Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Watts Engelsk Web PDF

Caricato da

Darren ThoonTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Watts Engelsk Web PDF

Caricato da

Darren ThoonCopyright:

Formati disponibili

Wa t t s

Index

Premia 4

Kargo 6

Fmcx 8

Press on band 10

Specialised tyres 12

sHERPA 14

Hpt-qz4 16

DL-QZ1 18

Skid steer 20

Wheels 22

Urethane 24

Watts catalog / April 2009 3

Premia

one of the best

performing solid

resilient tyres

tyres in the industry

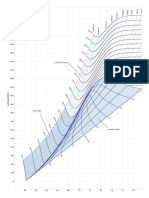

Premia from Watts is one of the best

performing solid tyres in the industry. 37.1

Enhanced performance of materials

40

handling E M IA machinery

OR* is

T S P R M P E T IT

WAT CO

A D IN G

increasingly being demanded in 35 key areas such as load, torque,

L E

20.5

acceleration and engine output, 3all

0 of which can be directly affected

by the right choice of tyre. 25

20.5

20.5

6.3

Watts has drawn upon its many 20 years of 1experience

12.9

and wealth

HOU

RS 7.6

of knowledge to produce what 1is5 considered to be one of the best

4.2

performing solid tyres in the industry

10 Premia. Recent independent WEAR

NT RATIO

tests prove conclusively that the5 Premia outperforms INED

A

Oother

MOU

F

AR

leading

%

REMAOVE D WE

TREA

tyres in areas such as wear, heat build

O R IGO V Eup and

H rolling resistance;

R O 007

IN A L G AN/2

DEPT d 25/J 12

0 checke : 700x

GRO TH /2006 re size

/AUG ANT Ty

DEP

this gives unrivalled running cost per hour ratios and reduced truck

e of te

t 08

st: starATSUKA

* Dat cation: H

IR

PL

Lo

downtime.

Best for wear

Best for energy efficiency

Best for stability

Best for driver comfort

Test

Best for reduced heat build up Field

E M IA R*

T S P R M P E T IT O

WAT

IN G CO

1251 LE A D

20.5

20.5

16.3

12.9

7.6

691

4.2

UNT

AMO F

O AR

INED D WE

REMAOVE T R E Am m

IN A L GRO TH

O R IGO V E DEP

GRO TH mm

DEP 007

WEAR /JAN/2

LIFE

mm ed 25

check

hours /2006

/AUG 00x12

art 08yre size: 7

moving on success of te st st T

* Date

www.industrialtyre.com the ultimate solid tyre

4 Watts catalog / April 2009

specifications

one of the best

performing solid

resilient tyres

tyres in the industry

Size Rim Width Tread Tyre loadings to E.T.R.T.O Nominal

Pattern Load wheels Steer wheels Dimensions

up to up to Overall Overall

16kph 25kph Width Diam.

kg kg mm mm

15 x 41/2 - 8 * 2.50 / 3.00 RIB 1040 800 115 380

15 x 41/2 - 8 3.00 TIB 1040 800 115 380

5.00-8 3.00 TIB 1415 1090 121 451

16 x 6-8 4.33 R-8 TIB 1270 975 151 412

18 x 7-8 4.33 R-8 TIB 2145 1650 146 457

specifications

140/55 - 9 4.00 E-9 TIB 1170 900 130 381

6.00-9 4.00 E-9 TIB 1885 1450 142 528

21 x 8-9 6.00 E-9 TIB 2755 2120 188 516

200/50-10 6.50 F-10 TIB 2470 1900 194 457

23 x 9-10 6.50 F-10 TIB 3160 2430 208 583

6.50-10 5.00 F-10 TIB 2340 1800 165 571

23 x 10-12 8.00 G-12 TIB 3770 2900 230 575

27 x 10-12 8.00 G-12 TIB 3900 3000 230 676

7.00-12 5.00 S-12 TIB 2920 2240 168 657

7.00-15 5.5 - 15 TIB 3545 2725 186 723

28 x 9-15 (8.15 -15) 7.0 - 15 TIB 3445 2650 206 700

8.25-15 6.50 TIB 4750 3650 203 813

28x12.5-15 9.75 - 15 TIB 5525 4250 287 692

250-15 7.0/7.5 - 15 TIB 4745 3650 211 713

300-15 8.0 - 15 TIB 5850 4500 241 814

355/65-15 9.75 - 15 TIB 7800 6000 300 818

All sizes available in Standard and Limpet except ( * ) 15x4.5-8 2.50 RIB ( Standard only )

All specifications are in accordance with E.T.R.T.O (European Tyre and Rim Technical Organisation)

TIB RIB

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 5

KARGO

the most popular and

well established solid

resilient tyres

tyre in the industry

Kargo from Watts is one of the most

popular and well established solid

tyres in the industry.

The Kargo is a three compound, all natural rubber solid

tyre. Excellent durability and performance make it a firm

favourite across a wide range of applications. Features

include creel bead technology in the base to prevent

slippage on the rim, a rolling rib increasing tyre footprint

as well as reducing rolling resistance. The Kargo is a high

performing tyre that remains the industrys favourite.

Excellent for wear

Excellent for energy efficiency

Excellent for cost ownership ratios

Excellent for choice, one of the widest ranges

in the industry

moving on success

www.industrialtyre.com the industry favourite

6 Watts catalog / April 2009

specifications

Size Rim Width Tread Tyre loadings Nominal Size Rim Width Tread Tyre loadings Nominal

Pattern to E.T.R.T.O Dimensions Pattern to E.T.R.T.O Dimensions

16kph 25kph Overall Overall 16kph 25kph Overall Overall

Load Steer Width Diam. Load Steer Width Diam.

kg kg mm mm kg kg mm mm

3.00-4 2.10/2.50-4 L 260 195 86 254 28x9-15 (8.15-15) *7.0-15 K2 3445 2650 218 699

3.00-4 2.50C-4 R 260 195 86 254 250-15 *7.0/*7.5-15 K2 4745 3650 255 724

4.00-4 2.10/2.50-4 L 525 410 98 300 7.50-15 5.0-15 L 3705 2850 190 762

380x115-8 2.50/3.00-8 R 1040 800 115 380 7.50-15 5.5-15 K2 3705 2850 190 762

resilient tyres

4.00/75-8 2.50/3.00-8 P 750 575 108 355 7.50-15 6.0/*6.5-15 L 3900 3000 216 762

4.00-8 2.50C-8 L,R 950 730 102 413 32x7.50-15 5.5-15 L 4530 3485 216 826

4.00-8 3.00D-8 K2,L,R 950 730 103 406 8.25-15 5.0/5.5-15 L 4530 3485 216 826

4.00 -8 3.25-8 L 950 730 121 413 8.25-15 6.0-15 L 4750 3650 216 826

4.00-8 3.75 R 950 730 130 409 8.25-15 *6.5-15 K2 4750 3650 203 818

15x4.5-8 *3.00/*3.25-8 R 1040 800 114 394 300-15 *8.0-15 K2 5850 4500 259 818

16x6-8 *4.33R-8 K2 1270 975 157 408 300-15 8.0-15 P 5850 4500 250 805

17x7-8 4.33R-8 P 1930 1485 156 432 350-15 (32x12.1-15) *9.75-15 K2 7085 5450 302 825

5.00-8 3.00/3.25-8 R 1415 1090 127 457 (355/65-15)

