Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spur, Helical, Bevel, and Worm Gears

Caricato da

Vinayak RaoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Spur, Helical, Bevel, and Worm Gears

Caricato da

Vinayak RaoCopyright:

Formati disponibili

Whats the difference

CARLOS GONZALEZ | Technology Editor

Whats the Difference

Between Spur, Helical,

Bevel, and Worm Gears?

G

ears are a crucial part of many motors and

machines. Gears help increase torque output

by providing gear reduction and they adjust

the direction of rotation like the shaft to the

rear wheels of automotive vehicles. Here are some basic types

of gears and how they are different from each other.

SPUR GEARS

The most common gears are spur gears and are used in

series for large gear reductions. The teeth on spur gears are

straight and are mounted in parallel on different shafts. Spur

gears are used in washing machines, screwdrivers, windup

alarm clocks, and other devices. These are particularly loud,

due to the gear tooth engaging and colliding. Each impact

makes loud noises and causes vibration, which is why spur

gears are not used in machinery like cars. A normal gear ratio 1. Spur gears are mounted in series on parallel shafts to achieve large

range is 1:1 to 6:1. gear reductions.

HELICAL GEARS

Helical gears operate more smoothly and quietly compared

to spur gears due to the way the teeth interact. The teeth on a

helical gear cut at an angle to the face of the gear. When two of

the teeth start to engage, the contact is gradual--starting at one

end of the tooth and maintaining contact as the gear rotates

into full engagement. The typical range of the helix angle is

about 15 to 30 deg. The thrust load varies directly with the

magnitude of tangent of helix angle. Helical is the most com-

monly used gear in transmissions. They also generate large

amounts of thrust and use bearings to help support the thrust

load. Helical gears can be used to adjust the rotation angle by

90 deg. when mounted on perpendicular shafts. Its normal

gear ratio range is 3:2 to 10:1.

2. Helical gears have a smoother operation due to the angle twist

creating instant contact with the gear teeth.

Whats the Difference

BEVEL GEARS

Bevel gears are used to change the

direction of a shafts rotation. Bevel

gears have teeth that are available

in straight, spiral, or hypoid shape.

Straight teeth have similar characteris-

tics to spur gears and also have a large

impact when engaged. Like spur gears,

the normal gear ratio range for straight

bevel gears is 3:2 to 5:1.

Spiral teeth operate the same as heli-

cal gears. They produce less vibration

and noise when compared to straight

teeth. The right hand of the spiral bevel 3. The image above shows two different configurations for bevel gears: straight and spiral

is the outer half of the tooth, inclined to teeth.

travel in the clockwise direction from

the axial plane. The left hand of the spi-

ral bevel travels in the counterclock-

wise direction. The normal gear ratio

range is 3:2 to 4:1.

Hypoid gears are a type of spiral gear

in which the shape is a revolved hyper-

boloid instead of conical shape. The

hypoid gear places the pinion off-axis

to the ring gear or crown wheel. This

allows the pinion to be larger in diam-

eter and provide more contact area. 5. This engine is using a conjunction of hyp-

The pinion and gear are often always 4. The cross-section of the motor in the oid gears and spiral bevel gears to operate

opposite hand and the spiral angle of image above demonstrates how spiral bev- the motor.

the pinion is usually larger then the el gears are used.

angle of the gear. Hypoid gears are used

in power transmissions due to their

large gear ratios. The normal gear ratio

range is 10:1 to 200:1.

WORM GEARS

Worm gears are used in large gear

reductions. Gear ratio ranges of 5:1 to

300:1 are typical. The setup is designed 6. In the hypoid gear above, the larger gear

so that the worm can turn the gear, but is called the crown while the small gear is

the gear cannot turn the worm. The called the pinion.

angle of the worm is shallow and as a

result the gear is held in place due to

the friction between the two. The gear 7. The model cross-section shows a typical

is found in applications such as convey- placement and use of a worm gear. Worm

or systems in which the locking feature gears have an inherent safety mechanism

can act as a brake or an emergency stop. built-in to its design since they cannot func-

tion in the reverse direction.

