Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lube-Tech: Keep Your Hydraulic System Clean of Varnish or Pay The Consequences

Caricato da

Darmawan PutrantoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lube-Tech: Keep Your Hydraulic System Clean of Varnish or Pay The Consequences

Caricato da

Darmawan PutrantoCopyright:

Formati disponibili

Lube-Tech

PUBLISHED BY LUBE: THE EUROPEAN LUBRICANTS INDUSTRY MAGAZINE

No.57 page 4

Keep Your Hydraulic System Clean of

Varnish or Pay the Consequences

The competitive nature of the hydraulics market has created a stick in the rotor slot. The

trend of increasing power outputs and at the same time smaller consequences are increased

fluid reservoirs. What are the consequences? The operating noise, decreased volumetric and

temperatures of hydraulic fluids used in these systems are signif- mechanical efficiency, increased

icantly higher, leading to greater risks of oxidation and thermal energy consumption, side plate

degradation of the additives in the fluid. Varnish, the result of scuffing, rotary seal damage

that degradation, can result in unplanned downtime, higher and possible bearing damage. Hydraulic system using fluid

maintenance costs and lower profitability. Are there solutions for varnish? containing new varnish-

reducing additive technology.

Electrostatic filtration systems

Over time, varnish build up can increase the friction inside the can remove contaminants, but these systems dont deal with

valves, especially those with fine tolerances such as servo and varnish formation causes, tend to be expensive and can be

proportional types, where this phenomenon can be especially susceptible to water contamination. Another is the commonly

troublesome. Varnish buildup may cause servo valves to stick in accepted practice for end users to routinely change or clean

an open position. The impact of sticking valves on the hydraulic servo valves in hydraulic equipment to keep their systems

system can be impaired responsiveness and reduced oil flow, running. One new valve can cost $3000 US, and the cost to

which results in overall loss of efficiency and increase in clean and refurbish a valve can be about $2000 US. And dont

maintenance costs. forget to add on the labour costs and the lost production costs

of shutting down the equipment.

What is varnish and how does it form? As oil ages, fluid

degradation is caused by oxidation, thermal decomposition and An ideal solution is using a hydraulic fluid that does not deposit

the natural process of additive consumption. Additives - varnish on surfaces. Fluids are now available that incorporate

performance-enhancing chemicals - are consumed over the life additive chemistry that reacts with the precursors of varnish,

of the fluid. Degradation byproducts increase as the oil ages, minimising the formation of tenacious, hard films on system

eventually forming varnish. hardware.

Since varnish is polar, it is attracted to metal surfaces such as Laboratory testing demonstrates the keep-clean feature of fluids

servo valves. Varnish starts as a sticky, soft residue. The sticky using this new technology. In industry-accepted pump tests, fluids

nature of this material allows it to attract wear debris, resulting containing many other additive technologies show varnish formation

in the formation of a sandpaper-like surface. Eventually, the soft, within 500 hours of operation. In the same pump tests, there was

sticky material transitions to a hard lacquer that can be very no evidence of varnish formation on system surfaces after 1,000

difficult to remove. hours of use with fluids containing the new additive technology.

But, how does that varnish harm equipment? Oil that has been Fluids containing the new technology are particularly suited to

oxidised generally doesnt lubricate very well. The result can be hydraulic applications where high temperatures - mobile

reduced oil flow, plugged filters, plugged valves, higher friction, equipment, plastic injection molding machines, glass transfer

poor heat transfer, and elevated operating temperature. Because systems, heavy presses, etc. - can be problematic and

varnish acts as an insulator, cooling capacity can be diminished. compromise the oils life. These fluids also are suitable for

equipment owners who want to extend the life of their oil and

A varnish-laden sump. their equipment, including valves, filters and pumps.

On top of that, varnish

shortens the lives of

equipment components Todays hydraulic fluids are being subjected to increasingly tough

such as valves, filters, operating conditions. Demands to raise production at the same

pumps, bearings and seals. time as oil volume is decreasing emphasize the need for high-

Whats the bottom line? quality hydraulic fluids. The new varnish-reducing additive

Hydraulic equipment chemistry is the perfect partner for hydraulic fluids used in those

performance suffers. harsher operating conditions.

