Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Celox For On-Line Process Control in Modern Steelmaking - Rudi Maes

Caricato da

Acrux KnightTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Celox For On-Line Process Control in Modern Steelmaking - Rudi Maes

Caricato da

Acrux KnightCopyright:

Formati disponibili

Celox for on-line process control

in modern steelmaking

Ing. R. Maes

Product Application Manager

Heraeus Electro-Nite

International N.V.

The masters when it comes

to control techniques

EN_brochure.indd 1 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

EN_brochure.indd 2 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

1. ABOUT CELOX 4

1.1 Measuring principle 4

1.2 Celox and measuring system description

5

1.2.1 Celox sensor

5

1.2.2 Celox lance and accessories

7

1.2.3 Instrumentation 9

1.3 Formulae 9

1.4 Standard operating procedure 13

1.5 Sensor precision 14

1.6 Sample comparison 17

2. FAST MEASUREMENTS OF OXYGEN, CARBON AND ALUMINUM VIA THE CELOX ROUTE 19

2.1 Oxygen determination 19

2.2 Carbon determination 20

2.3 Aluminium determination 21

3. CELOX FOR PROCESS CONTROL IN MODERN STEELMAKING 23

3.1 Decarburization control in converters and EAF 23

3.1.1 Quick carbon determination (Quick-Tap practice) 23

3.1.2 Calculation of pre-deoxidation additions 24

3.1.3 Control of bottom stir efficiency 25

3.2 Decarburization control at degassing stations 25

3.3 Deoxidation control at the ladle treatment station 26

3.3.1 LCAK- steel grades (slab casters) 26

3.3.2 Mn-Si killed steel grades (billet casters) 30

3.3.3 Successful continuous billet casting through oxygen control in mixed operations 34

3.4 Desulphurisation control 39

EN_brochure.indd 3 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

01 ABOUT CELOX

1.1 Measuring principle

Celox Principle Scheme

+

EMF

-

Thermocouple

+

R.T pO2 steel

EMF = ln

n.F pO2 ref

pO2 ref

pO2 steel Contact electrode Mo

Solid reference Cr/Cr2O3

Solid electrolyte ZrO 2 (MgO)

Bath contact electrode Fe

Fig.1: Celox measuring principle

The determination of the oxygen activity in molten metal is based on an electro-

chemical measurement. Magnesia stabilised zirconia is used as electrolyte. At high

temperatures this solid electrolyte allows the transfer of oxygen ions between steel

and the reference material in the electro-chemical cell. Schematically the cell can be

represented as follows:

Mo/Cr+Cr2O3//ZrO2.MgO//(O)Fe/Fe

electrode/ pO2ref. //electrolyte //pO2steel/electrode

From the generated EMF, the measured temperature and the known oxygen partial

pressure of Cr/Cr2O3, the oxygen partial pressure of the steel can be calculated using

Nernsts law. Note that the electrodes (Mo Fe thermocouple) generate a 24mV EMF

within a temperature range of 1500 to 1600 C.

Hence, a correction of 24mV is required to determine the thermo- dynamical value.

In absence of electronic conduction Nernsts law is represented by the following

formula:

E= RT ln (pO2steel)

4F (pO2ref.)

E= Electro-motive force (mV)

R= Gas constant

T= Measured temperature (K)

F= Constant of Faraday

pO2ref.= Oxygen partial pressure of the reference material (Cr/Cr2O3)

pO2 steel= Oxygen partial pressure in the steel

EN_brochure.indd 4 10/09/12 13:26

1.2 Celox and measuring system description

Fig. 2: Celox measuring system

Figure 2 represents the required hardware for an oxygen measurement in liquid steel:

- Celox sensor

- Immersion lance with inner compensating cable.

- Extension cable connecting the lance with the Multi-Lab instrument.

- Multi-Lab Celox instrument.

1.2.1 Celox Sensor

The Celox sensor includes an electrochemical cell for EMF measurement and a

Pt/PtRh thermocouple for temperature measurement. Compensation wires connect

oxygen cell and thermocouple to a connector making contact with the contact block of

the immersion lance. (see fig.1). Both measuring units are assembled within a conical

sand body, and covered by a steel and a cardboard slag cap in order to protect the

sensor during immersion through the slag into the steel.

For ensuring good contact with the molten metal, a steel ring is used. Doing this a

Fe-Mo thermocouple is introduced in the measuring circuit influencing the

EMF- output (24 mV between 1500-1650C) of the sensor.

The measuring head is pressed into a cardboard tube protecting the immersion lance.

EN_brochure.indd 5 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Sensor options

Four types of sensors are available:

Celox standard (CE**01****)

Celox probe

metal cap sand housing

thermocouple EMF-conductor

bath contact cardboard tube

oxygen cell compensation wire

cardboard cap

Fig. 3: Celox standard probe

Used for measurements from 50 ppm to more than 1000 ppm in steel baths without

aluminum. The Celox standard can be used in EAF and BOF for the determination of

the carbon content, but NOT for aluminum determination in the ladle.

Celox Al (CE**91****)

Celox Al probe

metal cap Coated sand housing

Thermocouple coated EMF-conductor

bath contact cardboard tube

oxygen cell compensation wire

cardboard cap

Fig. 4: Celox Al probe

EN_brochure.indd 6 10/09/12 13:26

The Celox Al sensor can be used for oxygen measurements from 1ppm to more than

1000 ppm.

All quartz and sand components of the Celox Al are coated with a special refractory

material. This prevents the reduction of these components by the aluminum present in

the bath, which could introduce errors in the measurement.

Celox Al can also be used to measure soluble Al in Al-killed steel grades and the

carbon content in EAF and BOF.

Celox Ti (CE**92****)

Important

In steel grades containing titanium (>0.02) a modified sensor named Celox-Ti has to

be used in case of soluble aluminum determination.

Celox tundish(CE**96****)

Celox Al probe

metal cap coated sand housing

thermocouple coated EMF-conductor

bath contact cardboard tube

oxygen cell compensation wire

cardboard cap

Fig. 5: Celox tundish probe

For response time reduction at low temperatures (tundish) this Celox-type does not

contain a thermal shock shield on top of the oxygen cell.

1.2.2 Celox lance and accessories

The construction of the lance is extremely important. Care must be taken to guarantee

an insulation of min. 2 Megaohm between:

The positive and negative legs of both, temperature and oxygen channels

The positive legs of temperature and oxygen

All legs and earth

EN_brochure.indd 7 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Polarity and colour coding of the contact block, mineral insulated inner cable, lance

plug and socket, and outer compensating cable must be correctly maintained.

The Heraeus Electro-Nite Celox lance has been designed so that it may be used

for temperature measurements only (Positherm) and for temperature and oxygen

(Celox).

For optimal protection of the internal compensation cable, the use of a telescopic

cardboard tube is recommended for applications in converters and furnaces. The

telescopic tube can be fixed firmly onto the lance by means of a conical coupling device

(order number LC33016077)

Automatic lances

Automatic lances operate in a harsh environment with a lot of radiation heath, dust,

fumes, moisture etc. In order to ensure reliable measurements, lance maintenance,

repair, exchange, and lance checks are required on a regular basis. Heraeus Electro-Nite

developed the Quick Connecting Lance system in order to enable a smooth and quick

lance exchange without causing a major inconvenience at the treatment station.

A composition drawing with reference numbers is given below.

CONVENTIONAL

LANCE

QCL Connector

1 SALESREF NO. : LC24016006

PART NO. : 118.003.6-

+5

330 0

1 2 3 2

QCL detachable part/S 4

7 SALESREF NO. : LC24016001

PART NO. : 108.057.6- QCL contactblock

SALESREF NO. : LC24016005

PART NO. : 118.002.6- 5

4 5 6 6

G 3/4

QCL fixed part/S

8 SALESREF NO. : LC24016000 ~381 min.16

PART NO. : 108.056.6-

Wire protection

max.30,5

7 9 QCL/S 8

Fig.6: Composition drawing

Quick connecting lance system

EN_brochure.indd 8 10/09/12 13:26

1.2.3 Instrumentation

As instrument we recommend the Multi-Lab Celox.

