Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

316 PDF

Caricato da

Viswanathan SrkDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

316 PDF

Caricato da

Viswanathan SrkCopyright:

Formati disponibili

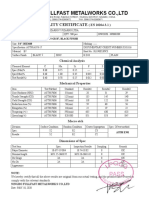

GLORIA MATERIAL TECHNOLOGY CORP.

EVERCUT 316

1. CHEMICAL COMPOSITION:

(wt%)

GRADE C Si Mn P S Ni Cr Mo Cu N Co

EVERCUT

max. max. 1.25 max. 0.023 10.00 16.00 2.00 max. max. max.

316

SPEC. 0.08 1.00 2.00 0.040 0.030 14.00 18.00 3.00 0.50 0.10 0.50

AIMING 0.04 0.20 1.40 max. 0.025 10.00 16.00 2.20 max. 0.05

---

RABGE 0.06 0.80 1.80 0.035 0.030 11.00 17.00 2.80 0.50 0.10

2. Mechanical Properties:

Tensile 0.2%Yield Reduction Brinell

Condition Strength

Elongation Grain Size

Strength of Area Hardness

Solution

ASTM

Heat Ksi N / mm2 Ksi N / mm2 % % HB E112

treated

75 515 30 205 40 50 187

spec. reported

min. min. min. min. min. min. max.

typical

86 590 41 283 51 74 149 NO.6

analysis

3.SPECIFICATION:

1.ASTM A484, A182, A276, A314, A473, A479

2.ASTM A193, Class 1, Grade B8M

3.ASTM A194, Class 1, Grade 8M/8MA

4.ASTM A320, Class 1, Grade B8M

5.ASME SA484

6.ASME SA193, Class 1, Grade B8M

7.ASME SA320, Class 1, Grade B8M

8.ASME SA182

9.ASME SA479

10.AMS 5648, 5648QQ-S-763E, 763F

11.MIL-S-862B

12.NACE MR0175

4.QUALITY CERTIFICATE STATEMEMT:

1.SOLUTION ANNEALING TEMPERATURE AND TIME:1900F4HOUR, WATER COOLED.

2.CORROSION TEST:PASSED PER ASTM A262 PRACTICE A&E.

3.MATERIAL FREE FROM CONTINUOUS CARBIDE NETWORK.

4.MACRO/ MICRO STRUCTURE:GOOD.

5.MATERIAL FREE FROM KNOWN CONTACT WITH MERCURY & RADIUM.

6.MATERIAL FREE FROM WELDS OR WELD REPAIRS.

7.MELTING PROCESS: AOD OR VOD. THEN Ca-Si TREATED.

8.NO PRODUCT THAT CONTAIN OR WERE MADE WITH ODC'S

5.Manufacturing range: 5500

G R O U P

Potrebbero piacerti anche

- Aaepl: TDC No. AAEPL/RM/lDocumento2 pagineAaepl: TDC No. AAEPL/RM/lSandip PandeNessuna valutazione finora

- Page 3 Tsi MTC Plate (MTC - 249)Documento2 paginePage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNessuna valutazione finora

- Coupler Plate RM Pipe TCDocumento1 paginaCoupler Plate RM Pipe TCshindemitesh17Nessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Raj RajeshNessuna valutazione finora

- 21app0808 MTR-14Documento1 pagina21app0808 MTR-14gmendoza.logistica3Nessuna valutazione finora

- Coupler Plate RM Pipe TC 2Documento1 paginaCoupler Plate RM Pipe TC 2shindemitesh17Nessuna valutazione finora

- C86200 Manganese BronzeDocumento1 paginaC86200 Manganese BronzeDeepak KumarNessuna valutazione finora

- Certif Tu inDocumento18 pagineCertif Tu inSri GangaNessuna valutazione finora

- A.S.T.M. B584-09a: WWW - Okendo.mxDocumento4 pagineA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNessuna valutazione finora

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Documento2 pagineNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNessuna valutazione finora

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Documento1 paginaRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNessuna valutazione finora

- Atul 30,36-LoescheDocumento16 pagineAtul 30,36-LoescheSales ITANessuna valutazione finora

- UGINEDocumento1 paginaUGINEjesusNessuna valutazione finora

- 9SMNPB28K-14.00 Hex Tc.Documento1 pagina9SMNPB28K-14.00 Hex Tc.Mechtek LabNessuna valutazione finora

- Garima Global Pvt. LTD.: Material Test CertificateDocumento2 pagineGarima Global Pvt. LTD.: Material Test CertificateGouravNessuna valutazione finora