5.00-8 *3.00/*3.25-8 K2 1415 1090 128 452 **6.00-16 4.5-16 L 1815 1395 165 711

5.00-8 3.50-8 L 1415 1090 128 452 **6.50-16 5.5-16 M,P 2600 2000 187 749

18x7-8 *4.33R-8 K2,P 2145 1650 156 457 **7.50-16 5.5-16 L 3965 3050 216 819

18x9-8 7.00E-8 L,P 2470 1900 211 457 **7.50-16 6.0/6.5-16 L 3965 3050 235 826

6.00-9 *4.00E-9 K2,R 1885 1450 150 527 **8.00-16 5.5-16 M,P 3965 3050 206 825

7.00-9 4.33-9 L 2340 1800 168 547 **9.00-16 5.5-16 M,P 4200 3350 229 832

22x9 6.50-9 L 2630 2020 232 565 355/50-20 10.00-20 K2 8970 6900 303 833

21x8-9 *6.00E-9 K2 2760 2120 201 528 7.50-20 6.0-20 L 3875 2980 203 895

200/50-10 *6.50F-10 K2 2470 1900 191 455 7.50-20 6.5-20 S 4150 3190 238 889

specifications

23x9-10 *6.50F-10 K2 3160 2430 212 582 7.50-20 7.5-20 S 4150 3190 238 889

6.50-10 5.00/5.50F-10 R 2340 1800 187 565 8.25-20 6.5/7.0/7.5-15 L 4380 3650 226 955

6.50-10 *5.00F-10 K2 2340 1800 170 568 8.25-20 7.0-15 K2 4380 3650 226 955

7.50-10 5.00/5.50F-10 L 3070 2360 187 622 9.00-20 6.5/7.0-15 K2 5400 4500 241 972

8.25-10 5.00F-10 L 3175 2440 184 667 10.00-20 6.5-20 L 5850 4875 254 1054

6.00-12 5.00S-12 P 2505 1925 187 584 10.00-20 7.0/7.5/8.0-20 L 6000 5000 254 1054

6.00-12 5.00S-12 L 2505 1925 187 622 10.00-20 7.5/8.0-20 M 6000 5000 254 1003

23x9-12 6.50-12 P 2505 1925 235 584 10.00-20 7.5/8.0-20 P 6000 5000 254 1003

23x10-12 *8.00G-12 K2 3770 2900 234 584 10.00-20 7.0/7.5/8.0-20 K2 6000 5000 250 996

7.00-12 *5.00S-12 K2 2920 2240 179 663 11.00-20 8.0/8.5-20 B,P 6540 5450 279 1095

7.00-12 6.50-12 L 3785 2910 210 660 12.00-20 8.0/8.5-20 B,P 7560 6300 279 1095

27x10-12 *8.00G-12 K2 3900 3000 241 673 12.00-20 10.0-20 B,P 7800 6500 380 1095

8.25-12 5.00S-12 L 3440 2645 191 718 12.00-24 8.5-20 B 8040 6700 288 1190

23x5 3.75P-13 L 1495 1150 159 629 12.00-24 10.0-20 B 9000 7500 326 1190

26 x 8.5-15 7.0-15 R 6000 4615 219 656 14.00-24 10.0-24 B 11100 9250 332 1320

7.00-15 5.0/6.0/6.5-15 L 3545 2725 198 724

7.00-15 *5.5-15 K2 3545 2725 198 724

7.00LP-15 6.0/6.5-15 L 3545 2725 206 685

8.15-15 6.5-15 L 3445 2650 210 705

(28x9-15)

R P B L

*Available as LIMPET

** Available with or without creel bead wires suitable for skid steer loaders

(LP) = Low Profile, signifies smaller outside diameter for specific fork lift brands

All specifications are in accordance with ETRTO (European Tyre and Rim Technical Organisation)

S M K2

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 7

Fmcx

the cost effective

high performance

resilient tyres

solid tyre

FMCX is a high performance, cost

effective tyre, designed to meet

performance requirements across

a wide range of applications.

The FMCX has been designed to provide a high

performance solid tyre solution at a cost effective

price. Unlike other tyres in its class the FMCX is a three

compound, natural rubber construction, where build

quality has not been compromised to meet price

expectations. Suitable across a wide range of applications

the FMCX delivers outstanding performance and value.

3 compound, 100% natural rubber content

High levels of wear, comfort

and energy efficiency

Creel bead wires to prevent rim slippage

Available in all popular sizes and compounds

Cross section of FCMX tyre

Tread compound

Sidewall

protection layer Centre compound

Base compound

High tensile creel bead wires

moving on success

www.industrialtyre.com value you can trust

8 Watts catalog / April 2009

specifications

the cost effective

high performance

resilient tyres

solid tyre

Size Rim Width Tread Tyre loadings to E.T.R.T.O Nominal

Pattern Load wheels Steer wheels Dimensions

up to up to Overall Overall

16kph 25kph Width Diam.

kg kg mm mm

*4.00-8 3.00 RIB 950 730 99 409

*4.00-8 3.00 QZ4 950 730 102 400

15x4.5-8 3.00 / 3.25 RIB 1040 800 102 378

specifications

15x4.5-8 3.00 / 3.25 QZ4 1040 800 109 375

5.00-8 3.00 QZ4 1415 1090 124 444

16x6-8 4.33 QZ4 1270 975 138 409

18x7-8 4.33 QZ4 2145 1650 144 456

6.00-9 4.00 QZ4 1885 1450 133 520

21x8-9 6.00 QZ4 2755 2120 188 526

200/50-10 6.50 QZ4 2470 1900 194 453

6.50-10 5.00 QZ4 2340 1800 151 564

23x9-10 6.50 QZ4 3160 2430 197 568

23x10-12 TBA QZ4 3770 2900 available from July 2008

7.00-12 5.00 QZ4 2920 2240 166 650

27x10-12 8.00 QZ4 3900 3000 246 660

7.00-15 5.50 QZ4 3545 2725 167 714

7.50-15 5.50 / 6.50 QZ4 3900 3000 192 732

28x9-15 7.00 QZ4 3445 2650 204 686

250-15 7.00 / 7.50 QZ4 4745 3650 208 710

300-15 8.00 QZ4 5850 4500 251 808

350-15 (355/65-15) 9.75 QZ4 7085 5450 295 811

8.25-15 6.50 QZ4 4750 3650 206 801

*10.00-20 7.50 / 8.00 LB105 6000 5000 249 1013

*11.00-20 8.50 LB105 6540 5450 276 1075

*12.00-20 8.00 / 8.50 LB105 7560 6300 276 1075

All sizes have 3 part construction

All sizes available in Limpet except those marked ( * )

All specifications are in accordance with E.T.R.T.O (European Tyre and Rim Technical Organisation)

QZ4 RIB LB105

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 9

Press on band

a powerful high

performance

industrial tyre

press on band

press on band

Watts are a world leader in

press-on-band tyres with a

comprehensive range of sizes,

treads and compounds designed

to meet customer requirements.

We have an extensive range of size and tread pattern

options to suit most major OEM applications and operating

environments. We place particular design emphasis on

producing tyres with a large footprint, square profile, low

heat build up and low rolling resistance.

Watts press-on-band tyres are also available in special

compounds such as non-marking white, wet grip

and electrically conducting for specialist operating

environments.