Potrebbero piacerti anche

- Aerator PremiumDocumento10 pagineAerator PremiumvijaykumarnNessuna valutazione finora

- Rolling Contact BearingDocumento29 pagineRolling Contact BearingBimlendra RayNessuna valutazione finora

- D3K D4K D5K Competitive SpecComparison-rev01MAY08Documento6 pagineD3K D4K D5K Competitive SpecComparison-rev01MAY08firman manaluNessuna valutazione finora

- OEM Approval GuideDocumento8 pagineOEM Approval GuideEsteban Fernando Meza IbacetaNessuna valutazione finora

- Fluid Coupling Torque Converter PDFDocumento22 pagineFluid Coupling Torque Converter PDFMahmud Saikat100% (1)

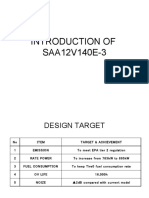

- 05 HD785-7 Engine 12V140-2 Presentation Part1Documento9 pagine05 HD785-7 Engine 12V140-2 Presentation Part1Satria Fajri100% (1)

- List of Gear StandardDocumento7 pagineList of Gear StandardManoj SinghNessuna valutazione finora

- Thermodynamic Analysis of IC Engine: Air-Standard CycleDocumento62 pagineThermodynamic Analysis of IC Engine: Air-Standard CycleTesfa TemesgenNessuna valutazione finora

- PC 3000-6 PDFDocumento8 paginePC 3000-6 PDFDashzeveg BayrsaikhanNessuna valutazione finora

- NTNDocumento39 pagineNTNanthony cordovaNessuna valutazione finora

- Bonfiglioli BrochureDocumento40 pagineBonfiglioli BrochureTauseef EjazNessuna valutazione finora

- N45MNT DS P2g04n004u PDFDocumento4 pagineN45MNT DS P2g04n004u PDFSecret64Nessuna valutazione finora

- Falk Gear Coupling PDFDocumento2 pagineFalk Gear Coupling PDFMaryNessuna valutazione finora

- Non Road Diesel Study CrackDocumento183 pagineNon Road Diesel Study CrackDonatas Pagojus100% (1)

- Why Wind Turbine Gearboxes FailDocumento4 pagineWhy Wind Turbine Gearboxes FailasantonyrajNessuna valutazione finora

- Bearing For Cement Industry - NDocumento20 pagineBearing For Cement Industry - NAjanta Bearing100% (1)

- Spherical Roller Bearing SKF CatlougeDocumento72 pagineSpherical Roller Bearing SKF Catlougemrkadu_61Nessuna valutazione finora

- Engine Crankshaft Deflection MeasurementDocumento9 pagineEngine Crankshaft Deflection MeasurementVannex MensidorNessuna valutazione finora

- Drive Shaft - WikipediaDocumento5 pagineDrive Shaft - WikipediaMohsen SharifNessuna valutazione finora

- Rolling Element BearingDocumento9 pagineRolling Element Bearingstallone21Nessuna valutazione finora

- Hce Vibro Attachments Catalogue en 211122Documento6 pagineHce Vibro Attachments Catalogue en 211122hamdi galipNessuna valutazione finora

- Full Line Guide Digital Only 17-05Documento47 pagineFull Line Guide Digital Only 17-05RIZA BAKIRNessuna valutazione finora

- CASE 400 Series 3 PDFDocumento4 pagineCASE 400 Series 3 PDFDian Sikumbang50% (2)

- Koyo 特殊環境軸承型錄Documento19 pagineKoyo 特殊環境軸承型錄Alan TsaiNessuna valutazione finora

- Lect 5 Reduction of Multiple Subsystems1Documento53 pagineLect 5 Reduction of Multiple Subsystems1SśēmǾǿ ŔämáďañNessuna valutazione finora

- Grid-Lign Fl4011 1209 WebDocumento2 pagineGrid-Lign Fl4011 1209 WebRenzo Jo LaurentNessuna valutazione finora

- Gear Displacement CalculationDocumento0 pagineGear Displacement CalculationRam GadekarNessuna valutazione finora

- Auma GreaseDocumento1 paginaAuma GreaseQuoc HungNessuna valutazione finora

- Potential Sources of Wear Metals in Used Lubricating Oil AnalysisDocumento4 paginePotential Sources of Wear Metals in Used Lubricating Oil Analysismaruf amaludinNessuna valutazione finora

- Gas Engine - MountingDocumento22 pagineGas Engine - MountingMauro DiazNessuna valutazione finora

- Springs CH 10 CompressionDocumento64 pagineSprings CH 10 CompressionMNuubhNessuna valutazione finora

- General Bearing Basics: SKF NotesDocumento37 pagineGeneral Bearing Basics: SKF NotesVinod Varadan SNessuna valutazione finora

- Cummins Engine Company, Inc M-90196 4BT3.9-MDocumento2 pagineCummins Engine Company, Inc M-90196 4BT3.9-Mคุณชายธวัชชัย เจริญสุข100% (1)

