Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Section 05 - Despiece Caja Ranger s15m

Caricato da

Francisco Arroyo0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

149 visualizzazioni150 pagineranger

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoranger

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

149 visualizzazioni150 pagineSection 05 - Despiece Caja Ranger s15m

Caricato da

Francisco Arroyoranger

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 150

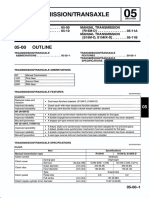

TRANSMISSION/TRANSAXLE

deena TRANSMISSION TECHNICAL DATA

[R15M-D]. . - 05-110 [S15M-D, S15MX-D].

MANUAL TRA\ SERVICE TOOLS

[S15M-D, S15MX-D] ....... 05-11B [RISM-D] ....... ee scenes

TECHNICAL DATA SERVICE TOOLS

[RISM-D].......2+++-0005 05-50A [S15M-D, S15MX-D]........ 05-60B

,

9

05-11-1

MANUAL TRANSMISSION [S15M-D, S15MX-D]

< 05-114

PRECAUTION [S15M-D, S15MX-D] ..

TOP COVER COMPONENT AND

EXTENSION HOUSING DISASSEMBLY

[S15M-D, S15MX-D] . . 05-11B-2

REVERSE GEAR COMPONENT AND

3RD/ATH GEAR COMPONENT

DISASSEMBLY

[S15M-D, S15MX-D] . - 05-11B-9

MAINSHAFT COMPONENT,

COUNTERSHAFT COMPONENT AND

‘TRANSMISSION CASE DISASSEMBLY

[S15M-D, S1SMX-D] . + 05-11-13

18T/2ND GEAR COMPONENT, 3RD/4TH

GEAR COMPONENT AND

COUNTERSHAFT DISASSEMBLY

[S15M-D, S15MX-D] . see ee+ O5-11B-16

SHIFT COMPONENT DISASSEMBLY

[S1SM-D, S15MX-D] .... + O5-11B-19

05-11B MANUAL TRANSMISSION [S15M-D, S15MX-D]

MANUAL TRANSMISSION PARTS

INSPECTION [S15M-D, S1S5MX-D] .. ..05-11B-21

‘SHIFT COMPONENT ASSEMBLY

[S15M-D, S15MX-D].

1ST/2ND GEAR COMPONENT, 3RD/4TH

GEAR COMPONENT AND

COUNTERSHAFT ASSEMBLY

[S15M-D, S15MX-D}.

MAINSHAFT COMPONENT,

COUNTERSHAFT COMPONENT AND

TRANSMISSION CASE ASSEMBLY

[S15M-D, S15MX-D].

REVERSE GEAR COMPONENT AND.

SRD/4TH GEAR COMPONENT

ASSEMBLY [S15M-D, S15MX-D].

TOP COVER COMPONENT AND

EXTENSION HOUSING ASSEMBLY

[S15M-D, S1SMX-D].

05-18-23

05-11B-26

05-11B-31

05-18-37

+ -05-11B-44

PRECAUTION [S15M-D, S15MX-D]

1. Clean the transmission exterior thoroughly using a steam cleaner or cleaning solvents before disassembly.

Warning

‘* Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes.

Wear protective eye wear whenever using compressed air.

D caution

© Cleaning sealed bearings using cleaning fluids or a steam cleaner can wash the grease out of the

bearing.

Coat all movable paris with the specified oil,

Replace parts whenever required.

@Nogsep

.. Clean the removed parts using cleaning solvent, and dry them using compressed ai.

Clean out all holes and passages using compressed air, and check that there are no obstructions.

Make sure each part is cleaned before assembling.

Remove old sealant from contact surfaces before applying new sealant.

Assemble the parts within 10 min after applying sealant. Allow all sealant to cure at least 30 min after

assembling before filing the transmission with transmission oll

‘Warning

* Although the stand has a self-locking brake system, there is a possil

lity that the brake may not

hold when the transmission is held in a lopsided position on the stand. This would cause the

transmission to turn suddenly, causing serious injury. Never keep the transmission tilted to one

side. Always hold the rotating handle firmly when turning the transmission.

05-11B-1

MANUAL TRANSMISSION [S15M-D, S15MX-D]

TOP COVER COMPONENT AND EXTENSION HOUSING DISASSEMBLY [S15M-D, SISMX-D]

jon housing and control rod) only if there is a malfunction. €

\ Ne

CO

er

05-11B-2

MANUAL TRANSMISSION [S15M-D, S15MX-D]

7 [rama 2 [Spina

|r ar [asa oes

gc foo 2 Settee

4 |Top cover, shift component (Oil seal (extension housing)

(Reso ibs Tp Gove Dsasconby Note) 2. | ev 05 18°30 Seal eonin housing

5 Jormcsge Soon Ne)

ee in Fash

[eens | an (fet 5 118-8 Bonin Housing Dnassenbly

aot (gee

[ 8 [Gasket 25_|Funnel

9 [Wave washer 26 | Control rod

10 [Change bush 27_| Oil passage

11_|Srif lover, Oil seal (control rod)