High load capacity

Square tread profile

Low rolling resistance

Good stability

moving on success

www.industrialtyre.com

10 Watts catalog / April 2009

specifications

Size Pattern Fork Lift at 16 Km/h Size Pattern Fork Lift at 16 Km/h

Inches Metric Equiv. Load Steer Inches Metric Equiv. Load Steer

Kg Kg Kg Kg

9 x 5-5 229x127-127 P 855 715 21x8-15 533x203-381 P, C 3025 2540

10.1/2x6-5 267x153-127 C 1245 1050 21x9-15 533x228-381 C, P 3475 2920

10x5-6 3/16 254x127-157 P 940 790 20x3 -16 508x89-406 P 980 825

10x3-6 254x76-159 P 465 395 20x8-16 508x203-406 P, C 2690 2260

10x4-6 254x102-159 P 700 590 20x9-16 508x228-406 P, C 3070 2580

10x5-6 254x127-159 P 915 770 22x6-16 559x153-406 P, F 2180 1830

10x6-6 254x153-159 P 1135 950 22x7-16 559x178-406 C, F 2650 2230

10x7-6 254x178-159 P 1410 1180 22x8-16 559x203-406 C, P 3130 2625

10x4-6 254x102-165 P 705 590 22x9-16 559x228-406 P, C 3600 3025

10x5-6 254x127-165 P 935 780 22x10-16 559x254-406 P, F 4080 3425

press on band

10 x 4-6 267x102-165 P 730 615 22x12-16 559x305-406 C, P 5030 4225

10 x 5-6 267x127-165 P 960 810 22x14-16 559x356-406 P 5990 5030

10 x 6-6 267x153-165 P 1190 1000 22x16-16 559x406-406 P 6930 5820

11x4-6 279x102-165 P 755 635 24x6-16 610x153-406 P 2240 1880

12x3 - 8 305x89-203 P 675 565 22x6-17 559x153-451 P 2150 1805

12x4-8 305x102-203 P 805 675 22 x 8-17 559x203-451 P 3035 2550

12x5-8 305x127-203 P, F 1065 890 26x6-20 660x153-508 P, C 2470 2075

13x3 -8 330x89-203 P 700 590 28x10-22 711x254-559 P 4985 4200

13x4 -8 330x114-203 P 1025 880 28x12-22 711x305-559 P 6175 5190

13x5-8 330x127-203 C, P 1150 965 28x14-22 711x356-559 P 7365 6190

13 x 3 -8 343x88-203 C 675 565 28x14-22 711x356-559 P 7367 6190

13 x 4 -8 343x114-203 C 1025 860 28x16-22 711x406-559 P 8310 6985

13 x5 -8 343x140-203 P, F 1345 1130 36x12-30 914x305-762 P 7285 6115

14x4 -8 356x114-203 P, C 1045 875 250x130-140 F, P 950 800

12 x 5-9 318x127-229 P 1105 930 230x75-170 P 400 340

13 x 110-10 330x110-254 P 900 760 230x85-170 P 465 390

13 x 5-10 330x127-254 P 1115 935 250x80-170 P 550 460

15 x 5-10 394x127-254 C 1315 1100 250x105-170 P 695 580

15 x 6-10 394x153-254 C 1665 1400 250x85-190 F, P 515 430

16 x 5-10 406x127-267 P, C 1345 1130 265x85-190 F, P 620 515

16 x 6-10 406x153-267 P, C 1710 1435 265x100-190 P 765 645

16 x 7-10 406x178-267 C, P 2070 1740 300x180-203 P 1565 1315

15 x 3 -11 381x89-286 P 800 670 280x75-220 P 530 445

15 x 5-11 381x127-286 P, C 1240 1040 365x160-220 P 1680 1410

15 x 6-11 381x153-286 P, C 1590 1340 380x160-220 P 1740 1465

16 x 5-11 413x127-286 P, C 1360 1145 360x85-270 P 795 665

16 x 6-11 413x153-286 P, C 1715 1440 405x130-305 P 1380 1160

16 x 7-11 413x178-286 C, P 2060 1735 405x220-305 P 2580 2165

16x4 -12 406x114-305 P 1170 980 405x260-305 P 2970 2495

16x3-12 1/8 406x76-308 P 665 555 425x150-305 P 1760 1485

16x3 -12 1/8 406x89-308 P 860 720 425x200-305 P 2470 2075

16x4-12 1/8 406x102-308 P 1000 840 425x260-305 P 3235 2720

16x5-12 1/8 406x127-308 P 1310 1100 425x300-305 P 3790 3185

17x5-12 1/8 432x127-308 C, P 1400 1180 450x300-305 P 4145 3480

17x6-12 1/8 432x153-308 C, P 1770 1485 410x90-308 P 945 790

18x5-12 1/8 457x127-308 C, P 1470 1230 410x115-308 P 1175 985

18x6-12 1/8 457x153-308 C, P 1870 1575 525x120-370 P 1455 1225

18x7-12 1/8 457x178-308 C, P 2280 1910 500x120-400 P 1270 1080

18x8-12 1/8 457x203-308 C, P 2680 2250 540x200-410 P 2975 2495

18x9-12 1/8 457x228-308 C, P 3090 2600 550x160-410 P 2280 1915

20x8-15 508x203-381 P, C 2825 2375 645x250-410 P 4685 3955

20x9-15 508x228-381 C 3240 2720 645x300-410 P 5275 4330

21x5-15 533x127-381 C 1640 1385 660x203-480 F, P 3615 3075

21x6-15 533x153-381 C 2100 1765 660x250-480 F, P 4160 3415

21x7-15 533x178-381 P, C 2560 2150 660x280-480 P 4765 3915

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 11

Specialised tyres

specialised tyres

for specific

environments

NON MARKING

special compounds

Non marking tyres are Watts most popular special compound product with

demand being driven by growth in food and pharmaceutical industries and the

corresponding increase in the need for clean warehouse environments. The

sidewall and tread compounds eliminate black driving marks as well as delivering

an excellent tyre performance in keeping with the entire Watts range.

ELECTRICALLY CONDUCTING

This compound is designed for use in operating environments where there is a

significant threat posed by fire or explosion such as munitions stores, firework

factories or petrochemical storage facilities. It gives an upper resistance limit of

500,000 ohms conforming to BS 2050/ISO 2883.

WETGRIP

This compound is designed to provide tyres with maximum traction properties

when in wet or slippery ground conditions such as dock yards, port areas,

abattoirs or outdoors areas during prolonged wet weather.

HEAT RESISTANT

This compound is designed for use where applications will encounter hot

materials such as in smelting plants and foundries. Like all Watts tyres, the

design and build also lead to reduced heat build up within the tyre which

helps to extend tyre life, even in these harsh environments.

moving on success

Other special compounds can be formulated in conjunction with Watts rubber technologists

www.industrialtyre.com and Tyre designers. All special compounds carry varying levels of price premium.

12 Watts catalog / April 2009

specialised tyres

for specific

environments

non marking

special compounds

Non Marking tread area with silica based Caution Watts Non

compound guaranteeing increased tread life Marking tyres do not permit

the inclusion of conductive

Three part compound construction for

a smoother ride, reduced heat build up components making the

and enhanced stability tyres electrostatically non-

conductive. If fitted in

Non Marking sidewall protection

environments where flammable

or explosive materials are

High tensile creel beads for increased

torque ensuring a safe and secure

present, anti static ground

fitment onto the wheel straps to earth the vehicle

should always be used.

wet grip

The results below show the average stopping distance comparing

standard compound with Watts Wet Grip compound.

No Load 500kg Load 1000kg Load 1700kg Load

Standard Wet Grip Standard Wet Grip Standard Wet Grip Standard Wet Grip

Compound Compound Compound Compound Compound Compound Compound Compound

Average stopping

distance over four 5.99m 3.1m 4.28m 2.71m 3.78m 2.7m 3.29m 1.95m

runs in metres

Wet Grip Results* 48% improvement 37% improvement 29% improvement 40% improvement

Typical Advantages of Wet Grip: Ground conditions heavy rain

Truck 2 tonne electric

Front tyre 23 x 9-10 Kargo K2

Rear tyre 18 x 7-8 Kargo K2

* The above are typical results over four controlled braking runs

electrically conducting

Caution Prolonged use of Watts Electrically Conducting Tyres in areas where

materials are present that cause swelling (ie oil, solvents) reduces the conductivity.

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 13

SHERPA

born to lead,

pneumatic tires

built to last

Born to lead, built to last

Sherpa is our premium industrial pneumatic tire. Sherpa has

been specifically designed to be a market leading tire; combining

the ultimate in design, construction and materials.

Sherpa offers exceptional longevity through its robust

construction, intelligent tread design and unique tread compound

whilst also delivering superb performance and load carrying

capacity. Extensive field and laboratory tests have proved that

Sherpa outperforms its competitors offering exceptional per

hour and whole life costs.

Available in a range of sizes and ply ratings Sherpa is quickly

becoming the benchmark by which other premium industrial

pneumatic tyres are measured.