- Catalog HydrSeals PDE3350-GB Pgs63-66Documento4 pagineCatalog HydrSeals PDE3350-GB Pgs63-66claudioandrevalverdeNessuna valutazione finora

- Stieber TDocumento96 pagineStieber Tadem özdilNessuna valutazione finora

- 777e Final DriveDocumento3 pagine777e Final DriveDaniel AmanorNessuna valutazione finora

- Rolling BearingDocumento39 pagineRolling BearingashaNessuna valutazione finora

- Vetus Diesel EngineDocumento80 pagineVetus Diesel EnginestartaxisNessuna valutazione finora

- KUBOTA MU5501 4WD Tractor - T-1037-1562-2016Documento9 pagineKUBOTA MU5501 4WD Tractor - T-1037-1562-2016Prashant PatilNessuna valutazione finora

- Modeling in Time DomainDocumento30 pagineModeling in Time Domainfarouq_razzaz2574Nessuna valutazione finora

- POWERTRAINDocumento10 paginePOWERTRAINarpitaNessuna valutazione finora

- 4-Stroke Diesel Engine InternshipDocumento14 pagine4-Stroke Diesel Engine InternshipBairi Rajesh100% (1)

- Hw300 AssembleDocumento111 pagineHw300 AssembleAndreiNessuna valutazione finora

- Twin Screw PumpsDocumento56 pagineTwin Screw PumpsAyman MedaneyNessuna valutazione finora

- 001 Turbo ChargerDocumento26 pagine001 Turbo ChargerfrankNessuna valutazione finora

- Hydroline R5a5 - 2Documento34 pagineHydroline R5a5 - 2HYDRAULICGURUNessuna valutazione finora

- Gear TrainDocumento19 pagineGear TrainGthulasi78Nessuna valutazione finora

- PC 1250 500 HR Service SheetDocumento5 paginePC 1250 500 HR Service SheetJamyansuren TseveendorjNessuna valutazione finora

- SOS Kit PDFDocumento22 pagineSOS Kit PDFHectorDeJesusNessuna valutazione finora

- 06 Undercarriage Tools PDFDocumento108 pagine06 Undercarriage Tools PDFMarco BacianNessuna valutazione finora

- Dana Drive ShaftDocumento32 pagineDana Drive Shaftsskumar79Nessuna valutazione finora

- PC400 400LC-8R PDFDocumento8 paginePC400 400LC-8R PDFAsmar FixNessuna valutazione finora

- Fatigue Failure of A Connecting RodDocumento16 pagineFatigue Failure of A Connecting RodCamilo Rojas GómezNessuna valutazione finora

- Thermal and Efficiency Characterization of A Low-Backlash Planetary GearboxDocumento10 pagineThermal and Efficiency Characterization of A Low-Backlash Planetary Gearboxra maNessuna valutazione finora

- BELAZ 7555 - enDocumento7 pagineBELAZ 7555 - endno256Nessuna valutazione finora

- CAT E1 3094 RipLoad BrochureDocumento6 pagineCAT E1 3094 RipLoad BrochureMOHAMEDNessuna valutazione finora

- Idler Groups: The Widest ChoiceDocumento8 pagineIdler Groups: The Widest ChoiceBaggerkingNessuna valutazione finora

- Arm II - LubricantsDocumento2 pagineArm II - LubricantsCarlos FernandoNessuna valutazione finora

- Spur, Helical, Bevel, and Worm GearsDocumento2 pagineSpur, Helical, Bevel, and Worm GearsFahad KhanNessuna valutazione finora

- Thesis ReportDocumento72 pagineThesis ReportMayur ShetNessuna valutazione finora

- Feral and Stray Cats - An Important Difference: BehaviorDocumento4 pagineFeral and Stray Cats - An Important Difference: BehaviorVinayak RaoNessuna valutazione finora

- An Overview of Caring For Outdoor CatsDocumento27 pagineAn Overview of Caring For Outdoor CatsKye YochamNessuna valutazione finora

- Warehousing and Supply Chain Management PDFDocumento149 pagineWarehousing and Supply Chain Management PDFVinayak RaoNessuna valutazione finora

- Feline Parvovirus (FPV) : Veterinary Guide 5Documento6 pagineFeline Parvovirus (FPV) : Veterinary Guide 5Vinayak RaoNessuna valutazione finora

- WM With SAP ERP PDFDocumento32 pagineWM With SAP ERP PDFSourav Ghosh DastidarNessuna valutazione finora

