Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Acetone Vapor Smoothing: A Postprocessing Method For 3D Printed ABS Parts

Caricato da

rsisinternationalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Acetone Vapor Smoothing: A Postprocessing Method For 3D Printed ABS Parts

Caricato da

rsisinternationalCopyright:

Formati disponibili

International Journal of Research and Scientific Innovation (IJRSI) | Volume IV, Issue V, May 2017 | ISSN 23212705

Acetone Vapor Smoothing: A Postprocessing Method

for 3D Printed ABS Parts

Chaudhari Aditya A.1, Godase Akshay M.2, Jadhav Ravindra S.3, Naik Abhijit V.4

1, 2, 3

Student, Mechanical Engineering Department, D.Y. Patil College of Engineering, Talegaon, Ambi, Pune, India

4

Assistant Professor, Mechanical Engineering Department, D.Y. Patil College of Engineering Talegaon, Ambi, Pune, India

Abstract - The 3D prototyping methodology is the cutting edge Properties of ABS material:

manufacturing technology in the world of fabrication at present.

Thermoplastics used in this process produces prototypes building Acrylonitrile Butadiene Styrene

layer by layer on top of each other, where getting a fine and

Boiling Temp :230-250 deg

smooth printed part is nearly impossible. Hence there is a huge

demand for the post processing of the 3D printed parts that drew Superior hardness , electrical insulation

the idea of this project. There are methods for the post

processing or finishing of the 3D printed prototype but they are Mainly reactive to acetone vapor

abstract and empirical. Under such circumstances, development

Reduces danger or clogging and jamming in the

of a simple and economical post processing unit could be

initiated for the enrichment of the 3D printed parts. The niche of nozzle

this project will be to design and develop a table top vapor

smoothening system for ABS 3D printed parts for real time

applications like prosthetics and orthotics. The 3D printed part

will be incorporated through few steps of processing in order to

achieve a smoother finished 3D printed part.

Keywords - prototyping, vapor smoothening, Fused deposition

modeling, 3D printed parts

I. INTRODUCTION

M anufacturing is the process of generation of goods

which makes human life easy. Manufacturing can be

done of any domestic to industrial component. In ancient

Fig. 1 ABS material

days, manufacturing was subtractive which was leading to 3D printing could be also done using digital files from

wastage of material. In modern days, additive manufacturing scanners that scans the object and produce the stl formats. The

took place of subtractive. In this era now additive advantage of using a 3D printer is that there will be no

manufacturing processes like 3D printing is widely used. 3D wastage of materials used, since its controlled via a

printing (or additive manufacturing, AM) is any of various computer. There is no requirement of any molding or casting

processes used to make a three dimensional object that comes for the production of designed prototype which saves money

under the method of Rapid Prototyping. In 3D printing and time!

technology, successive layers of material are laid down one

after the other under computer control until the entire

designed object is made from the raw material used.3D design

are created using CAD software's like CATIA, Pro e, Solid

works etc. The design should be then converted into Stl file

format i.e.; STereoLithography format, based on which the 3D

printer(s) works. This format slices the designed object or part

into spatial orientations like x, y, z- axis and each orientation

confirms the machine on how to proceed with the process of

manufacturing. 3D CAD designs can be of any complex

dimensions and shapes and wholly could be produced in a 3D

printer within less time compared to the conventional

Fig. 2 3D printer

methods. Thermoplastics are the raw materials commonly

used globally were PLA is the prime material used. Other Considering aesthetic and ergonomics of 3D printed parts post

materials like ABS, nylon, WPC etc. processing of this parts become important process. Hence

www.rsisinternational.org Page 123

International Journal of Research and Scientific Innovation (IJRSI) | Volume IV, Issue V, May 2017 | ISSN 23212705

vapor smoothening of 3D printed parts is preferred. Vapor The technique is also being used to improve the surface of

smoothening is a method of polishing plastics to enhance objects created with 3d printing techniques. As the printer

surface roughness or improve clarity. Resolution obtained by deposits layer upon layer

this printer is widely suitable for many applications, object is

of material to build the object, the surface is often not entirely

printed with high resolution and then material removal takes

smooth. Vapor polishing helps to increase smoothness of the

place which gives better results. Typically, a component is

surface. Acetone vapor bath to treat ABS 3D-printed parts is

exposed to a chemical vapor causing the surface to flow

an extremely effective (and only moderately dangerous) way

thereby improving the surface finish.

to create parts with a shiny, smooth finish. If the model is

dipped inside the acetone vapor bath or acetone is applied on

II. OBJECTIVES

the surface of model with brush then it leads into melting of

The objective of this project is to design and develop a table the surface. Using acetone vapor helps preserve detail while

top system for vapor smoothening of 3D printed Acrylonitrile giving a smooth and shiny finish.

