Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

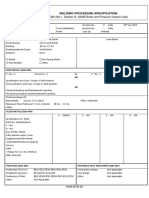

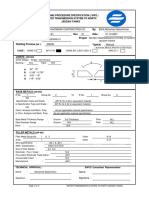

JOINTS (QW-402) : Groove Design of Test Coupon

Caricato da

beyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JOINTS (QW-402) : Groove Design of Test Coupon

Caricato da

beyCopyright:

Formati disponibili

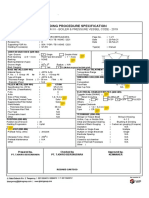

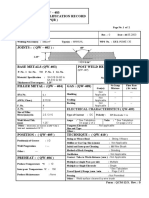

PRN007

Company Name: The Shaw Group, Inc./ B. F. Shaw, Inc.

Procedure Qualification Record No.: L8544 Date: April 6, 1994

WPS No.: 104

Welding Process(es) GTAW

Types (Manual, Automatic, Semi-Auto) Machine

JOINTS (QW-402)

SINGLE VEE GROOVE

70 DEGREE INCLUDED ANGLE

3/32 GAP

1/16 LAND

Groove Design of Test Coupon

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec.: SA333 to A333 Temperature: 1100oF - 1150oF

Type or Grade: Gr. 6 to Gr. 6 Time: Two (2) Hours Soak Time

P-No.: 1 to P-No.: 1 Other:

Thickness of test coupon: 1.125

Diameter of test coupon: 10 NPS

Other: The deposition of each pass did not exceed

1/8.

FILLER METALS (QW-404) GAS (QW-408)

Process:

SFA Specification: 5.18 Percent CFH

AWS Classification: ER70S-2 Gas(es) Composition Flow

Filler Metal F-No.: 6 (Mixture) Rate

Weld Metal A-No.: 1 Shielding He/Ar 75/25 30

Size of Filler Metal: .035 Trailing None None None

Other: Backing None None None

Weld Metal Thickness: 1.125

NOTES: ELECTRICAL CHARACTERISTICS (QW-409)

Current: DC Polarity: EN

AMPS: 90-240

Volts: 12-16

Tungsten Electrode Size: 5/32 (2% Thoriated)

Transfer Mode: N/A

Other:

POSITION (QW-405) TECHNIQUE (QW-410)

Position of Groove: 1GR Travel Speed: 2-3 IPM

Weld Progression: Rotated String or Weave Bead: String and Weave

Other: Oscillation: Width: Maximum

PREHEAT (QW-406) Multipass/Single Pass (per side): Multipass

o o

Preheat Temp.: 175 F Interpass Temp: 400 F Single or Multiple Electrodes: Single

Other: Other:

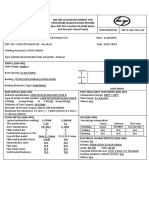

PQR No.: L8544 (PRN007)

QW-462.1(b)

Tensile Test (QW-150)

Ultimate Ultimate Type of Failure &

Specimen Width Thickness Total Load Unit Stress Location

No. (Inches) (Inches) Area lb psi

T-1-T .747 .508 .379 25,200 66,491 Ductile-Base

T-1-B .752 .476 .358 24,400 68,156 Ductile-Base

T-2-T .750 .497 .373 24,850 66,622 Ductile-Base

T-2-B .752 .462 .347 23,750 68,444 Ductile-Base

Guided-Bend Tests (QW-160)

Type and Figure No. Result

Side Bend No. 1 QW-462.2 Acceptable

Side Bend No. 2 QW-462.2 Acceptable

Side Bend No. 3 QW-462.2 Acceptable

Side Bend No. 4 QW-462.2 Acceptable

Toughness Tests (QW-170)

Specimen Notch Specimen Size Notch Test Impact Lateral Exp.

No. Location Type Temp. Values % Shear Mils

Fillet-Weld Test (QW-180)

Result Satisfactory: Yes ______ No _____ Penetration into Parent Metal: Yes _______ No _______

Macro-Results:

Other Tests

Type of Test:

Deposit Analysis:

Other:

Welders Name: Doug Tollison Clock No.: Stamp No.: G0

Test Conducted By: Welding Testing Lab, Inc. Laboratory Test No.: L8544

We certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME Code.

