Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

06-2 Data Sheet Oil Filter

Caricato da

Anonymous 9WNqHZCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

06-2 Data Sheet Oil Filter

Caricato da

Anonymous 9WNqHZCopyright:

Formati disponibili

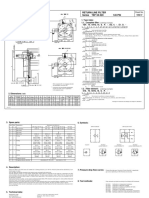

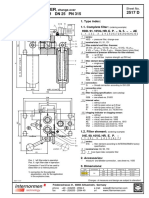

PRESSURE FILTER, change-over Sheet No.

Series DU 631-1950 DN 65-80 PN 32 2118 K

1. Type index:

1.1. Complete filter: (ordering example)

DU. 631. 10VG. 30. E. P. -. FS. 9. -. -. AE

1 2 3 4 5 6 7 8 9 10 11 12

1 series:

DU = pressure filter, change-over

2 nominal size: 631, 1001, 1950

3 filter-material and filter- fineness:

80 G = 80 m, 40 G = 40 m, 25 G = 25 m stainless steel wire mesh,

25 VG = 20 m(c), 16 VG = 15 m(c), 10 VG = 10 m(c), 6 VG = 7 m(c), 3 VG = 5 m(c) Interpor fleece (glass fibre)

25 API = 20 m, 10 API = 10 m Interpor fleece (glass fibre) according to API

10 P = 10 m paper

4 resistance of pressure difference for filter element:

30 = p 30 bar (01NL. 630) 10 = p 10 bar (01NR. 1000);

5 filter element design:

E = single-end open (DU 631) B = both sides open (DU 1001/1950)

S = with by-pass valve p 2,0 bar (DU 631) S1 = with by-pass valve p 3,5 bar (DU 631)

6 sealing material:

P = Nitrile (NBR) V = Viton (FPM)

7 filter element specification: (see catalog)

- = standard VA = stainless steel IS06 = see sheet-no. 31601 IS07 = see sheet-no. 31602

8 connection:

FS = SAE-flange connection 3000 PSI

9 connection size:

9 = 2 (DU 631) A = 3 (DU 1001/1950)

10 filter housing specification: (see catalog)

- = standard IS20 = ASME VIII Div.1 with ASME equivalent material, see sheet-no. 55217

IS06 = see sheet-no. 31605 (operating pressure max. 16 bar)

IS12 = see sheet-no. 41028

11 internal valve:

- = without

S = with by-pass valve p 2,0 bar (DU 1001/1950)

S1 = with by-pass valve p 3,5 bar (DU 1001/1950)

12 clogging indicator or clogging sensor:

- = without, OP = visual, see sheet-no. 1628

AOR = visual, see sheet-no. 1606, OE = visual-electrical, see sheet-no. 1628

AOC = visual, see sheet-no. 1606, VS1 = electronical, see sheet-no. 1607

AE = visual-electrical, see sheet-no. 1609, VS2 = electronical, see sheet-no. 1608

1.2. Filter element: (ordering example)

01NL. 630. 10VG. 30. E. P. -

1 2 3 4 5 6 7

1 series:

01NL. = standard filter element according to DIN 24550, T3

01NR. = standard-return-line filter element according to DIN 24550, T4

2 nominal size: 630 (01NL.); 1000 (01NR.); 1001 (01NR.) only with DU1950

Pos. I: left filter-side in operation

Pos. II: lright filter-side in operation 3 - 7 see type index-complete filter

2. Accessories:

- measure- and bleeder connections, see sheet-no. 1650

- evacuation and bleeder-conections, see sheet-no. 1651

- counter flanges, see sheet-no. 1652

- shut-off valve, see sheet-no. 1655

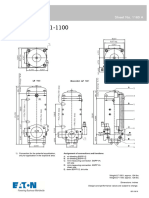

3. Dimensions:

type connection SAE-connection size A B C D E F G H J K L M N O P Q R S T weight kg

DU 631 DN 65 SAE 2 693 568 497 110 115 24 160 284 120 121 83 140 115 210 185 13,5 50,8 89 M12, 18 deep 90

DU 1001 DN 80 SAE 3 717 586 505 93,5 140 28,5 205 380 142 137 101 210 170 265 225 18 62 106,4 M16, 23 deep 116

DU 1950 DN 80 SAE 3 1119 988 907 93,5 140 28,5 205 380 142 137 101 210 170 265 225 18 62 106,4 M16, 23 deep 170

Changes of measures and design are subject to alteration!

