Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hydrogen Attack PDF

Caricato da

ChanoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hydrogen Attack PDF

Caricato da

ChanoCopyright:

Formati disponibili

Materials Science and Technology

ISSN: 0267-0836 (Print) 1743-2847 (Online) Journal homepage: http://www.tandfonline.com/loi/ymst20

Hydrogen attack of pressure-vessel steels

P. G. Shewmon

To cite this article: P. G. Shewmon (1985) Hydrogen attack of pressure-vessel steels, Materials

Science and Technology, 1:1, 2-11, DOI: 10.1179/mst.1985.1.1.2

To link to this article: http://dx.doi.org/10.1179/mst.1985.1.1.2

Published online: 02 Dec 2013.

Submit your article to this journal

Article views: 29

View related articles

Citing articles: 21 View citing articles

Full Terms & Conditions of access and use can be found at

http://www.tandfonline.com/action/journalInformation?journalCode=ymst20

Download by: [Universite Laval] Date: 09 May 2016, At: 09:13

Critical Hydrogen attack (HA) is a degradation process occurring in steel exposed to

hot, high-pressure hydrogen. It is caused by the nucleation, growth, and ultimate

assessment link-up into fissures of small methane bubbles - primarily on grain boundaries.

The location and growth kinetics of the submicrometre bubbles during the

incubation period before fissure formation has been studied only in the past few

Hydrogen attack years. Growth is limited primarily by grain-boundary diffusion, though creep of

the ligaments between bubbles can be limiting under certain conditions. The

of pressure- processes limiting bubble nucleation are unclear though there seems to be a

vessel steels critical stress (methane pressure plus applied stress) above which the bubble

density increases greatly. Alloying with Cr enhances the resistance to HA,

primarily by reducing the bubble density rather than by reducing the bubble

growth rate. The process of bubble growth and link-up is completely analogous to

that by which grain-boundary voids link-up to limit the creep ductility of alloys.

Simultaneous HA and creep leads to a marked acceleration of failure, though it is

unclear whether this is caused primarily by the enhancement of nucleation or by

growth. ,. MST/112

1985 The Institute of Metals. Manuscript received 9 August 1984; infinalform

8 October 1984. Professor Shewmon is in the Department of Metallurgical

P. G. Shewmon Engineering, Ohio State University, Columbus, Ohio, USA.

Downloaded by [Universite Laval] at 09:13 09 May 2016

Introduction dioxide bubbles during annealing in an oxidizing

atmosphere has been the subject of recent studies.10,11

The most important difference-between these cases and

Steel exposed to high-pressure hydrogen at temperatures the development of methane bubbles in PV steels is the

above 300C may appear to be unaffected for weeks, or value of the equilibrium gas pressure relative to the creep

even years, and then in a relatively short time can lose strength of the metal matrix. In the cases of copper, silver,

much of its ductility and strength. This is caused by the and nickel the equilibrium gas pressures far exceed the

nucleation, growth, and merging of methane bubbles along creep strength of the metal matrix so that most of the

grain boundaries to form fissures. This process is called incoming solute (hydrogen or oxygen) reacts near the

hydrogen attack (HA). It is distinctly different from the surface to form relatively large bubbles there, Le. bubble

more commonly studied hydrogen embrittlement of steel growth is limited by hydrogen or oxygen supply. This

which occurs at much lower hydrogen pressures and surface layer of large bubbles grows inward in a manner

temperatures. An understanding of the mechanism of HA is resembling that found for the internal oxidation of alloys.

of interest better to predict the behaviour of pressure However, the maximum (equilibrium) methane pressure

vessels containing hot high-pressure hydrogen, and also as that develops in steel leads to only very slow creep, and

another way to study the processes that limit creep thus the strength of the metal matrix greatly slows bubble

ductility in alloys. growth, i.e. bubble growth is not limited by hydrogen

Hydrogen attack was discovered about 60 years ago in supply. As a result the hydrogen will diffuse to a greater

Germany during the development of the process for the depth before it can react to form methane. Thus, bubbles

chemical synthesis of ammonia. 1,2 It has been of primary form homogeneously to an appreciable depth (many

concern to the petroleum industry since they have been the centimetres) beneath the surface of the steel. This matrix

main group who built large pressure vessels (PVs) to carry restraint also accounts for the substantial incubation time

out the hot hydrogenation of feedstock. With the before the bubbles grow to a size sufficient to affect the

consideration of the development of large plants to gasify mechanical properties, or be reliably observed by non-

coal, another group has developed an interest in this destructive examination techniques.

subject. This article begins with a summary of the factors that

Alloying with carbide-forming elements has improved influence the HA of steels and then a more detailed

the HA resistance of low-alloy steels, and allowed industry discussion is given of the models that have been developed

to minimize failures caused by this phenomenon. 3-6 to describe the nucleation and growth of the methane

However, until the last decade there has been relatively bubbles. The discussion is limited to the behaviour of

little study of the atomic processes that limit the nucleation carbon steel and 2'25Cr-lMo steel in a gaseous hydrogen

and growth of the bubbles. These recent studies have been atmosphere. However, exactly the same kind of

motivated by the availability of new experimental degradation and decarburization is found in boiler piping

techniques to study the submicrometre bubbles that grow made of carbon or low-alloy steel,12 and recently the

during the incubation period, as well as by the desire better formation of methane bubbles has been reported in

to address the question of what would limit the life and 18Cr-8Ni stainless steel exposed to a flame.13,14 In both

operating conditions for very large PVs in coal-gasification cases the hydrogen is generated by the oxidation of the

plants. steel by water. The hydrogen potential (chemical activity) is

The growth of internal gas bubbles in a metal through high but unknown.

the inward diffusion of a mobile gas atom and chemical The atomic processes involved in the growth of methane

reaction to form an insoluble gas molecule is a bubbles in steel bear many similarities to the slow growth

phenomenon found in several systems. The embrittlement of grain-boundary voids in the creep of alloys, and the

of oxygen-bearing copper 7 or silverS by the formation of models for methane-bubble growth will draw heavily on

steam bubbles during annealing in a hydrogen-bearing the creep models. Bubble nucleation in HA is less well

atmosphere is well established. The development of understood, as in the case of void nucleation in creep.

nitrogen bubbles and their growth to fissures has been However, it is clear that the bubbles in HA must nucleate

demonstrated in the nitriding of stee1.9 The embrittlement heterogeneously because of the relatively low methane

of carbon-bearing nickel by the formation of carbon pressures available to drive nucleation.

2 Materials Science and Technology January 1985 Vol. 1

Shewmon Hydrogen attack of pressure-vessel steels 3

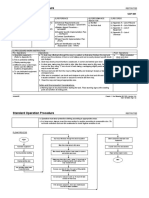

NELSON CURVES (API, 1977) several samples under a fixed pressure but at increasing

temperatures. A complete loss in ductility is usually found

over a temperature increment of 50 K.

600 3. Pressure. Hydrogen attack is not observed in carbon

II steel until the hydrogen partial pressure PH exceeds 1 MPa .

.\

C-)

At higher pressures the incubation time decreases slowly

~500

0::

1\. \ 2.25 Cr -1.0 Mo with increasing pressure, or equivalently the temperature

:;::)

t--

I ', . threshold for HA drops (see Fig. 1).

~LoU 400

a...

::E

LoU

t-- 300

< ------- O~MO

---

Steel

4. Alloying. Alloying with carbide-forming elements can'

significantly increase the steel's resistance to HA, that is,

the steel resists attack to a higher temperature. 3,5 The

.- .- .- _ . _. CARBON Steel elements most commonly added for this purpose are Cr

200

-'- and Mo. Reducing the carbon content is not an effective

10 15 20 MPa

approach since steels with only a few hundredths per cent

o 1 2 3 ksi of carbon are still attacked.2, 17 .

HYDROGEN PARTIAL PRESSURE 5. Microstructure. In carbon steel no changes are

Lines suggested by API as .upper limits of tempera-

obvious under the light microscope during the incubation

ture and pressure for use of various steels5 .

stage. However, work with the scanning electron

microscope (SEM) has shown that early in the incubation

period discrete bubbles develop on grain-boundary

carbides (see Fig. 2). These grow and ultimately link up to

Observations form thin fissures along the grain boundariesl8,19 (see

Fig. 3). These fissures in turn link together, and often vent

Downloaded by [Universite Laval] at 09:13 09 May 2016

methane to the surface.20 As long as the bubbles contain

The outline of the HA phenomenon was well defined by the equilibrium methane pressure, methane forms slowly

Naumann in the late 1930s.2,3 The Germans were then and there is very little decarburization of the matrix.

working with ammonia synthesis at 300-600C, and

However, once the methane in fissues vents to the surface,

21-96 MPa hydrogen pressure, as well as coal liquefaction methane forms as rapidly as carbon can diffuse to the

at 400-550C and up to 69 MPa of hydrogen. 1,2 In the fissure surface, and decarburization of the regions on either

intervening period the operating limits to avoid HA in side of the fissures proceeds rapidly. These decarburized

common alloys have been better defined, but the outlines of regions increase in thickness, and the entire surface layer

the phenomenon are unchanged. The maximum pressures may become 'cracked' and decarburized.

