mufti100% (1)

- Control of Crack WidthsDocumento55 pagineControl of Crack WidthsMahmood Mufti100% (1)

- 1.5D Bend Calculation Per B31.1-2018Documento84 pagine1.5D Bend Calculation Per B31.1-2018Amit SharmaNessuna valutazione finora

- Steam 67Documento2 pagineSteam 67jonathan_leal09Nessuna valutazione finora

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocumento8 pagineDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNessuna valutazione finora

- Torque-Tension Relationship For Stainless Steel F593 CW and F837 CWDocumento1 paginaTorque-Tension Relationship For Stainless Steel F593 CW and F837 CWgabriel_127971761Nessuna valutazione finora

- Eqn Reference ASME BPVC r1sDocumento5 pagineEqn Reference ASME BPVC r1sagarcia654127Nessuna valutazione finora

- Design of Weir Plate: X Q X B 2 / T 2Documento3 pagineDesign of Weir Plate: X Q X B 2 / T 2Husin SaputraNessuna valutazione finora

- Coupling UW16.2 KL Ver 1.1Documento4 pagineCoupling UW16.2 KL Ver 1.1gopaltryNessuna valutazione finora

- 300 - F&D Head Design Tool Ver E4.01Documento1 pagina300 - F&D Head Design Tool Ver E4.01Mo ZeroNessuna valutazione finora

- WELDOLET SIZING CHARTDocumento8 pagineWELDOLET SIZING CHARTSubramanian Shanmuga SundaramNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolssierroNessuna valutazione finora

- Arc Welding Filler Metal Selection ChartDocumento7 pagineArc Welding Filler Metal Selection Chartepriyono0% (1)

- Welding Neck Flanges 1Documento3 pagineWelding Neck Flanges 1bikkelbobNessuna valutazione finora

- 6 Series Weld FittingsDocumento10 pagine6 Series Weld FittingsNilesh MistryNessuna valutazione finora

- Introduction to Pressure Vessel Design and AnalysisDocumento122 pagineIntroduction to Pressure Vessel Design and AnalysisAnonymous d23gWCRQNessuna valutazione finora

- B Jack Nos For Cs Ss MaterialDocumento12 pagineB Jack Nos For Cs Ss MaterialfahadfiazNessuna valutazione finora

- Flange calculation as per ASME Section VIIIDocumento9 pagineFlange calculation as per ASME Section VIIIDarshan PanchalNessuna valutazione finora

- Standard SpecificationDocumento1 paginaStandard SpecificationĐạt TrầnNessuna valutazione finora

- ASME B16.5 Flange Material GuideDocumento5 pagineASME B16.5 Flange Material GuideAndrei Ionut UtaNessuna valutazione finora

- Calculating Stud Bolt length formulaDocumento2 pagineCalculating Stud Bolt length formulanirga100% (1)

- Stillwell Pipe ArrangementDocumento1 paginaStillwell Pipe ArrangementVishalDhiman100% (1)

- PB TW10 GBDocumento6 paginePB TW10 GBfebri_bontangNessuna valutazione finora

- Calculator - U Tubes - HSA & QtyDocumento4 pagineCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Calculation of Closing Time of PumpsDocumento1 paginaCalculation of Closing Time of PumpsTsouki TsoukiNessuna valutazione finora

- Sockolet, Threadolet Weight Chart (Unit in KG)Documento1 paginaSockolet, Threadolet Weight Chart (Unit in KG)gobiNessuna valutazione finora

- Air Valve BrochureDocumento27 pagineAir Valve Brochuredamith030Nessuna valutazione finora

- Design Considerations For Compact Heat ExchangersDocumento16 pagineDesign Considerations For Compact Heat ExchangersHaunted HunterNessuna valutazione finora

- Toriconical Head Ver 1.1Documento4 pagineToriconical Head Ver 1.1Iqbal AhmadsNessuna valutazione finora

- Stainless Steel Hex & Socket Head Screw Torque GuideDocumento1 paginaStainless Steel Hex & Socket Head Screw Torque GuideOrlando RNNessuna valutazione finora

- Torque-Tension Chart For Toplock NutDocumento1 paginaTorque-Tension Chart For Toplock NutIan FletcherNessuna valutazione finora