Friedenstrasse 41, 68804 Altlussheim, Germany

phone +49 (0)6205 - 2094-0 e-mail info-internormen@eaton.com

EDV 04/14 fax +49 - 06205 - 2094-40 url www.eaton.com/filtration

4. Spare parts: 5. Description:

Pressure filters, change-over series DU 631-1950 are suitable for operating pressure up to 32 bar.

item designation qty. dimension and qty. dimension and qty. dimension and

Pressure peaks can be absorbed with a sufficient margin of safety.

article-no. article-no. article-no. A three-way-change-over valve which is, integrated in the middle of the housing, makes it possible to switch from the dirty fil-

DU 631 DU 1001 DU 1950 ter-side to the clean filter-side without interrupting operation.

These filters can be installed as suction filters, pressure filters or return-line filters.

1 filter element 2 01NL.630 2 01NR.1000 4 01NR.1000

The filter element consists of star-shaped, pleated filter material which is supported on the inside by a perforated core tube and

or is bonded to the end caps with a high-quality adhesive. The flow direction is from outside to the inside.

01NR.1001 Filter finer than 40 m should use throw-away elements made of paper or Interpor fleece (glass fibre). Filter elements as fine

60 x 3,5 90 x 4 90 x 4 as 5 m(c) are available; finer filter elements on request.

Internormen Product Line filter elements are known as elements with a high intrinsic stability and an excellent filtration capabil-

2 O-ring 2 304377 (NBR) 4 306941 (NBR) 8 306941 (NBR)

ity, a high dirt-retaining capacity and a long service life.

304398 (FPM) 307031 (FPM) 307031 (FPM) Internormen Product Line filter are suitable for all petroleum based fluids, HW-emulsions, most synthetic hydraulic fluids and

125 x 3 185 x 4 185 x 4 lubrication oils.

Approvals according to TV, and the major Shipyard Classification Societies D.N.V.; B.V.; G.L.; L.R.S.; R.I.N.A.; A.B.S. and

3 O-ring 2 306025 (NBR) 2 305593 (NBR) 4 305593 (NBR)

others are possible.

307358 (FPM) 306309 (FPM) 306309 (FPM) The internal valve is integrated in the filter cover. After reaching the opening pressure the by-pass valve causes that an unfil-

24 x 3 24 x 3 tered partial flow passes the filter.

4 O-ring 1 303038 (NBR) 303038 (FPM) 6. Technical data:

304397 (FPM) 304397 (FPM) temperature range: - 10C to + 80C (for a short time + 100C)

115 x 3 140 x 3 operating medium: mineral oil, other media on request

max. operating pressure: 32 bar

5 O-ring 2 303963 (NBR) 304604 (NBR)

max. operating pressure at IS20: 16 bar

307762 (FPM) 307541 (FPM) test pressure: 64 bar

96 x 4 120 x 4 test pressure at IS20: 32 bar

6 O-ring 1 305190 (NBR) 305300 (NBR) connection system: SAE-flange connection 3000 PSI

housing material: EN-GJS-400-18-LT

308148 (FPM) 307991 (FPM) sealing material: Nitrile (NBR) or Viton (FPM), other materials on request

32 x 2,5 32 x 2,5 installation position: vertical

7 O-ring 1 306843 (NBR) 306843 (NBR) mini-measuring connections: G

evacuation-or bleeder connections: G

308268 (FPM) 308268 (FPM) volume tank DU 631: 2x 5,7 l

69,45 x 3,53 85,32 x 3,53 DU 1001: 2x 13,0 l

8 O-ring 2 305868 (NBR) 305590 (NBR) DU 1950: 2x 23,3 l

307357 (FPM) 306308 (FPM) Classified under the Pressure Equipment Directive 97/23/EC for mineral oil (fluid group 2), Article 3, Para. 3.

