Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M Series Manual Valve Gear: Features & General Specifications

Caricato da

rizky efrinaldoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M Series Manual Valve Gear: Features & General Specifications

Caricato da

rizky efrinaldoCopyright:

Formati disponibili

M SERIES MANUAL

VALVE GEAR

The quater-turn M series manual gear of Metso has

been engineered to meet the harduous

requirements of demanding industrial

environments. It has a cast iron construction and

high performance axial bearings to enable smooth

and accurate operation.

Corrosion protection is achieved by polyurethane

painting. These gear operators are well suited for

pulp and paper, energy and hydrocarbon, chemical,

power, waterworks, HVAC and most general process

industry applications.

Using seals with multiple sealing surfaces, the M

range is sealed to IP67 and achieves exceptional

durability.

Features & general specifications:

Sealed to IP67.

Aluminum indicator cap as standard

Self locking/high efficiency. Options

Cast iron enclosure, Steel input shaft Input padlock flange.

90 5 (adjustable) travel. VDI/VDE surface for accessories.

up to 8400 Nm / 74425 ft lbs output torque. Chainwheel operation.

-40...+120 C / -40...+250 F temperature range for High temperature grease with high temperature

continuous operation. O-rings (Tmax 160 C)

50% grease filled for life, thus maintenance free Oxygen compatible grease

Stroke: 0 - 90 ( 50 adjustable) Extended handwheel shaft

Polyurethane coating Low temperature -55 C

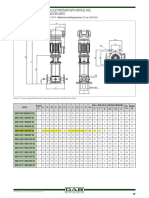

Torque output Torque input Weight Turns

M.A

Type Ratio to

Nm lbf. In Nm lbf. In 10% kg lbs. close

M07 37:1 330 2920 29 253 11.6 3.8 7.7 9,25

M10 37:1 500 4430 43 381 11.6 4.3 7.7 9,25

M12 34:1 1000 8860 83 735 12.0 10.0 18.7 8,5

M14 38:1 2000 17720 152 1347 13.2 18.2 30.9 9,5

M15 55:1 3250 28795 171 1515 19.0 26.2 48.5 13,75

M16 84:1 4500 39870 159 1409 28.3 36.8 70.5 21

M25 78:1 8400 74425 305 2702 27.5 60.8 123.5 19,5

6 MG 21 EN 9/2013

DIMENSIONS HOW TO ORDER

M07/20F05SR6P, where Other options

M07 = type of manual V = VDI / VDE surface

gear (only with 'P')

F1 C = chain wheel

G1

/20 = bore diameter

K F05 = mounting flange HT = high temp

R type OX = oxygen grease

SR6 = handwheel type CT = low temp

8

OPEN

P = padlock for

Y

1

handwheel

BC OFF CENTER

BORE

SHUT

B

9

11

Nr. Description Material Specification/Notes

V

12

1 Set-screw Carbon Steel 8.8 / DIN 916

10

Z 2 Worm Carbon Steel C45 / AISI 1045

3 Gasket NBR 70 Shore

1 2 3 4 5 6 7 4 Needle-Bearing AXK-AS -

N = number of holes

A S 5 Bushing Sintered Steel FP15

6 Oil-seal Nitrile -

7 Shaft Carbon Steel C45 / AISI 1045

U

8 Grease Lithium-Calcium Multipurpose EP-2

9 Position indicator Aluminum -

10 Coverplate Cast Iron GG25 / ASTM A48-40

11 Quadrant Ductile Iron GGG40 / ASTM D60-40-18

12 Body Cast Iron GG25 / ASTM A48-40

Dimensions, mm

Valve Hand

d, max N,

Unit Bore mounting G1, with F1, with Max. U, U, wheel

valve S number

size size flange std input std input A B V Y K R stem dia depth dia

shaft of holes

ISO 5211 shaft shaft height Z/ type

diameter

M6, M8,

M07 insert 15 F05+F07+F10 185 241 102 124 52 44 65 29 45 15 50, 70, 102 4,4,4 8, 11, 13