‘| hango sal 2 | Bett 188 6 bal cont oa) easel

ie [Cortel case | * lhe

1a [eantet or =e [Bush

14_[cenfered : (3 s-116-7 bush Doassonby te)

| Sri ap.

it ets spot os 20 | Sou 8116-7 Seaing Cap Dass Noe)

i a ‘31 [Retaining ring

16S ft mich 32 | Spout a gar

{o> [Seepns Co 2 Speed

05-11B-3

MANUAL TRANSMISSION [S15M-D, S15MX-D]

05-11B-4

1 [Ratease fork 3 _[oirpassage

2 [Release colar @|Controtrod end

3_|Dust boot 7_|ust boot

“1 |Top cover, shift component [Gasket

(See 05-118-5 Top Cover Disassembly Note.) [Wave washer

5-

MANUAL TRANSMISSION [S15M-D, S15MX-D)

70 [Change bush

23_[Breather

T1_[Shif lever

24 Transfer

25_|Blind cover

[2 [ans hitter

13_| Change seat

14_| Transfer neutral switch

15_[ Switch pin

76 [Spring

17_|Steel bal

18_|4xd indicator ewitch

[Extension housing

26 | (See 05-11B-6 Extension Housing Disassembly

Note.)

27_|Funnol

Oil seal (extension Rousing)

28 | (See 05-118-5 Oil Seal (extension housing)

Fomoval Note.)

19 | Vehicle speed sensor

20__|Neutral switch

21 _| Back-up light switch

22_[Breather dust boot

Oil Seal (extension housing) Removal Note

1. Remove the oil seal using a flathead screwdriver as shown in the figure.

4x2

axa

‘Top Cover Disassembly Note

1. Pry the seal open at the projection on the case

using a flathead screwdriver or similar too! as

shown in the figure, and then remove the top

cover.

Oil seal (control rod)

29 | (See 05-118- Oil Seal (control rod)

Note.)

Bush

(Gee 05-118-7 Bush Disassembly Note.)

isassembly

30

05-11B-5

Extension Housing Disassembly Note

1. Remove the extension housing component.

Note

* Pry open the seal atthe projection on the

case using a flathead screwdriver or similar

tool as shown in the figure, and then remove

the extension housing.

05-11B-6

TaN

il Seal (control rod) Disassembly Note

1. Using a flathead screwdriver, remove the oll seal as shown in the figure,

4x2

axa

MANUAL TRANSMISSION [S15M-D, S15MX-D]

€

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Sealing Cap Disassembly Note

1. Remove the sealing cap using the SST.

Caution

‘+ Remove the sealing cap only if there is

malfunction.

Bush Disassembly Note

4x2

1. Remove the bush using the SST.

2, Remove the bush using the suitable stee! bar

through the sealing cap hole as shown in the

figure.

Distance A: Approx. 200 mm {7.87 in}

Distance B: Approx. 17.0—17.5 mm {0.670—

0.688 in}

05-11B-7

MANUAL TRANSMISSION [S15M-D, S15MX-D]

4x4

1. Remove the bush using the SST.

Front side

Rear side

i

05-11B-8

MANUAL TRANSMISSION [S15M-D, S15MX-D]

REVERSE GEAR COMPONENT AND 3RD/ATH GEAR COMPONENT DISASSEMBLY [S15M-D, S15MX-D]_

4. Disassemble in the order indicated in the table.

Tocknut

4 _ | (ee 05-118-10 Mainshaft Rear Bearing locknut

‘and Countershaft Rear Bearing locknut

Disassembly Note.)

(Countershaft rear bearing

Thrust washer

05-11B-9

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Tooknat 22_[ Retaining ng

(See 05~118-10 Mainshaft Rear Bearing locknut 33” | Washer

‘and Countershatt Rear Bearing locknut Gomer laser e

Disassembly Note.) 24 .

118-12 Counter Lever Disassembly Note.

Mainshait rear bearing ieee te isassembly Note.)

(See 05-118-11 Mainshaft Rear Bearing _25_[Retaining bolt

4 sssembly Note.) 26 | Counter lever shaft component

| Bini loverse courier year /aiiait tan (See 05-11B-12 Counter Lever Disassembly Note,)|

7 Spacer 27_[Retaining bot

[Retaining bot | ‘Sth/reverse clutch hub and shift fork component

28 | (See 05-11B-12 Sthireverse Shift Fork

Reverse idler gear shafi component Disassembly Note).

9 | (See 05-118-11 Reverse Idler Gear Shaft

‘Component Disassembly Note.) 29 _|Bthireverse shift fork

70_[ Retaining ring '30_[Sth/reverse shift rod

Ti_| Thrust washer ‘31_[Detent ball

12_[Reverse idler gear 32_|Detent spring

73 [Needle bearing = '33_[ Clutch hub sleeve

14_| Thrust washer '34_| Synchronizer key

15__[ Reverse idler gear shat 35_[ Synchronizer key Rg

Friction damper - '36_|Bthireverse clutch hub

16 | (See 05-116-11 Reverse Idler Gear Friction 37__| Synchronizer ring

Damper Disassembly Note.) '38_[5th gear

17_[Reverse gear '39_|Needle bearing

18 [Needle bearing “40__| rd gear bearing inner race

19 _| Thrust washer 1_[Steel ball - |

20_| Thrust washer | “42_[ th counter gear ~

21_|Synchronizer ring

Mainahatt Rear Bearing lcknut and Countershaft Rear Bearing locknut Disassembly Note €

1. Slide the Grd/4th and 1st/2nd clutch hub sleeves

to lock the transmission into 4th and 2nd gears.

