Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Robbins 44RH C Low Profile

Caricato da

Sriram NambiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Robbins 44RH C Low Profile

Caricato da

Sriram NambiCopyright:

Formati disponibili

Atlas Copco Raiseboring equipment

Robbins 44RH C

Technical specification

Building on the proven design of our low profile and light

weight raise drills, the Robbins 44RH adds higher torque and

thrust to a small diameter raise drill. The 44RH is a versatile

and high production raise drill, for raise requirements in the

smaller diameter range.

Features

Control system Drive system

The Robbins raise drills apply to the well established and The single hydraulic drive power pack features variable

proven Atlas Copco Rig Control System (RCS) which adds speed and excellent torque limiting control

reliability and user friendliness The drive system consists of a hydraulic motor coupled

The electronic components of the RCS are common and in-line to a gearbox. It features the lowest inertia of all

interchangeable our drives and does not subject the drill string to high stall

The drill rig computer technology improves the drilling torques

accuracy, equipment reliability and serviceability

Integrated diagnostics and event logging system to assist in Derrick

equipment maintenance The entire drive train features a hollow centre, enabling

The system prevents human errors by built in interlocks efficient transmission of any flushing media to clear the

Standard functions include anti-jamming, auto makeup and pilot hole

gradual ramp up of power at the start of pilot drilling and Rigid crosshead columns provide efficient torque reaction

reaming extending the service life of the thrust cylinders

Trolley mounted operator panel with full-colour display The sturdy worktable is available with a manual or a

Power management. If there are limitations on site, this hydraulic wrenching system for fast and reliable pipe

feature monitors the outtake of the machine and limits it to threading

a preset value. The ground loading pipeloader offers safe and efficient pipe

handling

Robbins 44RH C

Specifications

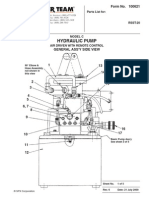

Motor Drive and thrust system

Two hydraulic motors connected in series Power................................................. 160/185 kW at 50/60 Hz

Radial-piston type with a rotating cylinder hollow shaft, Oil reservoir....................................................... 400 l (105 gal)

stationary housing Oil filtration..............................................................10 microns

Hydrostatic system Mineral hydraulic oil grade....................................................68

Build in heater in reservoir

Gearbox Proportional control of fast traverse and pipeloader

movements

Planetary-type reduction Off-line filtration system

Spherical roller thrust bearing for reaming Electric filling pump

Pre-loading of the bearings Water cooled

Individual bearings for reaming and box hole drilling

Traverse circuit:

Drivehead Pressure compensated variable displacement piston pump

Travers pump...................................... 140 cm3/rev (8.5 in3/rev)

Floating drive box with DI-22 thread Travers pump max pressure...........................................230 bar

Lubrication Feed circuit:

Pressure compensated variable displacement piston pump

.Oil from the hydraulic system is used for the lubrication of the Thrust pump........................................ 40 cm3/rev (2.4 in3/rev)

gearbox assembly.............................. 19 l/min (5 US gal./min) Trust pump max pressure...............................................330 bar

Filtration.................................................................... 25 micron

Water cooled Auxiliary circuit:

Fixed displacement gear pump

Pipeloader Auxiliary pump.................................22 cm3/rev (1.34 in3/rev)

Auxiliary pump max pressure........................................230 bar

Easy and safe pipe handling

Sturdy design Drive system:

Mounted on either side Rotation pump........................................................ 355 cm3/rev

Remote controlled Max pump pressure........................................................330 bar

Closed loop piston pump

Wrench system

Both hydraulic systems are monitored by the RCS system,

The Drivehead Wrap-around wrench consists of two splined temperature, pressures, levels and contamination.

wrench halves connected by a pivoting pin and is manually

inserted into the drivehead. The power pack comes with 10m hoses and are prepared for

A hydraulically operated worktable wrench remote controlled external closed loop cooling system.

from the operators control station.

Control system

Electrical system

Radio remote control for pipe loader

Separate cabinet inside the single power pack 15m cable to op-panel

Standard protection ground fault, over/ under voltage Power management

Phase fault and emergency stop Auto makeup log

Thermal overload protection for electrical motors Net force control

Bailing pressure supervision

Anti condensation heaters in electrical cabinet

Built in heaters in the electrical motor

Drive motor started by star/delta

Direct start of thrust motor

Power management. If there are power limits on site, this

feature monitor the power outtake of the machine and limits

it to a preset value

Auxiliary outlet..115 V/230 V

Robbins 44RH C

Measurements and weights

DERRICK 44RH C LOW PROFILE POWER PACK

Height extended 3 540 mm 139 3 250 mm 128 Length 3 300 mm 130

Height retracted 3 540 mm 139 3 250 mm 128 Height 1 690 mm 67

Width 1 780 mm 70 1 600 mm 63 Width 1 600 mm 63

Width pipeloader included 3 120 mm 123 2 600 mm 102 Weight 4 700 kg 10 362 lb

Depth 1 755 mm 69 1 650 mm 65

Weight 9 900 kg 21 825 lb 7 500 kg 16 535 lb

Weight pipeloader included 10 400 kg 22 928 lb 7 900 kg 17 417 lb

Drill angle (from horizontal) 90-60 90-60

DERRICK

H

POWER PACK

W D L

W

Optional equipment

Derrick Hydraulic system

Manual Worktable insert 15 or 20 meter hoses to Derrick

Semi-automatic Drivehead wrench Build-in heater in oil reservoirs

Extra long turnbuckles for drilling angels below 60 High pressure filtration

degrees Fire suppression system

Control System Closed loop cooling system

The advanced Radio remote control handles the pipe An external air/water cooler connected to the ordinary

loader, fast traverse, auto make up, break out, gear cooling circuit

shifting and the hydraulic worktable wrench.