Butadiene Styrene (ABS) parts. The primary focus will be on

There are several ways to smoothen 3D printed parts.

the development of an indigenous system using acetone as a

Examples are:

key reagent for

Sanding

the process. The 3D printed ABS parts will be instigated into

the system for smoothening of its surface and is envisioned Bead blasting

for its usage at home.

Vapor smoothing

III. METHODOLOGY Sanding

The process of sanding makes use of sand to smoothen out 3D

printed surfaces. Sanding is an inexpensive and proven

3D printing of an ABS part method to increase a smooth finish of your product. However,

it also has some pretty serious downsides. Here accuracy and

durability are key, it is important to keep in mind that how

much material the sanding process will remove Hence sanding

is not better option when one has to decrease layering and

Setting up of vapor smoothening increase smoothness.

system Bead Blasting

Another commonly used finishing process is bead blasting. In

order to remove layer lines small beads are sprayed on model

through nozzle. The process is quick, taking roughly 5 to 10

Experimentations on the vapor minutes to complete. Although part size is an issue, larger

smoothening technique parts cannot be finished with bead blasting. Also parts need to

be bead-blasted by hand, which makes mass finishing very

labor intensive.

Vapor Smoothing

Evaluation of the smoothened The printed object is dipped into a vapor tank containing

part liquid that is brought to boiling point. The vapor melts away a

part of the printed object and smooth surface is established. It

is the easy and affordable way to get the smooth finishing of

IV. CONCEPT the printed parts. There are different reagents whose vapors

can be used for smoothening process. They could be;

This method of polishing is frequently used to return clear

materials to an optical quality finish after machining. Internal Acetone

features of the components are better managed by vapor

polishing. Feature size changes of the plastic component Tetrahydrofuran (THF)

generally do not occur. Post stress relieving is usually Methyl ethyl ketone (MEK)

required as vapor smoothening sets up surface stresses that

can cause crazing. Plastics that respond to vapor smoothening Acetone

are polycarbonate, acrylic, polysulfone, PEI and ABS. Acetone is a colorless and highly flammable liquid. It has a

fruity and mint-like odor with a pungent taste. We can get

acetone naturally from plants, trees, volcanic gases, and forest

www.rsisinternational.org Page 124

International Journal of Research and Scientific Innovation (IJRSI) | Volume IV, Issue V, May 2017 | ISSN 23212705

fires, and as a by-product of the breakdown of body fat. Other heater, tin (for covering). Initially we took acetone in

substances, such as paints, varnishes, lacquers, fats, oils, container say 20-30 ml and container is placed on heater.

waxes, resins, printing inks, plastics, and glues dissolves in Small stand or aluminium foil paper we kept on acetone in

the acetone due its soluble property. It is used to make order to avoid direct contact between acetone and part.

plastics, fibers, drugs, rayon, photographic film, smokeless Covering tin is then placed on whole assembely to avoid

powder, and other chemicals. Precision parts can be cleaned mixing of acetone vapor with surrounding.

and dried with the help of acetone. Acetone has melting point

First, acetone is heated up to temperature slightly less than its

around 132.8 degree farhenite, but it has ability to melt at

melting point and then part to be smoothed is kept on stand.

room temperature. Many experiments have been performed

Acetone vapor then starts reacting with ABS part which on

using acetone vapor at room temperature, but they took up to

result vanishes marks on the surface of part and you get

40 minutes to smooth a part. Using a boiling acetone vapor

polished surface. This process takes less than 20 seconds time.

process can smooth a part in less than 10 seconds. Print

optical Technology, or lot of post-processing helps for But, simultaneously there are many disadvantages of this

complete smoothing of our printed part. traditional method such as:

Poor surface finish: As this is very basic system for vapor

smoothing it does not give better surface finish because

improper heating of acetone.

