Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Liebert Datamate 1.5 To 3 Ton Guide Specifications

Caricato da

sachinsaklani23Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Liebert Datamate 1.5 To 3 Ton Guide Specifications

Caricato da

sachinsaklani23Copyright:

Formati disponibili

Liebert DataMate

Guide Specifications

1 General

1 SUMMARY

These specifications describe requirements for a Thermal Management system. The system shall be

designed to control temperature and humidity conditions in rooms containing electronic equipment,

with good insulation and vapor barrier.

The manufacturer shall design and furnish all equipment to be fully compatible with heat

dissipation requirements of the room.

1 DESIGN REQUIREMENTS

The Thermal Management system shall be a Liebert DataMate factory assembled unit. The

refrigeration system shall be split, with the compressor located in a remote or close-coupled

condensing unit. The evaporator section shall be specifically designed for floor or wall-mounted

installation and serviceable from the front of the system. Condensing units shall be designed for

outdoor or indoor mounting, below the raised floor, above-dropped-ceiling, or in room installation.

Refer to Section 2.3 for condensing unit guide specifications.

Standard 60 Hz units shall be CSA-certified to the harmonized U.S. and Canadian product safety

standard, CSA C22.2 No 236/UL 1995 for Heating and Cooling Equipment and are marked with the

CSA c-us logo.

The system shall be AHRI Certified, the trusted mark of performance assurance for heating,

ventilation, air conditioning and commercial refrigeration equipment, using AHRI Standard 1360.

1 SUBMITTALS

Submittals shall be provided with the proposal and shall include: Single-Line Diagrams;

Dimensional, Electrical, and Capacity data: Piping and Electrical Connection Drawings.

1 QUALITY ASSURANCE

The specified system shall be factory tested before shipment. Testing shall include, but shall not be

limited to: Quality Control Checks, Hi-pot Test (two times rated voltage plus 1000 volts, per NRTL

agency requirements), and Metering Calibration Tests. The system shall be designed and

manufactured according to world class quality standards. The manufacturer shall be ISO 9001

certified.

1 ACCEPTABLE ALTERNATIVES

Acceptable alternatives shall be permitted with engineer's prior approval only. Contractor to submit

a detailed summary form listing all variations to include size deviations, electrical load differences,

functional and component changes and savings to end user.

SL-11035GS_REV5_1-17 1 Liebert DataMate Guide Specifications

2 Product

2 STANDARD FEATURES/ALL SYSTEMS

2 Evaporator Cabinet and Frame Construction

The cabinet and chassis shall be constructed of heavy gauge, painted furniture steel. The cabinet

shall be designed for easy installation and service access from the front only.

2 Air Distribution

The air distribution system shall be constructed with a quiet, direct-drive fan assembly equipped

with multiple double-inlet blowers, self-aligning sleeve bearings, and lifetime lubrication. Fan

motor(s) shall be permanent-split capacitor, high efficiency type, equipped with two speeds for air

flow modulation. Dehumidification shall utilize the lower fan speed.

Air filter shall be a cleanable polypropylene monofilament type over expanded aluminum with

aluminum frame with a MERV4 rating based on ASHRAE 52.2-007. It shall be easily removable from

the front of the system by means of quarter-turn fasteners and shall not require system shutdown for

service.

2 Microprocessor Control System

The control system shall be microprocessor-based, factory-wired into the system and tested prior to

shipment. The wall-mounted control enclosure shall include a 2-line by 16-character LCD providing

continuous display of operating status and alarm condition. An 8-key membrane keypad for setpoint/

program control, fan speed selection and unit On/Off shall be located below the display. The control

display shall be field-wired to the control board using 4-conductor field-supplied thermostat wire.

Temperature and humidity sensors shall be located in the wall box, which shall be capable of being

located up to 300 ft (91.4m) from the evaporator unit.