Outstanding longevity

Outstanding cost of ownership over whole life

Outstanding load carrying capability

Outstanding resistance to punctures

www.industrialtyre.com

14 Watts catalog / April 2009

specifications

born to lead,

pneumatic tires

built to last

Size Ply Dimensions Inflated Inflation Load Capacity Load Capacity Static

Rim Section Dimensions Pressure Fork Lift Truck Use Fork Lift Truck Use Load

+/-2% (mm) +/- 15% Up to 25 kmh Up to 35 kmh (Kg)

Recommended Alternative Overall Width Overall Diameter BAR Drive Steer Drive Steer

5.00 - 8 10 3.00D 3.25F 143 476 10.00 1415 1090 1363 1008 1646

16 x 6 - 8 16 4.33R - 164 434 10.00 2225 1710 1438 1064 1737

18 x 7 - 8 16 4.33R 5.00F 187 471 10.00 2145 1650 2063 1526 2492

6.00 - 9 10 4.00E - 173 551 8.50 1715 1320 1650 1221 1993

6.00 - 9 12 4.00E - 173 551 10.00 1885 1450 1813 1341 2190

21 x 8 - 9 16 5.00E - 216 546 10.00 2756 2120 2650 1961 3201

specifications

6.50 - 10 12 5.00F 5.50F 191 600 9.00 2145 1650 2063 1526 2492

7.00 - 12 14 5.00S - 207 685 9.00 2756 2120 2650 1961 3201

27 x 10 - 12 20 8.00G - 275 704 10.00 4615 3550 4440 3285 5360

7.00 - 15 14 5.50 5.00 213 761 9.00 3350 2575 3219 2382 3888

7.50 - 15 16 6.00 6.50 229 787 10.00 3900 3000 3750 2775 4530

8.25 - 15 16 6.50 7.00 253 853 9.25 4615 3550 4438 3284 5361

250 - 15 20 7.50 7.00 270 750 10.00 5730 3875 4844 3584 5851

300 - 15 20 8.00 - 324 857 9.00 6500 5000 6250 4625 7550

28 x 9 - 15 16 7.00 - 233 721 10.00 4095 3150 3938 2914 4757

32 x 12.1 - 15 24 9.75 - 338 879 10.00 7800 6000 7500 5550 9060

10.00 - 20 20 7.50 8.00 300 1104 10.00 6660 5120 6400 4736 7731

12.00 - 20 20 8.50 8.00 340 1181 8.25 7750 6588 7363 5765 9948

12.00 - 20 24 8.50 8.00 340 1181 9.65 8500 7225 8075 6322 10910

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 15

Hpt-qz4

superior quality

& driver comfort

hpt-qz4

pneumatics

The Watts HTP-QZ4 is a premium

quality, high performance industrial

pneumatic tyre, manufactured to the

highest specification using the latest

in rubber compounding technology.

The HTP-QZ4 features a heavy duty cross-ply construction with

a tough undertread and bead area. It has a reinforced sidewall to

give additional puncture protection and lower deflection than

other tyres in its class.

With its robust construction and wide profile the HTP QZ4

represents an advanced pneumatic option for todays industrial

tyre market.

Superior puncture protection

Excellent driver comfort

High resistance to sidewall damage

Lower deflection

moving on success

www.industrialtyre.com

16 Watts catalog / April 2009

specifications

Size Ply Dimensions Inflated Inflation Load Capacity Nominal Static

Rim Section Dimensions Pressure Fork Lift Truck Use Dimensions Loads

+/-2% (mm) +/- 15% Up to 25 kmh Up to 35 Kmh (Kg)

Recommended Alternative Section Width O.D. BAR Drive Steer Drive Steer

5.00 x 8 8 3.00D 3.25F 155 485 8.25 1235 950 1190 880 1435

5.00 x 8 10 3.00D 3.25F 155 485 10.00 1415 1090 1365 1010 1645

16 x 6 - 8 16 4.33R - 155 415 10.00 2225 1710 2140 1580 2580

18 x 7 -8 14 4.33R 5.00F 180 460 9.00 1885 1450 1815 1340 2190

18 x 7 - 8 16 4.33R 5.00F 180 460 10.00 2145 1650 2065 1525 2490

6.00 x 9 10 4.00E - 176 536 8.50 1715 1320 1650 1220 1995

6.00 x 9 12 4.00E - 176 536 10.00 1885 1450 1815 1340 2190

21 x 8 - 9 14 5.00E - 214 532 9.00 2535 1950 2437 1803 2945

21 x 8 - 9 16 5.00E - 220 535 10.00 2756 2120 2650 1961 3200

pneumatics

21 x 8 - 9 18 6.00E 7.00E 220 535 10.00 3020 2320 2900 2145 3500

6.50 x 10 10 5.00F 5.50F 190 585 7.25 1950 1500 1875 1390 2265

6.50 x 10 12 5.00F 5.50F 190 585 9.00 2110 1705 1985 1490 2575

6.50 x 10 14 5.00F 5.50F 190 585 10.00 2340 1800 2250 1665 2718

7.00 x 12 12 5.00S - 205 675 8.50 2678 2060 2575 1905 3110

7.00 x 12 14 5.00S - 205 675 9.00 2756 2120 2650 1961 3201

7.00 x 12 16 5.00S - 205 675 10.00 2912 2240 2800 2072 3382

23 x 9 - 10 14 6.50F 7.00 240 575 7.00 2756 2120 2650 1961 3200

23 x 9 - 10 16 6.50F 7.00 240 575 8.00 2990 2300 2875 2128 3473

23 x 9 - 10 18 6.50F 7.00 240 575 9.00 3159 2430 3037 2248 3670

23 x 9 - 10 22 7.00 - 240 585 10.50 3460 2660 3220 2460 4015

23 x 10.1 - 12 18 8.00G - 260 595 9.00 3385 2605 3110 2410 3935

23 x 10.1 - 12 22 8.00G - 260 595 10.25 4545 3495 4370 3235 5280

27 x 10 - 12 16 8.00G - 270 690 8.00 3900 3000 3750 2775 4530

27 x 10 - 12 18 8.00G - 270 690 9.00 4225 3250 4062 3006 4908

27 x 10 - 12 20 8.00G - 270 690 10.00 4615 3550 4440 3285 5360

5.50 x 15 8 4.50E - 157 670 7.25 1950 1445 1806 1336 2181

5.50 x 15 10 4.50E - 157 670 8.25 2070 1530 1912 1415 2310

7.00 x 15 12 5.50 5.00 195 723 8.25 3070 2360 2180 2360 3560

7.00 x 15 14 5.50 5.00 200 740 8.25 3070 2360 2950 2185 3565

7.00 x 15 16 5.50 5.00 200 740 9.00 3350 2575 3220 2380 3890

7.50 x 15 12 6.00 6.50 215 785 8.00 3445 2650 3312 2451 4000

7.50 x 15 14 6.00 6.50 215 785 9.25 3640 2800 3500 2590 4230

7.50 x 15 16 6.00 6.50 215 785 10.00 3900 3000 3750 2775 4530

28 x 9 - 15 (8.15 x 15) 12 7.00 - 220 710 7.00 2730 2100 2625 1945 2100

28 x 9 - 15 (8.15 x 15) 14 7.00 - 220 710 8.00 2958 2275 2845 2105 2275

28 x 9 - 15 (8.15 x 15) 16 7.00 - 220 710 9.00 3170 2440 3050 2255 2440

8.25 x 15 12 6.50 7.00 255 835 7.00 3900 3000 3750 2775 4530

8.25 x 15 14 6.50 7.00 255 835 8.00 4225 3250 4065 3005 4910

8.25 x 15 16 6.50 7.00 255 835 9.25 4615 3550 4440 3285 5360

250 - 15 16 7.50 - 231 725 8.25 4355 3350 4187 3098 5060

250 - 15 18 7.50 - 231 725 9.50 4745 3650 4560 3375 5510

250 - 15 20 7.50 7.00 245 735 10.00 5037 3875 4843 3584 5851

250 - 15 26 7.50 7.00 245 735 8.25 4355 3350 4190 3100 5060

28 x 12.5 - 15 24 9.75 - 305 705 10.00 6015 4625 5780 4280 5700

300 - 15 20 8.00 - 280 810 9.00 6500 5000 6250 4625 7550

32 x 12.1 - 15 24 9.75 - 320 805 10.00 7800 6000 7500 5550 7440

355/65 - 15 24 9.75 - 350 834 10.00 7800 6000 7500 5550 9060

300/75 - 15 18 8.00 - 300 840 7.50 5850 4500 5625 4160 6795

300/75 - 15 20 8.00 - 300 840 9.00 6500 5000 6250 4625 7550

10.00 x 20 16 7.50 8.00 300 1065 9.00 6000 5000 5750 4625 7550

10.00 x 20 20 7.50 8.00 300 1065 10.25 6660 5120 6400 4740 7730

12.00 x 20 16 8.50 8.00 335 1130 9.00 7500 6250 7500 5800 9440

12.00 x 20 20 8.50 8.00 335 1130 10.25 8250 6850 8250 6400 10345

PLEASE NOTE THAT IT IS VITALLY IMPORTANT THAT INFLATION PRESSURES

ARE MAINTAINED AND CHECKED ON A REGULAR BASIS.