This is an industrial, programmable micro-computer based instrument with an

outstanding measuring performance. For more detailed information, please consult our

Multi-Lab Celox brochure.

1.3 Formulae

Oxygen activity in liquid steel grades

The relationship between temperature (C), EMF(mV) and oxygen activity, for Celox, is

given by the following formula:

log a(O)= 1.36+0.0059*(E+0.54*(T-1550)+0.0002*E*(T-1550)) with E in mV, and T in C

and a(O) in ppm.

Celox

Relation T - EMF- a(O)

1600

1400 1550

1600

1200 1650

1700

1750

a(O) (ppm)

1000

800

600

400

200

0

-50 0 50 100 150 200 250

EMF (mV) Fig. 7: Relationship between EMF, a(O) and Temperature

In the Multi-Lab an additional a(O)-formula can be used and modified to suit specific

customer requirements:

a(O)=e^(f1+f2/T)*(((e^(f3+f4/T))^1/4+(e^(f5+f6/T))^1/4)*e^(f7*E/T+f8/T+f9)

(e^(f3+f4/T))^1/4)^2+f10

with E=EMF(mV) and T= temp.(C)+273

EN_brochure.indd 9 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

1: f1=8.27402

2: f2=16486.3

3: f3=56.2291

4: f4=-171243

5: f5=18.6325

6: f6=-86370

7: f7=11.6114

8: f8=290.28

9: f9=0.0000

10:f10=0.0000

Oxygen activity in Ni melts with a Fe-content <=30%

In this case the relationship between a(O), EMF and temperature is given by the

following formula:

a(O)=10^(f1+(f2+f3*(E+f4+f5*T))/(T+273))

with E=EMF (mV) and T=temp. (C)

1: f1=7.9485

2: f2=-15155

3: f3= 10.080

4: f4=-7.8000

5: f5=0.0219

The coefficients f1, f2, f3, f4, f5 can be modified.

Carbon in steel

The relationship between carbon, temperature and a(O) is given by :

log%C= f1+f2/T +f3*loga(O)

T=temp.(C)

1: f1=2.236

2: f2=-1303.0

3: f3=-1.0000

4: f4=start %C-calculation from a(O)=150 ppm

The coefficients f1,f2,f3,f4 can be changed.

The start of the %C calculation can be fixed with item 4 from a(O)=20 to 200 ppm. The

calculated %C will be displayed on the screen if the a(O) value exeeds this start value

and the EMF reaches positive values. Standard setting for f4=150 ppm.

10

EN_brochure.indd 10 10/09/12 13:26

% Soluble aluminum in steel

Up to 3 adjustable soluble aluminum formulae may be chosen to cover the whole

range. Each formula may be assigned with other constants and coefficients.

Range 1: EMF start value <=EMF< upper limit range1 (selec.)

Range 2: EMF upper range1<=EMF<upper limit range2 (selec.)

Range 3: EMF upper range2<=EMF<0mV (not selectable)

However, the standard setting is one formula for the whole range (from EMF start value

to 0mV)

If e.g. three different soluble Al-formulae should be available, following procedure

should be followed:

First, choose the upper limit of range 2 (select a value between the EMF start value and

O mV). This upper limit is at the same time the lower limit of range 3.

Second, choose the upper limit of range 1 (select a value between the EMF start value

and the upper limit of range 2). This upper limit of range 1 is at the same time the lower

limit of range 2.

For every range, a different soluble Al-formule can be introduced by changing the

constant and coefficients in the standard formula.

The standard Aluminum determination formula:

-300mV<=EMF<0mV

logAl=f1+f2*E/T+f3*exp(-E/T)+f4/T

E=EMF+24 (mV)

T=temp.(C)+273

Al= weight %

1: f1=439.7351

2: f2=-490.719

3: f3=-432.785

4: f4=-15944.7

IMPORTANT

In case of titanium alloyed steel grades Ti>0.02 the standard formula can not be used.

The coefficients have to be modified:

1: f1= 439.7351

2: f2= -490.719

3: f3= -433.9481

4: f4= -13491.1

11

EN_brochure.indd 11 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

The standard formula is valid for low alloy steel grades only.

In case of high alloy steel grades the formula can be adjusted by modifying the

coefficients f1, f2, f3 and f4.

Aluminum addition calculation formula

The Multi-Lab offers three different options:

1: No addition calculation

2: Al addition calculation with O- aim (ppm)

Kg Al = ((a(O)(ppm)-O-aim(ppm))*ton*0.11/yield1(%))

3: Al addition calculation with Al-aim (%)

Kg Al = (a(O)(ppm)*Ton*0.11/yield1 (%))+((Al aim( %)-

Al)*Ton*1000/yield2(%))

Yield 1: yield of the aluminum addition used for the removal of the free oxygen from the

liquid steel.

Yield 2: yield of the aluminum addition used to alloy the liquid steel in order to reach a

certain aluminum aim.

Calculation example:

start : 450 ppm

aim : 0.025% Al

Charge : 100 ton

Lower the oxygen content (yield : 60%)

Al(1)=(450-0)*1,1/10/0.6=82.5 kg

Raise the aluminum level(yield : 60%)

Al(2)=(0.025-0)*1000/0.6=41.6 kg

Total Al to add= Al(1) +Al(2)=124.1 kg

12

EN_brochure.indd 12 10/09/12 13:26

1.4 Standard operating procedure

In order to obtain accurate results, the following precautions should be taken:

Probes must be kept dry and handled carefully.

The lance and extension cable must be kept dry and in a good condition. Many

measurement errors are the result of lance or cable problems.

The probe must be well fixed onto the lance and immersed quickly through the slag

into the liquid metal to a depth of 30 to 40 cm, away from the ladle or furnace lining

and from the influence of the slag.

Gas stirring ( Ar, N2,) has to be stopped during Celox measurement. The

recommended waiting time after stirring is 60 seconds. In case waiting time is not

respected, wrong oxygen levels may be measured.

The electric power of the furnace has to be switched off during measurement.

Additions should be thoroughly mixed before measurement, typically for about 3-4

minutes.

Slag crusts should be kept thin, or the slag be fluxed to prevent mechanical damage

to the probe on immersion.

Temperature range from 1570 C up to 1740 C.

Use Celox tundish in case temperature is lower then 1570C.

13

EN_brochure.indd 13 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

27-1-99 11:50 HT-NO. : 32 Place : 1 Type : S No: 340

300 1650 Multi-lab

270 1640 Celox

240 1630

C

: [mV]

210 1620 TEMP: 1598.2 C

:

Tvar: -1.3 C

180 1610

TEMP

EMF: 216.2 mV

EMF

150 1600 Evar: -1.9 mV

a(O): 633.1 ppm

120 1590 C: 0.041 %

90 1580

60 1570

30 1560

0 1550

0.0 2.0 4.0 6.0 8.0 10.0 t (s)

Fig. 8: Typical temperature and

oxygen trace

1.5 Sensor precision

The measuring traces of both temperature, and oxygen signals are characterized

by stable plateaus and short response times. The recommended immersion time is

approximately 8 to 10 seconds.

The accuracy of the thermocouple wire is 0 to +4 C at 1554 C.

Oxygen cells used for the production of Celox are submitted to the most rigourous

quality control procedures.

All critical components such as the solid electrolyte, reference material etc. are all

manufactured in house by Heraeus Electro-Nite. In this way, quality is 100% assured

throughout the entire sensor production process.

14

EN_brochure.indd 14 10/09/12 13:26

Different cell assembly batches are tested in our induction furnace under fixed steel

conditions.

These different batches (blue and green dots) including the reference batch (red dots)

(fig. 9) are dipped alternately in one ladle.

Quality control

-125

-150

-175

mV

-200

-225

-250

10:12 10:14 10:16 10:18 10:20 10:22 10:24 10:26

Time

Fig. 9: Typical QA-sheet of a field trial

A regression analysis of the mV-signals will determine whether the batches are within

specs or not. Also the standard deviation within a batch is calculated.