M10

160/SR6

straight M6, M8,

M07 F05+F07+F10 185 241 102 124 52 44 65 29 55 25 50, 70, 102 4,4,4 8, 11, 13

20 or 25 M10

straight M6, M8,

M10 F05+F07+F10 187 243 102 124 52 44 65 29 55 25 50, 70, 102 4,4,4 8, 11, 13 200/SR8

20 or 25 M10

insert

M12 F10+F12 235 304 138 174 71 69 88 41 79 30 102, 125 4,4 M10, M12 13, 16

25 or 30 315/SR12

M12 straight 35 F10+F12 235 304 138 174 71 69 88 41 79 35 102, 125 4,4 M10, M12 13, 16

insert

M14 F12+F16 305 405 200 226 86 100 93 42 82 40 125, 165 4,4 M12, M20 16, 18

35 or 40

M14 straight 45 F12+F16 305 405 200 226 86 100 93 42 82 45 125, 165 4,4 M12, M20 16, 18

400/R16

M14 insert F10+F14 305 405 200 226 86 100 93 42 82 40 102, 140 4,4 M10, M16 13, 16

35 or 40

M14 straight 45 F10+F14 305 405 200 226 86 100 93 42 82 45 102, 140 4,4 M10, M16 13, 16

straight 35, 40,

M15 F10+F14 346 456 220 258 105 110 102 48 91 55 102, 140 4,4 M10, M16 13, 18

45, 50 or 55

500/R20

straight 35, 40,

M15 F12+F16 346 456 220 258 105 110 102 48 91 55 125, 165 4,4 M12, M20 16, 18

45, 50 or 55

M16 insert 45 or 55 F16+F25 387 530 285 323 130 143 124 55 111 55 165, 254 4, 8 M20, M16 18, 18

straight

M16 F16+F25 387 530 285 323 130 143 124 55 111 70 165, 254 4, 8 M20, M16 18, 18

65 or 70 600/R24

M25 straight F16+F25 412 597 370 402 182 170 160 59 121 85 165, 254 4, 8 M20, M16 18, 18

75 or 85

Subject to change without prior notice.

Metso Automation Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 VANTAA, Finland.

Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA.

Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independncia, 2500- Iporanga, 18087-101, Sorocaba-So Paulo, Brazil.

Tel. +55 15 2102 9700. Fax +55 15 2102 9748/49

Asia Pacific, 20 Kallang Avenue, Lobby B, #06-00, PICO Creative Centre, Singapore 339411, Singapore.

Tel. +65 6511 1011. Fax +65 6250 0830

China, 19/F, the Exchange Beijing, No. 118, Jianguo Lu Yi, Chaoyang Dist, 100022 Beijing, China.

Tel. +86-10-6566-6600. Fax +86-10-6566-2575

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai,

United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

Potrebbero piacerti anche

- Browning MedidasDocumento2 pagineBrowning MedidasPedro Miguel SolórzanoNessuna valutazione finora

- TorqTaper Plus 107-315 SMTP DimensionsDocumento2 pagineTorqTaper Plus 107-315 SMTP Dimensionsv8wfm8d8r7Nessuna valutazione finora

- Aggh PDFDocumento17 pagineAggh PDFTolea GheorghitaNessuna valutazione finora

- Nevera Samsung ConversionDocumento1 paginaNevera Samsung ConversionJuan Pablo Montero CarmonaNessuna valutazione finora

- Oky24-3 - 600a - 37028Documento1 paginaOky24-3 - 600a - 37028geradNessuna valutazione finora

- 4WRZ and 4WRH seawater resistant proportional directional valvesDocumento6 pagine4WRZ and 4WRH seawater resistant proportional directional valvesАлександр БулдыгинNessuna valutazione finora

- RR SR: 4 05/2014 - Art. Nr. 420010539902Documento6 pagineRR SR: 4 05/2014 - Art. Nr. 420010539902CleberNessuna valutazione finora

- Tba810s SGSDocumento6 pagineTba810s SGSjosue sotoNessuna valutazione finora

- 5B5-02 3PU 2pot Part 1Documento12 pagine5B5-02 3PU 2pot Part 1Witit WattanaNessuna valutazione finora

- NaamsDocumento20 pagineNaamslucian lunaNessuna valutazione finora

- 2HP 4P XP Us MotorsDocumento13 pagine2HP 4P XP Us MotorsOswaldo Romario Fernandez CuevaNessuna valutazione finora

