Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Executive Shirt

Caricato da

Srikanth Vasantada0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

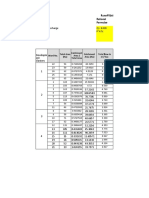

72 visualizzazioni8 pagineThis document summarizes production statistics for a garment factory. It details 15 operations involved in shirt production along with cycle times, workers, production rates, and inventory levels. The bottleneck operation is sewing with a cycle time of 3.9 minutes per shirt. Actual production capacity is 800 shirts with a utilization rate of 83%. Direct labor costs $3.84 per shirt.

Descrizione originale:

Titolo originale

Executive shirt.xlsx

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document summarizes production statistics for a garment factory. It details 15 operations involved in shirt production along with cycle times, workers, production rates, and inventory levels. The bottleneck operation is sewing with a cycle time of 3.9 minutes per shirt. Actual production capacity is 800 shirts with a utilization rate of 83%. Direct labor costs $3.84 per shirt.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

72 visualizzazioni8 pagineExecutive Shirt

Caricato da

Srikanth VasantadaThis document summarizes production statistics for a garment factory. It details 15 operations involved in shirt production along with cycle times, workers, production rates, and inventory levels. The bottleneck operation is sewing with a cycle time of 3.9 minutes per shirt. Actual production capacity is 800 shirts with a utilization rate of 83%. Direct labor costs $3.84 per shirt.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

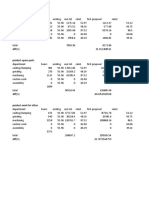

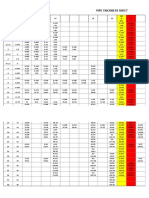

Operation Min/Shirt Workers number shirt/worker Total Shirts Type of opertaion

Cutting 1 4 480.00 1920 Cuttting

1 3.9 8 123.08 985 Sewing

2 2 4 240.00 960 Inspection

3 0.65 2 738.46 1477 Ironing

4 2.5 6 192.00 1152 Packaging

5 1.7 4 282.35 1129 Sum

6 0.66 2 727.27 1455

7 1.65 4 290.91 1164

8 1.55 4 309.68 1239

9 0.65 2 738.46 1477

10 1.8 4 266.67 1067

11 1.55 4 309.68 1239

12 1.7 4 282.35 1129

13 1.5 4 320.00 1280

14 1.95 4 246.15 985

15 1.75 4 274.29 1097

Sum 26.51

Bottle Neck Production = 960 shirts

Bottle neck Cycle Time = 0.5 (min/shirt)

Actual Production capacity= 800 shirts

Actual Cycle Time = 0.6 (min/shirt)

WIP Inventory = 11760 Shirt

Manufacturing Lead time = 7056 min

= 14.7 days

Capacity Utilisation = 83.3333 %

Direct Labor content = 26.51 min

Direct labot utilization = 69.04 %

Direct Labor Cost = 3.84 ($/shirt)

N of wokers No of macines Average WIP(60 Shirts)

4 1 16

48 48 144

4 12

4 4 12

4 12

64 196

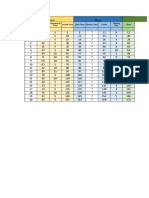

Operation Min/Shirt Workers number shirt/worker Total Shirts

Cutting 1 4 480.00 1920 0.94

Cutting 0.5 1 960.00 960

1 3.9 8 123.08 985

2 2 4 240.00 960

3 0.65 2 738.46 1477

4 2.5 6 192.00 1152

5 1.7 4 282.35 1129

6 0.66 2 727.27 1455

7 1.65 4 290.91 1164

8 1.55 4 309.68 1239

9 0.65 2 738.46 1477

10 1.8 4 266.67 1067

11 1.55 4 309.68 1239

12 1.7 4 282.35 1129

13 1.5 4 320.00 1280

14 1.95 4 246.15 985

15 1.75 4 274.29 1097

Sum 26.01

Bottle Neck Production = 960 shirts

Bottle neck Cycle Time = 0.5 (min/shirt)

Actual Production capacity= 900 shirts

Actual Cycle Time = 0.53 (min/shirt)

WIP Inventory = 1980 Shirt

Manufacturing Lead time = 1056 min

= 2.2 days

Capacity Utilisation = 93.7500 %

Direct Labor content = 26.45 min

Direct labot utilization = 75.03 %

Direct Labor Cost = 3.467 ($/shirt)

Type of opertaion N of wokers No of macines Average WIP(5 Shirts)