Reduction in part size: As there was direct contact of acetone

vapor and part, excess heating of acetone resulted in reduction

in part size

Tetrahydrofuran (THF) Less temperature control: Being very preliminary model there

were no connection of sensors, controllers, etc.

Tetrahydrofuran is a general purpose, highly volatile organic

solvent. It is a colorless, water-miscible, mobile liquid. In the

various synthesis processes it is used as starting material as it

has good solubility. THF can be recovered easily, without

decomposition, from off-gas streams and contaminated

solvents, making it suitable for closed-loop processes

designed to avoid pollution.

Methyl ethyl ketone (MEK)

In processes involving gums, resins, and cellulose acetate and

nitrocellulose coatings in vinyl films, common solvent known

as Butanone is used. Because of such inherent properties it

can be used in the manufacture of plastics, textiles, in the

production of paraffin wax, and in household products such as

lacquer, varnishes, paint remover, a denaturing agent for Fig. 3 Rectangular block (Test specimen)

denatured alcohol, glues, and as a cleaning agent. Even if its Table 1: Change in dimensions of test specimen

solvent properties are same as that of acetone, it melts at

higher temperature than it and has slower rate of evaporation. Parameters Original dimension Change in dimension

Acetone is the best liquid to treat ABS parts, either by

polishing or vapor smoothing, or using it to stick parts Length 50mm 0.09mm

together.

Width 30mm 0.05mm

V. EXPERIMENTATION

Thickness 20mm 0.3mm

At beginning stage, as we didnt have any sophisticated

system for vapor smoothing we performed the experiment at Hence, in order to avoid all these demerits of traditional vapor

very basic stage. We had a 3D printed part of ABS material on smoothing setup we have designed sophisticated system

the surface of which marks of material addition were present which will eliminate all problems associated with previous

which was making the part aesthetically poor. Hence to one.

improve surface finish of part we did vapor smoothening. For

vapor smoothing we preferred acetone as our chemical as its In the new sophisticated system basic idea of experimentation

properties are favorable for ABS parts. remains same. Some components get add in the new system in

order to achieve better results.

For vapor smoothing we require acetone, ABS part, container,

www.rsisinternational.org Page 125

International Journal of Research and Scientific Innovation (IJRSI) | Volume IV, Issue V, May 2017 | ISSN 23212705

7. Heater placed at the bottom of the system heats

acetone to convert into vapor.

8. This vapor polishes 3D printed part by reacting with

ABS material

9. Acetone vapor melts the material on the surface of

the part such that its roughness gets reduced. It does

not reduce total mass or geometrical parameters of

the part.

Fig. 5 Temperature controller by DIGICON

Fig. 4 CAD model of sophisticated vapor smoothing setup

Fig 4 shows exact model of the table top vapor smoothing

setup. This new system has display board at front in order to

display the temperature of vapor. For the detection of

temperature, temperature sensors are used. In market

various types of temperature sensors are available. Along

with that various knobs are provided to control the

temperature and for some other functions. This addition in the

new system is the remedy for the temperature control in the

Fig. 6 LC1-D173 Contractor control relay by TC

previous system. Inside the glass chamber at the bottom of

system heater is placed which is used to heat the acetone to

get converted into vapor. Above that small stand is placed on

which 3D printed part that to be polished is placed. Chamber

is surrounded by glass to avoid vapor loss to surroundings.

Also pungent smell of acetone vapor causes irritation and

headache so; to avoid this system is isolated from

surroundings.

Detailed Working Procedure

1. CAD model of the part that to be printed is prepared

using any CAD software.