Classified under ATEX Directive 94/9/EC according to specific application (see questionnaire sheet-no. 34279-4)

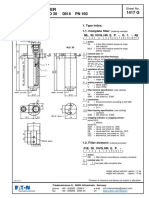

9 screw plug 8 G 8 G 10 G

304678 304678 304678 7. Symbols:

10 screw plug 2 G without indicator with by-pass valve with electrical with visual-electrical with visual-electrical

305003 indicator indicator indicator

AE 30 and AE 40 AE 50 and AE 62 AE 70 and AE 80

11 connecting pipe 2 - 90

313233

12 clogging indicator, visual 1 AOR or AOC see sheet-no. 1606

13 clogging indicator, visual 1 OP see sheet-no. 1628

14 clogging indicator, visual-electrical 1 OE see sheet-no. 1628

15 clogging indicator, visual-electrical 1 AE see sheet-no. 1609

16 clogging sensor, electronical 1 VS1 see sheet-no. 1607

17 clogging sensor, electronical 1 VS2 see sheet-no. 1608

with visual with visual-electrical with electronical with electronical

15 x 1,5 indicator indicator clogging sensor clogging sensor

18 O-ring 1 315357 (NBR) AOR/AOC/OP OE VS1 VS2

315427 (FPM)

22 x 2

19 O-ring 1 304708 (NBR)

304721 (FPM)

14 x 2

20 O-ring 2 304342 (NBR)

304722 (FPM)

21 screw plug 2 G 8. Pressure drop flow curves: Precise flow rates see Interactive Product Specifier, respectively

305003 p- curves; depending on filter fineness and viscosity.

22 pressure balance valve 1 9. Test methods: Filter elements are tested according to the following ISO standards:

ISO 2941 Verification of collapse/burst resistance

ISO 2942 Verification of fabrication integrity

item 21 execution only without clogging indicator or clogging sensor ISO 2943 Verification of material compatibility with fluids

ISO 3723 Method for end load test

ISO 3724 Verification of flow fatigue characteristics

E 2118 K

ISO 3968 Evaluation of pressure drop versus flow characteristics

ISO 16889 Multi-pass method for evaluating filtration performance

Potrebbero piacerti anche

- Return Line Filter Series TEF 55-320 145 PSI: Sheet NoDocumento2 pagineReturn Line Filter Series TEF 55-320 145 PSI: Sheet NoRonaldNessuna valutazione finora

- Filter Unit, Series UM 125 58 PSIDocumento2 pagineFilter Unit, Series UM 125 58 PSIhadNessuna valutazione finora

- PCT 1107278Documento2 paginePCT 1107278Ajaya RimalNessuna valutazione finora

- Fisa Tehnica Filtru Internormen hdd61-151 PDFDocumento2 pagineFisa Tehnica Filtru Internormen hdd61-151 PDFRizzoRo1Nessuna valutazione finora

- Fisa Tehnica Filtru Internormen Hdd61-151Documento2 pagineFisa Tehnica Filtru Internormen Hdd61-151RizzoRo1Nessuna valutazione finora

- ML 30, MLO 30 (1417G-English) PDFDocumento2 pagineML 30, MLO 30 (1417G-English) PDFEESL AACNessuna valutazione finora

- Filter Unit, Series UM 80 58 PSIDocumento2 pagineFilter Unit, Series UM 80 58 PSIAzmi AhmadNessuna valutazione finora

- Series TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 JDocumento4 pagineSeries TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 Jsanjay0910Nessuna valutazione finora

- (NBR)Documento4 pagine(NBR)Youghorta TIRNessuna valutazione finora

- Series DA 103 NPS 1" CLASS 150-300 PSI: PRESSURE FILTER, Change Over Sheet No. 2213ADocumento43 pagineSeries DA 103 NPS 1" CLASS 150-300 PSI: PRESSURE FILTER, Change Over Sheet No. 2213Avictor abrajanNessuna valutazione finora

- Pressure Filter, Series DA 2215: Nps 4" Class 150 PsiDocumento2 paginePressure Filter, Series DA 2215: Nps 4" Class 150 PsiRidha AbbassiNessuna valutazione finora

- Series TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LDocumento4 pagineSeries TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LRaid BekaltiNessuna valutazione finora