- Torque-Tension Relationship For ASTM A193/A193M B7 and B16 & A320/A320M L7 Bolts and Studs Clamp Load Specified As 75% of YieldDocumento1 paginaTorque-Tension Relationship For ASTM A193/A193M B7 and B16 & A320/A320M L7 Bolts and Studs Clamp Load Specified As 75% of Yielduli hasibuanNessuna valutazione finora

- RR Global Power Cable Price ListDocumento4 pagineRR Global Power Cable Price ListHemil PatelNessuna valutazione finora

- RR KABEL Price List - LT HT Cables - 01st February 2023Documento4 pagineRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNessuna valutazione finora

- Standard Steel Bolt Torque SpecificationsDocumento13 pagineStandard Steel Bolt Torque SpecificationsYvan Nuñez EscobedoNessuna valutazione finora

- Torque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsDocumento1 paginaTorque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsMarcos Chavarria ChNessuna valutazione finora

- Ropes For Material TransportationDocumento6 pagineRopes For Material TransportationJuanc Contreras FNessuna valutazione finora

- Comparision of Fabric Spreading TimeDocumento25 pagineComparision of Fabric Spreading TimeZaheer AhmadNessuna valutazione finora

- Torque Calculation of Various Grade BoltsDocumento2 pagineTorque Calculation of Various Grade BoltsMeng PamplonaNessuna valutazione finora

- Torque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsDocumento1 paginaTorque-Tension Relationship For ASTM A574 Socket Head Cap ScrewsRodrigo GutierrezNessuna valutazione finora

- Momente Strangere Suruburi Americane - ASTM A574Documento1 paginaMomente Strangere Suruburi Americane - ASTM A574tracam500Nessuna valutazione finora

- VF730 & VF733 - AGA ApprovedDocumento8 pagineVF730 & VF733 - AGA ApprovedJamyansuren TseveendorjNessuna valutazione finora

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Documento7 pagineKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNessuna valutazione finora

- 1.11.4.4 PHGTP08 AFC (As Built) - TP-408 PDFDocumento1 pagina1.11.4.4 PHGTP08 AFC (As Built) - TP-408 PDFStephanie ScottNessuna valutazione finora

- fb268 vt-1Documento7 paginefb268 vt-1Stephanie ScottNessuna valutazione finora

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Documento6 pagineRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadNessuna valutazione finora

- 1 s2.0 S1877705815045555 MainDocumento10 pagine1 s2.0 S1877705815045555 MainStephanie ScottNessuna valutazione finora

- Steel overhead ground and guy wires under 40 charsDocumento1 paginaSteel overhead ground and guy wires under 40 charsStephanie ScottNessuna valutazione finora

- Amortiguador Viscoso PDFDocumento3 pagineAmortiguador Viscoso PDFAdsa ScqNessuna valutazione finora

- Yield CriteriaDocumento23 pagineYield CriteriaJuan MNessuna valutazione finora

- TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocumento1 paginaTECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterOM PRAKASH PALNessuna valutazione finora

- Steel Overhead Ground Wire and Steel Guy Wire: Overhead Conductors Electric UtilityDocumento1 paginaSteel Overhead Ground Wire and Steel Guy Wire: Overhead Conductors Electric UtilityStephanie ScottNessuna valutazione finora

- Torque-Tension Chart For A307 Gr5 Gr8 Gr9 PDFDocumento1 paginaTorque-Tension Chart For A307 Gr5 Gr8 Gr9 PDFStephanie ScottNessuna valutazione finora

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDocumento1 paginaAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNessuna valutazione finora

- Steel GradesDocumento8 pagineSteel GradesBarranqueraBrotoNessuna valutazione finora

- Aisc 34Documento3 pagineAisc 34Stephanie ScottNessuna valutazione finora

- General Connections in Steel BuildingsDocumento17 pagineGeneral Connections in Steel BuildingsStephanie ScottNessuna valutazione finora

- 13wcee 757Documento15 pagine13wcee 757Stephanie ScottNessuna valutazione finora

- ACI 421.1R-99: Reported by Joint ACI-ASCE Committee 421Documento15 pagineACI 421.1R-99: Reported by Joint ACI-ASCE Committee 421Fred PrzNessuna valutazione finora

- E TN SFD Ubc97 Asd 001Documento5 pagineE TN SFD Ubc97 Asd 001Vivek GosaviNessuna valutazione finora

- 13wcee 757Documento15 pagine13wcee 757Stephanie ScottNessuna valutazione finora