commonly used commercially have decreased, the life of The formation of fissures is not homogeneous, but varies

components has appreciably increased, and the

from one part of the sample to another. Factors which

temperatures have remained roughly the same.

can increase the tendency of a region to fissure formation

Briefly, the characteristics of HA are: are: local cold work,2, 16,20 welding,21 and bands of

1. Incubation time. There is an extended period during inclusions.22,23 If the strings of inclusions run beneath and

which there are no changes in the room-temperature parallel to the external surface, fissures develop parallel to

mechanical properties of the steel exposed to hot, high- the surface, but the methane cannot vent to the surface.

pressure hydrogen. Then, in a relatively short time the This often results in surface blisters,2 which can become

mechanical properties deteriorate markedly, especially quite large.23

the toughness and ductility. 1,15,16 6. Mechanical properties. The easiest way to follow the

2. Temperature. The incubation time decreases rapidly effect of HA is by measuring mechanical properties at

with rising temperature. Equivalently, at any given pressure room temperature. In carbon steel fissuring always occurs

of hydrogen there is a temperature below which the and causes a clear shift in the mechanical properties. The

incubation time exceeds the life of the part, and no HA is effect is the earliest and most pronounced for impact

observed. This is the basis for describing the HA resistance

of alloys as is done in Fig. 1. A commonly used way to

study the susceptibility of an alloy to HA is to anneal

3 Bubble link-up into fissures: in this steel (REM-

treated Fe-O'2C, after 88 h, 450C, PH = 65 MPa)

local bubble density was higher and link-up into

2 Typical methane bubbles in HA of carbon steel fissures came earlier than in Fig. 2; however, the

(Fe-O'3C ESR steel after 88 h, 450C, PH = 65 MPa) methane gas is still trapped in fissures since pearlite

{Ref. 18) dissolution (decarburization) is negligible18

Materials Science and Technology January 1985 Vol. 1

4 Shewmon Hydrogen attack of pressure-vessel steels

properties, and next most severe for the ductility, while the bubbles. At lower temperatures where methane formation

ultimate tensile strength and the yield stress are last and is slower, and/or at later stages where the bubbles link up

least affected.2,15 to form fissures, the existence of the equilibrium pressure in

In unstressed, quenched and tempered (QT) 2'25Cr-1Mo the bubbles is less clear. However, during the long

steel Erwin24 reported no change in the room-temperature incubation time before bubble link-up the bubbles grow

tensile properties after 5 years at 540C and 21 MPa slowly and it seems quite probably that equilibrium is a

hydrogen even though a bubble volume fraction of between good approximation, at temperatures above 275-300C.

001 and 01 had developed. Under these stress-free Several experimental observations point to this.19,28-30

conditions bubbles form and grow, but fissuring does not The methane that generates HA in steel is formed by the

occur. However, Cuiffreda et al.25 showed that 138 MPa reaction

of hydrogen at 455C reduced the creep ductility

MxC+2H2=CH4+xM (1)

significantly in a test that failed in 6 months. Also, Wanagel

et a1.26 found that modest exposure to hydrogen (14 MPa, For Fe3C in carbon steel the activity of the carbide and the

600C, 20 d) developed methane bubbles sufficient to metal can be taken as unity. The equilibrium constant K

reduce the stress-rupture life materially in subsequent tests for this reaction can be written as

in an inert atmosphere at 600C. Both of these creep tests

were done under hydrogen-exposure conditions that would

1m = KIJ . . . . . . . . . . . . . . . (2)

have developed much less bubble volume by HA alone where 1m and IH are the fugacities of methane and

than was developed in Erwin's long-time tests. hydrogen, and Ao and AM are the activities of carbon and

7. Decarburization. The depth of decarburization in the metal (iron) atoms. For Fe3C, 1m is given by the

normal service 450C) should be negligible unless equation

fissuring develops to aid transport to and from the ambient

In/m=-13'3+13700/T+2InPH (3)

gas. In Cr-Mo steels exposed to hydrogen Masaoka

Downloaded by [Universite Laval] at 09:13 09 May 2016

et ai.2 7 reported surface decarburization and 'cracks' along where the fugacity of the hydrogen gas has been taken

grain boundaries near the surface. At 450C decarburiza- equal to its partial pressure, i.e~ hydrogen is assumed to

tion was negligible. Even after 1000 h at 600C the depth of behave ideally.31

decarburization was only 0'3-04 mm. The depth of grain- Odette and Vagarali32 have developed an equation of

boundary cracking (fissuring) at 600C increased with the state for methane in this range of temperature and

depth of decarburization and with PH' but was less than pressure. They show that 1m is adequately described by an

the depth of decarburization. equation of the form

(4)

where

Mechanisms C(T) = 2'375/T + 178 x 10- 3 1m > 104 MPa }

= 1187/T+309 X 10-3 (5)

Lengthening the incubation time is the critical factor in 103 <1m < 104 MPa

preventing HA. The use of sensitive dilatometry and the = 0005 1m < 103 MPa

SEM have established that during essentially all of the

The combination of these equations leads to relations

incubation period many small (submicrometre) methane

between PH2 and PCH4 as shown in Fig. 4. Note that at low

bubbles are growing on the grain boundaries of the stee1.19

hydrogen pressures and higher temperatures the lines on

Thus an analysis of the kinetics of this early period

this log-log plot approach the slope of Pm ~ P~, as would

becomes an analysis of the rates of nucleation and growth

be expected for ideal gas behaviour, while at high hydrogen

of these small bubbles. The pressurized bubbles create

pressures and lower temperatures the non-ideality of the

discontinuities in the stress normal to the grain boundaries

methane leads to a nearly constant methane pressure,

that results in a stress gradient exactly the same as that

independent of PH2 This high-pressure behaviour is a

caused by the stress discontinuities formed by voids on

strong contributor to the nearly pressure-independent

boundaries in samples under an external load. Thus the

temperature limit for HA found in Fig. 1.

atomic processes involved in the nucleation and growth of

methane bubbles in steel closely resemble the slow growth

of grain-boundary voids during the creep of alloys, with the

formation of fissures in HA corresponding to the fracture

of the creep sample. 10 ksi Equilib. PMVS PH / II

/ II

Since the methane pressure provides the driving force for d -- [ar bon Steel 1/1

both nucleation and growth, the discussion of mechanisms ~a.. --- Cr-Mo Steel 1//

w

a

1.5 II I /

begins with the calculation of the maximum (equilibrium) 0::: / I /

:::> 3 ksi

methane pressure that can develop as a function of VI

VI

// / /

hydrogen pressure, temperature, and carbide type (carbon w

activity).

0:::

a..

z

w 1ksi

Ac= O.12~~//

/'/'

//> / / "71

II

~a ,/ / /

EQUiliBRIUM METHANE PRESSURE 0:::

/' / /

.",/' ,/,/ /

It is impossible to draw any valid conclusions about the 0

>- 0.5 /

/ / /

/' ,/

mechanism of bubble growth in HA unless the pressure :I: / /

.", /'

driving the expansion of the bubbles is known. The early ~a 0.3 ksi

/

/

.",

/

/'

/'

/'

/ /

--I ,/ .", ./

kinetic models assumed that the methane pressure equalled 0 0/ 550C ,/ 500 /(./450 500C

the methane fugacity. This led to such high driving 0.5 1.5 2 2.5 3 3.5

pressures that one always concluded that bubble growth LOG (METHANE PRESSURE7MPa)

occurred by matrix creep.

4 Methane pressure in equilibrium with steel as

The bubbles in which the methane forms are initially

function of hydrogen pressure and temperature:

very small, and growth is very slow. Thus, it seems clear solid lines are for carbon steels; broken lines are for

that at higher temperatures, and early in the incubation carbon activity 012 and reflect lower carbon

period, the equilibrium pressure is established in the activity found in commercial QT 2'25-1 Mo steel

Materials Science and Technology January 1985 Vol. 1

Shewmon Hydrogen attack of pressure-vessel steels 5

0.3

2 Carbon Activity

(Graphite Std. State)

>-

.....

~ E:20.3 MPa H2 >

"0~ 0 E: \6.9 MPa H2

~

U

X

0.2

~.c z

. 0

w dl

0:::

2

U

0.\

Downloaded by [Universite Laval] at 09:13 09 May 2016

19 20 21

T (20+ I"ogt) x 10-3

5 Activity of carbon, and dilatometric strain rates at 550C as function of tempering parameter36

Alloy steels is, much more iron IS In the carbides than assumed by

In steels alloyed with carbide-forming elements, like Geiger and Angeles. These high Fe/Cr ratios stem

chromium, the activity of carbon is lower than in carbon primarily from the low chromium content of the steel.

steels. Also, dilatometric measurements have established However, it is partly caused by the lack of chromium equi-

that the rate of HA of QT 2'25Cr-IMo is at least three libration between the carbides and regions of the alloy far

orders of magnitude slower than that of carbon steels at from the carbides owing to the slow diffusion of chromium.

the same temperature and hydrogen pressure. 1 7.33 Several

observations indicate the effect of alloying and heat GROWTH KINETICS

treatment on the microstructure and rate of HA: Models

The growth of methane bubbles in a steel requires that'

1. The line on the Nelson curve (see Fig. 1) for

several processes proceed simultaneously:

2'25Cr-lMo is about 200 K higher than for carbon steel.