Manufacturer: The Shaw Group, Inc./B.F. Shaw, Inc.

Date: April 7, 2000 By: ________________________________________

Potrebbero piacerti anche

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Documento2 pagineBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNessuna valutazione finora

- PRN005Documento2 paginePRN005beyNessuna valutazione finora

- JOINTS (QW-402) : Groove Design of Test CouponDocumento2 pagineJOINTS (QW-402) : Groove Design of Test CouponbeyNessuna valutazione finora

- PRN004Documento2 paginePRN004beyNessuna valutazione finora

- SWATHI PQR Procedure QualificationDocumento10 pagineSWATHI PQR Procedure QualificationMustu AkolawalaNessuna valutazione finora

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocumento10 pagineWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- PQR FormatDocumento2 paginePQR FormatBE GNessuna valutazione finora

- Mechanical Engineering M.Abdul GhoziDocumento4 pagineMechanical Engineering M.Abdul GhoziRizaldy PhoenksNessuna valutazione finora

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocumento5 pagineLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNessuna valutazione finora

- Aic Asf PQR 133Documento3 pagineAic Asf PQR 133AHMED MEDANYNessuna valutazione finora

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocumento3 pagineASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNessuna valutazione finora

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocumento4 pagine(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNessuna valutazione finora

- WPS 8 To 1-3-1 Rev2 (10-1-13)Documento5 pagineWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNessuna valutazione finora

- Welding Procedure Specification for Stainless SteelDocumento5 pagineWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Audco India Limited Welding Procedure Specification: LAB-005R1Documento3 pagineAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1Nessuna valutazione finora

- WPS, PQR, WPQ PoojaDocumento10 pagineWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- PQR Welding Procedure RecordDocumento2 paginePQR Welding Procedure RecordAtilio BarriosNessuna valutazione finora

- Gta+sma PQRDocumento3 pagineGta+sma PQRRahul MoottolikandyNessuna valutazione finora

- WPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsDocumento3 pagineWPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsAmjad PathanNessuna valutazione finora

- PQR With-PwhtDocumento2 paginePQR With-PwhtKarthikNessuna valutazione finora

- 1 5 1Documento5 pagine1 5 1daemsalNessuna valutazione finora

- QW483Documento2 pagineQW483Sc TanNessuna valutazione finora

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Documento2 pagineBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNessuna valutazione finora

- Final WPS - ItdcDocumento2 pagineFinal WPS - ItdcsarancivilrajNessuna valutazione finora

- WPS CuNiDocumento4 pagineWPS CuNiSripathyNessuna valutazione finora

- Wps Format Asme Sec - IxDocumento2 pagineWps Format Asme Sec - IxDeepu ChandranNessuna valutazione finora

- WPS-PQR RepairDocumento16 pagineWPS-PQR RepairmohammedetaNessuna valutazione finora

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Documento2 pagineQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNessuna valutazione finora

- Nit 2019 20 56 Wps 1569579575Documento16 pagineNit 2019 20 56 Wps 1569579575vijayachiduNessuna valutazione finora

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocumento3 pagineWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNessuna valutazione finora

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocumento5 pagineWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNessuna valutazione finora

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocumento2 pagineBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNessuna valutazione finora

- Aic Asf PQR 0122Documento2 pagineAic Asf PQR 0122AHMED MEDANYNessuna valutazione finora

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocumento5 pagineWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNessuna valutazione finora

- 2005-05 - WPS & PQR C5Documento6 pagine2005-05 - WPS & PQR C5misthahNessuna valutazione finora

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocumento2 pagineWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNessuna valutazione finora

- Welding Procedure SpecificationDocumento27 pagineWelding Procedure SpecificationGopakumar K100% (2)

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- WPS CuNiDocumento1 paginaWPS CuNiDieter Huaman ToscanoNessuna valutazione finora

- Procedure Qualification Record PQRDocumento3 pagineProcedure Qualification Record PQRNMBaihakiARNessuna valutazione finora