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 17

dl-qz1

value and

performance

dl-qz1

pneumatics

The DL-QZ1 from Watts offers excellent

value featuring an advanced tread

design which combines good traction

with exceptional performance.

Watts have developed this tyre as a cost effective, good

performing pneumatic tyre option to meet requirements from

the global forklift market. Our reputation for proven product

dependability, advanced tyre design and the highest standards

of manufacturing quality are all embodied in this tyre.

Available in a wide range of sizes and ply ratings the DL-QZ1

provides value and performance every time.

Good driver comfort

Good traction

Combines value with performance

moving on success

www.industrialtyre.com

18 Watts catalog / April 2009

specifications

value and

performance

Size Ply Weight Tread Rim Inflated Dimensions Inflation Load Capacity Ref Load

Rating Pattern Pressure For Counterbalanced Lift Trucks

pneumatics

Section Section +/- 15% BAR Up to 25Kph Up to 35 Kph

Height Width Load Steer Load Steer

4.00 x 8 8 5.00 QZ1 2.50/3.25-8 415 112 9.00 870 670 840 620 670

4.00 x 8 10 5.00 QZ1 2.50/3.25-8 415 112 10.00 950 730 915 675 730

5.00 x 8 8 6.5 QZ1 3.00/3.50-8 470 137 8.25 1235 950 1190 880 950

5.00 x 8 10 6.5 QZ1 3.00/3.50-8 470 137 10.00 1415 1090 1365 1010 1090

18 x 7 - 8 14 10.00 QZ1 4.33-8 465 173 9.00 1885 1450 1815 1340 1450

18 x 7 - 8 16 10.00 QZ1 4.33-8 465 173 10.00 2145 1650 2065 1525 1650

6.00 x 9 10 10.2 QZ1 4.00-9 540 160 8.50 1715 1320 1650 1220 1320

6.00 x 9 12 10.2 QZ1 4.00-9 540 160 10.00 1885 1450 1815 1340 1450

7.00 x 9 10 14.4 QZ1 4.33-9 590 190 8.50 2140 1645 2055 1520 1645

7.00 x 9 12 14.4 QZ1 4.33-9 590 190 9.70 2366 1820 2275 1685 1820

21 x 8 - 9 14 12.7 QZ1 5.00 E 535 200 9.00 2535 1950 2437 1803 1950

21 x 8 - 9 16 12.7 QZ1 6.00 E 535 200 10.00 2756 2120 2650 1961 2120

6.50 x 10 10 13.4 QZ1 5.00/5.50-10 590 175 7.75 1950 1500 1875 1390 1500

6.50 x 10 12 13.4 QZ1 5.00/5.50-10 590 175 9.00 2145 1650 2065 1525 1650

6.50 x 10 14 13.4 QZ1 5.00 F 590 175 10.00 2340 1800 2250 1665 1800

23 x 9 - 10 12 17.5 QZ1 6.50 F 595 225 5.75 2405 1850 2312 1711 1850

23 x 9 - 10 14 17.5 QZ1 6.50 F 595 225 7.00 2756 2120 2650 1961 2120

23 x 9 - 10 16 17.5 QZ1 6.50 F 595 225 8.00 2990 2300 2875 2128 2300

23 x 9 - 10 18 17.5 QZ1 6.50 F 595 225 9.00 3159 2430 3037 2248 2430

7.50 x 10 12 18.00 QZ1 5.00/5.50-10 645 205 8.00 2680 2060 2575 1905 2060

7.00 x 12 12 18.00 QZ1 5.00/6.50-12 676 190 8.50 2680 2060 2575 1905 2060

7.00 x 12 14 18.00 QZ1 5.00/6.50 -12 676 190 9.00 2755 2120 2650 1960 2120

8.25 x 12 12 23.7 QZ1 5.00-12 728 210 7.50 3245 2495 3120 2310 2495

27 x 10 - 12 12 23.3 QZ1 8.00-12 690 255 6.00 3250 2500 3125 2315 2500

27 x 10 - 12 14 23.3 QZ1 8.00-12 690 255 7.00 3640 2725 3405 2520 2725

27 x 10 - 12 16 23.3 QZ1 8.00-12 690 255 8.00 3900 3000 3750 2775 3000

7.00 x 15 10 22.5 QZ1 5.00/6.50-15 750 200 7.00 2745 2110 2640 1950 2110

7.00 x 15 12 22.5 QZ1 5.00/6.50-15 750 200 8.25 3070 2360 2950 2185 2360

7.00 x 15 14 22.5 QZ1 5.00/6.50-15 750 200 9.00 3380 2600 3250 2405 2600

7.50 x 15 10 23.7 QZ1 5.00/6.50-15 780 215 6.50 2958 2275 2845 2105 2275

7.50 x 15 12 23.7 QZ1 5.00/6.50-15 780 215 8.00 3445 2650 3315 2450 2650

7.50 x 15 14 23.7 QZ1 5.00/6.50-15 780 215 9.25 3640 2800 3500 2590 2800

28 x 9 - 15 (8.15 x 15) 12 23.00 QZ1 6.50/7.00-15 710 220 7.00 2730 2100 2625 1945 2100

28 x 9 - 15 (8.15 x 15) 14 23.00 QZ1 6.50/7.00-15 710 220 8.00 2958 2275 2845 2105 2275

28 x 9 - 15 (8.15 x 15) 16 23.00 QZ1 6.50/7.00-15 710 220 9.00 3170 2440 3050 2255 2440

8.25 x 15 12 30.00 QZ1 5.00/7.50-15 840 235 7.00 3900 3000 3750 2775 3000

8.25 x 15 14 30.00 QZ1 5.00/7.50-15 840 235 8.00 4225 3250 4065 3005 3250

8.25 x 15 16 30.00 QZ1 5.00/7.50-15 840 235 9.25 4615 3550 4440 3285 3550

8.25 x 15 18 30.00 QZ1 5.00/7.50-15 840 235 10.00 4745 3650 4565 3375 3650

250 - 15 16 31.35 QZ1 7.00/7.50-15 735 250 8.25 4355 3350 4190 3100 3350

250 - 15 18 31.35 QZ1 7.50 735 250 10.00 5037 3875 4843 3585 3875

300 - 15 20 51.5 QZ1 8.00 840 300 9.00 6500 5000 6250 5781 5000

10.00 - 20 16 62 QZ1 7.50 1055 278 9.00 6500 5000 6250 5781 5000

12.00 - 20 20 80 QZ1 8.50 1125 315 10.00 8970 6900 8625 6382 6900

DISTRIBUTED BY PLEASE NOTE THAT IT IS VITALLY IMPORTANT THAT INFLATION PRESSURES

ARE MAINTAINED AND CHECKED ON A REGULAR BASIS.