- Discontinued: TMT1HNCR Series Reliance Commercial Line Manual Toilet Flush Valve, Exposed 1.6 GPFDocumento2 pagineDiscontinued: TMT1HNCR Series Reliance Commercial Line Manual Toilet Flush Valve, Exposed 1.6 GPFSharrife JNessuna valutazione finora

- Shop Fox ManualDocumento67 pagineShop Fox Manualpr8Nessuna valutazione finora

- Mitsuindo Jaya Teknik M3P1 Wering PDFDocumento18 pagineMitsuindo Jaya Teknik M3P1 Wering PDFWinNessuna valutazione finora

- UH06Documento1 paginaUH06deprianto MNessuna valutazione finora

- SBCG - Rnav Amvol 1a Ilpux 1c Rwy 06 - Sid - 20180104Documento1 paginaSBCG - Rnav Amvol 1a Ilpux 1c Rwy 06 - Sid - 20180104Vinícius VazNessuna valutazione finora

- Manual: User SDocumento7 pagineManual: User SRoberd LeeNessuna valutazione finora

- g3.. Gear Pump..Re10039Documento10 pagineg3.. Gear Pump..Re10039vijayramchandra88Nessuna valutazione finora

- Engine Data Sensors - Oxygen Sensors, Throttle Actuator Controls, and Ignition SystemDocumento1 paginaEngine Data Sensors - Oxygen Sensors, Throttle Actuator Controls, and Ignition SystemDavid MVNessuna valutazione finora

- Underbody Clamp K... UZ T08: With Centering Pin, Self-Locking Type, For Seat Ø20 - 40 MMDocumento1 paginaUnderbody Clamp K... UZ T08: With Centering Pin, Self-Locking Type, For Seat Ø20 - 40 MMBe HappyNessuna valutazione finora

- Gold Crown AvionicsDocumento50 pagineGold Crown AvionicsJavierNessuna valutazione finora

- Emco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426Documento282 pagineEmco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426AyoubNessuna valutazione finora

- Ad-2 LFPTDocumento7 pagineAd-2 LFPTKevin LohierNessuna valutazione finora

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationDocumento1 paginaM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- KBRG 225dDocumento20 pagineKBRG 225djose vargasNessuna valutazione finora

- Ection UMP Anifolds: Ms - 06 - XX XXDocumento12 pagineEction UMP Anifolds: Ms - 06 - XX XXAlawdin Grand HydraulicNessuna valutazione finora

- NKVE-with-MCE-P - TS - ENG - CRIS-25Documento1 paginaNKVE-with-MCE-P - TS - ENG - CRIS-25InácioMendalaNessuna valutazione finora

- BF#3 100T WinchDocumento5 pagineBF#3 100T WinchT V KANNANNessuna valutazione finora

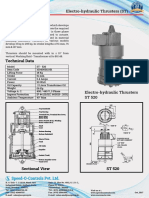

- Electro-Hydraulic Thrusters (ST) : Technical DataDocumento1 paginaElectro-Hydraulic Thrusters (ST) : Technical Datanikhil patleNessuna valutazione finora

- Dfoo Bobo-Dioulasso Rnav Rwy 24Documento1 paginaDfoo Bobo-Dioulasso Rnav Rwy 24luciano melchiondaNessuna valutazione finora

- Bleed Fan SelectionDocumento4 pagineBleed Fan Selectionomar abdullahNessuna valutazione finora

- Ssangyong Actyon D20DT Manual de Reparacion de Los DiferencialesDocumento24 pagineSsangyong Actyon D20DT Manual de Reparacion de Los DiferencialesHugo VillcaNessuna valutazione finora

- WIDDDocumento13 pagineWIDDWijayaNessuna valutazione finora

- Sierra Silverado Electrical Body Builders Manual Service Manual 2016 en USDocumento1.617 pagineSierra Silverado Electrical Body Builders Manual Service Manual 2016 en USOctavian GrecuNessuna valutazione finora