2, Remove the countershaft rear bearing locknut by

rotating it clockwise.

é

05-11B-10

MANUAL TRANSMISSION [S15M-D, S15MX-D]

3, Remove the mainshaft rear bearing locknut by

rotating it counterclockwise using the SST.

Mainshaft Rear Bearing Disassembly Note

1. Using the SSTs remove the mainshaft rear

bearing.

Reverse Idler Gear Shaft Component Disassembly Note

1. Remove the reverse idler gear shaft retaining bolt

and then remove the reverse idler gear shaft

‘component from the transmission case.

Reverse Idler Gear Friction Damper Disassembly Note

1. Remove the friction damper using a flathead

screwdriver.

(308-168)

ETE

05-11B-11

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Counter Lever Disassembly Note

Caution

‘© To prevent the shaft position from

deviating when removing the counter §

lever, remove the countershaft lever

‘component without loosening the

fockrut unless iis necessary lo

ONS | AL cccunsen

ca

Look NUT

PLATE:

Tear

Sth/reverse Shift Fork Disassembly Note

1. Remove the 5th/reverse shift rod retaining bolt. —

2. Remove the Sthteverse shit fork component and. || >"

Sth/reverse clutch hub component at the same

time. : @ = 7

ZZ

3

iG

q

05-11B-12

)

MANUAL TRANSMISSION [S15M-D, S15M;

1

MAINSHAFT COMPONENT, COUNTERSHAFT COMPONENT AND TRANSMISSION CASE DISASSEMBLY

[S15M-D, S15MX-D]

4, Disassemble in the order indicated in the table.

®

1 [Beaing er Bearing sim

2 [Front cover iindive gor Bearing ras

(S00 05-116-14 Front Cover Disassembly Note) (See 051 18-14 Bearing ace Disassembly Note)

3 [Phat pin Hanshi bring race

+ |Boaring sim (See 05-18-14 Bearing ce Disassembly Note)

= [oibate Countrsar font bearing

05-11B-13

MANUAL TRANSMISSION [S15M-D, S15MX-D]

70 | Countorehat rear bearing Tountarshah component

Mahshatt component 13. | (See 05-118-14 Mainshatt Component and

41. | (See 05-18-44 Mainshatt Component and |__| Gountersnatt Component Disassembly Note)

[Countershatt Component Disassembly Note.) 74 Front of seal €

Maindrve gear ~) [is Tranemission case

12. | (See 05-118-14 Mainshaft Component and

‘Countershaft Component Disassembly Note.)

Front Cover Disassembly Note

41. Remove the front cover,

Caution

* Insert the front cover tightening bolts

to the bolt holes for the front cover

disassembly, tighten the two bolts

uniformly and, then remove the front

cover.

Bearing Race Disassembly Note

1. Grasping the mainshaft and countershaft, move

them forward and back to remove the bearing

races,

Mainshaft Component and Countershaft Component Disassembly Note

1. Tiltthe mainshaft component as shown in the

figure and remove it from the transmission case.

2, Remove the maindrive gear.

05-11B-14

MANUAL TRANSMISSION [S15M-D, S15MX-D]

3, Tilt the countershaft component as shown in the

figure and remove it from the transmission case.

05-11B-15

D, S15MX-D]

Caution

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Deep GEAR COMPONENT, SRD/ITH GEAR COMPONENT AND COUNTERSHAFT DISASSEMBLY [S154

+ Remove the countershatt center bearing race only if there is a malfunction,

1. Disassemble in the order indicated in the table.

SK

erostttrscuna

~

amar

= Disassembly Note.)

05-11B-16

3. | (Seo 05-11B~18 Maindrive Gear Shaft Bearing ‘Spacer

Disassembly Note.) ‘Synchronizer fing

4 |[Maindrive gear shaft [Clutch hub sleeve

5 [Needle bearing

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Srevath atch hub 25_[Cutch hub sleeve

(See 05-118-17 Grdath Clutch Hub Component Tstlnd clutch hub

Disassembly Note.) 26 | (See 05-18-17 1stnd Clutch Hub Component

Synchronizer key spring Disassembly Note.)

Synchronizer key 27_| Synchronizer key spring

Synchronizer ring 28__[Synchronizerkey

Double cone 2_| Synchronizer ring

inner cone 30__[Double cone

Src gear 31 [Inner cone

Needle bearing 32_[2nd gear

Mainshafi center bearing 33_[Needle bearing

(See 05-18-17 tst2nd Clutch Hub Component Countershaft center bearing ace

Disassembly Note.) 7 84, | (Gee 05-118-18 Countershaft Center Bearing Race

Tt gear bearing inner race Disassembly Note)

Needle bearing Countershaft ront bearing race

Tet gear (See 0511818 Countershalt Front Bearing Race

as Disassembly Note) .

poe one [Countershatt

Synchronizer fg Maina

‘Srd/4th Clutch Hub Component Disassembly Note

1. Remove the retaining ring using the two flathead

screwdrivers.