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 19

skid steer

a powerful, high

performance

solid skid steer tyre

skid steer

solid skid steer

solid

Skid Steer from Watts - high quality,

high performance

Like its Pneumatic counterpart, the Solid Skid Steer performs effectively

in a wide range of conditions but does not compromise on quality or

driver comfort. The Solid Skid Steer offers excellent value and cost of

ownership, as well as eliminating costly downtime due to punctures - a

vital consideration in time sensitive industries like construction. Watts

offer a complete tyre and wheel unit for Skid Steer vehicles with the

wheel being reusable throughout the lifetime

of the machine. 10.0 (254) 2% OVERALL WIDTH

9.250 (235) TREAD WIDTH

30.910 (785) 2% OVERALL DIAMETER

DEEP TREAD LUGS TO GIVE GOOD TRACTION IN

TO SUIT 20.00 RIM

MUD AND LOOSE SOIL

EXTRA WIDE PROFILE LUGS FOR MAXIMUM

STABILITY

TO SUIT 7.50 RIM WIDTH

TREAD COMPOUND OPTIMISED TO GIVE

SUPERIOR WEAR

STEPPED TREAD DESIGN TO ASSIST SELF

CLEANING

CONVEX SIDEWALL DESIGN FOR INCREASED

WHEEL PROTECTION 20 PATTERNS

ALL NATURAL RUBBER COMPOUND

CREEL BEAD WIRES TO PREVENT RIM SLIPPAGE

Tyre Size Rim Size Tread Dimensions Load Capacities In Kgs

(Inches) Pattern +/- 2% (Skid Steer Loaders Only)

Overall Section

Diameter mm Width mm 16 Km/H

31x10-20 (10-16.5 pneumatic equivalent) 7.5-20 SSL 785 254 3500

moving on success 33x12-20 (12-16.5 pneumatic equivalent) 7.5-20 SSL 836 287 4900

www.industrialtyre.com 33x10.75-20 (12-16.5 pneumatic equivalent) 7.5-20 P ( Smooth) 826 267 4400

20 Watts catalog / April 2009

a powerful, high

performance

skid steer tyre

skid steer

pneumatic skid steer

pneumatic

Skid Steer from Watts - high quality,

high performance

The Watts Skid Steer Pneumatic is a powerful, high performance tyre

for todays Skid Steer machines. With a high ply construction, its robust

carcass protects against punctures, while its reinforced under tread and

sidewall technology prevent unwanted damage to both tyre and wheel.

It continues to match the demands of high performance Skid Steer

machines, offering superb traction, stability and keeping downtime to a

minimum.

EXTRA WIDE PROFILE

STEPPED TREAD

EXTRA THICK UNDERTREAD

EXTRA PLYS

EXTRA THICK SIDEWALL

RIM PROTECTION

HIGH TENSILE REINFORCED BEAD AREA

CARCASS

Tyre Size Ply Tread Rim Size Inflated Inflation Load Capacities

Rating Pattern (Inches) Dimensions +/- 2% pressure In Kgs

Overall Section (Bar) (Skid Steer Loaders Only)

Recommended Alternative Diameter mm Width mm 8 Km/H 16 Km/H

23x8.50-12 8 SSL 7.00-I 7JA 576 210 4 1050 850

27x8.50-15 8 SSL 7JA 680 205 4 1230 1020

10-16.5 10 SSL 8.25 773 264 5.2 2135 1687

12-16.5 12 SSL 9.75 831 307 5.5 2865 2435

14-17.5 14 SSL 10.5 921 349 5.5 3875 3061

15-19.5 14 SSL 11.75 12.25 1019 389 4.85 4565 3606

moving on success

www.industrialtyre.com

Watts catalog / April 2009 21

wheels

for all your

mechanical

handling needs

wheels

wheels

Watts Industrial Wheels is a leading supplier to the OEM sector of the materials

handling industry. We are a business based on high quality products and services,

with a track record and history that set us apart. As part of Watts Tyre Group

we posses considerable experience and knowledge gathered from 50 years as a

manufacturer and service provider dedicated to the industry.

Large stockholdings across a huge range of wheel rims and components ensure

rapid order turn around and delivery, both in Europe and worldwide. Quality is

a key part of who we are; we are an ISO 9001:2000 business and also hold the

ISO 14001-2004 environmental accreditation. At manufacturing level we hold

both the British weld standard BSEN 970 and the European weld standard EN ISO

3834-2 ensuring that our products are of the highest possible standard available.

We hold a comprehensive database of Wheel and Tyre assemblies which allows

us to design and manufacture in exact accordance with OEM specification.

Our in house design systems enable us to offer a bespoke service to customers

with specific or out of the ordinary wheel requirements. Our modern CNC

machinery, 3D drawing capabilities and purpose built manufacturing equipment

guarantees precision and accuracy of finished product, whilst our twin site

manufacturing base allows us to produce from single unit to large volume

production runs. We also produce steel bands in house which enables us to offer

an extensive range of POB wheel designs.

A key part of our offering has been our ability to offer a complete fitted wheel

and tyre solution to the OEM market. Our joint venture with Balkancar Zarya

has allowed us to greatly increase production to service this market and to

continue to meet demand from the OEM sector for high quality, reliable and

focused partners.

TAPERED BEAD SEAT

FIXED FLANGE TAPERED BEAD SEAT RING

SLIDE RING

LOCK RING

SPECIFIED RIM DIAMETER

RIM BASE

moving on success GUTTER REGION

DISC

www.industrialtyre.com

GUTTER GROOVE

22 Watts catalog / April 2009

for all your

mechanical

handling needs

wheels

applications

standard wheel & rim sections

Type Tyre Rim section Size/application

Resilient Limpet

1 Piece

(No rim components)

Light & Heavy Duty

for Single & Dual

2 & 3 Piece Resilient & Pneumatic

Applications

8 to 20

4 Piece Resilient & Pneumatic

Heavy Duty Resilient and

4 & 5 Piece Heavy Duty 20 to 35

Earthmover Pneumatic

Drop Centre Pneumatic OTR 8 to 24

Split/2 Piece Resilient & Pneumatic Light & Heavy Duty 8 to 12

5x5 to 22x24

Solid Rubber Also in Metric Sizes.

Press On Band Type

& Urethane Range includes Plain or

Keywayed Bores with or

without Bearings & Seals

OE fitments for worldwide customers

Watts Industrial Wheels are proud of our longstanding association with many of the worlds leading

forklift truck and material handling equipment manufacturers.

Global OEMs of the highest calibre specify Watts for Wheel and Tyre assemblies, which is fitting

testimony to the quality of our products, service and support.

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672 Certificate No. EMS 87656

www.industrialtyre.com BSEN ISO 9001:2000 BSEN ISO 14001:2004

Watts catalog / April 2009 23

urethane

high load,

long life tyres

urethane

urethane

For some industries an alternative to rubber tyres is a necessity. Harsh

industrial environments take their toll on materials handling applications

resulting in premature failure and high maintenance costs. Similarly the

increasing trend for high racking/heavy load warehousing has seen a rise

in demand for applications capable of bearing heavy loads for sustained

periods of time.

To meet these needs Watts have developed a group of polyurethane

elastomers capable of withstanding severe industrial service conditions

whilst providing high load carrying capabilities.

These elastomers are used in the manufacture of press-on-band tyres,

taper based tyres, direct bond tyres, pallet and castor wheels, as well

as complete wheel units, for applications ranging from fork trucks and

trailers, to handling equipment and production machinery.

Solid long life construction

Abrasion resistant

Temperature range from -50C to 120C

High load carrying capability

Oil, grease and chemical resistant

Non-marking properties

moving on success

www.industrialtyre.com

24 Watts catalog / April 2009

specifications

high load,

long life tyres

Watts supply a variety of sizes from 3 (75mm) to 48 (1200mm)

urethane

outside diameter.

There are 3 grades of polyurethane available, dependant on application

requirements;

Standard Ultrathane Plus Range Wheels & Rollers A 92A shore hardness

material with excellent dynamics. Watts manufacture a wide range of

wheels and rollers for use in widely varying applications. We also produce an

extensive range of press on band and direct bond tyres and offer a rebonding

service for customers own wheels.

Due to Ultrathanes excellent physical properties and resistance to abrasion

and wear and tear, Ultrathane Plus tyres can be used with confidence as an

alternative to rubber tyres in applications where design features necessitate

small diameter heavily laden solid tyres.

Premium UltraLoad Range A 96A hardness material which gives low

running temperatures and low rolling coefficients from -30C to +110C.

Vulkollan Range A Bayer registered polyurethane with outstanding

physical properties which is widely used by OE manufacturers.

OTHER SHORE HARDNESS MATERIALS ARE AVAILABLE FOR SPECIAL APPLICATIONS ON REQUEST.