- WPS 03 GtawDocumento3 pagineWPS 03 GtawBiswajit DeyNessuna valutazione finora

- WPS 10Documento2 pagineWPS 10Arab WeldersNessuna valutazione finora

- Procedure Qualification RecordDocumento6 pagineProcedure Qualification RecordGaurang PandyaNessuna valutazione finora

- METALS INSPECTION SERVICES WELDING PROCEDUREDocumento6 pagineMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNessuna valutazione finora

- PQR ForDocumento3 paginePQR ForAkash Singh TomarNessuna valutazione finora

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Documento3 pagineNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNessuna valutazione finora

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocumento4 pagineQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Nessuna valutazione finora

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- WPS Gtaw+smawDocumento2 pagineWPS Gtaw+smawAnand GNessuna valutazione finora

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 pagineWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNessuna valutazione finora

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocumento3 pagineDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNessuna valutazione finora

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocumento2 pagine0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNessuna valutazione finora

- WPS Gtaw) - 47Documento2 pagineWPS Gtaw) - 47Dharmendra BhardwajNessuna valutazione finora

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Documento2 pagineWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Transducer Handbook: User's Directory of Electrical TransducersDa EverandTransducer Handbook: User's Directory of Electrical TransducersNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Bilad 2018 01 21Documento25 pagineBilad 2018 01 21beyNessuna valutazione finora

- Pipeline & Piping ScheduleDocumento12 paginePipeline & Piping SchedulebeyNessuna valutazione finora

- CONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25Documento324 pagineCONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25http://secwatch.com100% (2)

- Well Test Interpreta TionDocumento6 pagineWell Test Interpreta TionbeyNessuna valutazione finora

- 01 - Fluid FlowDocumento76 pagine01 - Fluid FlowMubarak AhmadNessuna valutazione finora

- 4 Wti Wellsite ValidationDocumento6 pagine4 Wti Wellsite ValidationbeyNessuna valutazione finora

- Well Test Interpreta TionDocumento6 pagineWell Test Interpreta TionbeyNessuna valutazione finora

- 3 Wti Control of Downhole PDFDocumento6 pagine3 Wti Control of Downhole PDFAjendra SinghNessuna valutazione finora

- 2 Wti FundamentalsDocumento10 pagine2 Wti FundamentalsgdchanesNessuna valutazione finora

- Lube Oil Function Test ProcedureDocumento4 pagineLube Oil Function Test ProcedurebeyNessuna valutazione finora

- Algerian Petroleum Institute Drilling IntroductionDocumento210 pagineAlgerian Petroleum Institute Drilling IntroductionbeyNessuna valutazione finora

- 01 - Fluid FlowDocumento76 pagine01 - Fluid FlowMubarak AhmadNessuna valutazione finora

- API 14A UpdateDocumento13 pagineAPI 14A UpdateAnonymous 70lCzDJv100% (1)

- PRN List For Volume 1-113001Documento1 paginaPRN List For Volume 1-113001beyNessuna valutazione finora

- Engineering Data Book: Gas Processors Suppliers AssociationDocumento30 pagineEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Documento1 paginaPipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNessuna valutazione finora

- 14A - E12 PADocumento4 pagine14A - E12 PAbeyNessuna valutazione finora

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Documento1 paginaPipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNessuna valutazione finora

- 2 Cyclonic LayoutDocumento1 pagina2 Cyclonic LayoutbeyNessuna valutazione finora

- Section 17Documento11 pagineSection 17beyNessuna valutazione finora

- Three-View Drawings & Technical DiagramsDocumento150 pagineThree-View Drawings & Technical DiagramsMahesh KumarNessuna valutazione finora

- Piping Drawings Guide: PFDs, P&IDs, Isometrics & GADsDocumento89 paginePiping Drawings Guide: PFDs, P&IDs, Isometrics & GADsbey100% (2)

- ProjectDocumento48 pagineProjectManoj Kumar B0% (1)

- Chem 111 Course Outline & RefferencesDocumento2 pagineChem 111 Course Outline & Refferenceswanluv123100% (1)