Caution

* Do not reuse the retaining ring.

FLATHEAD SCREW

DRIVERS

RETAINING RING

2. Supporting the Srd/4th clutch hub with your hand

‘as shown in the figure, tap the mainshaft with a

plastic hammer to remove the Srd/4th clutch hub.

‘st/2nd Clutch Hub Component Disassembly Note

1. Using a press, remove the mainshaft center

bearing, 1st gear, 1st synchronizer ring

component, is¥/2nd clutch hub component, and

synchronizer ring component and 2nd gear at the

same time.

@ Caution

‘+ Be sure to support the mainshaft

component so that it does not fall.

05-11B-17

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Maindrive Gear Shaft Bearing Disassembly Note

1. Remove the maindrive gear shaft bearing using

the SST and press.

Countershatt Center Bearing Race Disassembly Note

1. Remove the countershatt center bearing race

using the SST and press,

Caution

+ Be sure to support the countershaft so

that it does not fall.

Countershaft Front Bearing Race Disassembly Note

1. Remove the countershaft front bearing race using

the SST.

05-11B-18

COE

——€

aS

MANUAL TRANSMISSION [S15M-D, S15MX-D]

SHIFT COMPONENT DISASSEMBLY [S15M-D, S15MX-D]

1. Disassemble in the order indicated in the table.

Pad

(See 05-11B-21 Shift Rod Disassembly Note)

17 [ataring bot [erp

2 [Deter bal spring 12S ore

3 [Rubber pus 13 [Deient bal, ping weal sng

4 _[Sth/reverse shift rod end 14 | 1st/2nd shift rod end

G | sieveree shit rod ag | island shod

(See 05-116-21 Shit Rod Disassemby Note) (See 05-18-01 Shit Rod Disassemby Note)

© [iteriock pin TE and ai ork

7interoc in 17_[Detent bal pring we, rng

@ | Stopper block 18 [Baffle plate ~ _|

9 [ard sit rod and 19 [Breather

Fo [erat shit od

05-11B-19

MANUAL TRANSMISSION [S15M-D, S15MX-D]

T_ [Retaining bot 76 [Sean shi od

2_|Detent ball, spring (Gee 05-1 18-21 Shit Rod Disassembly Note.)

‘3 [Rubber plug 17 _[lteriok pin

|4_|Stivreverse shiftrod end 18 _| rath shift fork

'_| Retaining ring [19 _[Detent bal, spring Seat, spring

6_|Plain washer 20_|tsV2nd shift rod end

7_[ Spring 21_|Retaining ring

8_[Push pin 22_|Plain washer

[8 [Retaining rng 23_[Spring

40 _[Detent ball, spring 24_ [Push pin =

+1 | stivreverse shift rod 25 | fsUland shiftred

(Gee 05-118-21 Shift Rod Disassembly Note) (Gee 05-18-21 Shit Rod Disassembly Note.)

12 Interlock pin 26_|teV2nd shit fork

13_[Interiock pin 27_|Detent ball, spring seat, spring

14_[ Stopper block 28_[Baffo pate

15 [rath shit rod end 29 _ [Breather

05-11B-20

,

shift Rod Disassembly Note

"1, Remove the spring pins from each of the shift

rods using a pin punch.

) 2 Place the shit mechanism in the neutral postion

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Caution

‘« When pulling out the shift rods, press the

top of each detent balll so that it doesn’t

spring out.

3, Pull out the shift rods from the top cover.

MANUAL TRANSMISSION PARTS INSPECTION [S15M-D, S15MX-D]

Clutch Hub Component

4. Measure the clearance between each shift fork

land clutch hub sleeve groove using a feeler

Dd gause.

* fnot within the specification, replace the shift

fork and clutch hub sleeve as a set.

Standard clearance between shift fork and

clutch hub sleeve groove

0.05—0.40 mm {0.002—0.015 in}

‘Maximum clearance between shift fork and

clutch hub sleeve groove :

0.5 mm {0.020 in}

Synchronizer Ring

7. Measure the clearance between the synchronizer

ring and flank surface of the gear using a feeler

gauge around the entire circumference.

* If not within the specification, replace the

synchronizer ring,

Standard clearance between synchronizer

ring and flank surface of gear

1.5 mm {0.059 in}

Maximum clearance between synchronizer

ring and flank surface of gear

0.8 mm {0.031 in} ae

Note

‘= Set the synchronizer ring squarely in the gear.

05-11B-21

Spring

1. Measure the free length of each spring.

* If not within the specification, replace the

spring.