Fig. 7 PT-100 Temperature sensor

2. CAD file is then converted into STL format by stereo

lithography technique. VI. RESULT

3. G-code is then generated using appropriate software. Many test specimens we printed through 3D printer and then

4. This G-code is fed to 3D printer and then part is polished by acetone vapor with sophisticated system. By

printed. In this way 3D part is obtained. observation we observed dramatic change in the surface

roughness of all specimens after polishing compare to that of

5. As this printed part as markings of layer by layer before polishing.

material addition it minimizes aesthetic look of the

object hence vapor polishing the best post processing From the available data we plotted graph of the surface

method is performed. roughness showing change in the surface roughness of four

same test specimens before and after vapor smoothing for the

6. In this technique, system as showed in Fig 4 is used. same interval of time.

www.rsisinternational.org Page 126

International Journal of Research and Scientific Innovation (IJRSI) | Volume IV, Issue V, May 2017 | ISSN 23212705

On the Y axis of the graph values of surface roughness in

micrometer are provided while on X axis numbers of

specimens are provided.

40

35 Surface

30 roughness

before

25 polishing in

20 micrometer Fig. 10 Part before vapor smoothing treatment

15 Surface

roughness

10 after

5 polishing in

micrometer

0

1 2 3 4

Fig. 8 Graph showing change in the surface roughness Fig. 11 Smoothen part after vapor smoothing treatment

Also, we can state that surface roughness is inversely

proportional to time in case of vapor smoothing. More the VII. CONCLUSION

time for which part and vapor are in contact less will be the Vapor smoothening of the 3D printed ABS part using a table

surface roughness value. top system incorporating acetone as a medium was carried out

We polished four same specimens for different time intervals. successfully to an extent. This method of post processing of

First specimen kept in chamber for 5 seconds, second, third the ABS 3D printed part for smoothening its surface was

and fourth for 10, 15, 20 seconds respectively. Then we iterated on visual inspection on time constraints which was an

observed that we get better surface finish if it is kept in abstract method turned out to be worthy enough. This method

contact with acetone vapor for more time was one of the fastest and less costly approaches of

smoothening of the 3D printed part made from ABS

Fig 9 shows surface roughness values for all four specimens thermoplastics. Proper care was taken during the process in

for their respective time interval. Specimen 1 is kept in order to avoid the accidental melting of the 3D printed part.

contact with acetone vapor for 5 seconds and its surface

roughness value is 9.9 micrometer. Similarly, for all other ACKNOWLEDGMENT

specimens.

The authors are grateful to TPO TECHNOLOGIES,

Bangalore, India for extending their facilities to carry out the

experimentation work. The authors also acknowledge the help

rendered by Mr. Sunil Dhambhare during the experimentation

and analysis phase.

REFERENCES

[1]. Sung-Uk Zhang., et al, Temperature dependent mechanical

properties of ABS parts fabricated by fused deposition modeling

and vapor smoothing, International Journal of Precision and

Manufacturing, May 2017.

[2]. I. Gibson, D.W.R., B. Stucker, Additive Manufacturing

Technologies: Rapid Prototyping to Direct Digital Manufacturing.

2010, New York: Springer.

[3]. Espalin, D., et al, Effects of Vapor Smoothing on ABS Part

Dimensions, in Rapid 2009 Conference and Exposition. 2009,

Society of Manufacturing Engineers: Schaumburg, IL, United

states.

Fig. 9 Surface roughness versus time graph for four specimens [4]. Dorcas v. kaweesa, et al, Investigating the impact of acetone

vapor smoothing on the strength and elongation of printed ABS

Change in the surface roughness observed during parts, Journal of the minerals, metals & materials society,

December 2016.

experimentation is as follow:

www.rsisinternational.org Page 127

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Indigenous Agricultural Knowledge and The Sustenance of Local Livelihood Strategies in Buabua and Kimbi The Lake Nyos Gas Disaster Resettlement Camps, NWR of CameroonDocumento12 pagineIndigenous Agricultural Knowledge and The Sustenance of Local Livelihood Strategies in Buabua and Kimbi The Lake Nyos Gas Disaster Resettlement Camps, NWR of CameroonrsisinternationalNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Determination of Bacteriological and Physiochemical Properties of Som-Breiro River in Ahoada East Local Government Area of Rivers State NigeriaDocumento4 pagineDetermination of Bacteriological and Physiochemical Properties of Som-Breiro River in Ahoada East Local Government Area of Rivers State NigeriarsisinternationalNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Multistage Classification of Alzheimer's DiseaseDocumento6 pagineMultistage Classification of Alzheimer's DiseasersisinternationalNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Design and Analysis of Disc Brake For Low Brake SquealDocumento9 pagineDesign and Analysis of Disc Brake For Low Brake SquealrsisinternationalNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Tomato Processing Industry ManagementDocumento5 pagineTomato Processing Industry ManagementrsisinternationalNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Coffee Shop ManagementDocumento5 pagineCoffee Shop ManagementrsisinternationalNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Online Grocery MarketDocumento6 pagineOnline Grocery MarketrsisinternationalNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Application of Big Data Systems To Airline ManagementDocumento4 pagineApplication of Big Data Systems To Airline ManagementrsisinternationalNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Impact of Organisational Behaviour and HR Practices On Employee Retention in Parcel Service Sector With Special Reference To TamilnaduDocumento3 pagineImpact of Organisational Behaviour and HR Practices On Employee Retention in Parcel Service Sector With Special Reference To TamilnadursisinternationalNessuna valutazione finora

- Management of Propylene Recovery UnitDocumento7 pagineManagement of Propylene Recovery UnitrsisinternationalNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Business Analysis of A Fast Food Restaurant ChainDocumento3 pagineBusiness Analysis of A Fast Food Restaurant ChainrsisinternationalNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Management of Home Textiles ExportDocumento12 pagineManagement of Home Textiles ExportrsisinternationalNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Management of A Paper Manufacturing IndustryDocumento5 pagineManagement of A Paper Manufacturing IndustryrsisinternationalNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Sweet-Shop ManagementDocumento8 pagineSweet-Shop ManagementrsisinternationalNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hassle Free TravelDocumento9 pagineHassle Free TravelrsisinternationalNessuna valutazione finora

- Aviation MeteorologyDocumento5 pagineAviation MeteorologyrsisinternationalNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Sustainable Methods Used To Reduce The Energy Consumption by Various Facilities in Airport TerminalsDocumento4 pagineSustainable Methods Used To Reduce The Energy Consumption by Various Facilities in Airport TerminalsrsisinternationalNessuna valutazione finora

- The Bridging Process: Filipino Teachers' View On Mother TongueDocumento5 pagineThe Bridging Process: Filipino Teachers' View On Mother TonguersisinternationalNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Wireless Radio Signal Drop Due To Foliage in Illuba Bore Zone EthiopiaDocumento4 pagineWireless Radio Signal Drop Due To Foliage in Illuba Bore Zone EthiopiarsisinternationalNessuna valutazione finora

- Optimization of Tungsten Inert Gas Welding On 6063 Aluminum Alloy On Taguchi MethodDocumento5 pagineOptimization of Tungsten Inert Gas Welding On 6063 Aluminum Alloy On Taguchi MethodrsisinternationalNessuna valutazione finora

- Keyboard Project LogbookDocumento31 pagineKeyboard Project Logbookapi-542535294Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- XYZware User Manual - EN - V3.3Documento50 pagineXYZware User Manual - EN - V3.3imagex5Nessuna valutazione finora

- Guidelines On Industry 4.0 and Drone Entrepreneurship For VET StudentsDocumento45 pagineGuidelines On Industry 4.0 and Drone Entrepreneurship For VET StudentsBxchung VuongNessuna valutazione finora

- 3D Printing For ArchitectsDocumento3 pagine3D Printing For Architectsru4angelNessuna valutazione finora

- bdbb6964 5Documento48 paginebdbb6964 5Cem AskerNessuna valutazione finora

- How Technology Will Change Our Lives in Twenty YearsDocumento5 pagineHow Technology Will Change Our Lives in Twenty YearsUmer KhanNessuna valutazione finora

- 3,4,5, ConclusionDocumento5 pagine3,4,5, Conclusionanon_65606604Nessuna valutazione finora

- The Impact and Application of 3D Printing Technology: Related PapersDocumento6 pagineThe Impact and Application of 3D Printing Technology: Related PapersGarapati MurarjiNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- 3D Slicer Settings For Beginners - 8 Things You Need To KnowDocumento21 pagine3D Slicer Settings For Beginners - 8 Things You Need To KnowMihaela AlinaNessuna valutazione finora