Measure While Drilling (MWD) Control station

Angle indication gives information on the derrick Platform with chair

angle on two axis in the RCS display

Length sensor for rate of penetration and automatic

shutdown of system at end of pipe. Tools

Reamer drop detection system when using catch rope Makeup and breakout tool

Bailing pump control

20 or 30 meter cable to OP-panel Transporters

RRA, Rig Remote Access

Diesel crawler

Air crawler

Electrical system Sled assembly

Soft starter for the drive pump motor

Electrical standards UL, CSA and AS3000 Operating equipment

20 or 30 meter cable to Derrick

Bit breaker box 9, 11

Starter bushing

Blooie system provides a controlled exit for return

bailing fluid and cuttings during pilot hole drilling

Float valve

Robbins 44RH C

Operation data

DERRICK 44RH C 44RH C LOW PROFILE

Nominal 1.5 m 5 ft 1.5 m 5 ft

Raise diameter

Range 1.0-1.8 m 3.5-6 ft 1.0-1.8 m 3.5-6 ft

Nominal 340 m 1 115 ft 340 m 1 115 ft

Raise length

Copyright 2012, Atlas Copco Rock Drills AB, rebro, Sweden. All product names in this publication are trademarks of Atlas Copco. Any unauthorized use or copying of the contents or any part thereof is prohibited. Illustrations and photos may

Maximum 610 m 2 000 ft 610 m 2 000 ft

show equipment with optional extras. No warranty is made regarding specifications or otherwise. Specifications and equipment are subject to change without notice. Consult your Atlas Copco Customer Center for specific information.

Reaming 75 kNm 55 000 ft-lbs 75 kNm 55 000 ft-lbs

Maximum torque

Break out 96 kNm 70 805 ft-lbs 96 kNm 70 805 ft-lbs

Reaming thrust 2 000 kN 450 000 lbs 2 000 kN 450 000 lbs

Stroke 1 710 mm 67 1 235 mm 49

Pilot 0-60 rpm 0-60 rpm

RPM

Reaming (red. torque) 0-16 rpm (16-25 rpm) 0-16 rpm (16-25 rpm)

Fast traverse rate 5.9 m/min 19.4 ft/min 5.9 m/min 19.4 ft/min

Traverse rate

Feed rate 3 m/min 9.8 ft/min 3 m/min 9.8 ft/min

Air 13 m3min (7bar) 459 ft3/min (100 psi) 13 m3min (7bar) 459 ft3/min (100 psi)

Bailing

Water 450 l/min 119 gallon/min 450 l/min 119 gallon/min

Power supply 165/190 kW (50/60 Hz) 165/190 kW (50/60 Hz)

Electrical Voltage 400-1000 V - 400-1000 V -

Frequency 50-60 Hz - 50-60 Hz -

Power requirement 198/227 kvA (50/60 Hz) 198/227 kvA (50/60 Hz)

Diameter 203 mm 8 203 mm 8

Drill pipe Optional 254 mm 10 254 mm 10

Length s/s 1 219 mm 48 750 mm 30

Diameter 229 mm 9 229 mm 9

Pilot hole

Optional diameter 279 mm 11 279 mm 11

Cooling water at 25C inlet temp. 60 l/min 15.8 gal/min 60 l/min 15.8 gal/min

9851 2963 01a

06/2012

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Is.10137.1982 0 PDFDocumento26 pagineIs.10137.1982 0 PDFSriram NambiNessuna valutazione finora

- ZW310 3.4-4.2 Cum PDFDocumento11 pagineZW310 3.4-4.2 Cum PDFSriram NambiNessuna valutazione finora

- Cifa Shutter PDFDocumento2 pagineCifa Shutter PDFSriram NambiNessuna valutazione finora

- Telebelt ProvisionDocumento30 pagineTelebelt ProvisionSriram NambiNessuna valutazione finora

- BackhoeLoader 4DX PDFDocumento2 pagineBackhoeLoader 4DX PDFSriram Nambi100% (1)

- Side Dump Loader 625e - SDLDocumento2 pagineSide Dump Loader 625e - SDLSriram NambiNessuna valutazione finora

- ProductBrochure A35FFS A40FFS EN 21 20026508-C 2012-08Documento3 pagineProductBrochure A35FFS A40FFS EN 21 20026508-C 2012-08Sriram NambiNessuna valutazione finora

- Robbins 34RH C QRS PDFDocumento4 pagineRobbins 34RH C QRS PDFSriram NambiNessuna valutazione finora