DISTRIBUTED BY

Watts Tyre Group

Church Road, Lydney

Glos. GL15 5EN UK

Tel: +44 (0)1594 847100

Fax: +44 (0)1594 842429

Email: enquiries@watts-tyres.co.uk

Certificate No. Q 09672

www.industrialtyre.com BSEN ISO 9001:2000

Watts catalog / April 2009 25

26 Watts catalog / April 2009

Watts catalog / April 2009 27

Member of the BPW-Group

Watts Katalog 04.2009

Catalog

W atts

Potrebbero piacerti anche

- Dealer:: Tires For Rigid DumpersDocumento7 pagineDealer:: Tires For Rigid DumpersErsin SucuNessuna valutazione finora

- 12.00R24 ETOT Deliver Lower CPH and More RecapsDocumento1 pagina12.00R24 ETOT Deliver Lower CPH and More RecapsMaldonado YordanNessuna valutazione finora

- Land Rover Freelander 2 Tyre MarkingsDocumento2 pagineLand Rover Freelander 2 Tyre MarkingsJimmy TudeskyNessuna valutazione finora

- Coats Tire ChangerDocumento32 pagineCoats Tire ChangergomooneyNessuna valutazione finora

- TIANLI Broschuere FORST 2019 20seiten EN v4.0Documento11 pagineTIANLI Broschuere FORST 2019 20seiten EN v4.0cleber ruyNessuna valutazione finora

- Amar AustraliaDocumento31 pagineAmar AustraliabalaNessuna valutazione finora

- RC 45 - RC 55 Rim Clamp Tire Changer ManualDocumento28 pagineRC 45 - RC 55 Rim Clamp Tire Changer ManualmechanicsNessuna valutazione finora

- RPN 20230220 Tech NotebookDocumento5 pagineRPN 20230220 Tech NotebookNima FakherNessuna valutazione finora

- Rotex Poly-Norm: Torsionally Flexible CouplingsDocumento32 pagineRotex Poly-Norm: Torsionally Flexible CouplingsAlessandro OliveiraNessuna valutazione finora

- Freedom Tyres 4.3.1e - Pirelli OTR - AG Product Images Link From The PHP Tyre ImageDocumento18 pagineFreedom Tyres 4.3.1e - Pirelli OTR - AG Product Images Link From The PHP Tyre Imageavram.marian.1396Nessuna valutazione finora

- Goodyear Consumer - Tyre - Technology - Master - PDF-v1 - 0Documento80 pagineGoodyear Consumer - Tyre - Technology - Master - PDF-v1 - 0jorge gonzalezNessuna valutazione finora

- Amar-Windmill Products List With ProfileDocumento23 pagineAmar-Windmill Products List With ProfilebalaNessuna valutazione finora

- Amar Profile UpdatedDocumento22 pagineAmar Profile UpdatedbalaNessuna valutazione finora

- Tural Tires Ca Talogue: Tianjin United Tire & R Ubber Intern Ational Co .,LTD (Tutric)Documento36 pagineTural Tires Ca Talogue: Tianjin United Tire & R Ubber Intern Ational Co .,LTD (Tutric)Sedat KahramanNessuna valutazione finora

- CHAPTER 2 Tires&WheelsDocumento131 pagineCHAPTER 2 Tires&WheelsEssa YimerNessuna valutazione finora

- Range & Pattern Digest: Sumitomo Rubber Industries LTDDocumento12 pagineRange & Pattern Digest: Sumitomo Rubber Industries LTDIrfan BroheNessuna valutazione finora

- Wind Turbine SparesDocumento29 pagineWind Turbine Sparesbala100% (1)

- Goodyear's Radial Tyre For Wheel Loaders and Graders.: The Goodyear RT-3BDocumento2 pagineGoodyear's Radial Tyre For Wheel Loaders and Graders.: The Goodyear RT-3BRasoolKhadibiNessuna valutazione finora

- AP Profile NewDocumento28 pagineAP Profile NewbalaNessuna valutazione finora

- OTR Tyre Awareness PDFDocumento313 pagineOTR Tyre Awareness PDFHugh O'Brien Gwaze100% (1)

- Eng Data Book LlantasDocumento84 pagineEng Data Book Llantaslucas ronaldo coronel mendozaNessuna valutazione finora

- CFBC Brochure 5augDocumento5 pagineCFBC Brochure 5augghane toleNessuna valutazione finora

- AAF Product Leaflet RollOMat enDocumento2 pagineAAF Product Leaflet RollOMat enChuy CantúNessuna valutazione finora

- Ready For Anything: New On/Off Truck Tyre RangeDocumento6 pagineReady For Anything: New On/Off Truck Tyre RangewillupowersNessuna valutazione finora

- Brief Introduction: ADVANCE Brand. We Are The OE Supplier of Some FamousDocumento21 pagineBrief Introduction: ADVANCE Brand. We Are The OE Supplier of Some FamousАлександр ФедоровNessuna valutazione finora

- OMet 4Documento2 pagineOMet 4Jeuz Llorenz C. ApitaNessuna valutazione finora

- Amar-Windmill Product LatestDocumento27 pagineAmar-Windmill Product LatestbalaNessuna valutazione finora

- SPECTRUM - SRO-1812 Ficha TécnicaDocumento1 paginaSPECTRUM - SRO-1812 Ficha TécnicaJorge ArturoNessuna valutazione finora

- Amar WindmillDocumento23 pagineAmar WindmillbalaNessuna valutazione finora

- No Faster Prop On The Water: Step 1. Engine/DRIVE Step 2. Installation Kit Step 3. PropellerDocumento2 pagineNo Faster Prop On The Water: Step 1. Engine/DRIVE Step 2. Installation Kit Step 3. PropellerjitmarineNessuna valutazione finora

- Tire Sizing & Ratings - All Makes & ModelsDocumento10 pagineTire Sizing & Ratings - All Makes & ModelsIancu GabrielNessuna valutazione finora

- 2015 PCR CatalogDocumento22 pagine2015 PCR CatalogDennis IbacacheNessuna valutazione finora

- 20 Years Young Grown Up For Quiet SuccessDocumento16 pagine20 Years Young Grown Up For Quiet SuccessAngel Ninaquispe BardalesNessuna valutazione finora

- Catalogo GOODYEARDocumento8 pagineCatalogo GOODYEARCarlos Alberto Rozo R.Nessuna valutazione finora

- Sturaco 7098Documento1 paginaSturaco 7098Tudor RatiuNessuna valutazione finora

- Ozka Tires PresentationDocumento43 pagineOzka Tires PresentationpapatangocomercialNessuna valutazione finora

- What Is WearDocumento16 pagineWhat Is Wearluis martinezNessuna valutazione finora

- ISEF - Company Profile - ENG - 2023Documento11 pagineISEF - Company Profile - ENG - 2023bertocco.bNessuna valutazione finora

- Lawn Tractors: Brand & Model Price Overall Score Test Results FeaturesDocumento54 pagineLawn Tractors: Brand & Model Price Overall Score Test Results FeaturesJ DNessuna valutazione finora

- 02 A Template For Structural Analysis of An IndustryDocumento7 pagine02 A Template For Structural Analysis of An IndustryMahathiNessuna valutazione finora

- New On-Vehicle Brake Lathe: Using The Pro-Cut PFM 9.0Documento8 pagineNew On-Vehicle Brake Lathe: Using The Pro-Cut PFM 9.0BBNBGHNessuna valutazione finora

- Investment Proposal Tyre IndustryDocumento3 pagineInvestment Proposal Tyre IndustrySandeep KumarNessuna valutazione finora

- Stemco Oil SealsDocumento4 pagineStemco Oil SealsAbdul AhadNessuna valutazione finora

- FIBRO-Gas Springs - The Safer Choice Optimum Safety For Tools and OperatorsDocumento1 paginaFIBRO-Gas Springs - The Safer Choice Optimum Safety For Tools and Operatorsks2000n1Nessuna valutazione finora

- Prediction of Torque Response During The: Engagement of Wet Friction ClutchDocumento13 paginePrediction of Torque Response During The: Engagement of Wet Friction ClutchmhmdNessuna valutazione finora

- Puncture RepairDocumento28 paginePuncture Repairadriadi tantono100% (1)

- Tenaris University - International Standards and Recommended Practices For Assuring Structural Reliability On Octg ProductsDocumento31 pagineTenaris University - International Standards and Recommended Practices For Assuring Structural Reliability On Octg ProductsSudish Bhat100% (1)