2 Monitoring

The LCD shall provide On/Off indication, operating mode indication (cooling, heating, humidifying,

dehumidifying), fan speed indication and current day, time, temperature and humidity (if applicable)

indication. The monitoring system shall be capable of relaying unit operating parameters and alarms

to the Liebert iCOM CMS and/or the Liebert SiteScan monitoring systems.

2 Control Setpoint Parameters

Temperature Setpoint: 65-85F (18 to 29C)

Temperature Sensitivity: 1 to 9.9F (1 to 5C)

Humidity Setpoint: 20-80% RH

Humidity Sensitivity: 1 to 30% RH

The microprocessor can be set within these ranges; however, the unit may not be able to control to

extreme combinations of temperature and humidity.

SL-11035GS_REV5_1-17 2 Liebert DataMate Guide Specifications

2 Unit Controls

2 Compressor Short-Cycle Control

The control system shall prevent compressor short-cycling by a 3-minute timer from compressor stop

to the next start.

2 Common Alarm and Remote On/Off

A common alarm relay shall provide a contact closure to a remote alarm device. Two (2) terminals

shall also be provided for remote On/Off control. Individual alarms shall be enabled or disabled

from reporting to the common alarm.

2 Setback Control

The control shall be user-configurable to use a manual setpoint control or a programmable, time-

based setback control. The setback control will be based on a 5 day/2 day programmed weekly

schedule with capability of accepting 2 events per program day.

2 Temperature Calibration

The control shall include the capabilities to calibrate the temperature and humidity sensors and

adjust the sensor response delay time from 10 to 90 seconds. The control shall be capable of

displaying temperature values in F or C.

2 System Auto Restart

For startup after power failure, the system shall provide automatic restart with a programmable (up

to 9.9 minutes in 6-second increments) time delay. Programming can be performed either at the wall-

mounted controller or from the central, site-monitoring system.

2 Alarms

2 Unit Alarms

The control system shall monitor unit operation and activate an audible and visual alarm in the

event of the following factory preset alarm conditions.

High Temperature (max 90F, 32.2C)

Low Temperature (min 35F, 1.7C)

High Humidity (max 85% RH)

Low Humidity (min 15% RH)

High Water Alarm - Lockout Unit Operation

High Head Pressure

Loss of Power

Compressor Short Cycle

2 Custom Alarms (2x)

Humidifier Problem

Water Detected

Custom Alarm (1)

SL-11035GS_REV5_1-17 3 Liebert DataMate Guide Specifications

Custom Alarm (2)

User-customized text can be entered for the two (2) custom alarms

2 Alarm Controls

Each alarm (unit and custom) shall be individually enabled or disabled (except for high head

pressure and high water in condensate pan) and can be programmed for a time delay of 0 to 255

seconds of continuous alarm condition to be recognized as an alarm. Each alarm shall also be

enabled or disabled to activate the common alarm (except high head pressure and high water in

condensate pan).

2 Audible Alarm

The audible alarm shall annunciate at the LCD wall box any alarm that is enabled by the operator.

2 Common Alarm

A programmable common alarm shall be provided to interface user selected alarms with a remote

alarm device.

2 Remote Monitoring and ControliCOM CMS and BMS

The Liebert iCOM CMS system shall provide hardware, Web Interface, Administration Portal, and

Mobile Apps to remotely view, control, and monitor the Liebert DataMate system. The CMS web

card shall be field mounted with communications wiring routed from the Liebert DataMate system

to the CMS control board, power provided separate from the Datamate unit, and Ethernet cable

providing network access to the world-wide web or to a BMS if required. The iCOM CMS Mobile App

shall provide real-time, read-only data from each Liebert DataMate registered and wired to an iCOM

CMS system. Notifications shall be provided via SMS text message or email to each registered User

who has been added to the Administration portal and assigned to receive alarm notifications from a

unit.

The iCOM CMS Web Interface shall be used to register systems to the Mobile Cloud, remotely access

unit-level display settings via a web URL which shall provide read/write capability to the Liebert

DataMate system for setpoints, alarms, sensor calibration and other settings found on the unit level

display.