Cuttting 5 2 36

Sewing 48 48 288

Inspection 4 24

Ironing 4 4 24

Packaging 4 24

Sum 65 396

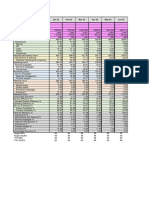

Operation Min/Shirt Workers number shirt/worker Total Shirts

Cutting 1 4 480 1920

1 3.9 7 123 862

2 2 3 240 720

3 0.65 1 738 738

4 2.5 5 192 960

5 1.7 3 282 847

6 0.66 1 727 727

7 1.65 3 291 873

8 1.55 3 310 929

9 0.65 1 738 738

10 1.8 3 267 800

11 1.55 3 310 929

12 1.7 3 282 847

13 1.5 3 320 960

14 1.95 3 246 738

15 1.75 3 274 823

Sum 26.51

Bottle Neck Production = 720 shirts

Bottle neck Cycle Time = 0.667 (min/shirt)

Actual Production capacit = 800 shirts

Actual Cycle Time = 0.675 (min/shirt)

WIP Inventory = 9060 Shirt

Manufacturing Lead time = 6115.5 min

= 12.74 days

Capacity Utilisation = 100.0000 %

Direct Labor content = 26.51 min

Direct labot utilization = 80.15 %

Direct Labor Cost = 3.491 ($/shirt)

Type of opertaion N0 of wokers No of macines Average WIP(5 Shirts)

Cuttting 4 1 16

Sewing 36 36 108

Inspection 3 9

Ironing 3 3 9

Packaging 3 9

Sum 49 151

720 shirts 480 min

800 shirts 533.3333333333 min

OT 54 min

1 hr

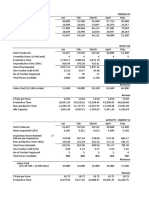

Operation Min/Shirt Workers number shirt/worker Total Shirts

Cutting 0.5 1 960 960

1 3.9 1 123 123 Average 3 Shirts Per Work

2 2 1 240 240 WIP

3 0.65 1 738 738

4 2.5 1 192 192

5 1.7 1 282 282

6 0.66 1 727 727

7 1.65 1 291 291

8 1.55 1 310 310

9 0.65 1 738 738

10 1.8 1 267 267

11 1.55 1 310 310

12 1.7 1 282 282

13 1.5 1 320 320

14 1.95 1 246 246

15 1.75 1 274 274

Sum 26.01

Bottle Neck Production = 123 shirts

Bottle neck Cycle Time = 3.9 (min/shirt)

Actual Production capacity = 100 shirts

Actual neck Cycle Time = 4.800 (min/shirt)

WIP Inventory = 50 Shirt

Manufacturing Lead time = 240 min

= 0.50 days

Capacity Utilisation = 81.3008 %

Direct Labor content = 26.01 min

Direct labot utilization = 33.87 %

Direct Labor Cost = 7.680 ($/shirt)

Average 3 Shirts Per Worker+cutting

50

Potrebbero piacerti anche

- TSR 9047 Monster and Treasure Assortment Sets 1-3 (Level 1-9) (2nd Printing)Documento36 pagineTSR 9047 Monster and Treasure Assortment Sets 1-3 (Level 1-9) (2nd Printing)Peter Bearden100% (12)

- Do's & Don't - Belt ConveyorDocumento3 pagineDo's & Don't - Belt ConveyorHimanshu AgarwalNessuna valutazione finora

- T5U7SDocumento11 pagineT5U7SJ.ROMERO100% (12)

- Zmqov Vogue Usa November 2016Documento259 pagineZmqov Vogue Usa November 2016Zu Carmen Ahumada Adrian100% (1)

- Tiny Critter PatternsDocumento10 pagineTiny Critter Patternsbeebee100% (2)

- Drafting Patterns For WomenDocumento13 pagineDrafting Patterns For Womenzzz2299100% (2)

- Dec 2017 KPI Downtime ReportDocumento90 pagineDec 2017 KPI Downtime ReportsatfasNessuna valutazione finora

- Executive Shirt Company, Inc.: Group No 3 Section BDocumento14 pagineExecutive Shirt Company, Inc.: Group No 3 Section Byuveesp5207Nessuna valutazione finora

- Executive Shirt Company Inc Case StudyDocumento14 pagineExecutive Shirt Company Inc Case StudyPuneet AgarwalNessuna valutazione finora

- Operations ManagementDocumento6 pagineOperations ManagementManmeet KaurNessuna valutazione finora

- Airthread SolutionDocumento30 pagineAirthread SolutionSrikanth VasantadaNessuna valutazione finora