- Tratamientos de FlotacionDocumento35 pagineTratamientos de FlotacionGiroshi Roberth Reyes VillarNessuna valutazione finora

- Lewatit Monoplus TP 260: Product InformationDocumento5 pagineLewatit Monoplus TP 260: Product InformationChang Chee HongNessuna valutazione finora

- Submerged PumpDocumento8 pagineSubmerged Pumpbramantiya100% (1)

- Lab Report 2Documento11 pagineLab Report 2Irene BalinbinNessuna valutazione finora

- Kuis 2Documento3 pagineKuis 2Yodha WirandanuNessuna valutazione finora

- Unraveling The Structure of Iron (III) Oxalate Tetrahydrate and Its Reversible Li Insertion CapabilityDocumento9 pagineUnraveling The Structure of Iron (III) Oxalate Tetrahydrate and Its Reversible Li Insertion CapabilityOlga Viviana Cardenas LunaNessuna valutazione finora

- LDH Pointe ScientificDocumento2 pagineLDH Pointe ScientificDaria Vîrtic100% (1)

- 7solutions Datasheet Gaztox enDocumento2 pagine7solutions Datasheet Gaztox enForum PompieriiNessuna valutazione finora

- Determining The Rate Law From Experimental DataDocumento45 pagineDetermining The Rate Law From Experimental Datasospeter barasaNessuna valutazione finora

- 4-2 Rha 2Documento1 pagina4-2 Rha 2Dragan LazicNessuna valutazione finora

- Formation of The Heavy ElementsDocumento17 pagineFormation of The Heavy ElementsSheiloiNessuna valutazione finora

- Sensors - Temperature BOSCHDocumento5 pagineSensors - Temperature BOSCHJulian FaelliNessuna valutazione finora

- GAMSAT TopicsDocumento7 pagineGAMSAT TopicsSewon KimNessuna valutazione finora

- 21st Century General Chemistry 1Documento382 pagine21st Century General Chemistry 1Sreedevi Krishnakumar100% (1)

- Ancorsteel 1000 BDocumento5 pagineAncorsteel 1000 BobinakanuNessuna valutazione finora

- H-HS-0007C Chlorine Bleach Mold Mildew RemoverDocumento1 paginaH-HS-0007C Chlorine Bleach Mold Mildew RemoverJuliana Wong100% (2)

- Land RemUKDocumento6 pagineLand RemUKGabriel Orantes ArguelloNessuna valutazione finora

- IL-6 Testing ProtocolDocumento7 pagineIL-6 Testing ProtocolUMMID WashimNessuna valutazione finora

- Cell Membrane Transport: A Guide to Passive and Active ProcessesDocumento2 pagineCell Membrane Transport: A Guide to Passive and Active ProcessesZei-chen LocabenNessuna valutazione finora

- HW Hydraulics (setII) Ch3Documento4 pagineHW Hydraulics (setII) Ch3Zairah Francisco100% (1)

- Cooler Condenser Design for Vapor-Gas MixturesDocumento1 paginaCooler Condenser Design for Vapor-Gas MixturesNind's Chef0% (1)

- Chemical EquilibriumDocumento2 pagineChemical EquilibriumDaniel Loh100% (1)

- SCM25 steel alloy properties and applicationsDocumento1 paginaSCM25 steel alloy properties and applicationsPeterWayNessuna valutazione finora

- BS en Iso 12944-1-2017Documento41 pagineBS en Iso 12944-1-2017Dwarakanathan Makkada YuvarajNessuna valutazione finora

- E-NTU Heat Transfer: LibraryDocumento7 pagineE-NTU Heat Transfer: LibrarySergio AymiNessuna valutazione finora

- Rock Mechanics Calculations: Wood-Biot-Gassmann EquationsDocumento20 pagineRock Mechanics Calculations: Wood-Biot-Gassmann EquationsHcene HcenNessuna valutazione finora

- en 10213 2007 Steel Castings For Pressure Purposes PDFDocumento29 pagineen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNessuna valutazione finora

- Air Separation Unit PDFDocumento2 pagineAir Separation Unit PDFbodhi_cheNessuna valutazione finora