- TDIOilGasCatalog PDFDocumento31 pagineTDIOilGasCatalog PDFakamalapuri388Nessuna valutazione finora

- Kaydon 390 MTDocumento7 pagineKaydon 390 MTExpertum99Nessuna valutazione finora

- Aviation Tire CareDocumento58 pagineAviation Tire CareEleazarNessuna valutazione finora

- Apar IndDocumento16 pagineApar IndDev PurohitNessuna valutazione finora

- Trelleborg TWS Light Industrial Tires ENG 2017 LRDocumento16 pagineTrelleborg TWS Light Industrial Tires ENG 2017 LRArmando CorreiaNessuna valutazione finora

- Gear TDMDocumento1 paginaGear TDMtestNessuna valutazione finora

- Machine Alignment Slide ShowDocumento3 pagineMachine Alignment Slide Showdionisio emilio reyes jimenezNessuna valutazione finora

- Pirelli NovateckDocumento4 paginePirelli NovateckRaza MajeedNessuna valutazione finora

- 2.new Freestyle - Rest of IndiaDocumento1 pagina2.new Freestyle - Rest of IndiaSaurabh SinhaNessuna valutazione finora

- Kenda kr601 Spec Sheet PDFDocumento2 pagineKenda kr601 Spec Sheet PDFRob ZelNessuna valutazione finora

- Top 10 TipsDocumento2 pagineTop 10 TipsmijaelmagioriNessuna valutazione finora

- TDI Marine Air Starters PDFDocumento15 pagineTDI Marine Air Starters PDFMayor Paz GonzálezNessuna valutazione finora

- Roller Skates Express & Heavy Duty WheelsDocumento38 pagineRoller Skates Express & Heavy Duty WheelsDarren ThoonNessuna valutazione finora

- General Solideal InformationDocumento16 pagineGeneral Solideal InformationDarren ThoonNessuna valutazione finora

- 893 922Documento30 pagine893 922Darren ThoonNessuna valutazione finora

- Form Pressure Generated by Fresh ConcretDocumento15 pagineForm Pressure Generated by Fresh ConcretDarren ThoonNessuna valutazione finora

- 120 Tons TADANO TG 1200M 1 PDFDocumento4 pagine120 Tons TADANO TG 1200M 1 PDFDarren ThoonNessuna valutazione finora

- GBT 1591-2008 - High Strength Low Alloy Structural SteelDocumento16 pagineGBT 1591-2008 - High Strength Low Alloy Structural SteelDarren ThoonNessuna valutazione finora

- Watts Engelsk WebDocumento28 pagineWatts Engelsk WebDarren ThoonNessuna valutazione finora

- Brittle Facture of A Crane HookDocumento10 pagineBrittle Facture of A Crane HookDarren ThoonNessuna valutazione finora

- Jadual Tariff MicecaDocumento248 pagineJadual Tariff MicecaDarren ThoonNessuna valutazione finora

- Manual For The Design of Timber Building Structures To Eurocode 5 - CD Amendments - May 2008Documento1 paginaManual For The Design of Timber Building Structures To Eurocode 5 - CD Amendments - May 2008Darren ThoonNessuna valutazione finora

- PLC1102 ASS'Y: All Dimensions Are Metric MillimetersDocumento1 paginaPLC1102 ASS'Y: All Dimensions Are Metric MillimetersDarren ThoonNessuna valutazione finora

- 12 - Floor VibrationDocumento3 pagine12 - Floor VibrationDarren ThoonNessuna valutazione finora

- BB Bar BrochureDocumento7 pagineBB Bar BrochureDarren ThoonNessuna valutazione finora

- Ee-502 Unit - IDocumento2 pagineEe-502 Unit - IVARAPRASADNessuna valutazione finora

- Assignment 1Documento3 pagineAssignment 1Carolyn WangNessuna valutazione finora

- Hiley TableDocumento5 pagineHiley TableHanafiahHamzahNessuna valutazione finora

- PPT5. SeptIITK - Crystal - Imperfections - DislocationsDocumento92 paginePPT5. SeptIITK - Crystal - Imperfections - DislocationsKartik Shankar KumbhareNessuna valutazione finora

- 106L Course ReaderDocumento408 pagine106L Course ReadercurufinorNessuna valutazione finora

- Good 1983Documento352 pagineGood 1983ASDA75% (4)

- Elecon GearboxDocumento19 pagineElecon GearboxShirley Farrace100% (3)

- BSS - Report - Effect of Heat in A Building DemonstratorDocumento15 pagineBSS - Report - Effect of Heat in A Building DemonstratorAh Mok100% (1)

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocumento1 paginaMollier Enthalpy Entropy Chart For Steam - US Unitslin tongNessuna valutazione finora

- Full U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeDocumento4 pagineFull U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeSanjib MandalNessuna valutazione finora

- Ch-21 Runoff TrianglesDocumento9 pagineCh-21 Runoff TrianglesIsha TachhekarNessuna valutazione finora

- 5-Canal Irrigation SystemDocumento23 pagine5-Canal Irrigation Systemwajid malikNessuna valutazione finora

- 0606 Additional Mathematics: MARK SCHEME For The May/June 2015 SeriesDocumento9 pagine0606 Additional Mathematics: MARK SCHEME For The May/June 2015 Serieswai yanNessuna valutazione finora

- C.KESAVAN - Diploma EEE: Phone No Mail IdDocumento3 pagineC.KESAVAN - Diploma EEE: Phone No Mail IdKesavan ChinaswmiNessuna valutazione finora

- Pearson Product-Moment Correlation Coefficient Table of Critical ValuesDocumento2 paginePearson Product-Moment Correlation Coefficient Table of Critical ValuesOdy AjjaNessuna valutazione finora

- Air Conditioner: Owner'S ManualDocumento80 pagineAir Conditioner: Owner'S Manualfred MaxNessuna valutazione finora

- Hall 2005 NapaeinaDocumento10 pagineHall 2005 NapaeinaKellyta RodriguezNessuna valutazione finora

- Data Cable Containment SizingDocumento21 pagineData Cable Containment SizingAngelo Franklin100% (1)

- Baulkham Hills 2012 2U Prelim Yearly & SolutionsDocumento11 pagineBaulkham Hills 2012 2U Prelim Yearly & SolutionsYe ZhangNessuna valutazione finora

- NumaticsFRLFlexiblokR072010 EsDocumento40 pagineNumaticsFRLFlexiblokR072010 EsGabriel San Martin RifoNessuna valutazione finora

- RCC-DI-AC PipeDocumento10 pagineRCC-DI-AC PipeNaveen NagisettiNessuna valutazione finora

- 16 - Bit RISC Processor Design For Convolution Application Using Verilog HDLDocumento64 pagine16 - Bit RISC Processor Design For Convolution Application Using Verilog HDLchandra sekhar100% (1)

- Astm A394 2008 PDFDocumento6 pagineAstm A394 2008 PDFJavier Ricardo Romero BohorquezNessuna valutazione finora

- V1 N2 1980 RabenhorstDocumento6 pagineV1 N2 1980 Rabenhorstraa2010Nessuna valutazione finora

- Integrals - Integral Calculus - Math - Khan Academy PDFDocumento7 pagineIntegrals - Integral Calculus - Math - Khan Academy PDFroberteleeroyNessuna valutazione finora

- Installation, Operation, and Maintenance ManualDocumento54 pagineInstallation, Operation, and Maintenance ManualIsmael Berlanga ResNessuna valutazione finora

- S406 Specifications For The Supply of Stone PDFDocumento6 pagineS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaNessuna valutazione finora

- Template Question BankDocumento11 pagineTemplate Question Bankeshwar_worldNessuna valutazione finora

- Brazil (1997) The Communicative Value BW PDFDocumento200 pagineBrazil (1997) The Communicative Value BW PDFJuan LopezNessuna valutazione finora

- Application Note Usrp and HDSDR Spectrum MonitoringDocumento14 pagineApplication Note Usrp and HDSDR Spectrum MonitoringcaraboyNessuna valutazione finora