Detent ball springs for 1st/2nd and 3rd/4th

shift rods

‘Standard length: 22.5 mm {0.886 in}

Detent ball spring for Sth/reverse shift rod

‘Standard length: 24.97 mm {0.9831 in}

‘1st/2nd select lock spindle spring [4x2]

Standard length: 57.5 mm {2.26 in}

Push pin spring for 1st/2nd shift rod end [4x4]

Standard length: 32.8 mm {1.29 in}

Standard length: 41.0 mm {1.61 in}

‘Standard length: 24.97 mm {0.9831 in}

Mainshatt

1, Measure the mainshaft runout using a dial gauge.

* Ifit exceeds the maximum specification,

i replace the mainshatt.

| Mainshaft maximum runout

0.03 mm {0.0012 in}

Shift Rod End, Control Lever

1, Measure the clearance between the shift rod end.

and contro! lever using a feeler gauge.

* lfnot within the specification, replace the shift

rod end or control lever as a set.

Standard clearance between shift rod end and

control lever

0.5 mm {0.020 in} or less

05-11B-22

Di

Push pin spring for Sth/reverse shift rod end [4x4]

>

MANUAL TRANSMISSION [S15M-D, S15MX-D]

| oe

jee org

AN

Detent ball spring for Sth/reverse shift rod end [4x4]

:

SHIFT COMPONENT ASSEMBLY [S15M-D, S15MX-D]

1. Assemble in the order indicated in the table.

4x2

MANUAL TRANSMISSION [S15M-D, S15MX-D]

GD) 78-11. 1m (80-120 gem, 70-104 into

Ry

S

J Lif

é

6o-98Nm

e {7189 kam, 62-86 into,

@

Nan te,

+7 [oreathor TO ]erdath ahi ore

2 [Bae plate 1 Jnterock pin

3 [Detent ball, spring seat, aprng 72 [Interock pin

| isand shift rod 13. |ra/ath shift rod end

(See 05-11-25 Shift Rod Assembly Note) 1 stvreverse shit rod

3 _[ sand shit Tork 4 | (See 05-11B-25 Shi Rod Assembly Note.)

@_[tsvond shift rod end 7

7_|Interlock pin 16 |)

@[Detent ba, spring seat, spring 47 [Rubber plug

9 [seat shit oo 18 [Detoni ball, spring

(See 05~118-25 Shit Rod Assambly Note) 79 [Retaining bolt

05-11B-23

MANUAL TRANSMISSION [S15M-D, S15MX-D]

° 7.81.8 Nem (80—120 kgtem, 70-108 nto)

ny

Na 7

t a

®

69-98Nm

{7188 kam, 62-86 ina

os

(25-34, 19-25)

st

Nim tm, A)

1_ [Breather 16 _[interock pin

2 [Baffle pate 17_interiock pin

3_[Detent bal, spring seat, spring [iq Sthlreverse shit rod

‘stand shift rod (See 05-11B-25 Shit Rod Assembly Note)

4 | (See 05-118-25 Shitt Rod Assembly Note.) 79 | Stopper block

3 _[tetand shift fork 20” [Detent ball, spring 7]

[Push pin 21_[ Retaining ring

7_[Sering 22 [Push pin

[Pian washer (See 05-1 18-25 Push Pin Assembly Note.)

9 [Retaining ring : 23 [Spring

70 _| tst2nd shift rod end 24 [Plain washer

771_[Interock pin 25 [Retaining ring

¥2_[Detent bal, spring seat, spring 26 [Sthieverse shiftrod end

13, [Sedan shit rod 27 [Rubber plug

(See 05~118-25 Shit Rod Assembly Note) 28 [Detent ball, spring

4 [Sra shit Tork 29_[ Retaining bolt

15_[Srd/ath shift rod ond

05-11B-24

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Shift Rod Assembly Note

1. Install each shift rod.

> Caution

‘© Do not forget to insert the interlock pins.

Note

* Insert the shift rod while pressing the detent

ball with a flathead screwdriver as shown in

the figure.

Push Pin Assembly Note

1. Install the push pin.

Note

‘= Insert the push pin while pressing the detent

ball with a flathead screwdriver as shown in

the figure,

05-11B-25

MANUAL TRANSMISSION [S15M-D, $1: 5MX-D]

{ST/2ND GEAR COMPONENT, 3RD/4TH GEAR COMPONENT AND COUNTERSHAFT ASSEMBLY [S15M-D,

‘S15MX-D]

1. Assemble in the order indicated in the table. wenver

|

MOLYBDENUM :

(515 ig bisuttie

GREASE @

o

D

SELECTIVE

“Hh rrrorseecinen ovr monoue nats

1 a oo ‘aiand cus hab €

2 [Needle bearing 7 |{See 05-18-27 1ev2nd Clutch Hub Component

| fesembly Note)

3__[end gear

| ane cone | [Fe ]Ssnstronzor tay

5 [Double cone ‘9_[ Synchronizer key spring

| [6 _[Synchronizerring 10 _| Clutch hub sleeve

05-11B-26

MANUAL TRANSMISSION [S15M-D, S15MX-D]

‘Synchronizer ring

Gluich hub sleeve,

mm {in}

x 5 c

tsvand | 17.0 (0.669) | 591023) | 6.01020)

+ Be sure to align the synchronizer ring

projections with the inner cone notches.

+ Be sure to assemble the gears and the

synchronizer ring components while

aligning the double cone projections with

the gear holes as shown in the figure.