- Box Hole Borer PDFDocumento2 pagineBox Hole Borer PDFnambiiasNessuna valutazione finora

- TM Bro2013 PDFDocumento8 pagineTM Bro2013 PDFSriram NambiNessuna valutazione finora

- S175 Leaflet enDocumento2 pagineS175 Leaflet enSriram Nambi100% (1)

- EJC522Documento9 pagineEJC522Sriram NambiNessuna valutazione finora

- Cubex Peter CorcoranDocumento18 pagineCubex Peter CorcoranSriram Nambi100% (2)

- DSI Underground Systems Catalogue US 01Documento118 pagineDSI Underground Systems Catalogue US 01Sriram NambiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ca510 Atlas CopcoDocumento249 pagineCa510 Atlas CopcoBruno RibeiroNessuna valutazione finora

- Renault Technologie Roumanie: Titu Tehnical CenterDocumento26 pagineRenault Technologie Roumanie: Titu Tehnical CenterBadica DuduNessuna valutazione finora

- Board Exam AE Reviewer Volume IIDocumento84 pagineBoard Exam AE Reviewer Volume IIChristine Joy Allas RapanotNessuna valutazione finora

- P8 WildenDocumento32 pagineP8 WildenWalter LrNessuna valutazione finora

- Government of Pakistan National Vocational and Technical Training CommissionDocumento31 pagineGovernment of Pakistan National Vocational and Technical Training CommissionOxaLic AcidNessuna valutazione finora

- 111211-Deel1 PILARWKYDocumento170 pagine111211-Deel1 PILARWKYDiaz MichaelNessuna valutazione finora

- EGE Operator GuidelinesDocumento25 pagineEGE Operator Guidelineskhanh123ctmNessuna valutazione finora

- Basics of Diesel Power PlantDocumento33 pagineBasics of Diesel Power PlantJKKNessuna valutazione finora

- CV Juan David Sinisterra August 2022Documento7 pagineCV Juan David Sinisterra August 2022Satulan IngenieriaNessuna valutazione finora

- Water FeaturesDocumento3 pagineWater FeaturesAlly GepigaNessuna valutazione finora

- System Practices For Ammonia RefrigerationDocumento27 pagineSystem Practices For Ammonia RefrigerationAnonymous 1XHScfCI100% (1)

- Lanair MX 300 ManualDocumento52 pagineLanair MX 300 ManualjoelamadoNessuna valutazione finora

- HAROS 10 M Cube Per Day PQDocumento5 pagineHAROS 10 M Cube Per Day PQAhmed BadweNessuna valutazione finora

- Catalogo Partes New Holland B110BDocumento1.349 pagineCatalogo Partes New Holland B110Bedhuam89% (18)

- G50S003 3 NCS PDFDocumento173 pagineG50S003 3 NCS PDFChandraranga De SilvaNessuna valutazione finora

- 4 and 6 Submersible Manual 09-13 - WEBDocumento24 pagine4 and 6 Submersible Manual 09-13 - WEBnikosag86Nessuna valutazione finora

- Pumps Vaccum - Bvi: Manual of Installation, Operation and MaintenanceDocumento40 paginePumps Vaccum - Bvi: Manual of Installation, Operation and MaintenanceStaman1988Nessuna valutazione finora

- CH.10 Drawing & DocumentsDocumento97 pagineCH.10 Drawing & DocumentsSUDIPTA MANDALNessuna valutazione finora

- Pump CurvesDocumento8 paginePump CurvesKrishna Chaitanya KalagaNessuna valutazione finora

- Centrifuge Oilseperator ManualDocumento82 pagineCentrifuge Oilseperator Manualmavericksailor100% (3)

- 412 MM CH28 Fuel SystemDocumento208 pagine412 MM CH28 Fuel SystemMuhammad VALA100% (1)

- Eaton Hydraulic Power PackDocumento6 pagineEaton Hydraulic Power PackthomasoburNessuna valutazione finora

- UL Certificate of Compliance DP DQ DR DS DT - Sflb.ashxDocumento3 pagineUL Certificate of Compliance DP DQ DR DS DT - Sflb.ashxEduardo CondeNessuna valutazione finora

- Annezasofia - Asg Chap 3Documento12 pagineAnnezasofia - Asg Chap 3anneza sofiaNessuna valutazione finora

- Vacuum Dewaterimg: New Way For Concrete Flooring by Tremix MethodDocumento7 pagineVacuum Dewaterimg: New Way For Concrete Flooring by Tremix Methodsachinkarape4844Nessuna valutazione finora

- Grundfos CR 3 15 A A A e HqqeDocumento10 pagineGrundfos CR 3 15 A A A e HqqeAan AndianaNessuna valutazione finora

- National Fittings & Accessories Ltd-R1Documento3 pagineNational Fittings & Accessories Ltd-R1npengineering4Nessuna valutazione finora

- RSST 20Documento10 pagineRSST 20Giuliano DeiasNessuna valutazione finora

- Centrifugal Pump - CatalogueDocumento152 pagineCentrifugal Pump - CatalogueKOWSHIK 4310Nessuna valutazione finora