Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Introduction

Caricato da

Rajinder Maan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni4 paginenothing special

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentonothing special

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni4 pagineIntroduction

Caricato da

Rajinder Maannothing special

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

Introduction

When a solid is stretched, compressed, or deformed in some other way, it is said to

contain

a strain. To produce a strain in a solid one must apply some force to the solid, for

example by

pressing on its surface. Note that the word strain refers to the deformation, not to

the force

required to produce that deformation. The strain thus produced, will in general vary

as a function

of position within the body of the object. Thus, at every point within the body of the

object, we

can quantify the strain both by the magnitude of the stretching of the body at that

point and by

the direction and way in which it is stretching. At some points within the body the

strain may be

a pure elongation or compression of the material while at other points the strain

may be a shearing

deformation.

Strain is a measurement of deformation. However, if you apply a force to a larger

amount of

material, it will deform more than applying that force to a smaller amount of

material. We want

to know the material property that tells us how much a material will deform, thus

we must divide

our measured deformation by the amount of material to give us a unitless quantity.

Thus, strain is

defined as:

"=

_L

L

=

change in length

total length

(1)

The Youngs Modulus is given by the ratio of stress to strain for the stretching-type

strains

only. In other words, there is no shear involved. For example, the Youngs Modulus of

a particular

metal could be measured by subjecting a wire made of this metal to a stretching

force, as we do

in this lab. The ratio of the stress being applied to the resulting strain in the wire is

the Youngs

Modulus, Y. (By the way, the Poisson Ratio is the ratio of the relative length change

due to

stretching to the relative narrowing of the wire due to the stretching. We will not be

concerned

with the Poisson ratio in this lab.)

In the case of a stretched wire, the stress in the wire will be uniform and equal to

the ratio of

the applied force to the cross-sectional area of the wire:

_=

F

A

(2)

47

where F is the force applied in the direction you are measuring (in another direction

would

cause shear, which is delt with with other Moduluss but not in the Youngs Modulus

which we are

studying). Since the Youngs Modulus is stress over strain, then:

Y=

_

"

=

F/A

_L/L

(3)

Additional Notes:

_L (and therefore also the strain) will be negative for compression stresses and

positive for

tension stress.

Recall that Hookes law describes the amount of change in the length of a spring

as being

directly proportional to the force applied to it:

F = k_L (4)

Where F is the force exerted, _L is the amount of elongation or compression and k is

a

constant of proportionality that describes the stiffness of the spring. (The minus sign

is a

historical convention applied in to allow k to be positive.)

When considering the length change of a material, the Youngs Modulus relates the

stress and

the strain in the same way that Hookes constant relates elongation to force

_ = Y " (5)

In the case of a wire, Hookes constant of the wire is related to the Youngs Modulus

as follows

k=

F

_L

=

A_

L

(6)

Procedure

We will measure the change in length of a wire as it supports an ever increasing

load. In the

Youngs Modulus apparatus illustrated in Figure 1, a wire is suspended from the top

of the frame.

Masses are added to the mass-hanger attached to the bottom of the wire in order to

stretch the

wire. To ensure a well-functioning apparatus, you will need to familiarize yourself

with the bubblelevel

and micrometer assembly. Figure out how it works! In particular, figure out how the

various

parts move relative to one another and why.

1. Make a labeled diagram (not just an artists sketch) of the bubble-level and

micrometer assembly.

In a few sentences explain how the mechanism works, referring to the various parts

of the labeled diagram. Make sure you note which parts are free to move, pivot, turn

etc.

2. Once you are sure you understand how the mechanism works, check that it is

properly oiled

and that the screws, particularly the set screws supporting the pivoting plate are

correctly

adjusted. Make sure the cylinder holding the wire collet moves freely within the hole

through

the base plate (below the pivoting plate) and that it is not catching on the pin that

keeps the

cylinder from turning.

48

Figure 1: The Youngs Modulus apparatus.

3. Have a careful look at your wire. Make notes on any kinks, twists or other

imperfections you

may see.

4. Measure the wire diameter with a micrometer, avoiding any kinks in the wire.

Make several

measurements at various positions along the wire and find the average. Calculate

the area of

the wire.

5. With one kilogram of weight on the wire (e.g. just the large mass hanger itself),

measure the

total length L of the wire. Explain the purpose of this step.

6. With 1 kg still suspended by the wire, make a few practice measurements of the

micrometer

reading. Then, if needed adjust the vertical location of the sled holding the

micrometer and

bubble assembly until it is approximately level with 6 kilograms of suspended mass.

Make a

few more practice measurements and then remove all the suspended mass

including the mass

hanger.

7. First we will do a rough measurement run. Starting with a suspended mass of 1

kg (just the

large mass hanger), measure and record the wire extension as a function of

suspended mass

in increments of 2 kg or 3kg, until the suspended mass reaches 11 kg. In any case,

do not

exceed a total suspended mass of 12 kg as the wire may break. Note that the wire

extension

at a suspended mass of M is simply the micrometer reading at that suspended mass

minus

the initial micrometer reading (in this case with 1 kg suspended).

49

8. By hand, make a rough plot of wire extension _L versus suspended mass M. If it is

approximately

linear, draw a by-eye best-fit line through the data. Calculate the Youngs modulus

of the wire from the slope of the best-fit line.

9. Now we will do a much more careful measurement run. Starting with a mass of

approximately

0.05kg, measure the wire extension as a function of suspended mass between 0.05

kg and 1.0

kg in increments of no more than 0.05 kg (50 g). When you reach one kilogram,

change the

size of the increments to 0.2 kg, until you reach a total mass of 2 kg. Then change

the size

of the increments to 0.5 kg until you reach 12 kg. Do not exceed a total suspended

mass of

12 kg as the wire may break. Record the mass and corresponding length changes to

a table

with column headings: Suspended Mass, Length Change, Stress, and Strain.