Typically the standard deviation is lower than 1.2 mV.

The final product release is given after a success full field trial at the ladle treatment

station of a local steel plant. Fig.9 show the results of a typical test and a Celox

certificate.

15

EN_brochure.indd 15 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Celox certificate

16

EN_brochure.indd 16 10/09/12 13:26

1.6 Sample comparison

In case the sensor is used for carbon or aluminum determination, the Celox readings

are often compared with sample analysis. In general the carbon determination on a

sample with a spectrometer is quite reliable. The aluminum determination on a sample

however is a little bit more complicated. In this respect we can distinguish two types

of aluminum analysi:

- Aluminum soluble representing the metallic aluminum in the steel

- Aluminum total representing the total of metallic aluminum and the aluminum

present as inclusions.

It is important to know that Celox Al determines the soluble aluminum only and

should be compared with the metallic aluminum.

A spectrometer can give two results; aluminum total and/or aluminum soluble. In case

the spectrometer analysis is used for the correlation with Celox, one should be aware

that significant differences can occur due to the sample quality.

A researcher investigated the homogeneity of samples (Fig. 10) from different suppliers.

Spark position on sample

Distance 5 mm

of border

7 8

6

1

4 5

5

3 6 2

2 7

1 8 3

4

Fig. 10: Spark position on sample

17

EN_brochure.indd 17 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Al total

400

Relative concentration

300

Supplier D

A B

200

C

100

0

1 2 3 4 5 6 7 8

Position on the lollipop sample

Fig. 11: Al-total determination on

samples from supplier A,B,C,D.

Al soluble

140

Relative concetration

Supplier

120 A BC D

100

80

60

1 2 3 4 5 6 7 8

Fig. 12: Al-sol. determination on

Position on the lollipop sample

samples from supplier A,B,C,D

Aluminum total analysed with a spectrometer is critical and shows a relatively large

spread on the spark position on the sample and supplier. The variation in the aluminum

soluble determination is more reliable provided good quality samples, proper sample

preparation and precise analytical equipment are used.

CONCLUSION

Celox Al determines aluminum soluble.

18

EN_brochure.indd 18 10/09/12 13:26

FAST MEASUREMENTS OF

OXYGEN, CARBON AND

ALUMINUM VIA THE CELOX ROUTE

02

2.1 Oxygen determination

Oxygen determination in unalloyed low carbon steel grades

The measuring principle is explained in chapter 1.1. The relationship between

temperature (C), EMF (mV) and oxygen activity, for Celox, is given by the following

formula:

log a(O)= 1.36+0.0059*(E+0.54*(T-1550)+0.0002*E*(T-1550)) with E in mV and T in C

and a(O) in ppm.

The graphs give the T, EMF and a(O) relationship.

Celox

Relation T - EMF- a(O)

1600

1400 1550

1600

1200 1650

1700

1000 1750

a(O) (ppm)

800

600

400

200

0

-50 0 50 100 150 200 250

EMF (mV) Fig. 13: Relationship between EMF, a(O) and Temperature

Oxygen determination in alloyed steel grades

In case of alloyed steel the measured oxygen activity can be converted to oxygen

concentration taking into account the interaction coefficients of the alloying elements:

with (%O)= a(O)celox/FOX

log FOX= eOX*(%X) + eOY*(%Y) +

%O = oxygen concentration

a(O) = oxygen activity measured by Celox

FoX = activity coefficient

eOX = interaction coefficient for element X

%X = alloying element content

19

EN_brochure.indd 19 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Deoxidation calculations are based on oxygen concentration.

The interaction coefficients used in order to calculate FoX are given in the table

hereafter.

eoX interaction coefficients for different elements

element X eOX Range from 0 to (%) Investigator

Al -1.17 3 Olette-Gatellier

C -0.37 1 Fischer-Janke

Cr -0.037 20 Fischer-Janke

Mn -0.030 25 Fischer

Mo 0.07 25 Fischer-Janke

Ni 0.006 60 Fischer

P 0.014 4 Fischer

S -0.104 4.4 Fischer

Si -0.14 2 Gatellier-Olette

Zr -0.44 1.8 Buzek

Please note that depending on the investigator, differences in the interaction

coefficients might occur.

2.2 Carbon determination

The carbon determination with Celox in EAF and BOF is based on the oxygen-carbon

relationship described in the following reaction.

C + O CO

Thermodynamically the reaction can be expressed as follows:

K= pCO/(C*a(O))

Assuming that the p(CO) equals 1 and by measuring the temperature and the oxygen

activity, the carbon can be calculated.

Fig. represents the oxygen - carbon relationship at 1600 C for

pCO =1

The C*a(O) product depends on the partial pressure of the CO. Often, converters use

argon bottom stirring in order to speed up the converter process. In these cases the

pCO does not equal 1 and therefore the formula has to be adjusted accordingly.

See chapter 3.1 Decarburization control in converters and EAF.

The standard formula used in Multi-Lab:

log%C= 2.236 1303/T log a(O)

20

EN_brochure.indd 20 10/09/12 13:26

Relation Carbon - a(O) at 1600C

(Celox)

1400

1200

1000

100 ppm = 0.003 %C

a(O) (ppm)

800

600

400

200

0

0 0.05 0.1 0.15 0.2 0.25 0.3

C (%) fig. 14: Relation a(O)-carbon at 1600 C and pCO=1

T=temp. (C) and a(O) in ppm

2.3 Aluminum determination

The aluminum determination by oxygen activity measurement is based on the reaction:

2Al + 3O Al2O3

Figure 15 represents the relationship between Al, a(O)

and EMF at 1600 C

Celox

Relation Al and a(O) at 1600C

70 35

60 30

a(O)

Al

50 25

a(O) (ppm)

Al (10-3 %)

40 20

30 15

20 10

10 5

0 0

-200 -180 -160 -140 -120 -100 -80 -60 -40 -20 0

EMF (mV)

Fig. 15: Al, a(O) and mV relationship at 1600C

21

EN_brochure.indd 21 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Note that Celox Al gives a very high accuracy in the low aluminum range. A large

variation in EMF corresponds with a small change in aluminum content.

In the Multi-Lab the standard formula is:

log(Al)=439.7351-490.719*E/T 432.785* exp(-E/T)- 15944.7/T

with E= EMF+24(mV) and T= Bath temp. in K

The result for Aluminium is in points. 1 point Al = 0,001%

22

EN_brochure.indd 22 10/09/12 13:26

CELOX FOR PROCESS CONTROL

IN MODERN STEELMAKING

03

3.1 Decarburization control in converters and EAF.

3.1.1 Quick carbon determination

When producing low carbon heats in an electric furnace or converter, it is important

to have a quick and accurate method for oxygen and carbon determination in order to

save time and money.

A Celox measurement is the quickest way to determine oxygen activity and carbon

content compared to sampling and analysis in the laboratory.

Using Celox the steelmaker can tap the converter without waiting for the final sample

analysis (so called quick- tapping praxis). Depending on the speed of the lab, the tap to

tap time can be shortened by 5 to 10 minutes. This results in increased productivity and

steel output (3 to 4 heats per day), as well as energy and refractory savings.

Carbon determination

1000

900 =Practical Values

800

700

a(O) in ppm

600

500

400

300

p(CO) =1 bar

200

100

p(CO) =0.5 bar

0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

C-Content in %

Fig. 16: Carbon - a(O) relation in the converter

Carbon determination with Celox is based on the equilibrium between oxygen and

carbon at the end of the blowing process (fig. 16).In the high oxygen and corresponding

low carbon range the relation carbon versus oxygen is sharp enough to predict carbon

within a 10% accuracy range.

Important

Celox has a high precision to determine the carbon content up to 0.15 %C, but not

higher. Carbon contents higher than 0.15% can be determined more precisely and

quickly by means of thermal analysis, using the Heraeus Electro-Nite probes TapTip,

Quick-Lab or Econ-O-Carb cup.