- 3D Printing in General DentistryDocumento10 pagine3D Printing in General DentistryFrancisca BarrientosNessuna valutazione finora

- Effects of Interlocking On Interlayer Adhesion and Strength of Structures in 3D PrintingDocumento10 pagineEffects of Interlocking On Interlayer Adhesion and Strength of Structures in 3D PrintingAliReza ZiaratiNessuna valutazione finora

- Fabbing Practices - An Ethnography in Fab Lab AmsterdamDocumento96 pagineFabbing Practices - An Ethnography in Fab Lab Amsterdamaghalim86Nessuna valutazione finora

- Project Anjali DaterattaDocumento55 pagineProject Anjali DaterattaNischal RaoNessuna valutazione finora

- DSM Resins & Functional Materials: Highlights 2018Documento3 pagineDSM Resins & Functional Materials: Highlights 2018杨惠玲Nessuna valutazione finora

- The Role of Powder Layer Thickness On The Quality ofDocumento8 pagineThe Role of Powder Layer Thickness On The Quality ofAbdul KhaladNessuna valutazione finora

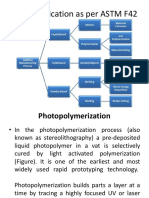

- AM Classification As Per ASTM F42Documento19 pagineAM Classification As Per ASTM F42RajijackNessuna valutazione finora

- Future Trends of Information TechnologyDocumento12 pagineFuture Trends of Information TechnologyEZRA FABRIZIO CELIZ QUIÑONESNessuna valutazione finora

- ThermalAnalysisbyFiniteElementsofHotendsfor3D Q2Documento6 pagineThermalAnalysisbyFiniteElementsofHotendsfor3D Q2Satyam KNessuna valutazione finora

- Perspectives of 3D Printing Technology in Orthopaedic SurgeryDocumento7 paginePerspectives of 3D Printing Technology in Orthopaedic SurgeryOstaz100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Arcam Q10 Technical DataDocumento2 pagineArcam Q10 Technical Datamihaisoric1617Nessuna valutazione finora

- AeroDef India Brochure 2024Documento4 pagineAeroDef India Brochure 2024Resonous ComNessuna valutazione finora

- Science & Tech GOVERNMENT POLICIES & INITIATIVES in NewsDocumento63 pagineScience & Tech GOVERNMENT POLICIES & INITIATIVES in NewsDEEKSHA GUPTANessuna valutazione finora

- Concrete 3D Printing - How It Works & Applications - All3DP PDFDocumento8 pagineConcrete 3D Printing - How It Works & Applications - All3DP PDFmehdi_hoseineeNessuna valutazione finora

- Normal Edge Decal Tutorial HQ PDF + Unity ShaderDocumento36 pagineNormal Edge Decal Tutorial HQ PDF + Unity ShaderkouzaNessuna valutazione finora

- MME 9651 - Additive Manufacturing: Department of Mechanical and Materials EngineeringDocumento5 pagineMME 9651 - Additive Manufacturing: Department of Mechanical and Materials Engineeringzubair ahmedNessuna valutazione finora

- Techbriefs 23ADT06Documento56 pagineTechbriefs 23ADT06Jose A. HerreraNessuna valutazione finora

- Evermotion Archexteriors Vol 15 PDFDocumento2 pagineEvermotion Archexteriors Vol 15 PDFJenniferNessuna valutazione finora

- Digital TwinsDocumento5 pagineDigital TwinsNhung Nguyễn HồngNessuna valutazione finora

- Reprap Prusa Mendel Build Manual - 2Documento14 pagineReprap Prusa Mendel Build Manual - 2Laxmikanth ReddyNessuna valutazione finora

- Industry 4.0 - From Vision To ImplementationDocumento31 pagineIndustry 4.0 - From Vision To ImplementationThomas BerthelotNessuna valutazione finora

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityDa EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityValutazione: 5 su 5 stelle5/5 (1)

- Cyber War: The Next Threat to National Security and What to Do About ItDa EverandCyber War: The Next Threat to National Security and What to Do About ItValutazione: 3.5 su 5 stelle3.5/5 (66)