- Nurturing Kittens and MomDocumento4 pagineNurturing Kittens and MomsuaterguvanNessuna valutazione finora

- Project Synopsis Cover PageDocumento4 pagineProject Synopsis Cover PageVinayak RaoNessuna valutazione finora

- Warehouse Management PDFDocumento22 pagineWarehouse Management PDFJitender BhardwajNessuna valutazione finora

- Fundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFDocumento17 pagineFundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFVinayak RaoNessuna valutazione finora

- Fundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFDocumento17 pagineFundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFVinayak RaoNessuna valutazione finora

- Warehousing and Inventory Management: PoliciesDocumento8 pagineWarehousing and Inventory Management: PoliciesVinayak RaoNessuna valutazione finora

- Account Statement From 1 Aug 2020 To 31 Aug 2020: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocumento1 paginaAccount Statement From 1 Aug 2020 To 31 Aug 2020: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceVinayak RaoNessuna valutazione finora

- JDA Warehouse Management BrochureDocumento12 pagineJDA Warehouse Management BrochureFran LopNessuna valutazione finora

- Fundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFDocumento17 pagineFundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFVinayak RaoNessuna valutazione finora

- Class IV-FinanceDocumento19 pagineClass IV-FinanceVinayak RaoNessuna valutazione finora

- Nurturing Kittens and MomDocumento4 pagineNurturing Kittens and MomsuaterguvanNessuna valutazione finora

- Warehousing and Inventory Management: PoliciesDocumento8 pagineWarehousing and Inventory Management: PoliciesVinayak RaoNessuna valutazione finora

- Warehousing and Supply Chain Management PDFDocumento149 pagineWarehousing and Supply Chain Management PDFVinayak RaoNessuna valutazione finora

- Syllabus - PGD - DS - Batch-7 PDFDocumento12 pagineSyllabus - PGD - DS - Batch-7 PDFVinayak RaoNessuna valutazione finora

- Fundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFDocumento17 pagineFundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFVinayak RaoNessuna valutazione finora

- JDA Warehouse Management BrochureDocumento12 pagineJDA Warehouse Management BrochureFran LopNessuna valutazione finora

- Worksheet Chapter 1Documento28 pagineWorksheet Chapter 1Vinayak RaoNessuna valutazione finora

- An Overview of Caring For Outdoor CatsDocumento27 pagineAn Overview of Caring For Outdoor CatsKye YochamNessuna valutazione finora

- German Credit Data Target - CSVDocumento50 pagineGerman Credit Data Target - CSVVinayak RaoNessuna valutazione finora

- Numbers of ClassifierDocumento49 pagineNumbers of ClassifierDurgesh KumarNessuna valutazione finora

- Langley1987 Article ResearchPapersInMachineLearninDocumento4 pagineLangley1987 Article ResearchPapersInMachineLearninnagarjunaNessuna valutazione finora

- Syllabus - PGD - DS - Batch-7Documento12 pagineSyllabus - PGD - DS - Batch-7Vinayak RaoNessuna valutazione finora

- German Credit Data Target - CSVDocumento50 pagineGerman Credit Data Target - CSVVinayak RaoNessuna valutazione finora

- Paper 5Documento4 paginePaper 5s_sarafNessuna valutazione finora

- Paper 5Documento4 paginePaper 5s_sarafNessuna valutazione finora

- Hamza Akbar: 0308-8616996 House No#531A-5 O/S Dehli Gate MultanDocumento3 pagineHamza Akbar: 0308-8616996 House No#531A-5 O/S Dehli Gate MultanTalalNessuna valutazione finora

- MarimbaDocumento5 pagineMarimbaLeonardo D'AngeloNessuna valutazione finora

- Cooperative LinuxDocumento39 pagineCooperative Linuxrajesh_124Nessuna valutazione finora

- Carpentry NC Ii: Daniel David L. TalaveraDocumento5 pagineCarpentry NC Ii: Daniel David L. TalaveraKhael Angelo Zheus JaclaNessuna valutazione finora

- Zanussi Parts & Accessories - Search Results3 - 91189203300Documento4 pagineZanussi Parts & Accessories - Search Results3 - 91189203300Melissa WilliamsNessuna valutazione finora

- GMDSSDocumento1 paginaGMDSSRahul rajeshNessuna valutazione finora

- Amazon VS WalmartDocumento5 pagineAmazon VS WalmartBrandy M. Twilley100% (1)