23

EN_brochure.indd 23 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Carbon formula

The relationship between carbon, temperature and a(O) is given by :

Log%C= f1+f2/T +f3*loga(O)

T=temp.(C)

1: f1=2.236

2: f2=-1303.0

3: f3=-1.0000

4: f4=start %C-calculation from 150 ppm

The coefficients f1,f2,f3,f4 can be changed.

The start of the %C calculation can be fixed with item 4 from a(O)=20 to 200 ppm. The

calculated %C will be displayed on the screen if the a(O) value exeeds this start value

and the EMF reaches positive values. Standard setting for a(O)=150 ppm.

3.1.2 Calculation of pre-deoxidation additions

An oxygen measurement in the EAF or converter is also used to calculate the

deoxidation additions to be added to the tapping stream or to the transfer ladle.

Knowing the oxygen level is especially beneficial for low carbon steels having relatively

high and fluctuating oxygen levels. A carbon content of 0.02% for example corresponds

to an oxygen level between 600 and 1000 ppm depending on the blowing practice.

Aluminium addition calculation formula

The Multi-Lab offers three different options:

1: No addition calculation

2: Al addition calculation with O- aim (ppm)

Kg Al= ((a(O)(ppm)-O-aim(ppm))*ton*0.11/yield1(%))

3: Al addition calculation with Al-aim (%)

Kg Al= (a(O)(ppm)*Ton*0.11/yield1 (%))+((Al aim( %)-

Al)*Ton*1000/yield2(%))

Yield 1: the yield of the aluminum addition used for the removal of the free oxygen

from the liquid steel.

Yield 2: the yield of the aluminum addition used to alloy the liquid steel in order to

reach a certain aluminum aim.

24

EN_brochure.indd 24 10/09/12 13:26

Calculation example:

start : 450 ppm

aim : 0.025% Al

Charge : 100 ton

Lower the oxygen content (yield : 60%)

Al(1)=(450-0)*1,1/10/0.6=82.5 kg

Raise the aluminum level(yield : 60%)

Al(2)=(0.025-0)*1000/0.6=41.6 kg

Total Al to add= Al(1) +Al(2)=124.1 kg

3.1.3 Control of bottom stirring efficiency

Inert gas such as argon or nitrogen is blown into the converter through e.g. porous

bricks in order to reduce the C-O product and to enhance the decarburization rate.

The argon bubbling will shift the C-O equilibrium line downwards. See fig. 16. By

measuring the oxygen with Celox and carbon with a sample after blowing it is possible

to check the argon stirring efficiency.

3.2 Decarburization control at degassing stations

Decarburisation process in RH-OB

1000

Change C O = 19500

800 in practice

a(O) in ppm

600

Oxygen

Blowing

400

ge

an

Ch

tric

200 me

hio

c

St

0 100 200 300 400 500 600 700 800 900

C-content in ppm fig. 17: Decarburization process in RH-OB (8)

25

EN_brochure.indd 25 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

The graphic describes the decarburization process of ULC steel grades in a RH-

OB. In this example the carbon content before treatment is 380 ppm. In theory

(stoechiometric change) the decarburization process will follow the dotted line. In

reality however the decarburization process will be infuenced by external oxygen

coming from the slag. At the end of the process a carbon content of 15 ppm and an

oxygen content of around 250 ppm is obtained. Extra oxygen blowing is required

in case the carbon content before degassing is higher than 380 ppm otherwise the

decarburization process will be too long or the carbon target will not be reached.

In case the carbon content is lower than 380 ppm, the decarburization will be faster but

the end oxygen will be higher and more aluminum will be required to kill the steel.

RH- degassers require an even tighter control of oxygen (400 to 500ppm) and carbon

(200 to 250 ppm). If no oxygen is blown in the steel during the RH treatment, the

final carbon content will depend on the oxygen and carbon level before vacuum. The

target is to obtain the lowest carbon content (<20 ppm) and a reproducible low oxygen

content (250 ppm) at the end of the treatment.

The example above shows clearly that a close control of oxygen and carbon is required

for efficient and low cost decarburization.

3.3 Deoxidation control at the ladle treatment station

One of the main purposes of ladle metallurgy is to adjust the chemical analysis of the

steel in order to have a composition appropriate for the continuous caster.

The deoxidation praxis for billet and slab casters must be distinguished, because of the

different steel grades.

3.3.1 LCAK- steel grades (slab casters)

The aluminum aim for this type of steel is normally around 0.040%.

Because of the equilibrium between oxygen and aluminum, Celox is not only suitable

to measure the oxygen activity but also the soluble aluminum content. This method

has a relative accuracy of 10%.

26

EN_brochure.indd 26 10/09/12 13:26

Celox

Relation Al and a(O) at 1600C

70 35

60 30

a(O)

Al

50 25

a(O) (ppm)

Al (10-3 %)

40 20

30 15

20 10

10 5

0 0

-200 -180 -160 -140 -120 -100 -80 -60 -40 -20 0

EMF (mV)

Fig. 18: Al-O relation for LCAK

A first Celox is normally used after a preliminary stir at the ladle station. Now the

steelmaker can evaluate exactly the situation.

Is the melt in the oxygen range (100 to 200 ppm a(O)) or is it already in the Al range

(0.005 to 0.020% of Al)? In case the melt is in the oxygen range, the aluminum

addition calculation can not be done properly based on sample analysis only. A Celox

measurement allows the steel maker to calculate the necessary Al additions not only to

kill the steel (reduce the O to nearly zero) but also to reach the aimed Al level, nearly in

one step. Aluminum yields may vary strongly depending on the oxidation- state of the

slag carried over into the ladle. In case of highly oxydized ladle slags, several aluminum

addition steps may be required to reach the final aluminum target because the oxygen

in the slag will react with the added deoxidant.

Following this deoxidation practica described above, the steelmaker can save several

minutes per heat. After the aluminum addition and the required homogenisation stir,

a further Celox-Al measurement can be made in order to check the final aluminum

content before sending the ladle to the continuous caster.

The difference between the total Al- value (sample analysis) and soluble aluminum

(Celox) gives the steelmaker an idea about the steel cleanliness. At the end of the ladle

treatment both values should be within a few points.

The figure above is based on real measurements in a steel ladle.

27

EN_brochure.indd 27 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Al Celox vs. Al - Lab

80

70

60

50

Al- Lab

40

30

20

AL new Celox formula

10 Linear (Al new Celox formula)

0

0 10 20 30 40 50 60 70 80

Fig. 19: Correlation Al celox Al Celox

and Al lab

% Soluble aluminum in steel

Up to 3 adjustable soluble aluminum formulae may be chosen to cover the whole

range. Each formula may be assigned with other constants and coefficients.

Range 1: EMF start value <=EMF< upper limit range1 (selec.)

Range 2: EMF upper range1<=EMF< upper limit range2 (selec.)

Range 3: EMF upper range2<=EMF< OmV (not selectable)

However, the standard setting is one formula for the whole range (from EMF start value

to OmV)

If e.g. three different soluble Al-formulae should be available, following procedure

should be followed:

First, choose the upper limit of range 2 (select a value between the EMF start value and

0 mV). This upper limit is at the same time the lower limit of range 3.

Second, choose the upper limit of range 1 (select a value between the EMF start value

and the upper limit of range 2). This upper limit of range 1 is at the same time the lower

limit of range 2.

For every range, a different soluble Al-formula can be introduced by changing the

constant and coefficients in the standard formula.

28

EN_brochure.indd 28 10/09/12 13:26

The standard Aluminum determination formula:

-300mV<=EMF<OmV

logAl=f1+f2*E/T+f3*exp(-E/T)+f4/T

E=EMF+24 (mV)

T=temp.(C)+273

Al= weight %

1: f1=439.7351

2: f2=-490.719

3: f3=-432.785

4: f4=-15944.7

IMPORTANT

In case of titanium alloyed steel grades Ti>0.02% the standard formula can not be

used. The coefficients have to be modified:

1: f1= 439.7351

2: f2= -490.719

3: f3= -433.9481

4: f4= -13491.1

The standard formula is valid for low alloy steel grades only.