- 002.9 Optiview YT (Rev - K - 03)Documento16 pagine002.9 Optiview YT (Rev - K - 03)Gurunadha rao kankakalaNessuna valutazione finora

- Isimak Ec-Ge Wiring Diagram & Part ListDocumento5 pagineIsimak Ec-Ge Wiring Diagram & Part ListtoufikNessuna valutazione finora

- TDA7293Documento12 pagineTDA7293Radulescu LucianNessuna valutazione finora

- Ad-2 LFMCDocumento7 pagineAd-2 LFMCfrantic69Nessuna valutazione finora

- CL4 - Column - Assembly - Rev 00Documento1 paginaCL4 - Column - Assembly - Rev 00Mohamed MounirNessuna valutazione finora

- Umpco: CAGE CODE No. 18076 Part NumberDocumento4 pagineUmpco: CAGE CODE No. 18076 Part NumberFredNessuna valutazione finora

- 7MPa clamp dimensions and optionsDocumento2 pagine7MPa clamp dimensions and optionsLeonardo AlexNessuna valutazione finora

- LM35 Temperature Sensor TitleDocumento1 paginaLM35 Temperature Sensor TitleWalter CruzNessuna valutazione finora

- Doga Rulman Dana Gözü S.B.gennDocumento31 pagineDoga Rulman Dana Gözü S.B.gennemrah nalbantNessuna valutazione finora

- North America NW v50510Documento1 paginaNorth America NW v50510SnowlyNessuna valutazione finora

- T6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane PumpDocumento56 pagineT6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane Pumpbadawai sallamNessuna valutazione finora

- 120V - 100W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyDocumento13 pagine120V - 100W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyvetchboyNessuna valutazione finora

- Charging SystemDocumento2 pagineCharging SystemMohamed AdelNessuna valutazione finora

- EDLW DortmundDocumento17 pagineEDLW Dortmunddaniel.namendorfNessuna valutazione finora

- 90 150 KvaDocumento2 pagine90 150 KvaEslSukkurNessuna valutazione finora

- Panel DemanganDocumento1 paginaPanel DemanganadinahariNessuna valutazione finora

- Cruise Control, CVT and Shift Indicator, Engine ControlDocumento25 pagineCruise Control, CVT and Shift Indicator, Engine ControlNhật Đặng100% (1)

- Lathe Tooling Guide: A Reference Guide To Understanding How Cutting Tools Work and Which Inserts They Pair WithDocumento11 pagineLathe Tooling Guide: A Reference Guide To Understanding How Cutting Tools Work and Which Inserts They Pair WithmallardfirstNessuna valutazione finora

- Engine Data Sensors - Pressure and TemperatureDocumento1 paginaEngine Data Sensors - Pressure and TemperatureDavid MVNessuna valutazione finora

- N-0900-P-01-01 - Tailing Tower (C-0902)Documento11 pagineN-0900-P-01-01 - Tailing Tower (C-0902)Darrel Espino AranasNessuna valutazione finora

- My PDMSDocumento4 pagineMy PDMSNavaneeth PurushothamanNessuna valutazione finora

- Substation - 2 ModelDocumento26 pagineSubstation - 2 ModelSolanki SamarthNessuna valutazione finora

- Skcl/Clo Cali, Colombia: Manga 1 ArrivalDocumento13 pagineSkcl/Clo Cali, Colombia: Manga 1 ArrivalMarianoV81Nessuna valutazione finora

- PLC - Ctrinh (Ups)Documento4 paginePLC - Ctrinh (Ups)Trần Đức HoàngNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Grab Lenovo Srvice Cnter To Pku Airport and Jkat Airport To HomeDocumento5 pagineGrab Lenovo Srvice Cnter To Pku Airport and Jkat Airport To Homerizky efrinaldoNessuna valutazione finora

- Flushing Centrifugal Pumps MethodsDocumento6 pagineFlushing Centrifugal Pumps Methodsrizky efrinaldoNessuna valutazione finora

- Bolt Torque Values - FLUOROLON (Sheet Ring Gaskets / Raised Face Flanges)Documento5 pagineBolt Torque Values - FLUOROLON (Sheet Ring Gaskets / Raised Face Flanges)rizky efrinaldoNessuna valutazione finora

