Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gpalliedmaturitymatrix8planning Scheduling1rev3 130926135255 Phpapp02 PDF

Caricato da

Anonymous OuY6oAMggxTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gpalliedmaturitymatrix8planning Scheduling1rev3 130926135255 Phpapp02 PDF

Caricato da

Anonymous OuY6oAMggxCopyright:

Formati disponibili

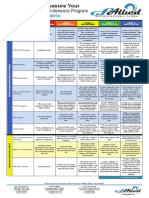

Ways to Measure Your

Planning and Scheduling, 1

Maturity Matrix

Elements LEVEL

LEVEL 11 LEVEL

LEVEL 22 LEVEL 3 LEVEL

LEVEL 44 LEVEL

LEVEL 55

NOT ENGAGED

NOT ENGAGED EXPERIMENTING

EXPERIMENTING ENLIGHTENED GOOD PRACTICE

GOOD PRACTICE BEST PRACTICE

BEST PRACTICE

Planners have been formally Processes are well All affected individuals have

trained. Affected individuals defined, with maintenance received specific training

Planners have attended

have been provided and operations leaders to expectations. Training is

Planning Education No formal training provided. a formal planner training

awareness training but given specific training on ongoing for new hires. All

course or workshop.

nothing related to specific expectations with additional personnel modeling expected

expectations. on-the-job coaching. behaviors.

Planners strictly focused

Role and responsibilities Planners develop and

Expectations of full-time on future work. Zero

not clearly defined. Planner assemble limited job

Planner Role and planners well defined. Still involvement with

No planner role identified. is involved with reactive packages. Dedicated planner

Responsibilities an excessive amount of time reactive work. Roles and

work and parts chasing. No as a full-time resource.

spent on non-core activities. responsibilities are clearly

dedicated planner. Unclear expectations.

adhered to.

Formal expectations

Standardized format for

High level work procedures developed for job plan format

job plans established; Level IV + Evidence of

developed for large jobs and and content that is generally

No effective work procedures expectations on quality and continuous improvement

Standard Work outages. Heavily dependent followed. Job plans are

or accurate time estimates content are subjective. No system in place.

Procedures on OEM manuals. Standard developed for work on critical

developed by planner. clear expectations for which Craftspersons involved in

set of expectations for job assets. Moving towards

jobs should have a detailed review and approval process.

plan content not established. quantitative vs. subjective

plan developed.

inspection criteria.

Jobs are grossly Job estimates are generally Jobs are broken down into

Level IV + Job plan includes

overestimated (1/2 shift or full more accurate; basic steps and tasks with a time

estimates for coordination

Job plans have no estimated shift) and not taken seriously estimating process applied. estimate rolled up into a total.

Labor Estimation and other outside resources.

labor hours assigned. in scheduling process. No Estimates are usually Accepted as accurate and

Estimates adjusted based on

formal estimating techniques accepted as being accurate utilized in building the weekly

history/craft feedback.

PLANNING

are used. but are often overridden. schedule.

Planner reviews some job

Planner visits large or Job site visits and significant

Job site visits are rare or Planner visits job sites for plans with maintenance

complex job sites during interaction with those who

Job Site Visits non-existent while planning high profile jobs only while supervisors and technicians

planning only when no pre- will perform the work is a

work. planning work. at the job site to ensure

existing job plan exists. standard practice.

completeness.

Level IV + Methods to

Planner makes reference to Planner prepares detailed

address these hazards

No identification of Safety/ Planner includes high-level generic safety procedures list of safety hazards and

Identification of Safety are provided. Permits are

Tag out/Permit requirements references to site safety or requirements on the references permits required

Requirements pre-populated as much as

by the planner. policies on work order. work order based on the based on job task breakdown

possible and included in the

equipment type/environment. and site visit.

work packet.