2. Geiger and Angeles31 found, as have several other (i) the solution and diffusion of hydrogen

authors, 3.34 that the resistance to HA in quenched Cr-Mo (ii) the solution and diffusion of carbon

steels increased appreciably with tempering. They also (iii) the formation of methane gas

concluded that the thermodynamic properties of the more (iv) the movement of iron atoms away from the growing

stable M23C6 and M7C3 carbides formed by tempering bubble.

could be approximated by using the free energy of

formation of Cr23C6 and Cr7C3. From this they concluded Figure 7 shows the steps that must occur sequentially, or in

parallel, for the growth of methane bubbles. Anyone of

that the activity of carbon should drop by roughly three

these processes could be rate controlling, but analysis40-44

orders of magnitude as tempering removed the M3C from

the steel.

3. Baker and Nutting35 report that during extended

tempering of QT 2'25Cr-IMo steel at 690C all of the

M3C disappears and is replaced by M23C6 or M7C3.

Parthasarathy and Shewmon36 have recently measured o XT 1 50

6 XT2

the carbon activity of QT 2'25Cr-IMo steel at 550C as a -15 o XT3

function of the amount of tempering. They did this by XT4 CD

Q

o 8M

equilibrating the steel with pure Ni.37 Results are shown in 1: )(

Fig. 5, where the degree of tempering ranged from --001

to 100 times that of commercial practice. Note that though

;;;

.5

-16

10 5

e\ll

the carbon activity drops continuously with increasing 5

-17

tempering, there is no sharp drop in the carbon activity or

rate of growth (hydrogen attack) with extended tempering.

Figure 6 shows growth rate v. Pm. STEM analysis of the 5.0 5.2 5.4 5.6 5.8 6.0

carbides confirmed that the extended tempering indeed

eliminated the M3C (Ref. 38) as reported by Baker and \n (P- ..2l:

r

)

Nutting. However, the carbon activity in the tempered

6 Strain rate v. driving force for QT 225Cr-1 Mo

Cr-Mo steel dropped to little less than one-tenth that of (Ref. 36): a slope of 10 corresponds to grain

normalized carbon steel. This is primarily due to the fact boundary diffusion limited growth, while a slope

that the M23C6 and M7C3 formed in the heavily tempered greater than unity would stem from some creep

steel had Fe/Cr ratios of 7: 3 and 6: 4, respectively,39 that control

Materials Science and Technology January 1985 Vol. 1

6 Shewmon Hydrogen attack of pressure-vessel steels

Hydrogen Diffusion Carbide DissolutIon -----2b--------401

to the Bubble t

{ Carbon Diffusion

f (a) 9 b

Methane

f

Generatlon at

t he Bubble Surface

Parallel Process I

( bl

Surface Diffusion

of Fe Atoms

Bubble Growth

Towards Bubble Tip

by Direct Power

t Law or Dislocation

Diffusion of Fe Creep

Atoms Along the

Grain Boundary

(c I

I

I

Accommoda t i on by I

Creep of the I

I

Adja~ent Grains I I I I

II I I

r--- aj-----+-- f3-l--a

Downloaded by [Universite Laval] at 09:13 09 May 2016

7 Diagram of sequential and parallel steps involved in i+1~

hydrogen attack of steel40

a bubbles of radius a and spacing 2b on grain boundary; arrows

normal to boundary represent sign and magnitude of local stress in

matrix which results from uniform deposition of atoms between

//

bubbles; b bubble which has changed to a disc-shaped bubble; this

and experimental observations17,19,45 all support the occurs with higher stress (Pm+lTn) and greater relative boundary

conclusion that during the incubation stage the growth is diffusion (Obi Os); c representation of discontinuous nature of

'bubbled' boundary segments on grains of diameter d; regions

limited by the movement of iron atoms away from the represented by P must accommodate expansion of bubbled

developing bubble. The discussion here deals only with the boundaries via lattice creep and boundary sliding .

diffusion and creep processes that limit the growth of 8 Diagrams of spacing and distribution of bubbles

bubbles. used to describe bubble growth

Iron atoms can be moved away from a bubble by

diffusing over the bubble surface to the grain boundary

and then along the boundary, or by elongating the region

between the bubbles by lattice creep. Each of these them, d is the grain diameter, Db the boundary-diffusion

processes has been investigated, and equations are coefficient, bb the boundary thickness, and Q the molar

available describing the rate of bubble growth as a function volume. The function h(a/b) is about unity and changes

of the driving pressure and various kinetics very slowly with a until (a/b)2 > 0'5, that is, until quite late

parameters.46-53 in the development of fissures. Note that the rate of growth

It will be assumed that the bubble density is uniform increases as only the first power of P.

with a spacing 2b over an essentially continuous sheet of The bubbles lose atoms only on the plane of the

grain boundaries across the sample, see Fig. 8. This boundary. To maintain the nearly spherical equilibrium

assumption is supported by the observation that after a shape of the bubble, atoms must diffuse over the surface to

relatively short nucleation transient the growth rate replenish those lost down the boundary. If the ratio

observed indilatometric studies is a function only of Db/Ds > 1 (Ds is the surface-diffusion coefficient), and

temperature and hydrogen pressure, being independent of P > 2y/a, then this surface-diffusion adjustment is too slow

time, as well as temperature/pressure excursions. and the bubbles grow into disc-shaped bubbles,46,47 see

Consider first the case of grain-boundary diffusion- Fig. 8. The equation for the observed expansion of a

limited growth. The diffusion equations are solved for the sample then becomes

case in which the atoms diffusing out of the bubble along

E:sd = (fb/d)(DsbsQ/RT)(a/b2)p2j(a/b) ..... (8)

the boundary deposit at a uniform rate over the entire

region between bubbles. where j(a/b) is a different function than h(a/b), but has the

The primary force acting to enlarge the bubble is same properties for our purposes. Here the rate of

methane pressure Pm. This will be resisted by the surface- expansion increases as p2, thus with high forces the

tension pressure 2y/a, where a is the bubble radius and y is bubbles will become crack-like. Such a stage can sometimes

the surface tension. In engineering systems any applied be found in carbon steels, but it has not been observed in

stress develops a stress acting normal to the boundary (in' alloy steels, presumably because Pm is too low. It is worth

which provides an additional force enhancing growth. (Any noting that for these disc-shaped bubbles the rate at which

resulting creep of the PV will accelerate the growth of the the bubble radius increases, da/dt increases as p3 Thus

bubbles still more, but here (in will be considered as a static fissures would develop with a smaller overall external

supplement to the gas pressure.) The total driving force P strain, as one would expect.

will thus be The region between the bubbles is stressed by the high-

pressure methane. If the pressure becomes high enough,

(6)

this can lead to creep of the matrix according to the

The externally observed growth rate for the case of constitutive equation

boundary diffusion is

(9)

E:bd = (fbjdb2)(DbbbQjRT)Ph(a/b). . . . . . . (7)

This leads to an equation for the creep contribution to the

where fb is the fraction of grain boundaries with bubbles on overall growth of the sample under HA of:49

Materials Science and Technology January 1985 Vol. 1

Shewmon Hydrogen attack of pressure-vessel steels 7

t:cr = (fb b/d) B((3/2n)/(b/a)3/0 -lJo po. . . . . . (10) inferences can be drawn about the rate-controlling

processes if the rate data are described with the equation

Note that the force is raised to the power n, which in the

case of iron is '" 7. E=AP~exp(-Qm/RT) (12)

Dyson has noted that voids form on only a fraction of

the grain boundaries in a sample undergoing creep, and Note that Qm reflects only the temperature dependence of

that if this fraction is small enough a cage of grains with the diffusion process limiting the motion of iron atoms,

uncavitated boundaries will surround any cavitated while QH contains both the temperature dependence of the

boundary.48 The cavitated boundary and the surrounding diffusion process and the dependence of methane pressure

cage of void-free grains must expand at the same rate, so on temperature at constant hydrogen pressure. The

the cage may restrain the growth of the cavitated pressure exponent m in equation (12) should be directly

boundary. It is possible that the same cage effect would comparable with the exponents of P in the model rate

occur in restraining the growth of discrete bubble-covered equations, equations (7), (8), or (10).

grain boundaries in samples undergoing HA, especially in Carbon steel Several steels have been studied using

the more creep and HA resistant alloys like the Cr-Mo dilatometry and the data fit with equation (12). Domains of

steels. different rate-controlling processes have been observed. If

Whether or not this type of restraint occurs is an the bubbles nucleate uniformly over a continuous surface

important question in the development of more HA of many grain-boundary segments, then the rate of growth

resistant steels. Increasing the chromium content reduces of the sample will be given by the equations for Ebd, or Esd

the equilibrium methane pressure Pm, but also reduces the However, there will be some segments of grain boundary

alloy's creep resistance somewhat. A higher creep strength with no bubbles, and these regions will have to

can be obtained with addition of Ti or V (Ref. 54). accommodate the expanding boundaries on either side via

Parthasarathy49 argues that in the HA of commercial lattice creep. Steels apparently differ in the degree to which

Cr-Mo steels the fraction of boundaries with bubbles is the bubbled grain-boundary segments form a continuous

Downloaded by [Universite Laval] at 09:13 09 May 2016

sufficiently high for the cage restraint not to exist. Also, he path across the sample. This difference might be

obtains good agreement between his model and the represented by the ratio of the average values of IX and f3 in

observed data without including the restraint effect. It is Fig. 8e. If this ratio is 1 then the bubbled boundaries will

also noteworthy that there was a drop from 218 to 154 in form an essentially continuous path across the sample, and

the Vickers hardness between the two most highly the rate of growth will be given by Ebd' If the ratio is less

tempered samples in Fig. 5, yet the change in theHA rate than unity the initial expansion may be given by Ebd or Esd,

is negligible, that is, E is proportional to the activity of but after the bubbles on the bubbled segments grow to

carbon, but does not change with a change in matrix link up the next stage of growth will be controlled by

strength. lattice creep in the regions between the bubbled segments.