In case of high alloy steel grades the formula can be adjusted by modifying the

coefficients f1, f2, f3 and f4.

Aluminium addition calculation.

The required amount of aluminum to reach a certain oxygen aim or aluminum aim

can easily be calculated. See chapter 1.2.3.

The Multi-Lab offers three different options:

1: No addition calculation

2: Al addition calculation with O- aim (ppm)

Kg Al= ((a(O)-O-aim(ppm))*ton*0.11)/yield1(%))

3: Al addition calculation with Al-aim (%)

Kg Al= (a(O)*Ton*0.11/yield1 (%))+((Al aim %-Al)*

Ton*1000/yield2(%))

29

EN_brochure.indd 29 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Yield 1: yield of the aluminum addition used for the removal of the free oxygen from the

liquid steel.

Yield 2: yield of the aluminum addition used to alloy the liquid steel in order to reach a

certain aluminum aim.

Calculation example:

start : 450 ppm

aim : 0.025% Al

Charge : 100 ton

Lower the oxygen content (yield : 60%)

Al(1)=(450-0)*1,1/10/0.6=82.5 kg

Raise the aluminum level(yield : 60%)

Al(2)=(0.025-0)*1000/0.6=41.6 kg

Total Al to add= Al(1) +Al(2)=124.1 kg

3.2.2 Mn-Si-killed steel grades (billet casters).

When producing Si-Mn-killed steel, the oxygen content is controlled by the Si and Mn

contents. Next figure shows the equilibrium between Si, Mn and oxygen in the LF.

Equilibrium diagram Si-Mn-a(O) (for 1550C)

Al2O3

Mn_Si_Al_a(O) T=1550C

a(O) ppm

0,100

2 3

0,050

3

0,020

2

0,010 5

0,005

10

0,002

Al(sol) (%)

Mn (%)

1

0,001

20 Fe + Mn 10 0,8

Liquid Silicates

30 + Al2O3 + SiO2 0,6

40 20 0,5

50

30 0,4

40 0,3

50

60

80 70

9 0,2

11 100 0

0 SiO2

0,1

0,01 0,02 0,04 0,06 0,10 0,20 0,30 0,50 0,80 1 2 3 4 5 6 78 10

Fig. 20: Equilibrium diagram

Si-Mn-a(O) at 1550 C Si (%)

30

EN_brochure.indd 30 10/09/12 13:26

The deoxidation practice for billet casters is based on the adjustment of the oxygen

level between two values.

The upper limit is given by the presence of pinholes and blowholes in the billet. The

lower limit is set by the phenomenon of the nozzle clogging.

Upper limit

In steel grades with relatively low Si and Mn contents, the oxygen content might be

pretty high. During solidification in the billet casters mould carbon monoxide will

be released resulting in the formation of pinholes under the surface of the billet. The

maximum admissible oxygen content is mainly a function of the carbon content.

The higher the carbon content, the lower the critical oxygen content.

Maximum oxygen level to prevent pinholes

100

90

T=1550C

80

1,0

70

a(O) in ppm

60

0,8

pCO = 1-(pH2+pN2)

50

0,6

pCO = 1(atm)

40

0,4

30

0,2

20

10

0

0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8

C(%) Fig. 21: Maximum oxygen level to prevent pinholes

Partial pressure of H and N

10

Temperature on the

solidification front

8 =1525C

1.2

1.0

6 pH +pN (atm)

H (ppm)

0.8

0.

6

4 0.

4

0.

2

2

0.

1

0.

05

0

0 20 40 60 80 100 120 140

N (ppm) Fig. 22: Partial pressures of H2 and N2

31

EN_brochure.indd 31 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

The next figure shows the maximum admissible oxygen content in the steel as function

of the carbon content in order to avoid pinholes.

Also the presence of the gases N2 and H2 increases the risk of pinhole formation.

Figure 22 gives the total partial pressure of N2 and H2 depending on the nitrogen and

hydrogen content of the steel.

Since pCO +pN2 +pH2 must be smaller than 1 atm., the critical pCO can be calculated.

Next figure indicates the critical oxygen level for different values of pCO.

[O]max. vs. [N], [H] and [C]

80

[H] = 4 ppm

60

[O] ppm

[N] (ppm)

40

60

20

80

100

0 0,02 0,04 0,06 0,08 0,1

Fig. 23: Max. oxygen content in

the LF as a function of carbon,

C(%)

nitrogen and hydrogen.

[O]max. vs. [N], [H] and [C]

80

[H] = 6 ppm

60

[O] ppm

40

[N] (ppm)

20

60

80

0 0,02 0,04 0,06 0,08 0,1

Fig. 24: Max. oxygen content in

the LF as a function of carbon, C(%)

nitrogen and hydrogen.

32

EN_brochure.indd 32 10/09/12 13:26

In case of relatively low max. silicon and manganese specifications an additional

amount of aluminum might be required to lower the oxygen content.

In this case the necessary aluminum can be calculated since it is proportional to the

difference between measured oxygen content and maximum oxygen content:

Kg Al= ((a(O)-Omax.(ppm))*ton*0.11)/yield1(%))

with

a(O) max. : maximum oxygen activity in the LF acc. to fig. (ppm)

a(O ) : measured oxygen activity in the LF (ppm)

yield(Al): yield of the Al deoxidant

After Al addition a control measurement can be made to check the oxygen content and

the residual Al, if any present.

Next figure indicates the critical oxygen content in the LF as a function of carbon,

nitrogen and hydrogen. The relation ship described in this fig. is based on

thermodynamics and a shift might be required to make it fit with your local casting

practice.

Oxygen measurements in the LF enable the steel maker to check whether the melt is

sufficiently killed to ensure a reliable casting process.

Lower oxygen limit

If open tundish nozzles are used, the maximum admissible aluminum content is

limited, otherwise the tundish nozzles could clog due to the oxidation of aluminum

by entrapped air in the steel stream or reoxidation by slag or ladle refractory

material(spinels).

The maximum tolerable Al-content to prevent clogging of the tundish nozzles depends

on the nozzle diameter.

log Al= -1.25 +1.74*log D with D= nozzle diameter (mm)

(Al in points. 1 point Al = 0,001%)

Exceptionally it might be impossible to lower the oxygen content with Al to a level

low enough to avoid blowholes and to keep the metallic aluminum content below its

critical value to avoid clogging. If this is the case, part of the oxygen can be removed by

adding SiCa, which will also improve the castibility of the steel. Another solution could

be to add part of the aluminum directly in the mould of the billet caster. This, however,

will increase the Al2O3 inclusion content of the billets.

The optimum SiCa or mold Al addition can be calculated from an oxygen measurement.

The use of Celox oxygen probes in the LF gives following benefits (Production of steel

grades with low Si and Mn contents.):

33

EN_brochure.indd 33 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

Increased steel quality:

A correct setting of the oxygen content will decrease the number of blowholes.

Avoid casting problems:

Reduced break-out risk and tundish nozzle risk.

Improved steel cleanliness by carefully carried out deoxidation practice.

3.3.3 Successful continuous billet casting through oxygen control in mixed

operation

Presentation given by Dr. Wolfgang Glitscher at SEASI conference Saigon Vietnam, year

2000

Abstract:

Most western billet casters are operated mixed, as open stream caster with

metering nozzles producing reinforcing concrete grades, and as shrouded

mould level controlled caster producing quality long products. This mixed

production allows for a flexible adaptation to changing market conditions, as

downstream processing equipment is equally suited in most cases.

Todays lean steel plant logistics require a flexible use of the available steel

casting ladles. In most cases the same ladle serves the shrouded caster with

aluminum killed steel, and is used without relining for the next campaign for

silicon killed steel casting. In such a scenario castability problems are observed

in open stream casting whenever a ladle is used having been charged with an

aluminum killed grade before.