- Executive Shirt Company: Case Study Analysis by Lg-4Documento9 pagineExecutive Shirt Company: Case Study Analysis by Lg-4AD RNessuna valutazione finora

- Chin. 50 A Pilgrims Visit To The Five Terraces MountainsDocumento5 pagineChin. 50 A Pilgrims Visit To The Five Terraces MountainsleishNessuna valutazione finora

- Exec Shirt CompDocumento14 pagineExec Shirt CompAshish AdikeNessuna valutazione finora

- Accounting NotesDocumento22 pagineAccounting NotesSrikanth Vasantada50% (2)

- Depreciation AccountingDocumento5 pagineDepreciation Accountingboiroy0% (1)

- Napkin Folding ManualDocumento116 pagineNapkin Folding Manualsim hamim100% (1)

- 230 Magma Crack Sealer Operator ManualDocumento44 pagine230 Magma Crack Sealer Operator Manualdominicparramore100% (2)

- KizumonogatariDocumento391 pagineKizumonogatarimarcipanmacsekNessuna valutazione finora

- Regular Shirt Labor Content (Processing Time in Minutes/shirt) Number of Workers (M) Minutes/shirt/worker Capacity (M/proce Ssing Time)Documento2 pagineRegular Shirt Labor Content (Processing Time in Minutes/shirt) Number of Workers (M) Minutes/shirt/worker Capacity (M/proce Ssing Time)Rahul MayankNessuna valutazione finora

- Make Collar 3.9 2 0.65 2.5 1.7 0.66 1.65 1.55Documento10 pagineMake Collar 3.9 2 0.65 2.5 1.7 0.66 1.65 1.55Vishal PatyalNessuna valutazione finora

- Executive Shirt CompanyDocumento12 pagineExecutive Shirt CompanymishikaNessuna valutazione finora

- Executive Shirt UDocumento6 pagineExecutive Shirt UJaideep SarkarNessuna valutazione finora

- Session 4 - Executive Shirt CompanyDocumento8 pagineSession 4 - Executive Shirt Companyrahulb88Nessuna valutazione finora

- Executive Shirt Company, Inc.: Group No 3 Section BDocumento14 pagineExecutive Shirt Company, Inc.: Group No 3 Section BNitinNessuna valutazione finora

- Cutting: 1.5 Min For Each Layer (60 Layers) 30 Min To Cut & Remove From TableDocumento4 pagineCutting: 1.5 Min For Each Layer (60 Layers) 30 Min To Cut & Remove From TableNitinNessuna valutazione finora

- Operation Min/Shirt Workers Number Shirt/worker Total ShirtsDocumento10 pagineOperation Min/Shirt Workers Number Shirt/worker Total ShirtsSrikanth VasantadaNessuna valutazione finora

- Executive Shirt .Group 12 and Group 10Documento24 pagineExecutive Shirt .Group 12 and Group 10NitinNessuna valutazione finora

- Executive Shirt Company, Inc.: Group No 3 Section BDocumento14 pagineExecutive Shirt Company, Inc.: Group No 3 Section BAbhishek KumarNessuna valutazione finora

- Executive Shirts CompanyDocumento12 pagineExecutive Shirts CompanymanasNessuna valutazione finora

- Session 5 2023 OM-I Part 1Documento42 pagineSession 5 2023 OM-I Part 1Yogita ChoudharyNessuna valutazione finora

- 21PGDM152 - RACHIT MRINAL - Executive Shirt Co. Inc. AssignmentDocumento8 pagine21PGDM152 - RACHIT MRINAL - Executive Shirt Co. Inc. AssignmentRachit MrinalNessuna valutazione finora

- Kalkulator 272Documento31 pagineKalkulator 272Tony ToNessuna valutazione finora

- WB 13 ProsesDocumento11 pagineWB 13 ProsesRestu DpNessuna valutazione finora

- Answers To Discussion On SimulationDocumento5 pagineAnswers To Discussion On SimulationJusmine Claire PrimeroNessuna valutazione finora

- PRKTKM Kelompok 9Documento65 paginePRKTKM Kelompok 9Sudirman SyuaibNessuna valutazione finora

- Huron AutomotiveDocumento2 pagineHuron Automotivesumit guptaNessuna valutazione finora

- GSM Fabric Thickness Fabric Cover Factor Bending LengthDocumento4 pagineGSM Fabric Thickness Fabric Cover Factor Bending LengthPalashNessuna valutazione finora