Some BOMs developed, Level III + Formal plan BOMs developed to the

but only for a small portion in place to address component level with minor

Level II + Some BOMs are

of equipment. Most are shortcomings on BOMs. exceptions. Continuous

Bill of Materials (BOM) Equipment-specific BOMs do linked to drawings, item

incomplete or inaccurate; Focus on equipment improvement and corrections

Management not existent. number, and lead time for

almost never formally level. Plan is clearly being a standard process. BOMs

delivery.

reviewed or corrected/ executed with results of are standard part of CAPEX

updated. efforts evident. process.

BOMs and job history

Technicians identify their own Planners work with

No predetermination of utilized, but gaps exist. BOMs and past job history

materials and the planner maintenance supervisors and

needed materials. Materials Planner expends a significant leveraged extensively.

Determination of places the order. List is quite technicians along with past

acquisition is entirely up to amount of time researching Delays in job execution due

Required Materials often inaccurate. Job delays job history to develop list.

technicians on the fly while materials. Job delays from to missing materials are a

from missing material are Storeroom runs during job

executing job. missing materials only very rare occurrence.

common. execution still common.

occasionally occur.

Continued on back...

North America Europe Latin America Middle East Asia-Pacific

World Headquarters GPAllied EMEA

4200 Faber Place Drive Guldensporenpark 21-Blok C

Charleston, SC 29405 B-9820 Merelbeke, Belgium

o. 888.335.8276 o. +32(0)9.210.17.20

f. 843.414.5779 f. +32(0)9.210.17.28

www.gpallied.com

Ways to Measure Your

Planning and Scheduling, 1

Maturity Matrix

Elements LEVEL

LEVEL 11 LEVEL

LEVEL 22 LEVEL 3 LEVEL

LEVEL 44 LEVEL

LEVEL 55

NOT

NOT ENGAGED

ENGAGED EXPERIMENTING

EXPERIMENTING ENLIGHTENED GOOD

GOOD PRACTICE

PRACTICE BEST

BEST PRACTICE

PRACTICE

Materials kitting and staging

Materials kitting and staging Kitting is standard practice

No kitting process in place. Materials lay down areas occurs for all outage jobs

occurs for most outage jobs with few errors. Kits are kept

Materials acquired on the exist in storeroom; informal and most weekly/daily work.

Materials Kitting and only ad hoc for weekly/ in a secure area, verified for

fly by technicians and process, much confusion and Storeroom personnel receive

daily work. Technicians drive accuracy against the work

supervisors. inaccuracy. pick-lists and assemble the

the process. order and easily identified.

kits.

PLANNING

Level III + Improvement

Work orders are returned to Level IV + Component

Work orders are returned suggestions, materials

planner with hours (actual codes and failure codes.

to planner for closeout, consumed, and actual

Work orders are not returned almost always matches Failure information can be

Work Order Closeout but contain very little hours spent. History allows

to the planner for closeout. estimate) and no indication discerned from work order

if any useful feedback management reporting on

of missing materials. Planner history to drive reliability

(Fixed, Done, Complete). MTBF and Planned vs.

occasionally makes updates. improvements.

Actual hours.

Scheduling meeting occurs Scheduling meeting occurs

Level III + Attendees are on

with a standard agenda, like clockwork and is efficient

Scheduling meeting only time and actively engaged

date, time, and required - standard time, place,

Scheduling meetings occurs for outages attended in the scheduling meeting.

Scheduling Meeting attendees. Production agenda. Operations drives

not held. Organization only by maintenance Moderate level of confidence

Participation attends meetings on meetings. Formal approval

completely reactive. personnel. Production does exists in the developed

occasion, but not actively process (Maintenance

not attend. schedule. Maintenance

engaged when present. and Operations). Senior

driven.

Schedule not taken seriously. Management sponsorship.