- PCT 3557915Documento4 paginePCT 3557915earquaz23Nessuna valutazione finora

- Instrumento de Presion PDFDocumento2 pagineInstrumento de Presion PDFAlison RuizNessuna valutazione finora

- Filter Unit, Series UM 40 PN4: MobileDocumento2 pagineFilter Unit, Series UM 40 PN4: MobileAmar KevricNessuna valutazione finora

- Filtro para Gas de Italpump - Datos TécnicosDocumento6 pagineFiltro para Gas de Italpump - Datos TécnicostiemposmodernosNessuna valutazione finora

- Cartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMDocumento2 pagineCartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMJulio Enrique Oliver CuelloNessuna valutazione finora

- ABO Ball ValveDocumento6 pagineABO Ball ValveSunil BajpaiNessuna valutazione finora

- HAND SPRAY GUN Based On Customer Satisfaction HAND SPRAY GUN Based On Customer SatisfactionDocumento2 pagineHAND SPRAY GUN Based On Customer Satisfaction HAND SPRAY GUN Based On Customer SatisfactionantokinNessuna valutazione finora

- Pall Water - Prelude Filters and Housings - x100 HousingDocumento2 paginePall Water - Prelude Filters and Housings - x100 HousingNAHASALI11Nessuna valutazione finora

- NAF-Knife Knife Gate Valves FK 24.31 (5) GB: Primary CharacteristicsDocumento6 pagineNAF-Knife Knife Gate Valves FK 24.31 (5) GB: Primary CharacteristicsNguyen KhaNessuna valutazione finora

- Leil - o 0230.001.2017 Addendum A - SpecificationDocumento15 pagineLeil - o 0230.001.2017 Addendum A - SpecificationehferreiraNessuna valutazione finora

- Series TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 HDocumento4 pagineSeries TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 Hnemi90Nessuna valutazione finora

- 4 Delta Series FiltersDocumento10 pagine4 Delta Series Filtersgiovanni1912Nessuna valutazione finora

- DetonatorsDocumento1 paginaDetonatorsMcSOLA ONessuna valutazione finora

- OMEGA AIR-Clean Air For Hospitals - SF Filter SF006 and 0310-VSFDocumento1 paginaOMEGA AIR-Clean Air For Hospitals - SF Filter SF006 and 0310-VSFabsahkahNessuna valutazione finora

- Series: Unidirectional Seal Knife Gate ValveDocumento2 pagineSeries: Unidirectional Seal Knife Gate ValveAnnie De WildeNessuna valutazione finora

- E Hoov Mc003 e B TubingDocumento16 pagineE Hoov Mc003 e B TubinghansegvNessuna valutazione finora

- JP Marine Catalogue EN - v1.3 - ImpellerPages51 55Documento5 pagineJP Marine Catalogue EN - v1.3 - ImpellerPages51 55Monika Edyta ChojnackaNessuna valutazione finora

- GW WS020 1004 E TankcoolDocumento3 pagineGW WS020 1004 E TankcoolNiki PratamaNessuna valutazione finora

- Gravity Drip Kit BrochureDocumento4 pagineGravity Drip Kit BrochuretongaiNessuna valutazione finora

- Technical Details R1-1Documento1 paginaTechnical Details R1-1parth sapariaNessuna valutazione finora

- AS Ilters: Pmax 2 Bar Pmax 6 BarDocumento6 pagineAS Ilters: Pmax 2 Bar Pmax 6 BarPablo MartinezNessuna valutazione finora

- Tbe For Osbl (SBS)Documento5 pagineTbe For Osbl (SBS)benidbb100% (3)

- Flowserve Kämmer 191000Documento8 pagineFlowserve Kämmer 191000ALFREDO SANTANANessuna valutazione finora

- HK OIM Fil 314 Rev10.15Documento12 pagineHK OIM Fil 314 Rev10.15Ingeniería AplicacionesNessuna valutazione finora

- Table 1 - Symbols and Designations Reference Number Symbol Unit DesignationDocumento1 paginaTable 1 - Symbols and Designations Reference Number Symbol Unit DesignationSvapneshNessuna valutazione finora