- Lösungsteam 12 - Executive Shirt Company, Inc. - 69663Documento4 pagineLösungsteam 12 - Executive Shirt Company, Inc. - 69663Dhruv. ParsanaNessuna valutazione finora

- Lampiran Size Reduction FixDocumento6 pagineLampiran Size Reduction FixHabib Faisal YahyaNessuna valutazione finora

- Fisica FiinalDocumento3 pagineFisica FiinalRonald HurtadoNessuna valutazione finora

- Pipe Thickness ChartDocumento4 paginePipe Thickness Chartred patriotNessuna valutazione finora

- Pipe Thickness ChartDocumento4 paginePipe Thickness ChartAkhil JoseNessuna valutazione finora

- Customer Ran. # Arrival Time Start Time Service Time Finish Start Interarrival Time Waiting TimeDocumento4 pagineCustomer Ran. # Arrival Time Start Time Service Time Finish Start Interarrival Time Waiting TimeAprilleShaneTiedraNessuna valutazione finora

- Shear Box Test ReportDocumento6 pagineShear Box Test Reportnishan_ravin50% (2)

- Pipe Thickness ChartDocumento4 paginePipe Thickness ChartRahadian Dwi PutraNessuna valutazione finora

- 2022 Devland Loss and Waste SummaryDocumento294 pagine2022 Devland Loss and Waste SummaryMuluneh GashawNessuna valutazione finora

- Comparision of Fabric Spreading TimeDocumento25 pagineComparision of Fabric Spreading TimeZaheer AhmadNessuna valutazione finora

- ( ) (9.9) 76.98 Diámetro InicialDocumento2 pagine( ) (9.9) 76.98 Diámetro InicialJose SullcaNessuna valutazione finora

- Cipla P&L ExcelDocumento9 pagineCipla P&L ExcelNeha LalNessuna valutazione finora

- Aditya Surya Pratama 36B - Tugas StatistikDocumento22 pagineAditya Surya Pratama 36B - Tugas Statistikaditya surya pratamaNessuna valutazione finora

- Muh - Sofwwan Tahir EOQDocumento4 pagineMuh - Sofwwan Tahir EOQOwen TahirNessuna valutazione finora

- Betz Limit CalculationDocumento2 pagineBetz Limit CalculationShyam SundarNessuna valutazione finora

- Engineering Data, Summary of Productivity 2022Documento2 pagineEngineering Data, Summary of Productivity 2022Listya AnggrainiNessuna valutazione finora

- Cutting Time StudyDocumento11 pagineCutting Time Studytanya guptaNessuna valutazione finora

- Production BudgetDocumento17 pagineProduction Budgetanon_459698449Nessuna valutazione finora

- Chart Title: Jumlah Defect 0,00125 X Kecepatan Mesin 2Documento9 pagineChart Title: Jumlah Defect 0,00125 X Kecepatan Mesin 2Adrian Fikta NugrahaNessuna valutazione finora

- HmRAP Based Draiange Cost Calculation For Bidhannagar R1Documento12 pagineHmRAP Based Draiange Cost Calculation For Bidhannagar R1Suvranil BanerjeeNessuna valutazione finora

- Indbro - PDF PerformanceDocumento2 pagineIndbro - PDF PerformancevetbcasNessuna valutazione finora

- المصنف1Documento4 pagineالمصنف1yaseenalsidi5Nessuna valutazione finora

- Ejercicios en BiofarmaciaDocumento8 pagineEjercicios en BiofarmaciaAlan Luis CVNessuna valutazione finora

- Cross-Sectional AnalysisDocumento13 pagineCross-Sectional AnalysisSourajit SanyalNessuna valutazione finora

- R5 Plan Armare Grinzi Si CenturiDocumento1 paginaR5 Plan Armare Grinzi Si CenturiSnake666 SnakeNessuna valutazione finora

- 23-AREEB NASIR (Queuing Simulation-OEL)Documento2 pagine23-AREEB NASIR (Queuing Simulation-OEL)Areeb Nasir MughalNessuna valutazione finora

- Taylor Shirts Inc. - Operations ManagementDocumento8 pagineTaylor Shirts Inc. - Operations ManagementGeneNessuna valutazione finora

- Fairy Tales IslandDocumento14 pagineFairy Tales IslandShu RaNessuna valutazione finora

- Plantilla de Calificaciones y Asistencia v2-G1-2020Documento3 paginePlantilla de Calificaciones y Asistencia v2-G1-2020Deimy TorresNessuna valutazione finora