Precise oxygen probes ensure a correct level of dissolved oxygen in the steel

casting ladle, and enable correcting means in the tundish to prevent nozzle

clogging during casting and pin hole formation in the as-cast billet.

Looking at todays continuous billet casters and their product mix we see internationally

3 shop types casting

a) Reinforcing concrete steels in open stream

b) Quality long product steels submerged with tundish nozzle control

c) Both, a) and b) in a certain percentage share.

This paper deals with steel shops with a product mix as per c). Let us name it mixed

operation. The intention is to give a short but practical guideline for metallurgists,

casters and engineering specialists, and last but not least for the responsible steel shop

managers.

Steel casting ladles and their associated installations and consumables such as ladle

heaters, sliding gates, porous plugs etc. are an major cost factor in a steel plant, plus

34

EN_brochure.indd 34 10/09/12 13:26

they block space. This means the number of necessary ladles should be kept to a

minimum but allowing for enough flexibility in production. It will be outlined that

a lean ladle management is possible as well in mixed operation but requiring a

dedicated control technique.

PP - SEASI

a) C35 b) 41Cr4

S35C SCR 440

1035 S140

Rimming Steel Al-Killed Steel

aO ~ 50ppm aO ~ 3ppm

(Celox) (Celox)

Fig. 1 : Oxygen activity status of ladles prior to continuous casting.

a) Rimming steel grade Fig. 1 shows gives an example for 2 typical grades

b) Al-killed steel grade being cast on a billet caster:

Left a ladle filled with a Si-killed reinforcing concrete grade, and right a ladle with an

Al-killed quality grade. The relevant Celox oxygen levels are due to the difference in

deoxidation practice. As a result totally different ladle top slags form in these cases. The

next figure (Fig. 2) illustrates the main difference:

fig 2: Main differences in ladle top slag

composition with

a) reinforcing concrete steel and

b) Al-killed steel

35

EN_brochure.indd 35 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

The main slag components in case of concrete steel are calcia, magnesia, silica and

iron oxide. CaO comes from lime addition, magnesia from ladle refractory bricks, silica

mainly from deoxidation, and FeO in equilibrium with 50ppm oxygen activity in the

steel. Especially dolomite or magnesia ladle refractory lead to higher MgO content in

the slag, whereas high alumina refractory sends eroded alumina to the ladle top slag.

The important point is that typical concrete steel top slags as standard exceed 10% FeO.

Aluminum killed grades show significantly higher alumina content in its top slag, and if

correctly treated very low FeO values down to less than 1%. Main slag components are

thus calcia, alumina, magnesia, and silica.

After casting the ladle is usually tilted-over to remove residual steel and slag.

Dependent on temperature this removal is more or less successful. With long waiting

for cleaning after end of casting the ladle gets sticky and part of the residual steel and

top slag stay inside and form skull, Fig. 3.

fig 3: Empty and tilted ladle after

casting Al-killed steel grade

Having cast Al-killed steel, skull consists of Al-containing steel and the relevant top

slag. To a certain extent the whole lining has seen some penetration of steel and slag

as well with down going level when casting. This skull and the huge slag coated ladle

refractory surface send out non-metallic inclusions to the steel charge of the heat

tapped next. Their dissolution into the fresh steel is dependent on temperature and gas

purging intensity, but is always relatively slow, as skull and slag stick to the colder

refractory. Thus skull inclusion flotation to top slag is also idle, and maybe still ongoing

during continuous casting.

The type of inclusions in suspension with the steel in the ladle is dependent on the

oxygen activity status. Fig. 4 shows 3 standard types.

36

EN_brochure.indd 36 10/09/12 13:26

fig 4

Left and a) an Al-killed steel grade with ~ 3ppm oxygen activity. Inclusion types are

aluminates and spinels. Right and c) a concrete steel grade with ~ 50ppm oxygen.

Inclusion type is spherical oxide.

In between and b) our subject of interest: inclusions in transition from alumina/spinel

towards spherical oxide. Oxygen activity is 35ppm. Surprisingly literature as well gives

a figure of 35 for a mass flow ratio oxygen/aluminum where Hercynite (FeO-alumina

spinel) formation starts. This type is typical for a concrete steel grade tapped into a ladle

having carried an Al-killed steel grade before. As a result, concrete steel in mixed ladle

operation shows differences in oxygen level and inclusion types compared to a pure

concrete steel production. This has an impact on castability. Alumina and spinels are

known for their clogging behaviour in continuous casting. Fig. 5 shows tundish nozzle

clogging in submerged casting and open stream casting.

fig 5: Billet caster types

37

EN_brochure.indd 37 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

In case of a slide gate or stopper controlled nozzle as per a) the bigger nozzle clogs just

partly, and steel flow is almost unhampered, especially when Al-killed steel is Calcium

treated. On the right side in open stream casting the tundish nozzle is much smaller in

diameter, ~16mm is typical. In the event of clogging the tundish nozzle freezes rapidly

with the consequence of a premature end of casting. Steel plants in mixed operation

report this phenomenon of metering nozzle clogging just when relatively low in

oxygen activity, i.e. lower than 35ppm. With rising oxygen activity clogging disappears

completely allowing for long sequence casting. The most obvious reason is the

difference in inclusion morphology. Alumina, spinels, and inclusions in transition clog

whereas spherical oxides dont. A practical solution is needed to ensure good castability

over the full foreseen sequence in the same way as Calcium treatment does for Al-

killed grades. The key word here is oxygen control via the Celox route. This method

guarantees could castability for steel casting ladles in mixed operation, precise steel

oxidation (50ppm should be max.), and thus avoids pinhole formation in the as-cast

billet. Fig. 6 illustrates the treatment:

fig 6: Castability control by

Celox method

Prior to sending the ladle from treatment station to the caster a Celox measurement

is taken. A result lower than 35ppm indicates coming clogging problems. Slight oxygen

lancing by shallow gas injection corrects the oxygen activity to the desired range of 35

to 50ppm ensuring good castability.

Summary:

The Celox sensor method, as the worlds standard for oxygen control in liquid steel,

enables a lean ladle management in shops running in mixed operation, producing

both, concrete and quality Al-killed grades. Significant investment can be saved and

operational costs are optimized.

38

EN_brochure.indd 38 10/09/12 13:26

3.4 desulphurisation control

In practice, several methods are used to desulphurise steel in the ladle. The general

reaction is:

S+ MO O + MS

S = sulphur concentration in steel

MO = oxide

O = oxygen in steel

MS = sulphide

The reaction shows that in order to have an adequate desulphurisation, the oxygen

activity in the steel must be low. Otherwise, the desulphurisation agent will react

with the oxygen and not with the sulphur.

Desulphurisation

30

a(O) ppm

1560C < T <1600C 10

25

S (10-3 %) after treatment

20 7

4

15

3

10

2

0 5 10 15 20 25 30 35 40

S (10-3 %) before treatment Fig. 25: Desulphurisation prediction

Fig. 25 gives an example of how the treatment is carried out with SiCa additions

containing 0.8 kg Ca/ton of steel, combined with the influence of a synthetic slag. The

lines represent the oxygen activity measured before desulphurisation.

For a low oxygen content (2ppm) the sulphur will drop from e.g. 0.035% to about

0.007%. For a high oxygen content (10 ppm) the treatment is less effective: sulphur

drops from 0.035% to about 0.027%.Oxygen measurements help to achieve the low

oxygen content before the treatment by controlling the aluminum additions.

39

EN_brochure.indd 39 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

notes

40

EN_brochure.indd 40 10/09/12 13:26

notes

41

EN_brochure.indd 41 10/09/12 13:26

Celox

for on-line

process control in

modern steelmaking

notes

42

EN_brochure.indd 42 10/09/12 13:26

EN_brochure.indd 43 10/09/12 13:26

Design: www.tabeoka.be - Date of print: 00/00/2010

Heraeus Electro-Nite International N.V.