2 Remote Monitoring - Liebert SiteScan

All alarms shall be communicated to the Liebert site-monitoring system with the following

information: date and time of occurrence, unit number and present temperature and humidity.

2 CHILLED WATER SYSTEM COMPONENTS

2 Chilled Water Control

The water circuit shall include a 2-way slow-close On/Off solenoid valve. Design pressure shall be

300psi (2068kPa) with a maximum close-off pressure of 60psi (414kPa). Valve shall be spring return.

2 Chilled Water Coil

The cooling coil shall have a minimum of 2.6 ft.2 (.24m2) face area, 3 rows deep. It shall be

constructed of copper tubes and aluminum fins and be mounted in a galvanized condensate drain

pan. The coil shall be designed for a maximum face velocity of _____FPM (m/s) at ___ CFM (CMH).

The water circuit shall be designed to distribute water into the entire coil face area. The coil shall be

supplied with ___ F (C) entering water temperature, with a ___F (C) temperature rise. The coil

SL-11035GS_REV5_1-17 4 Liebert DataMate Guide Specifications

shall be supplied with ___ GPM (l/s) of chilled water and the pressure drop shall not exceed

______ psi (kPa).

2.2 DIRECT EXPANSION SYSTEM COMPONENTS

2.2.1 Direct Expansion Coil

The evaporator section shall include an evaporator coil, thermostatic expansion valve and filter-drier.

The evaporator coil shall have ___ ft.2 (m2) face area, ___ rows deep. It shall be constructed of copper

tubes and aluminum fins and have a maximum face velocity of ___ FPM (m/s) at _____ CFM (CMH).

An externally equalized thermostatic expansion valve shall control refrigerant flow. The evaporator

coil shall be factory-charged with R-407C refrigerant and sealed. The coil shall be provided with a

galvanized steel drain pan. The evaporator unit can be coupled directly with a water/glycol

condensing unit or mounted remote to the indoor or outdoor condensing unit.

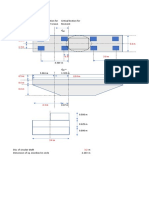

2.3 INDOOR AIR-COOLED CENTRIFUGAL FAN CONDENSING UNIT

Condensing unit components shall include condenser coil, scroll compressor, high-pressure switch,

Liebert Lee-Temp refrigerant receiver, head pressure control valve, hot gas bypass system and liquid

line solenoid valve. The hot gas bypass circuit shall be provided to reduce compressor cycling and

improve operation under low-load conditions. Units available for [(2-ton)(3-ton)] systems.

All components shall be factory-assembled, charged with R-407C refrigerant and sealed. No internal

piping, brazing, dehydration or charging shall be required. Condensing unit shall be designed for

95F (35C) ambient and be capable of operation to -30F (-34C). The condensing unit can be

mounted directly to the evaporator or can be mounted remote to the evaporator.

The condensing coil shall be constructed of copper tubes and aluminum fins. The condenser fan shall

be centrifugal type, double inlet, direct drive and shall operate at 1050 rpm (890 rpm @ 50 Hz). The

fan and motor shall be mounted on vibration isolators. The condenser fan shall be designed for

____CFM (CMH) at ____ (mm) w.g. external static pressure.

2.3 OUTDOOR AIR-COOLED PROP FAN CONDENSING UNIT

Condensing unit components shall include a condenser coil, a direct-drive propeller-type fan, a scroll

compressor, high-pressure switch, Liebert Lee-Temp receiver and head pressure control valve, hot

gas bypass system and liquid line solenoid valve. A hot gas bypass system shall be provided to reduce

compressor cycling and improve operation under low load conditions.

All components shall be factory-assembled, charged with R-407C refrigerant and sealed. No internal

piping, brazing, dehydration or charging shall be required. Condensing unit shall be designed for

95F (35C) ambient and be capable of operation to -30F (-34.4C).

The condenser coil shall be constructed of copper tubes and aluminum fins.

(Option) The 2- or 3-ton condensing unit shall be designed to operate at a sound level less than

58dBA.