= 26 | (See 05-11-28 Sr4th Clutch Hub Component

“12 [Double cone —_| [Assembly Note)

im BT_| Synchronizer rng

—— 28 [Spacer 7

Needle bearing Retaining ring

st gear Dearing inner race 29 | (See 05-11-28 Sralath Clutch Hub Component

Mainshaft center bearing [Assembly Note)

(See 05-1 18-27 1sV/2nd Clutch Hub Component i

soy = ewe

18 [Needle bearing Maindrive gear shaft bearing

[3rd gear 82 | (See 05-11B-29 Maindrive Gear Shaft Bearing

Inner cone | Assembly Note.)

Double cone 35_| Scoop ring

Synchronizer ring 34_ [Needle bearing

(Clutch hub 35_|Couniershaht

(Ses 05~1 1-28 arth Clutch Hub Component Countershaft contar bearing mae

Assembly Note) 26 | (See 05-1 18-29 Countershatt Center Bearing Race

Synchronizer key, ‘Assembly Note)

(See 05-1 18-28 rath Clutch Hub Component [Gountershaft rent bearing yao

Assembly Note) 37 | (See 05~11B-20 Countershalt Front Bearing Race

‘Synchronizer key spring ‘Assembly Note)

(See 05~1 18-28 rath Clutch Hub Component

‘Assembly Note)

1st/2nd Clutch Hub Component Assembly Note

Caution

‘ Be sure to assemble the clutch hub

components and synchronizer ring

components while aligning the

synchronizer ring grooves with the A Paes

synchronizer keys.

‘+ The standard synchronizer key

dimensions are as follows: a

05-11B-27

‘* Align the clutch hub sleeve alignment

mark with the clutch hub synchronizer

key installation position and assemble.

Caution

‘* When using a press, be careful not to.

damage the parts.

1. Using a SSTs and press, assemble the needle

bearing, 2nd gear, synchronizer ring component

(2nd), 1st/2nd clutch hub component,

synchronizer ring component (ist), 1st gear,

needle bearing, needle bearing race and

mainshaft center bearing to the mainshaft at the

same time.

3rd/4th Clutch Hub Component Assembly Note

1. Assemble the Srd/4th clutch hub component,

Caution

© The standard synchronizer key

imensions are as follows:

mm {in

MANUAL TRANSMISSION [S15M-D, S15MX-D]

ALIGNMENT MARK.

'SYNCHRONIZER KEY

49 8034 201

EOI

A] 8 c

Bralain__ | 17.0 (0.669) | 591025) | 5020)

‘+ Be sure to align the synchronizer ring

projections with the inner cone notches.

+ Be sure to assemble the gears and the

synchronizer ring components while

aligning the double cone projections with

the gear holes as shown in the figure.

05-11B-28

aT

MANUAL TRANSMISSION [S15M-D, S15MX-D]

* Align the clutch hub sleeve alignment

mark with the clutch hub synchronizer

key installation position and assemble.

ALIGNMENT MARK

‘SYNCHRONIZER KEY

)

2. Install the 3rd/4th clutch hub component to the

mainshaft.

8. Install the spacer.

4. Install the retaining ring.

5. Measure the clearance between retaining ring

and spacer.

* If not within the specification, adjust by

choosing the proper retaining ring,

3rd/ath clutch hub end play

(00.05 mm {0.0—0.0019 in}

Srd/4th clutch hub retaining ring

Thickness (mm (inj)

7.50 (0.0591) |

1.55 (0.0610) Tara

1.60 (0.0680),

7.65 (0.0650)

0.0669),

1.75 0.0688)

780 0.0708)

7.85 (0.0728)

1:9070.0748)

1.95 (0.0768),

Maindrive Gear Shaft Bearing Assembly Note

1. Assemble the maindrive gear shaft bearing using

the SSTs,

Countershatt Center Bearing Race Assembly Note

1. Assemble the countershait center bearing race a

using the SSTs.

49 F401 331

CORES

05-11B-29

MANUAL TRANSMISSION [S15M-D, S1 5MX-D]

Countershaft Front Bearing Race Assembly Note

1. Assemble the countershaft front bearing race

using the SSTs,

05-11B-30

CCITT

a

MANUAL TRANSMISSION [S15M-D, S15MX-D]

MAINSHAFT COMPONENT, COUNTERSHAFT COMPONENT AND TRANSMISSION CASE ASSEMBLY

[S15M-D, S15MX-D]

7 1 Assemble nthe onterineeatedin the tabe

77-268

(81—269, 13.218.)

Hon 0

) [a Freres case aaa component

Counters component {See 05-118" Mndve Gear Component,

(Gee 05-1 18-22 Maindrive Gear Component, Mainshaft Component and Countershatt

| Mainshaft Component and Countershaft | Component Assembly Note.)

[Component Assembly Note.)

05-11B-31

MANUAL TRANSMISSION [S15M-D, S15MX-D]

annie gear

4. |{Se0 05-18-32 Maindrive Gear Component,

Mainshatt Component and Gountershat

[Component Assembly Note.)