- Programa Completo Completacion InicialDocumento23 paginePrograma Completo Completacion InicialAlejandro JaramilloNessuna valutazione finora

- Nutsche Pressure Filter M.S.Structure As Per Drawing No: Fagun SetDocumento3 pagineNutsche Pressure Filter M.S.Structure As Per Drawing No: Fagun Setakshay deepak rautNessuna valutazione finora

- PFI Pentek Big Blue HousingDocumento2 paginePFI Pentek Big Blue Housingbennypartono407Nessuna valutazione finora

- Sweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (60 - ) - (S - N 434700101 & Above, 714400101 & Above) - SweeperDocumento3 pagineSweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (60 - ) - (S - N 434700101 & Above, 714400101 & Above) - SweeperLeidys ORTIZ CONEONessuna valutazione finora

- 15K Tube Cleaning NozzlesDocumento39 pagine15K Tube Cleaning NozzlesAlfred Hernandez Mendoza100% (1)

- Pump-Out Plug: A) DescriptionDocumento13 paginePump-Out Plug: A) DescriptionROBERTO ANDRES SIZA REYNessuna valutazione finora

- Merlin Plus (PRF RO) All Languages - 13210143470Documento90 pagineMerlin Plus (PRF RO) All Languages - 13210143470Brenda Yolanda Alemán LaraNessuna valutazione finora

- IM en 8 260 110 F68V F68YDocumento2 pagineIM en 8 260 110 F68V F68Y2m8vzmsz5qNessuna valutazione finora

- Rev MR TATA 1 MGDocumento6 pagineRev MR TATA 1 MGSurajNessuna valutazione finora

- F450 en 04Documento4 pagineF450 en 04Brian WebbNessuna valutazione finora

- Service Instructions: SP 1A - SP 5ADocumento11 pagineService Instructions: SP 1A - SP 5AMuhammad AlpianNessuna valutazione finora

- GC Consumables GCMS Consumables Brochure - GC Consumables GuideDocumento15 pagineGC Consumables GCMS Consumables Brochure - GC Consumables GuideSupervision ServicioNessuna valutazione finora

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocumento2 pagineModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNessuna valutazione finora

- Gate Valve Os&yDocumento6 pagineGate Valve Os&yJOHN NIKKONessuna valutazione finora

- Resilient-Seated Gate Valves Outside Screw and Yoke General DescriptionDocumento6 pagineResilient-Seated Gate Valves Outside Screw and Yoke General DescriptionNikhil JaiswalNessuna valutazione finora

- KS 159590 Concatenate 54261142Documento42 pagineKS 159590 Concatenate 54261142Raddy SantosoNessuna valutazione finora

- Support Items: Panasonic Factory Solutions Co., LTDDocumento48 pagineSupport Items: Panasonic Factory Solutions Co., LTDMelchiades OliveiraNessuna valutazione finora

- En Periodical Reject Separator PSNDocumento2 pagineEn Periodical Reject Separator PSNPham van QuyetNessuna valutazione finora

- 2 Ends PP FDY-210317Documento18 pagine2 Ends PP FDY-210317Audop CompanyNessuna valutazione finora

- Flat Cylinder DZF-18-80-P-A: Catalogue PageDocumento3 pagineFlat Cylinder DZF-18-80-P-A: Catalogue PageAbraham PerezNessuna valutazione finora

- Hawle Ventili20-200Documento2 pagineHawle Ventili20-200Kenan HotiNessuna valutazione finora

- Sweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperDocumento3 pagineSweeper (Brushes With Convoluted Sections) (Two Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperJhon Atencio LopezNessuna valutazione finora

- Sight Glass General Characteristics: Flow Indicator 7.1. Visoflow WO1 - GM/GKDocumento1 paginaSight Glass General Characteristics: Flow Indicator 7.1. Visoflow WO1 - GM/GKAnonymous 9WNqHZNessuna valutazione finora

- CPU FW History Overview - 3ADR020152M0401Documento3 pagineCPU FW History Overview - 3ADR020152M0401Anonymous 9WNqHZNessuna valutazione finora

- vg30sp 14 PDFDocumento2 paginevg30sp 14 PDFAnonymous 9WNqHZNessuna valutazione finora