(Option) The 2- or 3-ton condensing unit shall be designed for design ambient operation of 105F

(40.6C).

(Option) The condenser coil shall be phenolic-coated for extended coil life in coastal areas.

SL-11035GS_REV5_1-17 5 Liebert DataMate Guide Specifications

2.3 INDOOR CLOSE-COUPLED WATER/GLYCOL CONDENSING UNIT

The water/glycol-cooled condensing unit shall include a scroll compressor and a water/glycol cooled

condenser, and shall be capable of being close-coupled to the evaporator module. The water/glycol

cooled condenser shall be designed to balance the heat rejection at ______ F (C) entering

water/glycol temperature with a flow rate of ___ GPM (l/s) and have a total system pressure drop of

_____ ft of water (kPa). An adjustable two-way water regulating valve shall be included. The

condenser water/glycol circuit shall be designed for a static operating pressure of 150psi (1034kPa).

All components shall be factory assembled, charged with R-407C refrigerant, sealed and be capable

of being connected to the evaporator section using quick connect refrigerant couplings and integral

wiring harness for single point power connection for close-coupled system. No refrigeration piping,

brazing, dehydration or charging shall be required.

2.3 INDOOR REMOTE WATER/GLYCOL-COOLED CONDENSING UNIT

The water/glycol condensing unit shall include a scroll compressor, high-pressure switch, coaxial

condenser, water-regulating valve, hot gas bypass system and liquid line solenoid valve. A hot gas

bypass circuit shall be provided to reduce compressor cycling and improve operation under low-load

conditions. All components shall be factory-assembled, charged with R-407C refrigerant and sealed.

No internal piping, brazing dehydration or charging shall be required. Units available for [(2-ton)(3-

ton)] systems.

The water/glycol condensing unit shall be equipped with a coaxial condenser having a total system

pressure drop of ______ ft. of water (kPa) and a flow rate of ______ GPM (l/s) with ______ F (C)

entering water/glycol temperature.

The condenser circuit shall be pre-piped with a [(2-way) (3-way)] regulating valve which is head-

pressure actuated.

The condenser water/glycol circuit shall be designed for a static operating pressure of [(150psi

(1034kPa)) (350 PSI (2413 kPa))].

2.4 FACTORY-INSTALLED OPTIONS

2.4.1 Electric Reheat

The electric reheat shall be low-watt density, tubular element and shall include agency approved

safety switch to protect the system from overheating. The capacity of the reheat coil shall be

______ BTU/HR, ____ kW, controlled in 1 stage.

2.4.2 Steam Generating Humidifier

The environmental control system shall be equipped with a steam generating humidifier that is

controlled by the microprocessor control system. It shall be complete with disposable canister, all

supply and drain valves, 1" (25.4mm) air gap on fill line, inlet strainer, steam distributor, and

electronic controls. The need to change canister shall be annunciated on the microprocessor wall-box

control panel. The humidifier shall have a capacity of 3 lb./hr. (1.4kg/h). An LED light on the

humidifier assembly shall indicate cylinder full, overcurrent detection, fill system fault, and end of

cylinder life conditions.

SL-11035GS_REV5_1-17 6 Liebert DataMate Guide Specifications

2.5 SHIP-LOOSE ACCESSORIES

2.5.1 Remote Sensors

The unit shall be supplied with remote temperature and humidity sensors. The sensors shall be

connected to the unit by a 30 ft. (9m) shielded cable.

2.5.2 Condensate Pump

The condensate pump shall have the capacity of _____ GPH (___ l/h) at ___ ft. head (___ kPa). It shall

be complete with integral float switch, discharge check valve, pump, motor assembly and reservoir. A

secondary float switch shall be provided to permit field wiring to the unit control to shut down the

evaporator upon a high water level condition.

2.5.3 Refrigerant Line Sets

Pre-charged refrigerant line sets shall be available from Vertiv Co. in proper lengths for application.