Backlog largely inaccurate

Schedule is developed using Backlog is generally

and not taken seriously. Next

Backlog is not considered a combination of backlog considered accurate and

Operations/ weeks schedule originates Ready backlog is the primary

when developing a schedule. and last minute emergency most jobs are only scheduled

Maintenance Use from both the backlog and driver for building the

Daily reactive coordination lists. Team understands the from backlog, not necessarily

of Backlog for on-the-spot production schedule. Backlog size and

occurs vs. weekly importance of scheduling strictly from the ready

Scheduling requests. Many very old (>90 age appropriate.

scheduling. from the backlog, but still backlog (total backlog as

days) jobs on the backlog;

struggles with execution. well).

backlog is large.

Level IV + Schedule is

Schedule is published on a Schedule is passively Schedule is published

regularly and actively

Largely verbal agreements network drive or emailed. posted and displayed in and displayed in all areas.

reviewed with personnel

Schedule and informal lists. Shared Rarely viewed/passive maintenance shops/areas Schedule is regularly posted

at set date/time/place;

Communication only between small subset of communication/small subset only. Frequency of updates at set date/time/place;

published at least one

workforce. of organization aware of sporadic and rarely paid awareness of schedule

week in advance. Minimal

existence. attention to. content/importance varies.

coordination delays.

Labor Hours formally

Scheduling based Level IV + Formal process

Available resources not scheduled to 100%. Front

on availability of in place for schedule

Personnel react entirely taken into consideration line supervisors react to

resources; significant breakers. Resource

to radio/trouble calls from during scheduling. Personnel schedule breakers, but

portion of schedule utilization is very high.

Resource Utilization production/maintenance select their jobs from an no formal process exists.

empty to accommodate Personnel assigned to jobs

supervisors. Resource assignment box; no names Resource utilization is

emergencies. Resources the week before. Schedule

availability not known. listed. Resource utilization moderate. Jobs assigned to

not scheduled to 100% breakers analyzed for

low. personnel the day prior to

availability. improvement.

work.

Number of work orders Only tracking work order Compliance measured by

completed is tracked. completion rate. Formal dividing the total number of Level IV + Method formalized

Numbers are suspect to standard in place but not labor hours completed by the and consistently followed.

Measuring Schedule Not measured. No

manipulation; methods of consistently followed. total number of labor hours Organization regularly tracks

Compliance accountabilities set.

measurement are sporadic Measurement published scheduled. Measurements and seeks out improvement

and variable. No system of regularly; results not used to formalized and trended, but opportunities.

accountability. drive improvement. not always followed.

North America Europe Latin America Middle East Asia-Pacific

World Headquarters GPAllied EMEA

4200 Faber Place Drive Guldensporenpark 21-Blok C

Charleston, SC 29405 B-9820 Merelbeke, Belgium

o. 888.335.8276 o. +32(0)9.210.17.20

f. 843.414.5779 f. +32(0)9.210.17.28

www.gpallied.com

Potrebbero piacerti anche

- Mini-Fill Touch Manual v2 en 2016Documento30 pagineMini-Fill Touch Manual v2 en 2016Anonymous OuY6oAMggxNessuna valutazione finora

- MPS Day1 World Class Reliability PerformanceDocumento142 pagineMPS Day1 World Class Reliability Performancemelator100% (1)

- Position Description - Reliability EngineerDocumento7 paginePosition Description - Reliability EngineerAnonymous OuY6oAMggxNessuna valutazione finora

- Senior Asset Planner - M&E (HDWKS)Documento8 pagineSenior Asset Planner - M&E (HDWKS)Anonymous OuY6oAMggxNessuna valutazione finora

- Draw Now 30 Easy Exercises For BeginnersDocumento78 pagineDraw Now 30 Easy Exercises For BeginnersDanut Alexandru100% (1)

- Project Management ProcessDocumento18 pagineProject Management Processvineetkrs002Nessuna valutazione finora

- Productflyer - 978 3 319 02677 0Documento1 paginaProductflyer - 978 3 319 02677 0Anonymous OuY6oAMggxNessuna valutazione finora

- Senior Asset Planner - M&E (HDWKS)Documento8 pagineSenior Asset Planner - M&E (HDWKS)Anonymous OuY6oAMggxNessuna valutazione finora