- JSBRR 09Documento1 paginaJSBRR 09Anonymous 9WNqHZNessuna valutazione finora

- Rhythm 4: Standard TuningDocumento1 paginaRhythm 4: Standard TuningAnonymous 9WNqHZNessuna valutazione finora

- 10 1 Manual Data SheetDocumento6 pagine10 1 Manual Data SheetAnonymous 9WNqHZNessuna valutazione finora

- AC500 CPU: Task Configuration Basic ModuleDocumento29 pagineAC500 CPU: Task Configuration Basic ModuleAnonymous 9WNqHZNessuna valutazione finora

- Chord Change Tips, Open Chord To Barre Chord: by Lisa MccormickDocumento2 pagineChord Change Tips, Open Chord To Barre Chord: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Product News ACM 03 2015 AC500 New CPU PM595 - Rev1 - If AwardDocumento2 pagineProduct News ACM 03 2015 AC500 New CPU PM595 - Rev1 - If AwardAnonymous 9WNqHZNessuna valutazione finora

- More Formula Testing, With The E Minor Chord: by Lisa MccormickDocumento2 pagineMore Formula Testing, With The E Minor Chord: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Let'S Test The Formula, With A D Minor Chord: by Lisa MccormickDocumento2 pagineLet'S Test The Formula, With A D Minor Chord: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Barre Chord Change Strategies, 5Th-String Root: by Lisa MccormickDocumento2 pagineBarre Chord Change Strategies, 5Th-String Root: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- What Is A 'Minor Chord' Made Of?: by Lisa MccormickDocumento2 pagineWhat Is A 'Minor Chord' Made Of?: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Play The Mini-Song, 'Eddie'S Ghost Came Back!': by Lisa MccormickDocumento2 paginePlay The Mini-Song, 'Eddie'S Ghost Came Back!': by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Let'S Revisit, and Read, 'Ode To Joy': by Lisa MccormickDocumento2 pagineLet'S Revisit, and Read, 'Ode To Joy': by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Barre Chord Change Tips, From 5Th-Root To 6Th-Root: by Lisa MccormickDocumento2 pagineBarre Chord Change Tips, From 5Th-Root To 6Th-Root: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Learn The Mini-Song, 'Eddie'S Ghost Came Back!': by Lisa MccormickDocumento2 pagineLearn The Mini-Song, 'Eddie'S Ghost Came Back!': by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Barre Chord Change Strategies, 6Th-String Root: by Lisa MccormickDocumento2 pagineBarre Chord Change Strategies, 6Th-String Root: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Barre Chord Change Tips, From 6Th-Root To 5Th-Root: by Lisa MccormickDocumento2 pagineBarre Chord Change Tips, From 6Th-Root To 5Th-Root: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Major Chords in The Key of D: by Lisa MccormickDocumento1 paginaMajor Chords in The Key of D: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Major Chords in The Key of A: by Lisa MccormickDocumento1 paginaMajor Chords in The Key of A: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Minor Chords in The Key of A: by Lisa MccormickDocumento1 paginaMinor Chords in The Key of A: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Master The Chord Changes in The Key of D: by Lisa MccormickDocumento1 paginaMaster The Chord Changes in The Key of D: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Minor Chords in The Key of D: by Lisa MccormickDocumento1 paginaMinor Chords in The Key of D: by Lisa MccormickAnonymous 9WNqHZNessuna valutazione finora

- Major Scale Sequencing 3Documento1 paginaMajor Scale Sequencing 3Anonymous 9WNqHZNessuna valutazione finora

- Basic Strumming Patterns 1Documento1 paginaBasic Strumming Patterns 1Anonymous 9WNqHZNessuna valutazione finora

- Experiments With An Axial Fan: Page 1/3 10/2010Documento3 pagineExperiments With An Axial Fan: Page 1/3 10/2010Priyam ParasharNessuna valutazione finora

- Phase ShifterDocumento7 paginePhase ShifterNumanAbdullahNessuna valutazione finora

- V1 001 PDFDocumento20 pagineV1 001 PDFG100% (2)

- Group 2 (Oacc39)Documento3 pagineGroup 2 (Oacc39)viernazanne.viadoNessuna valutazione finora