By Rob Profilet, The Lubrizol Corporation

For example, in high-

performance vane pumps,

LINK

varnish adhering to the

www.lubrizol.com

vanes can cause the vane to

26 LUBE MAGAZINE No.84 APRIL 2008

Potrebbero piacerti anche

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDa EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisValutazione: 5 su 5 stelle5/5 (1)

- Waste Management in the Chemical and Petroleum IndustriesDa EverandWaste Management in the Chemical and Petroleum IndustriesNessuna valutazione finora

- Hydraulic Oil & SealsDocumento98 pagineHydraulic Oil & Sealsppritamddaw100% (1)

- Hydac Plastic Injection Molding MachinesDocumento12 pagineHydac Plastic Injection Molding MachinespeterNessuna valutazione finora

- The Most Cutting Fluid ProblemsDocumento5 pagineThe Most Cutting Fluid ProblemsAndriya NarasimhuluNessuna valutazione finora

- Hydraulic FluidsDocumento26 pagineHydraulic FluidsharryNessuna valutazione finora

- Improving Rolling Mill Lube Oil PDFDocumento4 pagineImproving Rolling Mill Lube Oil PDFRaj Kumar SinghNessuna valutazione finora

- Protect Your Machinery and Minimize Down TimeDocumento20 pagineProtect Your Machinery and Minimize Down TimeHugo CiprianiNessuna valutazione finora

- Seaworthy WhitepaperDocumento3 pagineSeaworthy WhitepaperJuan Alejandro Cañas ColoradoNessuna valutazione finora

- Varnish Potential Analysis - TestOilTestOilDocumento5 pagineVarnish Potential Analysis - TestOilTestOilCristiano TaddeiNessuna valutazione finora

- HOC Xtreme (Dau Thuy Luc)Documento11 pagineHOC Xtreme (Dau Thuy Luc)Sinh LeNessuna valutazione finora

- S-Flow Houillon Viscometer - UpdatedDocumento31 pagineS-Flow Houillon Viscometer - UpdatedAlamin Saj EngineeringNessuna valutazione finora

- Effective Varnish Removal From Turbine Lubrication SystemsDocumento9 pagineEffective Varnish Removal From Turbine Lubrication SystemsOsman AhmedNessuna valutazione finora

- Filtration Focus Fixes Faults: Fluid Power in ActionDocumento4 pagineFiltration Focus Fixes Faults: Fluid Power in ActionFraz AhmadNessuna valutazione finora

- FluidsDocumento20 pagineFluidsJhon Arreaga AguilarNessuna valutazione finora

- Emerging Problem of Lubricant Varnish MAM 201007 PDFDocumento5 pagineEmerging Problem of Lubricant Varnish MAM 201007 PDFCeciliagorraNessuna valutazione finora

- HTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P1Documento4 pagineHTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P1jorsueNessuna valutazione finora

- Deposit FormationDocumento2 pagineDeposit FormationsalleyNessuna valutazione finora

- Basic Techniques of ImpregnationDocumento7 pagineBasic Techniques of ImpregnationYjr Arun KumarNessuna valutazione finora

- Turbine Oil AnalysisDocumento12 pagineTurbine Oil Analysismanuelsum100% (2)

- Hydraulic FluidsDocumento14 pagineHydraulic FluidsBird JacquesNessuna valutazione finora

- Varnish in Turbine OilsDocumento6 pagineVarnish in Turbine OilsToppy Toppy100% (1)

- "Greener" Hydraulic LubricantDocumento3 pagine"Greener" Hydraulic LubricantJosh LeBlancNessuna valutazione finora

- Varnis AcrDocumento9 pagineVarnis AcrAcademia de ConfiabilidadNessuna valutazione finora

- Additives For High Solids and Water-Borne CoatingsDocumento12 pagineAdditives For High Solids and Water-Borne CoatingsWIlliam CheungNessuna valutazione finora

- Wax RemediationDocumento3 pagineWax RemediationDonna GrayNessuna valutazione finora