- AISC Bolt ConnectionDocumento76 pagineAISC Bolt ConnectionStephanie ScottNessuna valutazione finora

- AISC Bolt ConnectionDocumento76 pagineAISC Bolt ConnectionStephanie ScottNessuna valutazione finora

- A 923 ComparisonDocumento20 pagineA 923 ComparisonStephanie ScottNessuna valutazione finora

- RFP Construction Management ServicesDocumento8 pagineRFP Construction Management ServicesyvonneNessuna valutazione finora

- Imw 50 Single Con CabinaDocumento1 paginaImw 50 Single Con CabinaIgnacio LopezNessuna valutazione finora

- Cover LettersDocumento4 pagineCover LettersAli QuadriNessuna valutazione finora

- Ansi Asme b16.5 Class 150 Forged Flanges VJVMCHDocumento1 paginaAnsi Asme b16.5 Class 150 Forged Flanges VJVMCHZachary HuffmanNessuna valutazione finora

- GEZE Installation Instructions en 742566Documento120 pagineGEZE Installation Instructions en 742566PiotrNessuna valutazione finora

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-15-17Documento3 pagineASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-15-17Andres SilveyraNessuna valutazione finora

- Design specifications for NSCP 7th editionDocumento44 pagineDesign specifications for NSCP 7th editionJames HermoNessuna valutazione finora

- Gift City Cable Bridge (16052014) RevisedDocumento6 pagineGift City Cable Bridge (16052014) RevisedSwapnil KamerkarNessuna valutazione finora

- Tubulacao Dimensioes Globais Valvulas e ConexoesDocumento3 pagineTubulacao Dimensioes Globais Valvulas e ConexoesDouglas Fernandes Dos SantosNessuna valutazione finora

- Hoja de Cálculo en Threaded Coupling - EDITABLEDocumento2 pagineHoja de Cálculo en Threaded Coupling - EDITABLETIPAZONessuna valutazione finora

- Charter Group 3 PDFDocumento5 pagineCharter Group 3 PDFURVASH BURADNessuna valutazione finora

- Mechanical and Durability Properties of Lc3Documento7 pagineMechanical and Durability Properties of Lc3Wasiq AkramNessuna valutazione finora

- Áfico de Correlación Del Martillo Schmidt Miller 1965 PDFDocumento1 paginaÁfico de Correlación Del Martillo Schmidt Miller 1965 PDFalexanderNessuna valutazione finora

- The Ultimate Guide To Waterproofing SolutionsDocumento9 pagineThe Ultimate Guide To Waterproofing SolutionsNippon Paint Total Coating and Construction SolutionsNessuna valutazione finora

- Analysis of Tension MembersDocumento7 pagineAnalysis of Tension MembersAekJayNessuna valutazione finora

- Bill of Quantities: 1 Provisional SumDocumento3 pagineBill of Quantities: 1 Provisional Sumnitish JhaNessuna valutazione finora

- Ortal Installation Manual - Built-In ModelsDocumento86 pagineOrtal Installation Manual - Built-In Modelss111_sunilNessuna valutazione finora

- CARBON STEEL PIPES AND FITTINGS PRICE LISTDocumento4 pagineCARBON STEEL PIPES AND FITTINGS PRICE LISTIlham KelanaNessuna valutazione finora

- AC Plastiques 1,2,3 - General Catalog PDFDocumento5 pagineAC Plastiques 1,2,3 - General Catalog PDFRicardo BustamanteNessuna valutazione finora

- TunnellingDocumento37 pagineTunnellingrockyminNessuna valutazione finora

- Engineering Instructions - FTTH House WiringDocumento18 pagineEngineering Instructions - FTTH House WiringReena SharmaNessuna valutazione finora

- HVAC Flushing and Cleaning Method StatementDocumento3 pagineHVAC Flushing and Cleaning Method StatementMohmed SaydNessuna valutazione finora

- Gate DesignDocumento2 pagineGate DesignDineshkumar SNessuna valutazione finora

- Warkworth BridgesDocumento2 pagineWarkworth BridgesandreeaNessuna valutazione finora

- A Texas Home Is Designed To Authentically Represent Hacienda StyleDocumento5 pagineA Texas Home Is Designed To Authentically Represent Hacienda StyleJulieta Perez GomezNessuna valutazione finora