Line set length shall be [(15 ft. (4.5m)) (30 ft. (9m))] not to exceed 45ft (13.5m) in total length.

2.5.4 Refrigerant Line Sweat Adapter Kit

Provide a sweat adapter kit to permit field brazing of refrigerant line connections for application to

split systems.

2.5.5 Step-Down Transformer

A step-down transformer shall be provided for [(Indoor Evaporator) (Close-Coupled Water/Glycol

Condensing Unit) (Outdoor Air-Cooled Condensing Unit)] needing 277V input power

voltage. The transformer shall be coated with epoxy and contained in an enclosed, non-ventilated

electrical box with adaptable mounting brackets, suitable for [(indoor) (outdoor)] mounting.

2.5.6 Liebert Local Monitoring Systems, Auto-changeover and Leak Detection

Provide indicated quantities of the following:

______ Leak Detection System(s) Model __________________________________

______ Remote Monitor(s) Model ________________________________________

______ Auto-changeover Control(s) Model ________________________________

2.5.7 Liebert iCOM CMS Monitoring and Control System

A Liebert iCOM CMS Monitoring and Control System shall be provided for remote monitoring of the

Liebert DataMate unit. The Liebert iCOM CMS shall have the capability to remotely monitor via

mobile-device app and to monitor and change (at the user direction) the temperature and humidity

setpoints and sensitivities of each unit via a firewall-protected web interface. The application shall

provide the user with push-notifications of unit status and alarm information via SMS text or email

messages. Single phase power (120 V) and field wiring to Liebert DataMate and world-wide web are

required.

2.5.8 Liebert SiteScan Site Monitoring System

A Liebert SiteScan Site Monitoring System Model __________________ shall be provided for remote

monitoring of the Liebert DataMate unit and monitoring of other Liebert support equipment. The

Liebert SiteScan shall have the capability to monitor and change (at the user direction) the

temperature and humidity setpoints and sensitivities of each unit. The printer shall provide the user

with chronological alarm information. It shall also be capable of being programmed to print out

environmental conditions or operating modes at each unit.

SL-11035GS_REV5_1-17 7 Liebert DataMate Guide Specifications

2.5.9 Drycooler

The Liebert drycooler shall be a low-profile, direct-drive propeller fan-type air-cooled unit. The

drycooler shall be constructed with an aluminum cabinet and a copper-tube aluminum fin coil, and

one or more direct drive fans. All electrical connections and controls shall be enclosed in an integral,

NEMA 3R rated electrical panel section of the drycooler. The drycooler shall be quiet and corrosion

resistant.

The drycooler shall be designed for _____F (C) ambient.

2.5.10 Glycol Pump Package

The system shall include a centrifugal pump mounted in a weatherproof and vented enclosure. The

pump shall be rated for ____ gpm (l/s) at ____ ft. (kPa) of head, and operate on _____ volt, ____ phase,

______ Hz.

3 Execution

3 INSTALLATION OF AIR CONDITIONING UNITS

3 General

Install air conditioning units in accordance with manufacturers installation instructions. Install

unit plumb and level, firmly anchored in locations indicated and maintain manufacturer's

recommended clearances.

3 Electrical Wiring

Install and connect electrical devices furnished by manufacturer but not specified to be

factory-mounted. Furnish copy of manufacturer's electrical connection diagram submittal to

electrical contractor.

3 Piping Connections

Install and connect devices furnished by manufacturer but not specified to be factory-mounted.

Furnish copy of manufacturer's piping connection diagram submittal to piping contractor.

3 Supply and Drain Water Piping

Connect water supply and drains to air conditioning unit. Provide pitch and trap as manufacturer's

instructions and local codes require.

3 FIELD QUALITY CONTROL

Startup air conditioning units in accordance with manufacturer's start up instructions. Test controls

and demonstrate compliance with requirements.