- SAEA1303Documento65 pagineSAEA1303Jashuva JoNessuna valutazione finora

- Oil-Water Separators Design Applications Aug2020 RevisionDocumento4 pagineOil-Water Separators Design Applications Aug2020 RevisionFernando Ivan Fuentes RomoNessuna valutazione finora

- Flow Assurance HomeworkDocumento9 pagineFlow Assurance HomeworkLívia Costa MelloNessuna valutazione finora

- Oil Condition Monitoring Using Electrical ConductivityDocumento8 pagineOil Condition Monitoring Using Electrical Conductivityyony manoloNessuna valutazione finora

- Polymer Coating of Pumps Boosts Efficiency, Performance: Serving The Municipal Water/Wastewater IndustryDocumento4 paginePolymer Coating of Pumps Boosts Efficiency, Performance: Serving The Municipal Water/Wastewater IndustryManoj KTNessuna valutazione finora

- FoamsDocumento14 pagineFoamsJavier Danilo Aranda PinzonNessuna valutazione finora

- Fluid Viscosity Selection Criteria PDFDocumento13 pagineFluid Viscosity Selection Criteria PDFale_gatoNessuna valutazione finora

- Micro Bubble Flotation Technology in Secondary Tertiary Produced Water Treatment English A4Documento19 pagineMicro Bubble Flotation Technology in Secondary Tertiary Produced Water Treatment English A4DeepakKumarGorai100% (1)

- Lamination Adhesives: TechnicalDocumento120 pagineLamination Adhesives: TechnicalHabib kpbwlNessuna valutazione finora

- Jenbacher: Aid To Interpreting Used Oil Analyses of Engine LubricantsDocumento8 pagineJenbacher: Aid To Interpreting Used Oil Analyses of Engine LubricantsArîfNessuna valutazione finora

- Fire-Resistant Fluids: E-Books Download Weblog: Water Engineering WeblogDocumento8 pagineFire-Resistant Fluids: E-Books Download Weblog: Water Engineering WeblogalbertofgvNessuna valutazione finora

- CHAPTER - 1 - Ind. Hydraulics Hydraulic Oil AAiT - 2010Documento30 pagineCHAPTER - 1 - Ind. Hydraulics Hydraulic Oil AAiT - 2010Samuel WozabNessuna valutazione finora

- PEGGEN02Documento70 paginePEGGEN02aliijaz007100% (1)

- Ultrafiltration For Oily Industrial Water: Separation Dynamics Paper SeriesDocumento13 pagineUltrafiltration For Oily Industrial Water: Separation Dynamics Paper SeriesböhmitNessuna valutazione finora

- Hydraulic Fluid Purpose & PropertiesDocumento36 pagineHydraulic Fluid Purpose & PropertiesMullah FassudinNessuna valutazione finora

- CompletionDocumento62 pagineCompletionavanishNessuna valutazione finora

- Basics of Rotary Screw Compressor Lubricants-Tcm67-319606 PDFDocumento8 pagineBasics of Rotary Screw Compressor Lubricants-Tcm67-319606 PDFDarmawan Putranto100% (2)

- EDGE Desalters Forum FETDocumento8 pagineEDGE Desalters Forum FETMohamedHussein MohamedHusseinNessuna valutazione finora

- Aircraft Hydraulic Systems-1Documento54 pagineAircraft Hydraulic Systems-1Gabriel EstrellaNessuna valutazione finora

- Naptha Hydrotreating Catalysts PDFDocumento2 pagineNaptha Hydrotreating Catalysts PDFElena Ricci100% (1)

- Hydraulic FluidDocumento7 pagineHydraulic FluidAssassin's j :uNessuna valutazione finora

- HFD Catalog PvsDocumento11 pagineHFD Catalog PvshadhisNessuna valutazione finora

- Tribology in Marine ApplicationsDocumento19 pagineTribology in Marine ApplicationsNeeraj RajpalNessuna valutazione finora

- The Reclaimer Vol3 FinalDocumento6 pagineThe Reclaimer Vol3 Finalhmudassir_1Nessuna valutazione finora

- 2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Documento14 pagine2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Hanif Budhi CundomanikNessuna valutazione finora