‘Countershalt rent bearing

Couniershatrear bearing

Maindrive gear bearing race

Mainshat bearing race

Bearing cover

Front Oil Seal Assembly Note

1. Apply specified grease to the lip of a new oil seal

2. Install the oil seal to the front cover using the

SST.

Maindrive Gear Component, Mainshatt Component and

1. Install the countershaft component.

2, Install the maindrive gear.

3. Install the mainshaft component.

05-11B-32

10

Front ofl seal

(See 05-11B-82 Front Oil Seal Assembly Note.)

7

Bearing shim

2

13

Bearing shim

Oilbaffle

4

Pivot pin

15

Front cover

(See 05-1 18-32 Maindrive Gear Component,

Mainshaft Component and Countershaft

[Component Assembly Note.)

Countershatt Component Assembly Note

49 0813 235

MANUAL TRANSMISSION [S15M-D, S15MX-D]

4, Assemble the Mainshatt component and

Maindrive gear.

5. Install the countershaft front and rear bearing.

6. Install the maindrive gear bearing race and

mainshaft center bearing race.

7. Install the bearing cover with the arrow pointing to

the top of the case.

Tightening torque:

17.7—26.4 Nim (1.81—2.69 kgt-m, 13.1—19.4

ftbt}

05-11B-33

procedure,

(1) Set the clutch housing side upward and level the transmission case.

Caution

‘* Securely assemble the mainshaft, maindrive

that there Is no looseness or play.

(2) Using a depth gauge, measure the maindrive

gear bearing outer race height A.

(3) Using a depth gage, measure the maindrive

‘gear bearing retainer depth B.

(4) Calculate and select the correct maindrive

gear bearing shim thickness,

Formula:

BA

C: Dimension between the maindrive gear

bearing and bore in the front cover

B: Depth of the maindrive gear bearing bore

in the front cover

‘A: Maindrive gear bearing height

‘* Refer to the maindrive gear bearing shim

selective chart

Maindrive gear bearing shim selective chart

MANUAL TRANSMISSION [S15M-D, S15MX-D]

8, Select the mainshatt component and countershaft component bearing shims according to the following

gear component, and countershatt component so

BEARING SHIM

INSTALLATION SURFACE,

Dimension ¢ (mm {in}) “]_Shim thickness (mm {in})

(00571-00610) 14 (0.055)

(008110004) 15 (0056)

(0.0850—0.0886 180.069

(0.0800—0.0728 17 @06n

(00720-00767 iacoor

(0.7e8 00807) 1910075)

{0.0808 0.0840) 2.0 (0.079)

[© 61700805) _| 2.4 (0.083)

(0089600805) 22,0087)

{0.0828 0.0004) 2.3 (0.090)

(0.09986 1009) 24 (0.008)

{0.100403} 25 (0.098)

05-11B-34

od

©

©

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Dimension 6 (ram fn})_| Shim thickness (mm (i) |

(o:1ox4—0. 1082) 26 (0.102)

(oon 0.1120) 27 (0406)

(0128-01161) 228 (0.10)

(01620-1200) 2.9 (0.114)

(0. 13010-1340) 3.0 (0.118)

Maindrive gear shaft total end play

‘0.05—0.15 mm {0.002—0.0059 in}

(6) Using a depth gauge, measure the

countershaft front bearing depth D.

Note

‘© The countershaft bearing is located below

the contact surface of the case and front

cover.

(6) Using a depth gauge, measure the

countershatt front bearing retainer depth €.

(7 Galeuiate and select the correct countershat

front bearing shim thickness.

Formula: F=E +D

F: Dimension between the countershatt

‘front bearing and bore in the front cover

E: Depth of the countershaft front bearing

bore in the front cover

D: Countershaft front bearing depth

‘+ Refer to the countershatt front bearing

shim selective chart.

Countershaft front bearing shim selective chart

Dimension F(mm {in}) | Shim thickness (mm {in})

i ae

(0:1280—0.1818) 31 (0.122)

(0.i816—0.1850) 32 (0.128)

(0.i80-0.1897 33 (0:190)

(0.1998-0.1497) 3 (0394)

(0.1498—0.1476) 3.5 (0.198)

YD] cosarr—otsis) 36 (0:42)

(08160 1855) 37 (0147)

Countershaft total end play

0.15—0.25 mm {0.006—0.0098 in}

[ DePTH eaves /

(i

Ss

AS

oO

DEPTH GAUGE

BEARING SHIM

INSTALLATION SURFACE

05-11B-35

15MX-D]

MANUAL TRANSMISSION [S151

9. Position the maindrive gear bearing shim, oil baffle, and the countershatt bearing shim onto the front cover,

Note

‘+ If necessary, apply a light coat of petroleum jelly to the shims and oil baffie. €

10. Apply sealant to the contact surfaces of the

transmission case and front cover as shown in the

figure.

11. Install the pivot pin.

Tightening torque:

31—46 Nem {3.2—4.6 kgt-m, 2333 ttf}

TESTERS

12. Install the front cover to the transmission case.

Tightening torque:

19—25 N.m {2.02.5 kgf-m, 15—18 ft.lbf}

Note

‘* To prevent damage to the oil seal lip during

assembly, tape maindrive gear shatt splines.