- FAT SPLITTING PFD ANALYSIS AND KEY METRICSDocumento1 paginaFAT SPLITTING PFD ANALYSIS AND KEY METRICSrizky efrinaldoNessuna valutazione finora

- PGT003 Leaf Filter TrainingDocumento12 paginePGT003 Leaf Filter Trainingbeaa ayNessuna valutazione finora

- Glycerol ReprocessingDocumento83 pagineGlycerol Reprocessingrizky efrinaldoNessuna valutazione finora

- The Technology For The Oils & Fats IndustryDocumento7 pagineThe Technology For The Oils & Fats Industryrizky efrinaldoNessuna valutazione finora

- Vacuum CondenserDocumento4 pagineVacuum CondenserCecilia Tan0% (1)

- ENGINEERING DESIGN GUIDELINES Distillation Column Packing Hydraulics Rev1.2web PDFDocumento27 pagineENGINEERING DESIGN GUIDELINES Distillation Column Packing Hydraulics Rev1.2web PDFMohsen KadivarNessuna valutazione finora

- C250 - Punch List From Benni 14-4-21 - With RemarksDocumento44 pagineC250 - Punch List From Benni 14-4-21 - With Remarksrizky efrinaldoNessuna valutazione finora

- C312 - Weekly Site Report C250Documento9 pagineC312 - Weekly Site Report C250rizky efrinaldoNessuna valutazione finora

- Oxygen Scavenger MSDSDocumento10 pagineOxygen Scavenger MSDSAufa Jaya Perkasa LegalityNessuna valutazione finora

- Electric Multi-Turn ActuatorsDocumento8 pagineElectric Multi-Turn ActuatorsZarko MikicNessuna valutazione finora

- Pat List-Timas-Desalter PDFDocumento14 paginePat List-Timas-Desalter PDFrizky efrinaldoNessuna valutazione finora

- Pressure Leaf Filters: Clean Processes - ContinuouslyDocumento8 paginePressure Leaf Filters: Clean Processes - Continuouslyrizky efrinaldoNessuna valutazione finora

- Control Valves PositionerDocumento8 pagineControl Valves Positionerrizky efrinaldoNessuna valutazione finora

- Telecommunication Equipment Specification UpdatesDocumento27 pagineTelecommunication Equipment Specification Updatesrizky efrinaldoNessuna valutazione finora

- FC Mag - Process VariabilityDocumento5 pagineFC Mag - Process Variabilityrizky efrinaldoNessuna valutazione finora

- Nitro Nic 60Documento4 pagineNitro Nic 60rizky efrinaldoNessuna valutazione finora

- Limit Switch Training PDFDocumento23 pagineLimit Switch Training PDFrizky efrinaldoNessuna valutazione finora

- Pub003 002 00 - 0116Documento20 paginePub003 002 00 - 0116sivaNessuna valutazione finora

- Electric Actuator User ManualDocumento32 pagineElectric Actuator User Manualrizky efrinaldoNessuna valutazione finora

- Everything You Need to Know About Valve ActuatorsDocumento7 pagineEverything You Need to Know About Valve Actuatorsrizky efrinaldoNessuna valutazione finora

- Vlentb0300a4 LR PDFDocumento16 pagineVlentb0300a4 LR PDFrizky efrinaldoNessuna valutazione finora

- Rishabh Engineering CS 51 Piping Stress Analysis of HeatersDocumento4 pagineRishabh Engineering CS 51 Piping Stress Analysis of Heatersrizky efrinaldoNessuna valutazione finora

- Asc0 327Documento6 pagineAsc0 327rizky efrinaldoNessuna valutazione finora

- Axenbr1001 PDFDocumento12 pagineAxenbr1001 PDFrizky efrinaldoNessuna valutazione finora

- Control Valves PositionerDocumento8 pagineControl Valves Positionerrizky efrinaldoNessuna valutazione finora

- 5.2.1 Cavitation InceptionDocumento22 pagine5.2.1 Cavitation InceptionPung Kang QinNessuna valutazione finora

- Ms ProofDocumento4 pagineMs Proofrizky efrinaldoNessuna valutazione finora

- E02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaDocumento6 pagineE02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaSALMANNessuna valutazione finora