The values of Qm and m that should go into the

Experiment equations for E have not all been well determined for pure

Following the growth of submicrometre bubbles during the iron, but the best values are given in Tablel. They are

incubation period of HA requires either a very sensitive followed by one question mark if the value is based on

dilatometer (strain sensitivity less than 10- 5) or high- somewhat uncertain data, and two question. marks if the

magnification microscopy (over x 2000), Le. an SEM. It is values are educated guesses. It is possible that the grain-

only within the last few years that such techniques have boundary data are markedly influenced by the adsorption

been used to study HA. Work done previously could of impurities, as has been reported for nickel,56 but there

establish only the incubation time, that is, when the are no reliable data on the subject for steel.

bubbles link up and the expansion becomes rapid. McKimpson and Shewmon 19 measured the rate of HA

It has been demonstrated by dilatometry that at the of an ESR carbon steel (O'3%C) with a capacitance

hydrogen pressures of engineering interest (> 7 MPa) the dilatometer. They found appreciable change in the

bubble density quickly reaches a steady-state value, and the temperature and hydrogen-pressure coefficients, QH and u

growth rate t: becomes time independent, that is, E is a (equation (11)), on going from low Pm (high T, low PH) to

function only of temperature and hydrogen pressure during high Pm (low T, high PH)' In fact, QH increased from

the incubation period. 17.19 The results obtained can then 115 to 210 kJ moi -1, and the hydrogen-pressure exponent

be described by the expression u decreased from 19 to 0,6. This is what one would expect

t: = CP~exp(-QH/RT) (11)

from the non-ideality of methane (Fig. 4) if the same

process controlled the rate at both high and low Pm. If

where PH is the hydrogen pressure. these rate data are described in terms of Pm (equation (12)),

Since the methane pressure Pm is the actual driving force the Qm values for the two domains of Pm are essentially

that enters the mechanistic equations given above, clearer equal to 220 and 225 kJ mol- 1, while the values of mare

Table 1 Model predicted* and observed rate coefficients for hydrogen attack

Om(mod), m(obs),

Steel Control process kJ mol-1 m(mod) kJ mol-1 m(obs) A, }lm Ref.

Carbon Creep 290 7(7) 280 98 45

Grain-boundary diffusion 190(7) 1 250 17 1 1 45

225 12 045 17

10 Pm 220 16 20 45

10Pm 220 15 055 19

Surface diffusion 130(??) 2 115 33 45

225Cr-1 Mo (BM) 225 17 65 55t

(WM1) 313 66 55

(WM2) 249 34 5 55

* ? and?? after constants used in the model equations reflects the relative uncertainty in the experimental data available

for steel.

t Average of two BM heats.

Materials Science and Technology January 1985 Vol. 1

8 Shewmon Hydrogen attack of pressure-vessel steels

15 and 12, respectively. The values of m and Qrn agree m = 1 in heavily tempered steel, and thus supporting grain-

satisfactorily with those expected for boundary-diffusion- boundary diffusion as the rate-limiting process, at least in

controlled growth, and Parthasarathy found that such a soft Cr-Mo steels.

model fitted the data wen over the entire range with a There are few data on the HA resistance of welds for QT

bubble spacing b = 05 Jlm and a bubble radius 2'25Cr-1Mo, and these results differ. Table 1 includes

a = 005 Ilm (Ref. 49). growth data on the HA kinetics of two commercial weld-

Panda and Shewmon45 used dilatometry to study an Al- metal samples (WM 1 - shielded metal arc and WM2 -

killed carbon steel that nucleated bubbles on an submerged arc).55 Both WM samples grew up to ten times

appreciably smaller fraction of the grain-boundary faster than the base metal (BM in Table 1). Erwin24

segments than McKimpson and Shewmon's, and indeed studied the HA of ESR welds and detected no difference

most steels that have been studied.1s The bubbles between the BM, WM, and HAZ. Sakai and Kaji57

nucleated on these boundary segments initially seemed to reported a bubble density orders of magnitude higher in

grow by surface-diffusion control until they linked up to the HAZ of a welded plate than in the BM. Masaoka et

form a single bubble over the grain-boundary segment. The al.27 coarsened the austenite grain size of 2'25Cr-1Mo

values of Qrn and m for this initial stage are given in steel, called it 'simulated HAZ' and reported essentially no

Table 1 under 'Surface diffusion'. In the second stage the change in HA kinetics at 600C. Clearly, the variability in

large bubbles covering isolated grain-boundary segments the HA of welds is greater than that found in BM, but

grew with Qrn and m values much larger than in the first beyond that there are too few data, or too little

stage. These data are given in Table 1 under 'Creep' as the understanding, to draw firm"conclusions.

controlling process. Effect of creep Modern PV design emphasizes the use of a

The obse~ved values of Qrn and m given in Table 1 for ductile material so that local stress concentrations will be

grain-boundary and surface-diffusion controlled bubble eliminated by localized plastic flow without introducing

growth agree reasonably with those of the model cracks. For PVs in which creep is unimportant room-

Downloaded by [Universite Laval] at 09:13 09 May 2016

predictions, but are consistently somewhat higher than the temperature elongation provides a good indication of

values expected. This could be explained by a small lattice- adequate ductility. However, with longer time service at

creep contribution from the regions between the individual higher temperature, creep becomes a factor and creep

bubbles on a bubbled boundary,49 or from creep ductility is necessary to relieve local stress concentrations.

accommodation of the unbubbled boundary segments Creep elongations of 015-020 are typical for QT Cr-Mo

shown in Fig. 8c. steels, the elongation being limited by the growth and link-

225Cr-1Mo steel To produce a loss of room-temperature up of voids on grain boundaries.

mechanical properties in QT 2'25Cr-1Mo steel requires In samples undergoing HA, failure (bubble link-up into

exposure to extreme conditions of temperature and fissures) can occur with all strain arising from the

pressure, for example, PH = 30 MPa at 600C for 1000 h or distribution over the boundary of all of the atoms that

more. However, if the steel is inadequately tempered, HA is were initially in the volume occupied by bubbles. In this

observed at lower temperatures and pressures. 55 case the strain at fracture is approximated by

The dilatometric study of HA in this steel requires

greater sensitivity than in carbon steel, but has been

err = bfb/2d . . . . . . . . . . . . . . (13)

successfully carried out. QT 2'25Cr-1Mo steels are similar where it has been assumed that link up occurs when a

to carbon steels in that e = f(T, PH) over the great majority grows to b/2. Typically for carbon steel b = 05 Ilm,

of the incubation period. However, the behaviour of the d = 20 Jlm, and fb = 01, or err = 0'001, which agrees well

two steels differs fundamentally in the initial (bubble with the observed value of strain at the end of the

nucleation) stage of attack. At 500-550C a freshly QT incubation period in carbon steel.19

Cr-Mo steel exposed to 20 MPa of hydrogen expands at a In creep studies one would thus expect a significant

steadily decreasing rate until after a few days e stabilizes (at reduction in err if HA played a role in developing the

550C) or becomes immeasurably small (at 500C). This boundary fissures. This is indeed found to be the case, as

initial strain reflects the build-up of methane in existing was described above in the section 'Observations'. The

voids in the Cr- Mo steel as opposed to the nucleation of surprising thing is how mild the hydrogen exposure can be

many new bubbles in carbon steels. This difference between and still have a significant effect on the creep ductility. In

the two types of steel is discussed further in the next unstressed samples exposed to PH = 20 MPa, one observes

section. a drop in room-temperature elongation after 1000 h only

Dilatometric data on QT 2'25Cr-1Mo steel plate are after exposure at 600C or above. However, in a

given in Table 1 (labelled 'BM' for base metal). The values stress-rupture test (O'n = 310 MPa) run in Pm = 20 MPa

of Qrn and m are comparable to those found in carbon steel hydrogen there was clear evidence of a hydrogen-induced

when boundary diffusion limits growth. The orders-of- loss in ductility on exposure at only 455C (failure in

magnitude slower growth in the Cr-Mo steels (at the same 4500 h).25 If hydrogen does not change the number of

temperature) can be explained as follows. For primarily voids/bubbles on the grain boundaries this would represent

boundary-diffusion-controlled growth the rate e is propor- an increase of about 100 in the rate of bubble growth. The

tional to (1/b2d)F1'7 The reduction in carbon activity gives effect of creep probably results both from an enhanced

a drop in Pm = F of about 3, which raised to the 17 power bubble growth rate, and an enhanced nucleation of

is a factor of 6. The bubble spacing along boundaries b is bubbles, but to date no studies have been made indicating

about 10 times larger in the Cr-Mo steel than in the the relative contributions of the two effects.