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocumento2 pagineTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNessuna valutazione finora

- Product Certification Report: Sieve Analysis HardnessDocumento2 pagineProduct Certification Report: Sieve Analysis HardnessFreddy Taipe CruNessuna valutazione finora

- Week No 40,43 GR, 3 Day'sDocumento1 paginaWeek No 40,43 GR, 3 Day'sshinde rushiNessuna valutazione finora

- D72307 TC2 PDFDocumento2 pagineD72307 TC2 PDFshivdas bichukaleNessuna valutazione finora

- 106 QiplDocumento1 pagina106 QiplPRITESHNessuna valutazione finora

- Ab 2501 24 MTCDocumento3 pagineAb 2501 24 MTCVISHNU KKNessuna valutazione finora

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocumento1 paginaWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNessuna valutazione finora

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocumento2 pagineErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNessuna valutazione finora

- Kelston Cast Private Limited: Melting Production ReportDocumento1 paginaKelston Cast Private Limited: Melting Production ReportKELSTON CASTNessuna valutazione finora

- Seamless Tube and Fittings SpecificationDocumento3 pagineSeamless Tube and Fittings Specificationdu lich clipNessuna valutazione finora

- Garima Global Private Limited: Material Test CertificateDocumento2 pagineGarima Global Private Limited: Material Test CertificateRima AroraNessuna valutazione finora

- C89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006Documento1 paginaC89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006박준용Nessuna valutazione finora

- Chemical Composition: ASTM B103Documento1 paginaChemical Composition: ASTM B103MarcoAntonioNessuna valutazione finora

- D 01Documento1 paginaD 01pvdangNessuna valutazione finora

- Type 1 BricksDocumento20 pagineType 1 Bricksprachi410Nessuna valutazione finora

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocumento2 pagineChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNessuna valutazione finora

- Cood Goodweld Corporation: Batch No. CertificatesDocumento2 pagineCood Goodweld Corporation: Batch No. CertificatesmoodydoodyNessuna valutazione finora

- C63020 Nickel Aluminum Bronze - ConcastDocumento3 pagineC63020 Nickel Aluminum Bronze - ConcastBruno FaveroNessuna valutazione finora

- Test CertificateDocumento2 pagineTest CertificatePRITESH100% (1)

- TDC - SAE 8620 - Rev-04Documento2 pagineTDC - SAE 8620 - Rev-04ramanjotgill.ramanNessuna valutazione finora

- 6060 PropertiesDocumento3 pagine6060 Propertiesinterpon07Nessuna valutazione finora

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Documento2 pagineNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNessuna valutazione finora

- TDC 35C8Documento2 pagineTDC 35C8ramanjotgill.ramanNessuna valutazione finora

- Material TCDocumento1 paginaMaterial TCgmbakshiNessuna valutazione finora

- BBRF 12inch H.no. 4439Documento1 paginaBBRF 12inch H.no. 4439suria qaqcNessuna valutazione finora

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocumento7 pagineMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNessuna valutazione finora

- Electrode Booklet F Web 93Documento1 paginaElectrode Booklet F Web 93satnamNessuna valutazione finora

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocumento1 pagina1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNessuna valutazione finora

- Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesDocumento4 pagineMaterial Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesŠâįf ÄhmāđNessuna valutazione finora

- Ribo TC 324 (00000003)Documento1 paginaRibo TC 324 (00000003)Vinay YadavNessuna valutazione finora

- Garima Global Private Limited: Material Test CertificateDocumento2 pagineGarima Global Private Limited: Material Test CertificateRima AroraNessuna valutazione finora

- A105 (VF863)Documento1 paginaA105 (VF863)Suli HartoNessuna valutazione finora

- ESPARRAGO A-193 B7 3l4-10 X 3660Documento1 paginaESPARRAGO A-193 B7 3l4-10 X 3660Incoservspa cl100% (1)

- Wilfley Materials in Common UseDocumento1 paginaWilfley Materials in Common UsesasikumartvsNessuna valutazione finora

- T, RTFF ": Technical DataDocumento1 paginaT, RTFF ": Technical DataNirmit GandhiNessuna valutazione finora

- 4.0X1500. 23920 E250a DoDocumento1 pagina4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Kamal Cement Test CertificateDocumento115 pagineKamal Cement Test CertificateKuldeep ChakerwartiNessuna valutazione finora

- Varilla 1 1 - 4 A193 B7Documento1 paginaVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNessuna valutazione finora