10. Carefully plot stress versus strain with strain along the x-axis and stress along

the y-axis.

The slope of this will be the Youngs modulus for your material. Look up material

properties

and compare a standard Youngs modulus of steel to your experimental value.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Effects of Nonuniform Tire Contact Stresses On Pavement ResponseDocumento7 pagineEffects of Nonuniform Tire Contact Stresses On Pavement ResponseBarnali DebnathNessuna valutazione finora

- Epoxy Resin Admixture For ConcreteDocumento51 pagineEpoxy Resin Admixture For ConcretetarnoscribdNessuna valutazione finora

- An ABAQUS Tutorial by A Student For StudDocumento28 pagineAn ABAQUS Tutorial by A Student For StudsanthoshNessuna valutazione finora

- FunDBitS - Report D.1 - Fin PDFDocumento416 pagineFunDBitS - Report D.1 - Fin PDFprashant_cool_4_uNessuna valutazione finora

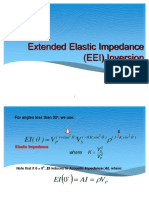

- Extended Elastic Impedance EEI Inversion PDFDocumento37 pagineExtended Elastic Impedance EEI Inversion PDFsonu420Nessuna valutazione finora

- Discussion I. Analyse and Differentiate Through A Brief Discussion Based On Data Obtained From Laboratory WorkDocumento5 pagineDiscussion I. Analyse and Differentiate Through A Brief Discussion Based On Data Obtained From Laboratory WorkZariff ZakiNessuna valutazione finora

- Annexa Flat-Slab Bridgeex 08102020Documento61 pagineAnnexa Flat-Slab Bridgeex 08102020Engr Aizaz AhmadNessuna valutazione finora

- LAB 11: UMT Elastic Bending Test: ObjectiveDocumento8 pagineLAB 11: UMT Elastic Bending Test: ObjectiveDrizzling ADNessuna valutazione finora

- Minefill 2020-21Documento450 pagineMinefill 2020-21ManuSachin100% (1)

- 2011 Bridge SarkadyDocumento17 pagine2011 Bridge SarkadyTan Duy LeNessuna valutazione finora

- AMT NU 1st Year Detail Syllabus Pub Date 30012019Documento20 pagineAMT NU 1st Year Detail Syllabus Pub Date 30012019hasan mdNessuna valutazione finora

- Linear Static Analysis of A Simply-Supported Truss: Workshop 7Documento22 pagineLinear Static Analysis of A Simply-Supported Truss: Workshop 7hfathollahiNessuna valutazione finora

- Design of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsDocumento71 pagineDesign of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsLavender HoneyNessuna valutazione finora

- Lee Jeeho ThesisDocumento163 pagineLee Jeeho Thesisclam2014Nessuna valutazione finora

- Structural Steel Design Columns For MSCEDocumento43 pagineStructural Steel Design Columns For MSCEIan100% (1)

- Influence of The Calender Pattern On The MechanicaDocumento183 pagineInfluence of The Calender Pattern On The MechanicautkayNessuna valutazione finora

- Designs Guide To en 1994-2, Eurocode 4Documento184 pagineDesigns Guide To en 1994-2, Eurocode 4Viet Duc Dang100% (3)

- Static - Non Linear Analysis (SOL 106) : Prepared By: Samartha H N Reviewed By: Date:08/08/2018Documento25 pagineStatic - Non Linear Analysis (SOL 106) : Prepared By: Samartha H N Reviewed By: Date:08/08/2018Vikas HNessuna valutazione finora

- 1304 3 PDFDocumento194 pagine1304 3 PDFHossein DoudiNessuna valutazione finora

- Design Aid For Unstiffened Triangular Steel Brackets Based On Elastic StabilityDocumento12 pagineDesign Aid For Unstiffened Triangular Steel Brackets Based On Elastic StabilitySid ShendgeNessuna valutazione finora

- Glass Transition Temperature of PolymersDocumento8 pagineGlass Transition Temperature of PolymersOsho AryanNessuna valutazione finora

- Soil Young's ModulusDocumento4 pagineSoil Young's ModulusHK KhooNessuna valutazione finora

- UntitledDocumento441 pagineUntitledLuan PhanNessuna valutazione finora

- Br. No. PierDocumento33 pagineBr. No. PierAnish ThakurNessuna valutazione finora

- Adina Crack 2 PDFDocumento50 pagineAdina Crack 2 PDFAdolfo Gálvez VillacortaNessuna valutazione finora

- (2018) Seyed Amid TahamiDocumento10 pagine(2018) Seyed Amid TahamiIlyas H. AliNessuna valutazione finora

- Sample - Calculation - Point Fix - Elizabeth House - Glass Bridge CalculationDocumento69 pagineSample - Calculation - Point Fix - Elizabeth House - Glass Bridge CalculationRonald RoblesNessuna valutazione finora

- Epm 952 As TPDocumento2 pagineEpm 952 As TPDaniel VillaflorNessuna valutazione finora

- Flat Rectangular Plate With Four Sides Fixed Under Uniform PressureDocumento4 pagineFlat Rectangular Plate With Four Sides Fixed Under Uniform PressureberylqzNessuna valutazione finora

- P.A. College of Engineering and Technology Palladam Road, Pollachi - 642 002 Department of Mechanical EngineeringDocumento26 pagineP.A. College of Engineering and Technology Palladam Road, Pollachi - 642 002 Department of Mechanical EngineeringRohit MunaNessuna valutazione finora