carbon steel, and the grain diameter d is about 25 times The enhancement of diffusion-controlled bubble growth

larger in the Cr- Mo steels. Multiplied together these by lattice creep would be entirely consistent with the

factors account for a difference in rate of 1500 between the theories of creep ductility in the literature. In the case

two types of steel. Alternatively, with a Qm of 225 kJ mol-1 of O'n = 0, the main force resisting bubble growth by

the Cr-Mo steel will attain the same e as the carbon steel grain-boundary diffusion stems from the requirement that

at 150 K higher temperature. However, since the bubbles the material leaving the bubbles diffuse and deposit

must grow further to merge in the Cr-Mo steel, 150 K uniformly over the entire region between the bubbles

understates the difference in useful temperature for the two (Fig. 8a). However, the strain rates observed in samples

steels. Figure 1 indicates an about 200 K difference. undergoing HA are only about 1% of that typical of

Figure 6 indicates a continuous drop in the force samples undergoing creep. Thus even relatively small rates

exponent m (equation (12)) with Pm' reaching a value of of creep due to an external stress could open up space

Materials SCience and Technology January 1985 Vol. 1

Shewmon Hydrogen attack of pressure-vessel steels 9

version of the API Nelson curve60 for carbon steel showed

a lower pressure limit for welded and/or cold-worked steel

L

o

than for annealed material. This would be consistent with

+ enhanced nucleation by both of these forming operations.

o Cold work also enhances the density of bubbles that

develops in Cr-Mo steels.61

Clugston et al.62 argued that the enhanced rate of

nucleation on boundaries was due to the inhomogeneity of

T ferrite deformation around the ends of carbides (especially

On

at grain boundaries). They give microscopic and analytical

-.L- -PM-lt- evidence to support this. A similar effect had previously

been reported for nickel-based superalloys. 63,64 In nickel

~g

'

b diff-. -""*I-----I(reep~

11r----------j1

alloys, cold work resulted in an increased void density at

grain boundaries and a significantly reduced creep

ductility.

{=

::Z:1 z:::L??::z:? n? 9 b

b-a------, r-!

b-a---I t

Carbon steels

Pishko et al. 18found that the HA of carbon steels develops

a mean bubble spacing of 1 /lm on the grain boundaries

that form the fracture surface, but found no inclusions

9 Creep v. grain-boundary (gb) diffusion coupling

under influence of external stress Go: for Go = 0 entire

inside these bubbles after fracture. These bubbles form at

relaxation is by gb diffusion over a distance b- a, carbide/ferrite interfaces. Their density is much higher than

while with an applied stress of Go > 0, the stress in the density of any inclusions visible with the optical

Downloaded by [Universite Laval] at 09:13 09 May 2016

lattice normal to gb, cr(r), rises but is limited by creep microscope or SEM. Thus these fine bubbles must form in

in central region; reduction of gb diffusion distance a way that is fundamentally different from those found at

from b- a to b'- a allows matching of rates of the large (10-1000 /lm) inclusions in older dirtier steels.

diffusion- and creep-limited regions Using a two-stage replica technique, Wang65 showed

that. only a negligibly small density of voids existed in

annealed steel before hydrogen exposure. The development

along the boundary for the material leaving the bubbles, of a high density of bubbles on exposure to high-pressure

and thus substantially shorten the required diffusion hydrogen is shown by the kinetic studies of Panda and

distance (see Fig. 9). The effect of lattice creep on void Shewmon,45 who found that if a carbon steel was heated

growth under an externally applied stress has been treated under 20 MPa of hydrogen no growth occurred on heating

by several authors.50-53 These authors find that in an in stages (over 6 d) from 275 to 350C. However, at 375C

intermediate range of applied stress the rate of void growth growth started and in a few hours the rate increased by

by boundary diffusion is appreciably enhanced because of over two orders of magnitude. Following this surge of

the shortened diffusion distance for atoms leaving nucleation the bubble density did not change measurably

boundary voids, and the concentration of the applied load with time or further HA at various temperatures and

in the region b - b' of Fig. 9. This results in a higher creep hydrogen pressures. This stable array of nuclei allowed

rate around the plane of the boundary than in the matrix, growth to be measured subsequently down to 275C.

and though the sample expands by creep, the localization McKimpson and Shewm'on19 had earlier obtained similar

of the creep results in a low-ductility fracture. results and initially exposed samples briefly to a high

Wanagel et al.26 have shown that a pretreatment with hydrogen pressure (20 MPa) at 375-400C to establish a

13 MPa hydrogen at 600C significantly decreases the stable bubble density.

stress-rupture ductility of 2'25Cr-lMo subsequently tested At low hydrogen pressures the nucleation of bubbles

in air. Thus the effect of HA on creep ductility seems to be proceeds more slowly but is an essential first step to HA.

due both to enhanced nucleation and growth of the Wang65 has measured the initial growth of annealed

bubbles. samples at low hydrogen pressures (2 MPa) and

400-500C. She found the rate to rise in successive stages

NUCLEATION or steps from an initially undetectable level to an easily

As was seen above in the discussion of growth, the density observable one. Presumably, this was caused by the

of bubbles that nucleate is one of the most important spreading of the stable high-density (one per square

variables in determining the rate of HA of a steel. It is also micrometre) layer of bubbles over sheets of grain

the least well understood aspect of the mechanism of HA. boundaries across the entire cross-section of the samples.

A summary of the observations is given as a preliminary.

Chromium-molybdenum steels

Inclusions In contrast to carbon steels, when Cr-Mo steels are

The steels in common use up to a decade ago contained a exposed to high-pressure hydrogen (20 MPa), there is no

much larger volume of larger inclusions than is found in initial rise in the rate of growth that would reflect the

the structural steel currently being produced. Gas bubbles nucleation of additional bubbles. In fact at 500C an"

easily form at stringered sulphide or silicate inclusions of a 20 MPa of hydrogen the growth initially starts at an easily

size easily observed in the light microscope. 2,20,22,58This measurable rate and then over a period of a few days drops

is probably due to pre-existing voids or lack of cohesion at to a negligible rate.33 The indications all point to a pre-

these interfaces. existing set of voids that fill with methane on exposure to

hydrogen. Using a two-stage replica technique Lopez and

Cold work Shewmon66 have shown that in QT 2'25Cr-1Mo steel a

Cold working an annealed carbon steel greatly increases high density of voids is formed at the tips of carbides

the rate of HA. This leads to earlier fissuring along the during tempering, especially between grain-boundary

grain boundaries20 and an enhanced rate of growth for the carbides. The methane-bubble density that subsequently

decarburized surface layer.2,22 Shih showed that heavy gives rise to HA is much lower, and this density remains

cold work by swaging leads to the development of bands of essentially constant independent of time during hundreds

methane bubbles within pearlite colonies. 59 The 1970 of hours of exposure to hydrogen at 20 MPa (Ref. 67).

Materials Science and Technology January 1985 Vol. 1

10 Shewmon Hydrogen attack of pressure-vessel steels

600 In the 225Cr-1Mo steel Lopez and Shewmon66 have

shown that the carbon-diffusion-limited growth of M3C

could force open voids at the tips of growing carbides, and

indeed find more than enough such voids in the tempered

c.J 500

~~ steel. This is a quite credible method of formation.

a::

=> However, it is not at all clear what keeps these voids from

!<t

a::

lLJ

sintering shut during the tempering operation before

~ 400 hydrogen exposure.

I-

Surface cracking has been reported in the vicinity of

nozzle attachments and girth welds in higher strength

QT 2'25Cr-1Mo steel after one year of service under

300 10 20 30 (MPa) conditions that were below the Nelson curve limits.71 The

2 3 4 5 (ksi) steel had been tempered to a tensile strength of over

HYDROGEN PRESSURE 900 MN m - 2 700 MN m - 2 is more typical and gives

satisfactory service). Surface cracking indicates local

10 Postulated operating limits for 225Cr-1 Mo based fissuring. The Pm generated by PH = 12 MPa at 450C is

on dilatometric data and limit of AVIV = 0001 at about 400 MPa and is not sufficient to cause fissuring.