SL-11035GS_REV5_1-17 8 Liebert DataMate Guide Specifications

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Sachin SaklaniDocumento1 paginaSachin Saklanisachinsaklani23Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Item Rate Boq: Sac Code Basic Price (RS.) Rate of GST (In %)Documento1 paginaItem Rate Boq: Sac Code Basic Price (RS.) Rate of GST (In %)sachinsaklani23Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Admission Form: Registration Class - Age Chart (In Years) On 1 AprilDocumento2 pagineAdmission Form: Registration Class - Age Chart (In Years) On 1 Aprilsachinsaklani23Nessuna valutazione finora

- Terminology Civil 3DDocumento38 pagineTerminology Civil 3Dsachinsaklani23Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- HIU Range Design GuideDocumento24 pagineHIU Range Design Guidesachinsaklani23Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Static Pressure Calculations V1.1Documento1 paginaStatic Pressure Calculations V1.1sachinsaklani23Nessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Report On Under-Floor Heating Design: Prepared By: Prepared For: Contract Number: DateDocumento11 pagineReport On Under-Floor Heating Design: Prepared By: Prepared For: Contract Number: Datesachinsaklani23Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- PipingDocumento34 paginePipingsachinsaklani23Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 3.10 Appendix A Design Brief Standard Format & Contents RequirementsDocumento2 pagine3.10 Appendix A Design Brief Standard Format & Contents Requirementssachinsaklani23Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 10 General PDFDocumento283 pagine10 General PDFsachinsaklani23Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- S.NO. Floor Area Name Area Tag Ac/Heating/VentilationDocumento29 pagineS.NO. Floor Area Name Area Tag Ac/Heating/Ventilationsachinsaklani23Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Deliverable ListDocumento7 pagineDeliverable Listsachinsaklani23Nessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Mep AssumptionsDocumento12 pagineMep Assumptionssachinsaklani23Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Id Sheet NumberDocumento73 pagineId Sheet Numbersachinsaklani23Nessuna valutazione finora

- HiDocumento7 pagineHisachinsaklani23Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 1 Detail 2 Detail 3 Detail 4 Detail: Rev Date Drawn Description CH'K'D App'dDocumento1 pagina1 Detail 2 Detail 3 Detail 4 Detail: Rev Date Drawn Description CH'K'D App'dsachinsaklani23Nessuna valutazione finora

- 22Documento4 pagine22sachinsaklani23Nessuna valutazione finora

- (HVAC Modeler) : Email: Skype ID: Bhupinder - Singh3622Documento4 pagine(HVAC Modeler) : Email: Skype ID: Bhupinder - Singh3622sachinsaklani23Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Example of Audit of An Air Conditioning System: André Philippe Hannay Cleide, Hannay Jules, Lebrun JeanDocumento12 pagineExample of Audit of An Air Conditioning System: André Philippe Hannay Cleide, Hannay Jules, Lebrun Jeansachinsaklani23Nessuna valutazione finora

- Ventilation Summary For Carpark & VRV System: (M /S) (M /S)Documento4 pagineVentilation Summary For Carpark & VRV System: (M /S) (M /S)sachinsaklani23Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- GB01 PPCS Super D21 W21 M05Documento1 paginaGB01 PPCS Super D21 W21 M05Kamal NathNessuna valutazione finora

- Bridge Design Standard For LGEDDocumento7 pagineBridge Design Standard For LGEDZubayer Ibna ZahidNessuna valutazione finora

- Question Paper Code:: Reg. No.Documento4 pagineQuestion Paper Code:: Reg. No.Guru PrakashNessuna valutazione finora

- 180427ze - Ds - BTR 3 GKW-ENX C-Flex 50264-3-2 600 V - 10082eDocumento2 pagine180427ze - Ds - BTR 3 GKW-ENX C-Flex 50264-3-2 600 V - 10082eRava SatrianiNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Chapter III. Lesson 5 The Nano WorldDocumento23 pagineChapter III. Lesson 5 The Nano WorldGheralyn BolardaNessuna valutazione finora

- Rust Build CalcDocumento2 pagineRust Build CalcMihai AlexandruNessuna valutazione finora