- En Open GearDocumento8 pagineEn Open GearJose FarroNessuna valutazione finora

- Kleentek 1Documento7 pagineKleentek 1Maria GriffinNessuna valutazione finora

- How Hydroprocessing Feed Filtration System Design Impacts Process Reliability and EfficiencyDocumento8 pagineHow Hydroprocessing Feed Filtration System Design Impacts Process Reliability and EfficiencyAyman FawzyNessuna valutazione finora

- Lubricating OilDocumento24 pagineLubricating OilShyam YadavNessuna valutazione finora

- Mar14 PDFDocumento2 pagineMar14 PDFsudhindra_tiwariNessuna valutazione finora

- Temperature Stability of Lubricants and Hydraulic FluidsDocumento8 pagineTemperature Stability of Lubricants and Hydraulic FluidsSalah ElgendyNessuna valutazione finora

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Documento9 pagineThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNessuna valutazione finora

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDa EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingValutazione: 5 su 5 stelle5/5 (3)

- Design and Failure Analysis of Four Stroke Six Cylinder Diesel Engine CrankshaftDocumento5 pagineDesign and Failure Analysis of Four Stroke Six Cylinder Diesel Engine CrankshaftDarmawan PutrantoNessuna valutazione finora

- Circle BarrelDocumento9 pagineCircle BarrelDarmawan PutrantoNessuna valutazione finora

- Investigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Documento7 pagineInvestigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Darmawan PutrantoNessuna valutazione finora

- Thuban GL4: Mild Extreme Pressure Automotive Gear OilDocumento1 paginaThuban GL4: Mild Extreme Pressure Automotive Gear OilDarmawan PutrantoNessuna valutazione finora

- Ariel Process WebDocumento9 pagineAriel Process WebDarmawan PutrantoNessuna valutazione finora

- Selected Failures of Internal Combustion Engine PistonsDocumento8 pagineSelected Failures of Internal Combustion Engine PistonsDarmawan PutrantoNessuna valutazione finora

- Jgekt PDFDocumento2 pagineJgekt PDFDarmawan PutrantoNessuna valutazione finora

- Equivalent Table Lub OilDocumento4 pagineEquivalent Table Lub OilDarmawan Putranto100% (1)

- GD705 5 PDFDocumento5 pagineGD705 5 PDFDarmawan PutrantoNessuna valutazione finora

- 769D 771D 773D 775D PDFDocumento116 pagine769D 771D 773D 775D PDFDarmawan Putranto100% (2)

- IDLE-Time: Cost / RiskDocumento17 pagineIDLE-Time: Cost / RiskDarmawan PutrantoNessuna valutazione finora

- Modern Automotive Technology Flyer and Order FormDocumento2 pagineModern Automotive Technology Flyer and Order FormDarmawan Putranto0% (1)

- 1 151125221535 Lva1 App6892Documento40 pagine1 151125221535 Lva1 App6892Darmawan PutrantoNessuna valutazione finora

- PSB Binder5Documento132 paginePSB Binder5Darmawan PutrantoNessuna valutazione finora

- Shell Helix Ultra Extra 5W-30: Performance, Features & Benefits Main ApplicationsDocumento2 pagineShell Helix Ultra Extra 5W-30: Performance, Features & Benefits Main ApplicationsDarmawan PutrantoNessuna valutazione finora

- Manual Power Train Caterpillar 777d Off Highway Truck ComponentsDocumento46 pagineManual Power Train Caterpillar 777d Off Highway Truck ComponentsDarmawan Putranto88% (25)

- Kenmore 253.16342101 Chest FreezerDocumento14 pagineKenmore 253.16342101 Chest FreezerJVH1978Nessuna valutazione finora

- Radiant Cooling Technology-InvensysDocumento8 pagineRadiant Cooling Technology-InvensysJavier BaronaNessuna valutazione finora

- FCI - ST80-SeriesDocumento12 pagineFCI - ST80-Seriesabdulkidwai2009Nessuna valutazione finora

- I3 MEGA Quick GuideDocumento1 paginaI3 MEGA Quick GuideJuan Manuel TalaveraNessuna valutazione finora