50000 h. The two curves for two weld metals are However, the residual stress, and thus O"n, in the surface

for no external load (O'n = 0) and for an external

layer could be as high as the yield at this temperature (400-

load giving an elastic stress of O'n = 100 MN m-2

The limit lines are not extended above PH = 30 M Pa

500 MN m - 2) (Ref. 72). Thus in welds and around nozzles

because of a possible increase in bubble density Pm + O"n would have exceeded the critical value of about

and growth rate in this region 600 MPa postulated as required for the nucleation of a

high density of bubbles. If such a limit exists then efforts to

Downloaded by [Universite Laval] at 09:13 09 May 2016

raise the strength of Cr-Mo steels 73 must be accompanied

Similar behaviour was seen for the base metal, weld metal, by a reduction in Ac and Pm to keep (Pm + O"n) < 600 MPa

and heat-affected zones of this PV steel. even in regions of high residual stress. (Such a limiting

The only evidence of bubble nucleation during HA of stress postulate would be consistent with the findings of

2'25Cr-1Mo steel is that of Thygeson and Molstad.68 They others 74,75 for the formation of cavities at inclusions

reported the development of grain-boundary fissures during ductile fracture.)

following exposure to 100 MPa hydrogen at 500C. In

carbon steel there is a threshold Pm of about 600 MPa

required to nucleate a high density of bubbles Predicting vessel performance

(PH = 3 MPa at 400C). If the Pm required to nucleate a

high density of bubbles in 2'25Cr-1Mo is the same, Fig. 4

The prediction of PV performance, and the criteria to be

indicates that a PH of about 30-35 MPa would be required

set for such performance are too complex a topic to discuss

for a carbon activity of 012. (The degree of tempering of

here. But it is clearly a primary goal of the work reviewed

the steel used by Thygeson and Molstad was unspecified, here (see Ref. 54). An approach to life prediction using the

but Ac = 012 seems reasonable.) dilatometric data is to choose a certain bubble volume as

defining the 'life' of the vessel and then calculate the time,

Mechanisms temperature, and PH conditions which would reach this.

Two processes seem to be important in the nucleation of

Figure 10 shows the limiting conditions of T and PH

bubbles during HA.

predicted by this approach for a bubble volume fraction of

1. Active nucleation of a high density of bubbles 0'001, a time of 50000 h (6'2 years), and O"n = 0 or

(b < 1 Jlm) on many grain boundaries to form a more or 0" n = 100 MN m - 2. Curves are given for the BM as well as

less continuous surface of bubbles through the sample. This the WM 1 and WM2 data shown in Table 1. It is seen that

leads to fissuring at relatively low sample strains (0001). It the weld-metal limits are clearly lower than for the base

clearly develops in carbon steels, and apparently develops metal, and that the effect of 100 MN m -2 static stress is

in QT 2'25Cr-1Mo steels at high pressures. It is postulated small.

that such active nucleation occurs at values of Such an approach ignores several factors; some are

F > 600 MPa in both carbon and low-alloy steels. helpful and some are not. It tends to underestimate the life

2. The formation of voids during the tempering of because:

2'25Cr-1 Mo, and the persistence of many of these through

(i) vessels have hydrogen on only one side and

long tempering operations to give rise to bubbles in HA.

hydrogen diffuses out the other side so that HA

This is the dominant process for F < 600 MPa.

proceeds only from one side. of the vessel

In carbon steel occasional voids are present at the ends (ii) vessels are usually clad with stainless steel and the

of carbide lamellae. The high density of bubbles nucleates requirement that the hydrogen diffuse through this

and spreads for Pm > 600 MPa and temperatures at or cladding to compensate for the hydrogen that

above 375C. The critical radius (2y/P m) for Pm = 600 MPa diffuses through the vessel lowers the hydrogen

is about 5 nm. If methane formed inside a void of this size activity in the PV steel beneath that for the PH in the

at say 400C it would force iron atoms into the boundary vessel.

tending to wedge open the interface at the next carbide

particle. If a void of > 25 nm were present there the This approach tends to overestimate the life because:

combined action of the methane inside the bubble and the (i) it neglects the accelerating effect of creep on the

wedging action of the atoms from the first void would bubble growth, and bubble nucleation

make it grow.41 These two bubbles would raise still further (ii) it neglects the local effect of residual stress and stress

the stress intensity in the surrounding boundary, and make concentrations around discontinuities which may

spreading of the bubbled region easier.69 Such a model be appreciably higher than 100 MN m - 2 in some

would require residual stress or small voids at the ends of regions

the carbides, but would allow the bursts of nucleation that (iii) there is no allowance for the scatter expected

are observed as well as the observed changes in the between different heats and different welds, and thus

morphology of bubble distribution.70 no lower bound on the variation to be expected .

. Materials Science and Technology January 1985 Vol. 1

Shewmon Hydrogen attack of pressure-vessel steels 11

33. P. G. SHEWMON and z. s. YU: in 'Advanced materials for

Acknowledgments pressure vessel service with hydrogen at high temperatures and

pressures', (ed. M. Semchysen), 85-92; 1982, New York,

American Society of Mechanical Engineers.

This work was performed under the continuing sponsor- 34. T. MITSUO, K. YAMATO, and T. SAITOH: in 'Advanced materials

ship of the Division of Materials Science, Office Basic for pressure vessel service with hydrogen at high temperatures

Energy Science, US Department of Energy. Dr T. A. and pressures', (ed. M. Semchysen), 69; 1982, New York,

Parthasarathy has given repeated assistance in preparing American Society of Mechanical Engineers.

the manuscript. Writing this paper was greatly aided by a 35. R. G. BAKER and J. NUTTING: J. Iron Steel Inst., 1959, 192,

Humboldt Foundation, Senior Scientist Award, and the 257-268.

kind hospitality of Prof. H. Fischmeister and the Max- .36. T. A. PARTHASARATHY and P. G. SHEWMON: to be published in

Metall. Trans. A.

Planck-Institut fur Metallforschung, Stuttgart.

37. K. NATESAN, o. K. CHOPRA, and T. F. KASSNER: Nucl. Technol.,

1976, 28, 441.

38. R. ODETTE and u. C. SANTA BARBARA: personal communication.

References 39. R. LUNDBERG, M. WALDENSTROM, and B. UHRENIUS: Calphad,

1977, 1, 159.

40. G. SUNDARARAJAN and P. G. SHEWMON: Metall. Trans., 1981,

1. I. CLASS: Stahl Eisen, 1960, 80, 1117. 12A, 1761-1775.

2. F. K. NAUMANN: Stahl Eisen, 1937, 57, 889-899. 41. P. G. SHEWMON: Metall. Trans., 1976, 7A, 279-286.

3. F. K. NAUMANN: Stahl Eisen, 1938, 58, 1239-1250. 42. A. A. SAGUES, B. OKRAY HALL, and H. WIEDERSICH: SCI'.Metall.,

4. G. A. NELSON: Proc. Am. Petrol. Inst., 1949, 29, (3), 163-172. 1978, 12, 319-326.

5. 'Steels for hydrogen service at elevated temperatures and 43. H. M. SHIH and H. H. JOHNSON: Acta Metall., 1982, 30, 537-545.

pressures', Publication 941, 2 edn; 1977, New York, American 44. F. H. VITOVEC: Am. Petrol. Inst. Proc., 1964, 44, (3), 179-188.

Petroleum Institute. 45. B. PANDA and P. G. SHEWMON: Metall. Trans., 1984, 15A,

6. Stahl-Eisen-Werkstoflblatt 590-61, 'Druckwasserstoff- 487-494.

Downloaded by [Universite Laval] at 09:13 09 May 2016

besHindige Stahle'; Dusseldorf, Verlag Stahleisen. 46. T. J. CHUANG, K. J. KAGAWA, J. R. RICE and L. B. SILLS: Acta

7. S. HARPER, V. A. CALLCUT, D. W. TOWNSEND, and R. EBORALL: Metall., 1979, 27, 265-284.

J. Inst. Met., 1961-62, 90, 414-423, 423-429. 47. G. M. PHARR and w. D. NIX: Acta Metall., 1979,27, 1615-1631.

8. s. H. GOOD and w. D. NIX: Acta Metall., 1977,26,739. 48. B. F. DYSON: Met. Sci., 1976, 10, 349-353.

9. E. MITTEMEIJER et al.: Z. Metallkd., 1983, 74, 473-483. 49. T. A. PARTHASARATHY: unpublished work.

10. R. H. BRICKNELL and D. A. WOODFORD: Acta Metall., 1982, 30, 50. w. BEERE and M. V. SPEIGHT: Met. Sci., 1978, 12, 172-176.

257-264. 51. G. H. EDWARDS and M. F. ASHBY: Acta Metall., 1979, 27,

11. B. F. DYSON: Acta Metall., 1982, 30, 1639-1646. 1505-1518.

12. E. P. PARTRIDGE: J. Eng. Power (Trans. ASME), 1964, 86, 52. A. NEEDLEMAN and J. R. RICE: Acta Metall., 1980, 28,

311-324. 1315-1332.

13. R. J. RIOJA, M. YACAMAN, M. MORENO, and A. PERAZA: SCI'. 53. T.-L. SHAM and A. NEEDLEMAN: Acta Metall., 1983, 31,

Metall., 1982,16, 129-134. 919-926.

14. M. J. YACAMAN, T. A. PARTHASARATHY, and J. P. HIRTH: Metall. 54. P. G. SHEWMON, H LOPEZ, and T. A. PARTHASARATHY: in

Trans., 1984, 15A, 1485-1490. 'Research on chrome-moly steels', 1-8; 1984, New York,

15. L. C. WIENER: Corrosion, 1961,17, 137-143. American Society of Mechanical Engineers.

16. R. A. ALLEN, R. J. JANSEN, P. C. ROSENTHAL, and F. H. VITOVEC: 55. T. A. PARTHASARATHY, H. LOPEZ, and P. G. SHEWMON:

Proc. Am. Petrol. Inst., 1961, 41, 74-85. to be published in Me tall. Trans. A.