- SMS001R0Documento1 paginaSMS001R0PRASANTH PRASANTHNessuna valutazione finora

- Alloy 6082 - Rev2012Documento2 pagineAlloy 6082 - Rev2012Ysraels Santisteban DurandNessuna valutazione finora

- Chemical Composition: IS: 2062 Specification of Structural Steel For FabricationDocumento2 pagineChemical Composition: IS: 2062 Specification of Structural Steel For FabricationppglNessuna valutazione finora

- 2324MTC037 11362Documento1 pagina2324MTC037 11362Shrikrushna DalviNessuna valutazione finora

- C60 68719 - 25 QtyDocumento1 paginaC60 68719 - 25 QtyMohammad Shanawaz MNessuna valutazione finora

- Inductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesDa EverandInductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesNessuna valutazione finora

- A 240 - A 240M - 04 - Qti0mc0wnaDocumento12 pagineA 240 - A 240M - 04 - Qti0mc0wnaViswanathan SrkNessuna valutazione finora

- Contract Review Rev2 1208Documento19 pagineContract Review Rev2 1208Viswanathan SrkNessuna valutazione finora

- Technical Reference Guide Fastenal K Factor and MoreDocumento62 pagineTechnical Reference Guide Fastenal K Factor and Moredlight0Nessuna valutazione finora

- Tables of International Standards, A ComparisonDocumento22 pagineTables of International Standards, A ComparisonViswanathan SrkNessuna valutazione finora

- 316 PDFDocumento1 pagina316 PDFViswanathan SrkNessuna valutazione finora

- Passivate Stainless Steel PartsDocumento2 paginePassivate Stainless Steel PartsViswanathan SrkNessuna valutazione finora

- SSWWWWDocumento6 pagineSSWWWWViswanathan SrkNessuna valutazione finora

- Araldite Ay103 1hy991 PDFDocumento4 pagineAraldite Ay103 1hy991 PDFViswanathan SrkNessuna valutazione finora

- Araldite Ay 103 1Documento1 paginaAraldite Ay 103 1Viswanathan SrkNessuna valutazione finora

- SW InsightDocumento13 pagineSW InsightViswanathan SrkNessuna valutazione finora

- Araldite Ay103 1hy991 PDFDocumento4 pagineAraldite Ay103 1hy991 PDFViswanathan SrkNessuna valutazione finora

- Ex 3 ADocumento2 pagineEx 3 AViswanathan SrkNessuna valutazione finora

- Araldite Ay103 1hy991 PDFDocumento4 pagineAraldite Ay103 1hy991 PDFViswanathan SrkNessuna valutazione finora

- SW DailyDocumento32 pagineSW DailyViswanathan SrkNessuna valutazione finora

- Ex 4 ADocumento3 pagineEx 4 AViswanathan SrkNessuna valutazione finora

- Wi 2015 12Documento64 pagineWi 2015 12Viswanathan SrkNessuna valutazione finora

- Moneylife 12 November 2015Documento68 pagineMoneylife 12 November 2015Viswanathan SrkNessuna valutazione finora

- Project1 - Diagram1Documento1 paginaProject1 - Diagram1Viswanathan SrkNessuna valutazione finora

- GateDocumento6 pagineGateParveen SwamiNessuna valutazione finora

- Shaper Tool Head AssemblyDocumento6 pagineShaper Tool Head Assemblyjagadeesh01Nessuna valutazione finora

- Ex 4 ADocumento3 pagineEx 4 AViswanathan SrkNessuna valutazione finora

- Ex 3 BDocumento1 paginaEx 3 BViswanathan SrkNessuna valutazione finora

- Ex 4 BDocumento1 paginaEx 4 BViswanathan SrkNessuna valutazione finora

- Antelope 21 December 2015Documento3 pagineAntelope 21 December 2015Viswanathan SrkNessuna valutazione finora

- For The First Time in India, Electrodes Put in Australian Man's Brain To Curb Depression - The Times of IndiaDocumento6 pagineFor The First Time in India, Electrodes Put in Australian Man's Brain To Curb Depression - The Times of IndiaViswanathan SrkNessuna valutazione finora

- Ex 2 ADocumento2 pagineEx 2 AViswanathan SrkNessuna valutazione finora

- Ex 1 BDocumento1 paginaEx 1 BViswanathan SrkNessuna valutazione finora

- Working Mind and The Thinking Mind - Lifestyle Article On SpeakingtreeDocumento3 pagineWorking Mind and The Thinking Mind - Lifestyle Article On SpeakingtreeViswanathan SrkNessuna valutazione finora

- Ex 1 ADocumento2 pagineEx 1 AViswanathan SrkNessuna valutazione finora