- Gacl Training ReportDocumento35 pagineGacl Training ReportDhruvin Shah100% (1)

- Crystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversityDocumento7 pagineCrystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversitybluecreteNessuna valutazione finora

- Ew548f & Ew648f PDFDocumento21 pagineEw548f & Ew648f PDFMadu BiruNessuna valutazione finora

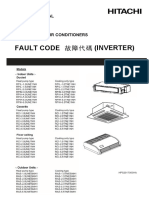

- Fault Code InverterDocumento11 pagineFault Code InverterHuawei HuaweiNessuna valutazione finora

- Borneras ChintDocumento2 pagineBorneras ChintGina Moron MoronNessuna valutazione finora

- 1 The Diagram Shows A Kettle of Boiling Water.: SublimationDocumento13 pagine1 The Diagram Shows A Kettle of Boiling Water.: SublimationNethuni KumarasingheNessuna valutazione finora

- Green Cosmos AKS Lining PDFDocumento8 pagineGreen Cosmos AKS Lining PDFMeng WaiNessuna valutazione finora

- A Presentation BY Mbah Chinedu Drilling Engineer Segofs Energy Services LimitedDocumento16 pagineA Presentation BY Mbah Chinedu Drilling Engineer Segofs Energy Services LimitedAwani KesterNessuna valutazione finora

- Ammonia Mass BalanceDocumento24 pagineAmmonia Mass BalanceNurulFatimahalzahra100% (1)

- Gold Leaf TechniqueDocumento4 pagineGold Leaf TechniqueBapake MariaNessuna valutazione finora

- A Basic Guide of Arc Welding Electrodes: by Bruce BauerleinDocumento4 pagineA Basic Guide of Arc Welding Electrodes: by Bruce BauerleinRajeev KhantwalNessuna valutazione finora

- Nanoparticle-Stabilized Foam With Controllable Structure For Enhanced Foamed ConcreteDocumento12 pagineNanoparticle-Stabilized Foam With Controllable Structure For Enhanced Foamed ConcreteDm EerzaNessuna valutazione finora

- Lista de ContagemDocumento316 pagineLista de ContagemNgongiAhil KomboraNessuna valutazione finora

- Cutback Bitumen Medium Curing MCDocumento3 pagineCutback Bitumen Medium Curing MCEng Venance MasanjaNessuna valutazione finora

- Polyalk WP PDFDocumento2 paginePolyalk WP PDFhunky11Nessuna valutazione finora

- Manual Triplex PumpDocumento45 pagineManual Triplex PumpSalineñoApasionado100% (1)

- Practical Guide To Free-Energy DevicesDocumento6 paginePractical Guide To Free-Energy Devicesoveryounity100% (2)

- Alluvial Soil Paper PDFDocumento12 pagineAlluvial Soil Paper PDFawanishNessuna valutazione finora

- Database of Embodied Energy and Water Values For MaterialsDocumento3 pagineDatabase of Embodied Energy and Water Values For MaterialsMax Yanac TelleriaNessuna valutazione finora

- TSPP9Documento90 pagineTSPP9Ian NaylorNessuna valutazione finora

- FC190 AR Motec 32 EN V50.00Documento30 pagineFC190 AR Motec 32 EN V50.00Venypierre ParraNessuna valutazione finora

- Lecture 01Documento77 pagineLecture 01shreekanth bapatNessuna valutazione finora

- mm10001 4-16-15 Rev K 2Documento43 paginemm10001 4-16-15 Rev K 2Jay R SVNessuna valutazione finora

- Recent Advances in Graphene-Based Nanocomposites For Automotive and Off-Highway Vehicle ApplicationsDocumento34 pagineRecent Advances in Graphene-Based Nanocomposites For Automotive and Off-Highway Vehicle ApplicationsAg PradhiNessuna valutazione finora

- Investigatory File On Foaming Capacity of SoapsDocumento16 pagineInvestigatory File On Foaming Capacity of SoapsAditya Pratap Singh Sengar86% (7)

- Extraction and Uses of Metals 3 MS PDFDocumento7 pagineExtraction and Uses of Metals 3 MS PDFAngus AnizNessuna valutazione finora