17. G. SUNDARARAJAN and P. G. SHEWMON: Me tall. Trans., 1980, 56. R. A. PADGETT and c. L. WHITE: SCI'. Metall., 1984, 18,

l1A, 509-516. 459-462.

18. R. PISHKO, M. G. McKIMPSON, and P. G. SHEWMON: Me tall. 57. T. SAKAI and H. KAJI: Tetsu-to-Hagane (J. Iron Steel Inst. Jpn),

Trans., 1979, lOA, 887-894. 1978, 64, 66-75.

19. M. G. McKIMPSON and P. G. SHEWMON: Me tall. Trans., 1981, 58. H. M. SHIH and H. H. JOHNSON: SCI'.Metall., 1977, 11, 151-154.

12A, 825-834. 59. H. M. SHIH: PhD thesis, Cornell University, Ithaca, NY, 1978.

20. M. RANSICK and P. G. SHEWMON: Metall . .Trans., 1981, 12A, 60. 'Steels for hydrogen service at elevated temperatures and

17-22. pressures', Publication 941, 1 edn; 1970, New York, American

21. G. A. NELSON: Proc. Am. Petrol.Inst., 1965,45, (3), 190-195. Petroleum Institute.

22. R. E. ALLEN, P. C. ROSENTHAL, R. J. JANSEN, and F. H. VITOVEC: 61. z. J. SU, D. STONE, J. WANAGEL, and CHE-YU LI: Int. J. Struct.

Proc. Am. Petrol. Inst., 1961, 41, (3), 74-85. Mech. Mater. Sci., in press.

23. G. SOREL and M. J. HUMPHRIES: Mater. Perform., Aug. 1978, 17, 62. s. F. CLUGSTON, J. R. WEERTMAN, and P. G. SHEWMON: Metall.

33-41. Trans., 1983, 14A, 695-699.

24. w. E. ERWIN: Proc. Am. Petrol. Inst., 1981, 61, (3), 120-134. 63. B. DYSON, M. S. LOVEDAY, and M. J. RODGERS: Proc. R. Soc.,

25. A. R. CUIFFREDA, N. B. HECKLER, and E. B. NORRIS: in 'Advanced 1976, A349, 245-259.

materials for pressure vessel service with hydrogen at high 64. T. SAEGUSE, M. UEMURA, and J. R. WEERTMAN: Metall. Trans.,

temperatures and pressures', (ed. M. Semchysen), 53; 1982, 1980, l1A, 1453-1458.

New York, American Society of Mechanical Engineers. 65. MING-MIE WANG: unpublished work, Ohio State University.

26. J. WANAGEL, T. J. HAKKARAINEN, and CHE-YU LI: in 66. H. LOPEZ and P. G. SHEWMON: Acta Metall., 1983, 31,

'Application of 225Cr-IMo steel for thick walled pressure 1945-1950.

vessels', STP 755, 93-108; 1982, Philadelphia, Pa, American 67. H. LOPEZ and P. G. SHEWMON: unpublished work.

Society for Testing and Materials. 68. J. R. THYGESON, Jr and M. MOLSTAD: J. Chem. Eng. Data, 1964,

27. I. MASAOKA et al.: in 'Current solutions to hydrogen problems 9, (2), 309-315.

in steel', (ed. C. Interante and G. Pressouyre), 242-248; 1982, 69. J. P. HIRTH: Res Mech. Lett., 1981, 1, 3-5.

Metals Park, Ohio, American Society for Metals. 70. P. G. SHEWMON, c. RICHIED, M. McKIMPSON, and M. RANSICK:

28. H. H. PODGURSKI: Trans. AIME, 1961, 221, 389-394. SCI'.Metall., 1980, 14, 545-548.

29. M. NATAN and H. H. JOHNSON: Metall. Trans., 1983, 14A, 71. w. E. ERWIN and J. G. KERR: Weld. Res. Counc. Bull., 1984,

963--971. (275).

30. T. A. PARTHASARATHY: PhD thesis, Ohio State University, 1983. 72. J. A. GULYA and R. A. SWIFT: in 'Research on chrome-moly

31. G. H. GEIGER and o. F. ANGELES: 'Study of effects of high- steels', 9-30; 1984, New York, American Society of

temperature, high-pressure hydrogen on low-alloy steels', Mechanical Engineers.

Publication 945; 1975, New York, American Petroleum 73. 'Research on chrome-moly steels'; 1984, New York,

Institute. American Society of Mechanical Engineers.

32. G. R. ODETTE and s. s. VAGARALI: Metall. Trans., 1982, 13A, 74. A. S. ARGON and J. 1M: Metall. Trans., 1975, 6A, 839-851.

299-302. 75. F. M. BEREMIN: Metall. Trans., 1981, 12A, 723-731.

Materials Science and Technology January 1985 Vol. 1

Potrebbero piacerti anche

- HYDRAULIC HOSE GUIDEDocumento12 pagineHYDRAULIC HOSE GUIDEWahyuni SalmanNessuna valutazione finora

- Preliminary Inspection Report of Line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60 (Pipe Rack)Documento3 paginePreliminary Inspection Report of Line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60 (Pipe Rack)Anonymous YRyGcKPNessuna valutazione finora

- AM Series 45-200 D170 Rev D-W OM PDFDocumento15 pagineAM Series 45-200 D170 Rev D-W OM PDFNestor SalasNessuna valutazione finora

- Annual OkDocumento22 pagineAnnual OkdennisjuntakNessuna valutazione finora

- Xtreme King BulldogDocumento12 pagineXtreme King BulldogGustavo Eduardo Vargas RaynholdsNessuna valutazione finora

- T 48Documento7 pagineT 48Anonymous s3xePANessuna valutazione finora

- Technical & Price Proposal On Line Leak Sealing On Straight Pipe 2 Inchi PDFDocumento5 pagineTechnical & Price Proposal On Line Leak Sealing On Straight Pipe 2 Inchi PDFandistwn99Nessuna valutazione finora

- Data Ta 2017Documento131 pagineData Ta 2017Anonymous ZgxsFIe100% (1)

- Safety Data Sheet for FSC-7C Leak Sealing CompoundDocumento3 pagineSafety Data Sheet for FSC-7C Leak Sealing CompoundSagu LempengNessuna valutazione finora

- TCW Tube CleaningDocumento56 pagineTCW Tube CleaningMarcela Vargas GomezNessuna valutazione finora

- TM-81 Condenser Cleaner 5125Documento6 pagineTM-81 Condenser Cleaner 5125gshdavidNessuna valutazione finora

- MM610i Portable ID FlangeDocumento3 pagineMM610i Portable ID FlangeAnonymous Jg8w6EEBANessuna valutazione finora

- Introduction To Pressure Seal ValvesDocumento3 pagineIntroduction To Pressure Seal ValvesGanci ZebroNessuna valutazione finora

- 1156-PT-038 (306) RP 1317Documento1 pagina1156-PT-038 (306) RP 1317el_sharkawy2011Nessuna valutazione finora

- HIRAC For Project Retubing ACHEDocumento2 pagineHIRAC For Project Retubing ACHEragilNessuna valutazione finora

- FRM-3025 (Hot Work Permit) OkeDocumento1 paginaFRM-3025 (Hot Work Permit) OkerizkiNessuna valutazione finora

- 2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1Documento1 pagina2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1BennyNessuna valutazione finora

- TECOtubeexpanders BROCHUREDocumento56 pagineTECOtubeexpanders BROCHUREMontajes Industriales EOS, MIESANessuna valutazione finora

- Full MKAPR Evidence Audit SMK3-04 MedcoDocumento114 pagineFull MKAPR Evidence Audit SMK3-04 MedcoSALIM ALI AFIFFNessuna valutazione finora

- Recruitment, Selection and Training of Workers: Revision QuestionsDocumento1 paginaRecruitment, Selection and Training of Workers: Revision QuestionsBinSayeed100% (1)

- 20 Catalog Krisbow 9 WeldingDocumento14 pagine20 Catalog Krisbow 9 WeldingEnrique da MattaNessuna valutazione finora

- GSB-Form-245 Dimension Inspection Report (Wall Thickness)Documento1 paginaGSB-Form-245 Dimension Inspection Report (Wall Thickness)Made GileeNessuna valutazione finora

- Tube Pullout Testing Experience - Final PaperDocumento9 pagineTube Pullout Testing Experience - Final PaperRavi AbuwalaNessuna valutazione finora

- Solutions Looking For Problems... : BeamsDocumento16 pagineSolutions Looking For Problems... : BeamslifeadventureNessuna valutazione finora

- List Perijinan Unit Mesin Pt. Medan Sugar Industry: No Nama Ijin Nomor Ijin PengesahanDocumento2 pagineList Perijinan Unit Mesin Pt. Medan Sugar Industry: No Nama Ijin Nomor Ijin PengesahanRobby DamanikNessuna valutazione finora

- GSB-Form-246 Dimension Inspection Report (Circum)Documento1 paginaGSB-Form-246 Dimension Inspection Report (Circum)Made GileeNessuna valutazione finora

- 44 File2 Friction Welding Stir Welding-Course MaterialDocumento92 pagine44 File2 Friction Welding Stir Welding-Course MaterialTeguh SulistiyonoNessuna valutazione finora