- Tugas StatistikDocumento20 pagineTugas Statistikaditya surya pratamaNessuna valutazione finora

- Waktu Operasional Breaks Breakdown Kerusakan Mesin Setup 630 292 630 630Documento10 pagineWaktu Operasional Breaks Breakdown Kerusakan Mesin Setup 630 292 630 630valdisreinNessuna valutazione finora

- The Following Is The Example Discussed in The Class. The Solution Is The Next Worksheet. The Rationale Is Indicated in The Comments Inserted TherefofDocumento6 pagineThe Following Is The Example Discussed in The Class. The Solution Is The Next Worksheet. The Rationale Is Indicated in The Comments Inserted TherefofSrikanth VasantadaNessuna valutazione finora

- Tire City Case 1Documento28 pagineTire City Case 1Srikanth VasantadaNessuna valutazione finora

- Contant Workforce and Holding CostDocumento6 pagineContant Workforce and Holding CostSrikanth VasantadaNessuna valutazione finora

- Operation Min/Shirt Workers Number Shirt/worker Total ShirtsDocumento10 pagineOperation Min/Shirt Workers Number Shirt/worker Total ShirtsSrikanth VasantadaNessuna valutazione finora

- Assembly LineDocumento20 pagineAssembly LineSrikanth Vasantada0% (1)

- Base Case Case ADocumento4 pagineBase Case Case ASrikanth VasantadaNessuna valutazione finora

- Past Simple or Present PerfectDocumento59 paginePast Simple or Present Perfectmetha arsilitaNessuna valutazione finora

- Height, Body Build and Age When Describing People, We Use The Verb 'To Be' To Describe Height, Body Build and AgeDocumento6 pagineHeight, Body Build and Age When Describing People, We Use The Verb 'To Be' To Describe Height, Body Build and Agesantiago peña100% (1)

- Lace and Twist Stitch "Argyle" PatternDocumento2 pagineLace and Twist Stitch "Argyle" Patternapi-26191651100% (1)

- Anna Sui Corp. v. Forever 21, Inc. Et Al - Document No. 1Documento17 pagineAnna Sui Corp. v. Forever 21, Inc. Et Al - Document No. 1Justia.comNessuna valutazione finora

- Article ExerciseDocumento3 pagineArticle ExerciseSantikaAnggaraKristiNessuna valutazione finora

- Suspect Description FormDocumento2 pagineSuspect Description FormLuis AlmaguerNessuna valutazione finora

- Chosee Answer With Synonims: Listening: Skill 2Documento7 pagineChosee Answer With Synonims: Listening: Skill 2Tasya SalsabilaNessuna valutazione finora

- Idm MoschinoDocumento9 pagineIdm MoschinoDileshaa ParakhNessuna valutazione finora

- TDC001 TENA Direct Catalogue 0721Documento28 pagineTDC001 TENA Direct Catalogue 0721Kidz to Adultz ExhibitionsNessuna valutazione finora

- The Fisherman and His SoulDocumento31 pagineThe Fisherman and His SoulLéo ClerckNessuna valutazione finora

- Transmission 20141Documento116 pagineTransmission 20141Velu Samy100% (1)

- Pe-8 Q4 W7 V4Documento8 paginePe-8 Q4 W7 V4Ericzon SantosNessuna valutazione finora

- Grammar Hand Book ConciseDocumento35 pagineGrammar Hand Book ConciseNayab Khan SherwaniNessuna valutazione finora

- Plasma Cutter Safety: Personal Protective EquipmentDocumento4 paginePlasma Cutter Safety: Personal Protective EquipmentfrancisNessuna valutazione finora

- Dragon'sTail Weasley Wench HPDMDocumento398 pagineDragon'sTail Weasley Wench HPDMSilvers0ulNessuna valutazione finora

- Respuestas Primera ParteDocumento16 pagineRespuestas Primera ParteRobbieFürhMüllerNessuna valutazione finora

- DX DU: Self-Lubricating BearingsDocumento33 pagineDX DU: Self-Lubricating Bearingsguruchims100% (1)

- Domestic 1665 Sewing Machine Instruction ManualDocumento55 pagineDomestic 1665 Sewing Machine Instruction ManualiliiexpugnansNessuna valutazione finora

- Alexandre Dumas - The Memoirs of A PhysicianDocumento304 pagineAlexandre Dumas - The Memoirs of A Physicianpyromoon69Nessuna valutazione finora

- Under The Oak Tree - Season 2Documento236 pagineUnder The Oak Tree - Season 2jeromeebid04Nessuna valutazione finora