- We Amp 2013Documento339 pagineWe Amp 2013Anonymous OuY6oAMggxNessuna valutazione finora

- Position Description - Reliability EngineerDocumento7 paginePosition Description - Reliability EngineerAnonymous OuY6oAMggxNessuna valutazione finora

- NB604n Wireless Setup GuideDocumento33 pagineNB604n Wireless Setup GuideAnonymous OuY6oAMggxNessuna valutazione finora

- VardonDocumento2 pagineVardonAnonymous OuY6oAMggxNessuna valutazione finora

- PROJECT MANAGERS Implementation ManualDocumento127 paginePROJECT MANAGERS Implementation ManualAnonymous OuY6oAMggxNessuna valutazione finora

- Position Description - Electrical Asset Engineer - February 2016Documento2 paginePosition Description - Electrical Asset Engineer - February 2016Anonymous OuY6oAMggxNessuna valutazione finora

- Maintenance Planner Role ResponsibilitiesDocumento2 pagineMaintenance Planner Role ResponsibilitiesAnonymous OuY6oAMggxNessuna valutazione finora

- 11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFDocumento42 pagine11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFmsaad19103564100% (2)

- Maturity Matrix: Preventive Maintenance ProgramDocumento2 pagineMaturity Matrix: Preventive Maintenance ProgramAnonymous OuY6oAMggx100% (1)

- BobResume ReliabilityDocumento7 pagineBobResume ReliabilityAnonymous OuY6oAMggxNessuna valutazione finora

- Project Management "Made Simple": Using Technical and Behavioral Quick ConnectsDocumento30 pagineProject Management "Made Simple": Using Technical and Behavioral Quick ConnectsAnonymous OuY6oAMggxNessuna valutazione finora

- MPS Day1 World Class Reliability PerformanceDocumento142 pagineMPS Day1 World Class Reliability Performancemelator100% (1)

- Maintenance Planning: Brian Parsons of Foresight Solutions Says To Have A First Rate Planning System Makes All TheDocumento2 pagineMaintenance Planning: Brian Parsons of Foresight Solutions Says To Have A First Rate Planning System Makes All TheAnonymous OuY6oAMggxNessuna valutazione finora

- Maintenanceplanner PDFDocumento3 pagineMaintenanceplanner PDFAnonymous OuY6oAMggxNessuna valutazione finora

- Maintenance Planner Job DescriptionDocumento4 pagineMaintenance Planner Job Descriptionansar shafiiNessuna valutazione finora

- Maturity Matrix: Preventive Maintenance ProgramDocumento2 pagineMaturity Matrix: Preventive Maintenance ProgramAnonymous OuY6oAMggx100% (1)

- Document 1Documento2 pagineDocument 1Anonymous OuY6oAMggxNessuna valutazione finora

- Document 1Documento5 pagineDocument 1Anonymous OuY6oAMggxNessuna valutazione finora

- Document 1Documento5 pagineDocument 1Anonymous OuY6oAMggxNessuna valutazione finora

- Karma Cola LTD Credit Application FormDocumento4 pagineKarma Cola LTD Credit Application FormAnonymous OuY6oAMggxNessuna valutazione finora

- Karma Cola LTD Credit Application FormDocumento4 pagineKarma Cola LTD Credit Application FormAnonymous OuY6oAMggxNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Academic Emotions in Students' Self-Regulated Learning and AchievementDocumento15 pagineAcademic Emotions in Students' Self-Regulated Learning and AchievementAldo RamirezNessuna valutazione finora

- Q4M2 Giving Technical and Operational Def.2.0Documento60 pagineQ4M2 Giving Technical and Operational Def.2.0Shadow Gaming YTNessuna valutazione finora

- Decimal Unit PlanDocumento17 pagineDecimal Unit Planapi-288753185Nessuna valutazione finora

- Artifact #4: Multicultural Lesson Plan For English Language ArtsDocumento10 pagineArtifact #4: Multicultural Lesson Plan For English Language Artsapi-417980098Nessuna valutazione finora