- Epson EcoTank ITS Printer L4150 DatasheetDocumento2 pagineEpson EcoTank ITS Printer L4150 DatasheetWebAntics.com Online Shopping StoreNessuna valutazione finora

- Pep 2Documento54 paginePep 2vasubandi8Nessuna valutazione finora

- Competent Testing Requirements As Per Factory ActDocumento3 pagineCompetent Testing Requirements As Per Factory Actamit_lunia100% (1)

- Quiz EditedDocumento6 pagineQuiz EditedAbigail LeronNessuna valutazione finora

- Major Chnage at Tata TeaDocumento36 pagineMajor Chnage at Tata Teasheetaltandon100% (1)

- Imaging Anatomy Brain and Spine Osborn 1 Ed 2020 PDFDocumento3.130 pagineImaging Anatomy Brain and Spine Osborn 1 Ed 2020 PDFthe gaangster100% (1)

- Principles of Volumetric AnalysisDocumento5 paginePrinciples of Volumetric AnalysisMax TennerNessuna valutazione finora

- PresentationDocumento6 paginePresentationVruchali ThakareNessuna valutazione finora

- The Frozen Path To EasthavenDocumento48 pagineThe Frozen Path To EasthavenDarwin Diaz HidalgoNessuna valutazione finora

- 2017 Hu Spence Why Globalization Stalled and How To Restart ItDocumento11 pagine2017 Hu Spence Why Globalization Stalled and How To Restart Itmilan_ig81Nessuna valutazione finora

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDocumento9 pagineTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonNessuna valutazione finora

- 60 Plan of DepopulationDocumento32 pagine60 Plan of DepopulationMorena Eresh100% (1)

- Couvade SyndromeDocumento5 pagineCouvade SyndromejudssalangsangNessuna valutazione finora

- Principles of Inheritance and Variation - DPP 01 (Of Lecture 03) - Lakshya NEET 2024Documento3 paginePrinciples of Inheritance and Variation - DPP 01 (Of Lecture 03) - Lakshya NEET 2024sibasundardutta01Nessuna valutazione finora

- Benson Ivor - The Zionist FactorDocumento234 pagineBenson Ivor - The Zionist Factorblago simeonov100% (1)

- Preparation, Characterization, and Evaluation of Some Ashless Detergent-Dispersant Additives For Lubricating Engine OilDocumento10 paginePreparation, Characterization, and Evaluation of Some Ashless Detergent-Dispersant Additives For Lubricating Engine OilNelson Enrique Bessone MadridNessuna valutazione finora

- PNP Loan Application Form February 2021 16Documento6 paginePNP Loan Application Form February 2021 16Wilhelm RegaladoNessuna valutazione finora

- Lords of ChaosDocumento249 pagineLords of ChaosBill Anderson67% (3)

- Porsche Dealer Application DataDocumento3 paginePorsche Dealer Application DataEdwin UcheNessuna valutazione finora

- Operation Manual-KINGSTONE SDP-ENG-20120205 PDFDocumento49 pagineOperation Manual-KINGSTONE SDP-ENG-20120205 PDFJiménezNessuna valutazione finora

- American University of Beirut PSPA 210: Intro. To Political ThoughtDocumento4 pagineAmerican University of Beirut PSPA 210: Intro. To Political Thoughtcharles murrNessuna valutazione finora

- 2019 Auto Truck Key Blank Reference PDFDocumento188 pagine2019 Auto Truck Key Blank Reference PDFAlbert RodaNessuna valutazione finora

- AlligentDocumento44 pagineAlligentariNessuna valutazione finora

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionDa EverandThe Laws of Thermodynamics: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (51)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDa EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNessuna valutazione finora

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDa EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDa EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNessuna valutazione finora

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDa EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDa EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchValutazione: 4 su 5 stelle4/5 (10)

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyDa EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyValutazione: 5 su 5 stelle5/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesDa EverandWorkbook to Accompany Maintenance & Reliability Best PracticesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDa EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersValutazione: 4 su 5 stelle4/5 (13)

- Handbook of Mechanical and Materials EngineeringDa EverandHandbook of Mechanical and Materials EngineeringValutazione: 5 su 5 stelle5/5 (4)

- Mechanical Vibrations and Condition MonitoringDa EverandMechanical Vibrations and Condition MonitoringValutazione: 5 su 5 stelle5/5 (1)

- Relativity and Geometry: Foundations and Philosophy of Science and Technology SeriesDa EverandRelativity and Geometry: Foundations and Philosophy of Science and Technology SeriesValutazione: 5 su 5 stelle5/5 (1)