Centrum Zuid 1105

3530 Houthalen, Belgium

Phone + 32 (0) 11 / 60 02 11

Fax + 32 (0) 11 / 60 04 00

E-mail: info.electro-nite.be@heraeus.com

www.heraeus-electro-nite.com

EN_brochure.indd 44 10/09/12 13:26

Potrebbero piacerti anche

- Tdi Advanced Nitrox Final ExamDocumento8 pagineTdi Advanced Nitrox Final ExamMelissa LaCroce50% (2)

- Intellisave AX700Documento458 pagineIntellisave AX700OMAR GONZALEZ100% (2)

- Pre-Commission Cleaning of Pipework Systems PDFDocumento10 paginePre-Commission Cleaning of Pipework Systems PDFCarlos GulfoNessuna valutazione finora

- Stormwater Management Stormwater Management: Design and Installation Manual Design and Installation ManualDocumento55 pagineStormwater Management Stormwater Management: Design and Installation Manual Design and Installation ManualjopejiNessuna valutazione finora

- ArUco TutorialDocumento4 pagineArUco TutorialAcrux KnightNessuna valutazione finora

- Microbe Revision Quiz Year 8Documento2 pagineMicrobe Revision Quiz Year 8Sarah KKCNessuna valutazione finora

- PHOTOSYNTHESIS-Inquiry Based LearningDocumento5 paginePHOTOSYNTHESIS-Inquiry Based LearningRozelle Iligan-Dionisio100% (3)

- Excool - Data Centre Cooling Product Comparison Report: Desktop StudyDocumento38 pagineExcool - Data Centre Cooling Product Comparison Report: Desktop StudyEvrenNessuna valutazione finora

- N10P Mium 10991487enDocumento92 pagineN10P Mium 10991487enAnton LyakhovNessuna valutazione finora

- Pe Mium 02 10991487enDocumento96 paginePe Mium 02 10991487enAnton LyakhovNessuna valutazione finora

- Project Standard and Specifications Marine Loading Unloading Rev01webDocumento6 pagineProject Standard and Specifications Marine Loading Unloading Rev01webAnonymous 5ICLRlNessuna valutazione finora

- Design and Simulation of Continuous Distillation Columns PDFDocumento33 pagineDesign and Simulation of Continuous Distillation Columns PDFnghiemta18Nessuna valutazione finora

- The Cell Control ReportDa EverandThe Cell Control ReportNessuna valutazione finora

- Monsol Tunneltech 200 Series - Co No Vis Operating ManualDocumento67 pagineMonsol Tunneltech 200 Series - Co No Vis Operating Manualdavid.bradley83Nessuna valutazione finora

- PP Ambiente, Manual de Activated Sludge ProcessDocumento129 paginePP Ambiente, Manual de Activated Sludge ProcessveronicaNessuna valutazione finora

- MS Earthwork For Railway Formation Rev 6 PDFDocumento105 pagineMS Earthwork For Railway Formation Rev 6 PDFRavi Teja100% (1)

- MVAC Testing & Commissioning Procedure - 2007Documento245 pagineMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- A1-50 Architectural Precast Concrete CladdingDocumento25 pagineA1-50 Architectural Precast Concrete CladdingZYWNessuna valutazione finora

- 2119-CC-T-OM-001 Rev1 Operating ManualDocumento189 pagine2119-CC-T-OM-001 Rev1 Operating ManualDinh Nguyen VanNessuna valutazione finora

- Wind Turbine Operation & Maintenance Based On Condition Monitoring WTDocumento39 pagineWind Turbine Operation & Maintenance Based On Condition Monitoring WTrajNessuna valutazione finora

- Fundamentals of Slickline Operations AaaDocumento39 pagineFundamentals of Slickline Operations AaaVictor MartinezNessuna valutazione finora

- Users GuideDocumento70 pagineUsers GuideCARLOS100% (1)

- Full Download Book New Technologies For Emission Control in Marine Diesel Engines PDFDocumento41 pagineFull Download Book New Technologies For Emission Control in Marine Diesel Engines PDFbenjamin.contreras157100% (14)

- 7 Ami 70 enDocumento42 pagine7 Ami 70 enlcsd.juniorNessuna valutazione finora

- 11-QC40-F-750 - A Commissioning Test Procedure Forr I&C SystemDocumento30 pagine11-QC40-F-750 - A Commissioning Test Procedure Forr I&C SystemIbrahim AliNessuna valutazione finora

- 01 31462-01-02-01 - Inst - Manual - Rev2Documento120 pagine01 31462-01-02-01 - Inst - Manual - Rev2pRADEEP sNessuna valutazione finora

- 4th ModDocumento57 pagine4th ModFathima NazrinNessuna valutazione finora

- New Technologies For Emission Control in Marine Diesel Engines Kuwahara Download PDF ChapterDocumento51 pagineNew Technologies For Emission Control in Marine Diesel Engines Kuwahara Download PDF Chapterjonathan.lastrapes303100% (4)

- UppieDocumento117 pagineUppiemuhammed_bulanNessuna valutazione finora

- EG50R1-2T Subsea Operations-2021Documento37 pagineEG50R1-2T Subsea Operations-2021ahmezoNessuna valutazione finora

- AHU With HP Design Guide VLT Micro Drive FC 101.aspx PDFDocumento124 pagineAHU With HP Design Guide VLT Micro Drive FC 101.aspx PDFAseem Vivek MasihNessuna valutazione finora

- Load Test Plan No Activity Document Acceptance CriteriaDocumento2 pagineLoad Test Plan No Activity Document Acceptance Criteriaozi novtenNessuna valutazione finora

- Table of ContentDocumento14 pagineTable of ContentSukumar ChandranNessuna valutazione finora

- Limitorque MX-DDC-100 Accutronix Installation & Operation ManualDocumento60 pagineLimitorque MX-DDC-100 Accutronix Installation & Operation ManualEric Alberto Arrieta PerezNessuna valutazione finora

- CP Petrofac ProcedureDocumento34 pagineCP Petrofac ProcedureBou Lem100% (2)

- Columns Product Catologue Rev D MK 2Documento88 pagineColumns Product Catologue Rev D MK 2JDNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento17 pagineNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORNessuna valutazione finora

- Honeywell All Spec Wagner Technical ManualDocumento148 pagineHoneywell All Spec Wagner Technical ManualVasil StamenovNessuna valutazione finora

- Petroleum - Storage.tank - Systems 2021Documento80 paginePetroleum - Storage.tank - Systems 2021Cesar DiazNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento35 pagineNational Oil Corporation: Rev Date Description Checked ApprovedYousab Jacob100% (1)

- Procedure For The Design Construction of Distribution SysteDocumento189 pagineProcedure For The Design Construction of Distribution SystemgyoonNessuna valutazione finora

- Inversor Frequência Design Guide FC 101Documento124 pagineInversor Frequência Design Guide FC 101JandersonDiegoNessuna valutazione finora

- MG07B302 Design Guide FC 280Documento104 pagineMG07B302 Design Guide FC 280Dave DuasoNessuna valutazione finora

- Axiom Ami: by Stonel Installation, Maintenance and Operating InstructionsDocumento42 pagineAxiom Ami: by Stonel Installation, Maintenance and Operating InstructionsagapitolopesNessuna valutazione finora

- LOGSTOR Detect: LOGSTOR A/S Tel. +45 99 66 10 00 Handling and Installation 2011.09Documento56 pagineLOGSTOR Detect: LOGSTOR A/S Tel. +45 99 66 10 00 Handling and Installation 2011.09iulianhansaNessuna valutazione finora

- MS Electrical Cable InstallationDocumento11 pagineMS Electrical Cable InstallationAhmed Rashed ANessuna valutazione finora

- FC280 DG MG07B202Documento96 pagineFC280 DG MG07B202Tedjo KartonoNessuna valutazione finora

- MS Cable Installation 001Documento11 pagineMS Cable Installation 001Ahmed Rashed ANessuna valutazione finora

- Harvey G Cragon-Computer Architecture and Implementation-Cambridge University Press (2000)Documento328 pagineHarvey G Cragon-Computer Architecture and Implementation-Cambridge University Press (2000)motazNessuna valutazione finora