- Values, Ethics, and CharacterDocumento25 pagineValues, Ethics, and CharacterhIgh QuaLIty SVTNessuna valutazione finora

- Fiedler's Contingency Model of LeadershipDocumento11 pagineFiedler's Contingency Model of Leadershipjoy pamorNessuna valutazione finora

- DLL 4 2019 ElsDocumento4 pagineDLL 4 2019 Elsjoselyn bergonia100% (1)

- Protection PrayerDocumento2 pagineProtection PrayerRajan Xaxa100% (1)

- Tour Guiding ElementsDocumento11 pagineTour Guiding ElementsRocelle M. Joyce HermosuraNessuna valutazione finora

- Charlie and The Chocolate FactoryDocumento4 pagineCharlie and The Chocolate FactorypaschiasorinaNessuna valutazione finora

- Case Study-BP ChemicalsDocumento3 pagineCase Study-BP ChemicalsmiekNessuna valutazione finora

- Popular Sovereignty Is EnoughDocumento4 paginePopular Sovereignty Is EnoughdominatedebateNessuna valutazione finora

- Midterms - EL100Documento59 pagineMidterms - EL100Personal AdminNessuna valutazione finora

- BestMan GroomsManSpeechesDocumento14 pagineBestMan GroomsManSpeechesAdam LemonsNessuna valutazione finora

- Board Notes Compiled Final (Very Nice)Documento8 pagineBoard Notes Compiled Final (Very Nice)jun del rosarioNessuna valutazione finora

- Flanagan (2014) Unmet Needs Maladaptive ModesDocumento15 pagineFlanagan (2014) Unmet Needs Maladaptive ModesCristina ColoteloNessuna valutazione finora

- The Hypothesis and Assumptions of The StudyDocumento12 pagineThe Hypothesis and Assumptions of The StudyMaria Arlene67% (3)

- The Effects of Auditory Hallucination Symptom ManagementDocumento12 pagineThe Effects of Auditory Hallucination Symptom ManagementAndika FahruroziNessuna valutazione finora

- đề tham khảo số 11Documento3 pagineđề tham khảo số 11Nguyễn ThànhNessuna valutazione finora

- Anthropometry and ErgonomicsDocumento6 pagineAnthropometry and ErgonomicsNIKITA JAINNessuna valutazione finora

- 2 - The Evolution of Public Relations PDFDocumento9 pagine2 - The Evolution of Public Relations PDFAndré Paz0% (1)

- Research Methodology - Unit 2 - Week 1 - Group Discussion On ResearchDocumento3 pagineResearch Methodology - Unit 2 - Week 1 - Group Discussion On ResearchE.GANGADURAI AP-I - ECENessuna valutazione finora

- Effect of Sleep Deprivation On College Students' Academic PerformanceDocumento10 pagineEffect of Sleep Deprivation On College Students' Academic PerformanceVirgil Viral Shah0% (1)

- Personal Productivity EbookDocumento26 paginePersonal Productivity Ebookrcoca_1Nessuna valutazione finora

- YlCero FantasyDocumento31 pagineYlCero FantasyKiana ManatigaNessuna valutazione finora

- HapticityDocumento19 pagineHapticitySauda DarNessuna valutazione finora

- Principal CollegeDocumento4 paginePrincipal CollegeAnusha Verghese50% (2)

- Julian Langer - Feral Consciousness - Deconstruction of The Modern Myth and Return To The WoodsDocumento192 pagineJulian Langer - Feral Consciousness - Deconstruction of The Modern Myth and Return To The Woodsarief arfadNessuna valutazione finora

- The True Rosicrucian & Holy Grail Traditions - Online CoursesDocumento8 pagineThe True Rosicrucian & Holy Grail Traditions - Online CoursesPanther PantherNessuna valutazione finora

- Mark CousinsDocumento7 pagineMark CousinsParikshit NemaNessuna valutazione finora