- DNV-OS-C501 Composite Components Oct 2010Documento164 pagineDNV-OS-C501 Composite Components Oct 2010mseymour91Nessuna valutazione finora

- Joining Copper-Nickel Alloys GuideDocumento9 pagineJoining Copper-Nickel Alloys GuidehboodhaiNessuna valutazione finora

- Sop & Jsa For Flange LeakageDocumento2 pagineSop & Jsa For Flange LeakageSoumya ChatterjeeNessuna valutazione finora

- Welding and Cutting ProcedureDocumento7 pagineWelding and Cutting ProceduredennisjuntakNessuna valutazione finora

- ASTM A106 Working PresureDocumento4 pagineASTM A106 Working PresureAnkon MukherjeeNessuna valutazione finora

- Protem Catalogue EDocumento112 pagineProtem Catalogue EemadnaguibNessuna valutazione finora

- SOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)Documento1 paginaSOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)FendiNessuna valutazione finora

- Automatic Tool Feed and Retraction for Boring and Facing HeadsDocumento8 pagineAutomatic Tool Feed and Retraction for Boring and Facing HeadsMario TrianaNessuna valutazione finora

- MSDS FSC-2FDocumento3 pagineMSDS FSC-2FSagu Lempeng100% (1)

- Retubing Plan On Heat Exchanger in Methanol PlantDocumento22 pagineRetubing Plan On Heat Exchanger in Methanol PlantBayu FrilyanNessuna valutazione finora

- Header Plug Seal Weld ProcedureDocumento3 pagineHeader Plug Seal Weld ProcedureMohd Shafuaaz Kassim100% (1)

- Air Cooler Cleaning TechniqueDocumento4 pagineAir Cooler Cleaning Techniquedinakaranpatel100% (1)

- GSB-Form-247 Dimension Inspection Report (Nozzle)Documento1 paginaGSB-Form-247 Dimension Inspection Report (Nozzle)Made GileeNessuna valutazione finora

- AESV/AESU/AESV-LA Series Squirrel Cage Motors: IE1, IE2, IE3 Efficiency ClassesDocumento32 pagineAESV/AESU/AESV-LA Series Squirrel Cage Motors: IE1, IE2, IE3 Efficiency ClassesNeo Dinastian OnssalisNessuna valutazione finora

- 3PS Gaw 003Documento5 pagine3PS Gaw 003ravi00098Nessuna valutazione finora

- Welding Inspection Report for Pertamina PadalarangDocumento1 paginaWelding Inspection Report for Pertamina PadalarangabdiNessuna valutazione finora

- Emergency Intervention in Case of Chlorine Leaks: GEST 93/179 9 Edition December 2015Documento20 pagineEmergency Intervention in Case of Chlorine Leaks: GEST 93/179 9 Edition December 2015antonyabirawaNessuna valutazione finora

- Jotun's HPI concept protects hydrocarbon facilitiesDocumento20 pagineJotun's HPI concept protects hydrocarbon facilitiesPramod AthiyarathuNessuna valutazione finora

- GSB-Form-58 Non Conforming Report (NCR)Documento1 paginaGSB-Form-58 Non Conforming Report (NCR)Made GileeNessuna valutazione finora

- Friction Stir Welding and Processing X eDocumento275 pagineFriction Stir Welding and Processing X eMinh Nguyễn Phúc NhậtNessuna valutazione finora

- Nesl Training ManualDocumento91 pagineNesl Training ManualSOUMYA DEEP CHATTERJEENessuna valutazione finora

- SOP 001 Dust MoppingDocumento2 pagineSOP 001 Dust MoppingMade GileeNessuna valutazione finora

- MODEC Group confidential flange repair documentDocumento11 pagineMODEC Group confidential flange repair documentDenny AgusNessuna valutazione finora

- GSB Form 221 Purchase RequestDocumento2 pagineGSB Form 221 Purchase RequestMade GileeNessuna valutazione finora

- JNL-1241 Technical Data SheetDocumento3 pagineJNL-1241 Technical Data SheetAndrian TamsirNessuna valutazione finora

- Sop & Jsa For Pipe LeakageDocumento1 paginaSop & Jsa For Pipe LeakageSoumya ChatterjeeNessuna valutazione finora

- TIAL Installation Guide M80Documento2 pagineTIAL Installation Guide M80Yan FerizalNessuna valutazione finora

- FRM-3064 (Sanitation Checklist) OkeDocumento4 pagineFRM-3064 (Sanitation Checklist) OkerizkiNessuna valutazione finora

- Surface Pre-Heat ChartDocumento3 pagineSurface Pre-Heat ChartZainudinNessuna valutazione finora

- Final - Desginer For ASME U Designator VesselDocumento10 pagineFinal - Desginer For ASME U Designator VesselSantosh LatakeNessuna valutazione finora

- Pub 139 Copper Nickel Welding and Fabrication PDFDocumento32 paginePub 139 Copper Nickel Welding and Fabrication PDFG.SWAMI100% (1)

- Construction and Building Materials: Swathy Manohar, Manu Santhanam, Naresh ChockalingamDocumento12 pagineConstruction and Building Materials: Swathy Manohar, Manu Santhanam, Naresh ChockalingamKaren Melina Zapata ParedesNessuna valutazione finora

- Huang 2011Documento8 pagineHuang 2011Bikash ThakurNessuna valutazione finora

- Info Ozone Compatible MaterialDocumento2 pagineInfo Ozone Compatible MaterialsaracelyNessuna valutazione finora

- Ch-10 Grinding and FinishingDocumento83 pagineCh-10 Grinding and FinishingPrateek Bayal100% (1)

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Documento2 pagineAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57SathishbhaskarNessuna valutazione finora

- Experiment 5 - Tensile TestDocumento17 pagineExperiment 5 - Tensile TestSubuk T. Rathod0% (2)

- A 470 - 03 Piezas ForjadasDocumento8 pagineA 470 - 03 Piezas ForjadasWILLIAM ROMERONessuna valutazione finora

- Reaction Stoichiometry Balancer & Atom Economy CalculatorDocumento14 pagineReaction Stoichiometry Balancer & Atom Economy CalculatorshikaswaNessuna valutazione finora

- G 15 - 04 - Rze1 PDFDocumento5 pagineG 15 - 04 - Rze1 PDFRahmat Ramadhan PasaribuNessuna valutazione finora

- BS 1561Documento10 pagineBS 1561Islam FawzyNessuna valutazione finora

- AluminaDocumento5 pagineAluminaehsannasiri100% (1)

- Plating: Plating Is A Surface Covering in Which ADocumento6 paginePlating: Plating Is A Surface Covering in Which ASonti Mani kumarNessuna valutazione finora

- Welding PrincipleDocumento61 pagineWelding PrincipleRishu GroverNessuna valutazione finora

- Welding Inspector Question Rew290Documento45 pagineWelding Inspector Question Rew290dhasdj0% (1)

- History: Camel's Hair PencilDocumento3 pagineHistory: Camel's Hair Pencilkate trishaNessuna valutazione finora

- Chemistry 5070 Metals Grade 11Documento77 pagineChemistry 5070 Metals Grade 11Battlefield Forever0% (1)

- Workshop Manual 2016 PDFDocumento62 pagineWorkshop Manual 2016 PDFgiridharrajeshNessuna valutazione finora

- 0653 w16 QP 23Documento20 pagine0653 w16 QP 23yuke kristinaNessuna valutazione finora

- 2013 Asset HandbookDocumento98 pagine2013 Asset HandbookJeffrey FreitasNessuna valutazione finora

- Wiring Harnesses For Next Generation Automobiles: KiyotsuguDocumento4 pagineWiring Harnesses For Next Generation Automobiles: KiyotsuguVikas BabuNessuna valutazione finora

- Metal Fab CombiDocumento48 pagineMetal Fab CombiMike MoralNessuna valutazione finora

- Effective Cycle Chemistry ControlDocumento29 pagineEffective Cycle Chemistry ControlclesncronNessuna valutazione finora

- Ancient VMS Deposits: Geographical Distribution and Major DistrictsDocumento30 pagineAncient VMS Deposits: Geographical Distribution and Major DistrictsYoyok HartoyoNessuna valutazione finora

- WeldingDocumento64 pagineWeldingLiyana100% (1)

- Powerrail 2013 Catalog Emd CompletoDocumento96 paginePowerrail 2013 Catalog Emd CompletoSaMuell San100% (2)

- BS en 12878 2014 Pigments For ColoringDocumento34 pagineBS en 12878 2014 Pigments For ColoringPeter MohabNessuna valutazione finora

- All About BatteryDocumento4 pagineAll About BatteryCalvin KleinNessuna valutazione finora

- 1 s2.0 S0304386X02001391 MainDocumento7 pagine1 s2.0 S0304386X02001391 MainPetras PetricaNessuna valutazione finora

- Henri Sainte-Claire DevilleDocumento8 pagineHenri Sainte-Claire DevilleCharles JacobNessuna valutazione finora

- MSDSDocumento100 pagineMSDSyoyohairymonsterNessuna valutazione finora

- Changing Iron to SteelDocumento1 paginaChanging Iron to Steelretno pideksoNessuna valutazione finora

- Summer Packet Answers ExplainedDocumento11 pagineSummer Packet Answers ExplainedJohn SmithNessuna valutazione finora