- Gudenaaparken (Randers) - All You Need To Know BEFORE You GoDocumento8 pagineGudenaaparken (Randers) - All You Need To Know BEFORE You GoElaine Zarb GiorgioNessuna valutazione finora

- BS EN 12536-2000 Gas Welding Creep Resistant, Non-Alloy and Fine Grain PDFDocumento11 pagineBS EN 12536-2000 Gas Welding Creep Resistant, Non-Alloy and Fine Grain PDFo_l_0Nessuna valutazione finora

- E85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFDocumento8 pagineE85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFLuis TovarNessuna valutazione finora

- Prof. Herkutanto-JKN - Patient Safety Dan Etika 2016Documento30 pagineProf. Herkutanto-JKN - Patient Safety Dan Etika 2016galih wicaksonoNessuna valutazione finora

- Human Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDocumento3 pagineHuman Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDavid SabaflyNessuna valutazione finora

- Why Rife Was Right and Hoyland Was Wrong and What To Do About ItDocumento4 pagineWhy Rife Was Right and Hoyland Was Wrong and What To Do About ItHayley As Allegedly-Called Yendell100% (1)

- How To Restring An Acoustic Guitar Nicholas OngkowijayaDocumento9 pagineHow To Restring An Acoustic Guitar Nicholas Ongkowijayaplebeius31Nessuna valutazione finora

- Reynolds EqnDocumento27 pagineReynolds EqnSuman KhanalNessuna valutazione finora

- Nueva Ecija University of Science and Technology Gapan Academic Extension CampusDocumento4 pagineNueva Ecija University of Science and Technology Gapan Academic Extension CampusErmercadoNessuna valutazione finora

- CM29, 03-16-17Documento3 pagineCM29, 03-16-17Louie PascuaNessuna valutazione finora

- New Process Performance IE4 Motors: Product NotesDocumento2 pagineNew Process Performance IE4 Motors: Product NotesCali MelendezNessuna valutazione finora

- Guide To Linux+ (2 Edition) ISBN 0-619-21621-2 End of Chapter Solutions Chapter 4 SolutionsDocumento8 pagineGuide To Linux+ (2 Edition) ISBN 0-619-21621-2 End of Chapter Solutions Chapter 4 SolutionsNorhasimaSulaimanNessuna valutazione finora

- 2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Documento4 pagine2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Progress QueensNessuna valutazione finora

- λ-based Design Rules PDFDocumento3 pagineλ-based Design Rules PDFvinosujaNessuna valutazione finora

- Database Upgrade 10g To 11gDocumento28 pagineDatabase Upgrade 10g To 11gSubhasis1928Nessuna valutazione finora

- REA 101 Proteccion de Arco EléctricoDocumento64 pagineREA 101 Proteccion de Arco EléctricoIngJGMNessuna valutazione finora

- HGU User ManualDocumento72 pagineHGU User Manuallomayani100% (1)

- 300Mbps/150Mbps Wireless LAN Broadband Router: Quick Installation GuideDocumento2 pagine300Mbps/150Mbps Wireless LAN Broadband Router: Quick Installation GuideLuis AngelNessuna valutazione finora

- Kv2ci Oi PDFDocumento142 pagineKv2ci Oi PDFJethro AbanadorNessuna valutazione finora

- Lab 7Documento12 pagineLab 7api-25252422380% (5)

- Super CatalogueDocumento8 pagineSuper CatalogueITL200_UNessuna valutazione finora

- Sports Collection CatalogueDocumento31 pagineSports Collection CataloguesitarazmiNessuna valutazione finora

- Mathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringDocumento40 pagineMathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringVishal ShasiNessuna valutazione finora

- Report On Siddartha Bank LimitedDocumento24 pagineReport On Siddartha Bank LimitedSanim AmatyaNessuna valutazione finora

- MGT104 Assignment 3Documento11 pagineMGT104 Assignment 3Lê Hữu Nam0% (1)

- NNH4-65C-R6-V2: Electrical SpecificationsDocumento4 pagineNNH4-65C-R6-V2: Electrical SpecificationsAntony López GálvezNessuna valutazione finora