- BMPS-P4 - 0 (Emcs)Documento52 pagineBMPS-P4 - 0 (Emcs)almadridNessuna valutazione finora

- Sedco Forex Well Control ManualDocumento339 pagineSedco Forex Well Control ManualPaolo German TourNessuna valutazione finora

- 100953en de Manual Cegardlift Lxly v210Documento52 pagine100953en de Manual Cegardlift Lxly v210silviuNessuna valutazione finora

- A1-50 Architectural Precast Concrete CladdingDocumento28 pagineA1-50 Architectural Precast Concrete CladdingJacky TiongNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento37 pagineNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNessuna valutazione finora

- Kelox Handbook enDocumento53 pagineKelox Handbook enAlexandru ANessuna valutazione finora

- Egress For Disabled Occupants and LiftsDocumento66 pagineEgress For Disabled Occupants and LiftsclubberlangPCFNessuna valutazione finora

- 02 FS-PLCDocumento23 pagine02 FS-PLCDEBASISH SARKARNessuna valutazione finora

- Distributed Process Control ReportDa EverandDistributed Process Control ReportNessuna valutazione finora

- Verification of Systems and Circuits Using LOTOS, Petri Nets, and CCSDa EverandVerification of Systems and Circuits Using LOTOS, Petri Nets, and CCSNessuna valutazione finora

- Bridge Technology ReportDa EverandBridge Technology ReportNessuna valutazione finora

- Embedded Microcontroller Interfacing for M-COR ® SystemsDa EverandEmbedded Microcontroller Interfacing for M-COR ® SystemsNessuna valutazione finora

- StarLAN Technology ReportDa EverandStarLAN Technology ReportValutazione: 3 su 5 stelle3/5 (1)

- Cut Off Score For The Recruitment of Graduate Trianees Through GATE-2017 Against Advt. No. 3/2017 (R&P)Documento1 paginaCut Off Score For The Recruitment of Graduate Trianees Through GATE-2017 Against Advt. No. 3/2017 (R&P)NaveenKumarNessuna valutazione finora

- What Is The Difference Between NTFS and FAT32 File SystemDocumento10 pagineWhat Is The Difference Between NTFS and FAT32 File SystemAcrux KnightNessuna valutazione finora

- Xbee Interfacing Module ManualDocumento3 pagineXbee Interfacing Module ManualAcrux KnightNessuna valutazione finora

- Teen Slight Edge PDFDocumento176 pagineTeen Slight Edge PDFvincraig100% (5)

- Pi, PD, Pid ControllersDocumento21 paginePi, PD, Pid ControllersGanesh RadharamNessuna valutazione finora

- About SteelDocumento3 pagineAbout SteelAcrux KnightNessuna valutazione finora

- Introduction To MPU6050Documento2 pagineIntroduction To MPU6050Acrux KnightNessuna valutazione finora

- Presented By: K. S. SANTOSHDocumento11 paginePresented By: K. S. SANTOSHAcrux KnightNessuna valutazione finora

- Creating Workspace and Learning ROSDocumento2 pagineCreating Workspace and Learning ROSAcrux KnightNessuna valutazione finora

- Explorer RobotDocumento11 pagineExplorer RobotAcrux KnightNessuna valutazione finora

- Art Neowral System Ilovepdf CompressedDocumento764 pagineArt Neowral System Ilovepdf CompressedAcrux KnightNessuna valutazione finora

- The Chemical Engineer'S Role in Nuclear-Power-Reactor Design, Development and OperationDocumento5 pagineThe Chemical Engineer'S Role in Nuclear-Power-Reactor Design, Development and OperationNaveen TNessuna valutazione finora

- 9701 s02 QP 2Documento12 pagine9701 s02 QP 2nikhileshNessuna valutazione finora

- BEC198-1 PrelimsDocumento98 pagineBEC198-1 PrelimsClash Nikov100% (1)

- O2 Analyzer by Haider AliDocumento22 pagineO2 Analyzer by Haider Alidinzo ccsiNessuna valutazione finora

- Chapter 5 CorrectedDocumento43 pagineChapter 5 CorrectedKarthiKeyanNessuna valutazione finora

- Mars 1968Documento12 pagineMars 1968Minh Trần Nguyễn NhựtNessuna valutazione finora

- Renewable Energy: Enzhu Hu, Yufu Xu, Xianguo Hu, Lijun Pan, Shaotong JiangDocumento8 pagineRenewable Energy: Enzhu Hu, Yufu Xu, Xianguo Hu, Lijun Pan, Shaotong JiangAnass AkrimNessuna valutazione finora

- Liquid Waste ManagementDocumento12 pagineLiquid Waste ManagementTidus FarronNessuna valutazione finora

- Science Form 3 Chapter 6 - Land and Its Resources PDFDocumento5 pagineScience Form 3 Chapter 6 - Land and Its Resources PDFFarah Sofea Razali87% (15)

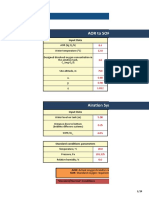

- AOR To SORDocumento24 pagineAOR To SORImtiaz HaqueNessuna valutazione finora

- RespirocytesDocumento5 pagineRespirocytesvarunyaNessuna valutazione finora

- Experiment No 6 Vitamin C EstimationDocumento2 pagineExperiment No 6 Vitamin C EstimationTran Thi Khanh Minh0% (1)

- Pahang JUJ 2012 SPM ChemistryDocumento285 paginePahang JUJ 2012 SPM ChemistryJeyShida100% (1)

- Detainable Deficiency by PSCDocumento23 pagineDetainable Deficiency by PSCSardar Sirajul Islam100% (3)

- OxBan HB Product Data SheetDocumento1 paginaOxBan HB Product Data Sheetsmithyry2014Nessuna valutazione finora

- Air Pollution: Learning OutcomesDocumento34 pagineAir Pollution: Learning Outcomesgita100% (1)

- MN501 Mine Ventilation Engineering 3L:1T:0P 4 Credits: Jharkhand University of Technology, RanchiDocumento68 pagineMN501 Mine Ventilation Engineering 3L:1T:0P 4 Credits: Jharkhand University of Technology, RanchiKunal KishorNessuna valutazione finora

- HDS Gas MetanoDocumento4 pagineHDS Gas MetanoJuan ChajuNessuna valutazione finora

- Chapter 5Documento95 pagineChapter 5Joel OuanoNessuna valutazione finora

- Classification of Matter (1.1) : LithosphereDocumento2 pagineClassification of Matter (1.1) : LithospheredavidNessuna valutazione finora

- 04 AWT Corrosion ControlDocumento72 pagine04 AWT Corrosion ControlTony NietoNessuna valutazione finora

- BioA4 09. Nutrition and Gas Exchange in PlantDocumento8 pagineBioA4 09. Nutrition and Gas Exchange in Plantthanks btNessuna valutazione finora

- 11U Pract Test StoichDocumento12 pagine11U Pract Test StoichNabila HanimNessuna valutazione finora

- IIT JEE SyllabusDocumento6 pagineIIT JEE SyllabusAbhijith RaviNessuna valutazione finora

- High-Temperature Corrosion and Materials Applications George Y. Lai, Editor, p1 DOI: 10.1361/hcma2007p001 All Rights ReservedDocumento445 pagineHigh-Temperature Corrosion and Materials Applications George Y. Lai, Editor, p1 DOI: 10.1361/hcma2007p001 All Rights ReservedFaraj HaiderNessuna valutazione finora

- AMCP 706-177, Properties of ExplosivesDocumento404 pagineAMCP 706-177, Properties of Explosiveswerdna67Nessuna valutazione finora

- Lockheed Field Service Digest FSD Vol.4 No.1 Intro L1649 Starliner Part 3 of 3Documento36 pagineLockheed Field Service Digest FSD Vol.4 No.1 Intro L1649 Starliner Part 3 of 3arizonaflyerNessuna valutazione finora