- The Importance of Understanding A CommunityDocumento23 pagineThe Importance of Understanding A Communityra sNessuna valutazione finora

- Magazine 55 EnglishPartDocumento50 pagineMagazine 55 EnglishPartAli AwamiNessuna valutazione finora

- ADC MethodDocumento16 pagineADC MethodPhilip K MathewNessuna valutazione finora

- Jurnal Metode Pelaksanaan Top Down B.ing PDFDocumento7 pagineJurnal Metode Pelaksanaan Top Down B.ing PDFBayu SamiajiNessuna valutazione finora

- POOJA TRADING CO. Price List for FRP Manhole CoversDocumento1 paginaPOOJA TRADING CO. Price List for FRP Manhole Coversmitesh20281Nessuna valutazione finora

- Mobile Phone Addiction 12 CDocumento9 pagineMobile Phone Addiction 12 Cvedang agarwalNessuna valutazione finora

- Public Speaking RulesDocumento12 paginePublic Speaking RulesAnonymous 0ejRGUpmo1Nessuna valutazione finora

- School Uniforms Argumentative EssayDocumento6 pagineSchool Uniforms Argumentative Essayfllahvwhd100% (2)

- Mohit Chakrabarti - Value Education - Changing PerspectivesDocumento79 pagineMohit Chakrabarti - Value Education - Changing PerspectivesDsakthyvikky100% (1)

- TableDocumento9 pagineTableShamlakan elghaoucheNessuna valutazione finora

- VUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - LowDocumento56 pagineVUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - Lowarmandoa71565Nessuna valutazione finora

- EPABX User's Guide for Making Calls and Using FeaturesDocumento4 pagineEPABX User's Guide for Making Calls and Using FeaturesPraveen KumarNessuna valutazione finora

- Cylindrical Plug Gage DesignsDocumento3 pagineCylindrical Plug Gage DesignskkphadnisNessuna valutazione finora

- Preparation for the entrance examDocumento4 paginePreparation for the entrance examMinh ChâuNessuna valutazione finora

- SATA Product Manual: Standard ModelsDocumento32 pagineSATA Product Manual: Standard ModelsEdy AprilyantoNessuna valutazione finora

- Jason Cafer Biosketch 8-2009Documento3 pagineJason Cafer Biosketch 8-2009Jason CaferNessuna valutazione finora

- Big Data Analytics and Artificial Intelligence inDocumento10 pagineBig Data Analytics and Artificial Intelligence inMbaye Babacar MBODJNessuna valutazione finora

- Cities Words and Images From Poe To ScorseseDocumento266 pagineCities Words and Images From Poe To Scorsesejcbezerra100% (2)

- Hydro Cyclone: Centripetal Force Fluid ResistanceDocumento10 pagineHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahNessuna valutazione finora

- Kent Lawrence LORDAN Grade-1Documento1 paginaKent Lawrence LORDAN Grade-1Kent Lawrence LordanNessuna valutazione finora

- L1Documento7 pagineL1Francisco Roberto Trujillo LeonNessuna valutazione finora

- Simulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaDocumento3 pagineSimulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaKrisumraj PurkaitNessuna valutazione finora

- CH 07Documento40 pagineCH 07Ambreen31Nessuna valutazione finora

- Industrial Applications of Olefin MetathesisDocumento7 pagineIndustrial Applications of Olefin Metathesisdogmanstar100% (1)

- Chapter 2 - Key Themes of Environmental ScienceDocumento34 pagineChapter 2 - Key Themes of Environmental ScienceJames Abuya BetayoNessuna valutazione finora

- Atuador Ip67Documento6 pagineAtuador Ip67Wellington SoaresNessuna valutazione finora

- Unit 30 WorkDocumento2 pagineUnit 30 WorkThanh HàNessuna valutazione finora

- Accomplishment Report - English (Sy 2020-2021)Documento7 pagineAccomplishment Report - English (Sy 2020-2021)Erika Ikang WayawayNessuna valutazione finora

- PSP StompFilter Operation ManualDocumento26 paginePSP StompFilter Operation ManualMoving BackwardsNessuna valutazione finora