- CFD Lab Question PaperDocumento2 pagineCFD Lab Question Papervenkee84Nessuna valutazione finora

- Structural Steel Design 1 Mini ProjectDocumento24 pagineStructural Steel Design 1 Mini ProjectMohd SaufiNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Final BillDocumento1 paginaFinal BillRajib MaharjanNessuna valutazione finora

- 1 s2.0 S2590007223000497 MainDocumento7 pagine1 s2.0 S2590007223000497 MainRavindu AriyarathneNessuna valutazione finora

- Thermal Performance Analysis of Earth-Air-Pipe-Heat Exchanger System With Different Backfilling MaterialsDocumento5 pagineThermal Performance Analysis of Earth-Air-Pipe-Heat Exchanger System With Different Backfilling MaterialsKamal Kumar AgrawalNessuna valutazione finora

- Fire Hazards and ControlsDocumento38 pagineFire Hazards and ControlsAbdul Rehman Afzal100% (1)

- Solar B.E.S.T.Documento24 pagineSolar B.E.S.T.Μιχάλης ΠολυδώρουNessuna valutazione finora

- Shear and Bending Moment DiagramDocumento21 pagineShear and Bending Moment DiagramFahim Faisal RaunaqNessuna valutazione finora

- Drawings and Certificates, Etc.: 4-1 Submerged Pump, ARTIKA160-4SDocumento20 pagineDrawings and Certificates, Etc.: 4-1 Submerged Pump, ARTIKA160-4Sprasad_satyamNessuna valutazione finora

- Sikafloor 81 EpoCem IDDocumento3 pagineSikafloor 81 EpoCem IDHendrias Ari SujarwoNessuna valutazione finora

- 1St Floor Lintel and False Slab Layout: Mani Civil WorksDocumento1 pagina1St Floor Lintel and False Slab Layout: Mani Civil Worksmanilesnarf5Nessuna valutazione finora

- Batel - Presentation 2020r1Documento63 pagineBatel - Presentation 2020r1HÜSEYİN GÜRTAŞNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- S - 11 - Concrete 04 Beam Slab Development LengthDocumento152 pagineS - 11 - Concrete 04 Beam Slab Development LengthEngr. Gazi Golam SarwarNessuna valutazione finora

- New Microsoft Office Excel WorksheetDocumento13 pagineNew Microsoft Office Excel WorksheetRavi TejaNessuna valutazione finora

- Proejcr ManduaDocumento552 pagineProejcr ManduaDanny NguyenNessuna valutazione finora

- Critical Section For Moment Critical Section For Shear and TorsionDocumento7 pagineCritical Section For Moment Critical Section For Shear and TorsionShashank Srivastava0% (1)

- 3119-600series Rev2 0912 LRes PDFDocumento8 pagine3119-600series Rev2 0912 LRes PDFAlper Emrah SakalsızNessuna valutazione finora

- Cara Menghitung Ukuran Pipa Kapiler RefrigerasiDocumento54 pagineCara Menghitung Ukuran Pipa Kapiler RefrigerasiZikko FirmansyahNessuna valutazione finora

- Mech-Vi-Design of Machine Elements II (10me62) - NotesDocumento368 pagineMech-Vi-Design of Machine Elements II (10me62) - Notesajrojas135986% (14)

- New Cements For The 21st Century The Pursuit of An Alternative To Portland CementDocumento14 pagineNew Cements For The 21st Century The Pursuit of An Alternative To Portland CementPopovac NetNessuna valutazione finora

- The Dead Weight Safety Valve Consists of A ValveDocumento4 pagineThe Dead Weight Safety Valve Consists of A ValveAsif Saleem0% (1)

- Introduction To Coiled TubingDocumento131 pagineIntroduction To Coiled TubingAmin Dehghani100% (2)

- Bed Material Specification CFBC BoilerDocumento1 paginaBed Material Specification CFBC BoilerElavarasan RamalingamNessuna valutazione finora

- York Fan and CoilDocumento4 pagineYork Fan and CoilPeralta Fco100% (1)