OCTETS

05-11B-36

MANUAL TRANSMISSION [S15M-D, S15MX-D]

REVERSE GEAR COMPONENT AND 3RD/ATH GEAR COMPONENT ASSEMBLY [S1SM-D, S1SMX-D]__

1. Assemble in the order indicated in the table. cen

7o-11 Nm

{80—112 Kgtcm, 70-97 into

(215-274, 156-198)

75-117

(errr,

57903)

om,

ean wean

7 Ez counter gear [5rd gear bearing inner race

2 [Steet ball (See 05-11B-38 5th Gear Bearing Inner Race

[Assembly Note.)

05-11B-37

MANUAL TRANSMISSION [S15M-D, S15MX-D]

25 [Needle bearing

26 | Reverse gear ~

(See 05-118-40 Reverse Gear Assembly Note.)

5th Gear Bearing Inner Race Assembly Note

1. Install the steel ball to the countershatt.

2. Align the ball groove position of the 5rd gear

bearing inner race and assemble it to the

countershatt.

05-11B-38

a [Needle bearing 27 Fon damper

[5th gear 28__[Reverse idler gear shaft

6 _| Synchronizer ring 29__| Thrust washer

7_[Btneverse clutch hub 30 __[ Needle bearing

@_| Synchronizer key spring 31__[loverse idler gear

‘| Synchronizer key 32_| Thrust washer

10 [Clutch hub sleeve '33__[ Retaining ring

11_[Detent spring Reverse idler gear shal component

12_[Detent ball 34, | (S00 05-11-41 Reverse Idler Gear Component

78_|Sthireverse shift rod sesame Med

[14 |stvreverse shit fore 35 [Retaining bolt _

Bith/everse clutch hub and shit fork component 36_{Spacer

45 | (See 05-118-89 5th Counter Gear, Sth/Reverse 'S7__| Reverse counter gear

Clutch Hub Component and SthvFeverse Shit Fork Mainshaft rear bearing

‘Assembly Note) ga_|(See 05-118-42 Mainshatt Rear Bearing and

76 [Retaining bolt Countershaft Rear Bearing Locknut Assembly

Counter lever shaft component Note)

47. | (S00 05-118-41 Counter Lover Shaft Assembly Locknut -

Note.) gq | (See 05-118-42 Mainshatt Rear Bearing and

75 RoGnG Ba | Countershaft Rear Bearing Locknut Assembly

[Fetal Note.)

19 [Counter lever @0_[ Thrust washer

20_[Washer (Gountershaft rear bearing

21_| Retaining ng 41_ | (See 05-118-42 Mainshatt Rear Bearing and

22_| Thrust washer (Countershatt Rear Bearing Locknut Assembly

23 Thrust washer Note)

: cock

24_| Epes go | (See 05-11B-42 Mainshaft Rear Bearing and

‘Countershaft Rear Bearing Locknut Assembly

Note.)

MANUAL TRANSMISSION [S15M-D, S15MX-D]

5th Counter Gear, Sth/Reverse Clutch Hub Component and Sth/Reverse Shift Fork Assembly Note

1. Assemble the Sth drive gear and Sth/reverse clutch hub component.

Caution

) * Be sure to assemble the clutch hub components and synchronizer ring components while aligning

the synchronizer ring grooves with the synchronizer keys.

+ The standard synchronizer key —

dimensions are as follows:

rn fn} A c

x 3 ¢

Swe | EO IO TOR | SAS OAT | BOLO A)

* Align the clutch hub sleeve alignment —

mark with the clutch hub synchronizer

key installation position and assemble.

ALIGNMENT MARK.

SYNCHRONIZER KEY

) 2, Assemble the Sth counter gear component, Sth/

reverse clutch hub component, and Sthireverse

shift fork component as a single unit.

8, Install the Sth/reverse shift rod retaining bolt.

Tightening torque:

21.6—30.4 N-m {2.21—3.09 kgf-m, 16.0—22.4

ftlbf}

4, Install the thrust washer.

05-11B-39

MANUAL TRANSMISSION [S15M-D, S15MX-D]

5, Measure the clearance between thrust washer

and groove of the countershatt.

* If not within the specification, adjust by

choosing the proper thrust washer.

Sth/Reverse clutch hub end play

(00.05 mm {0.0—0.0019 in}

[STHWREVERSE

CLUTCH HUB

END PLAY

Sth/Reverse clutch hub thrust washer

“Thickness (mm {in))

3.00 {0.118}

3.05 {0.120} aT

3.10 {0.122}

3.15 (0.124)

3:20 {0.126}

3:05 (0.128)

3:30 (0.130)

3.35 (0.192)

3.40 (0.134)

Reverse Gear Assembly Note

1. Measure the clearance A and B,

(1) Caloulate and select the thrust washer

thickness.

Formula: C = A-B

C: Dimension between the 5th/Reverse

clutch hub and reverse gear

B: Reverse gear height

A: Dimension between the Sth/Reverse

clutch hub and thrust washer

Th

REVERSEGEAR |

‘+ Refer to the reverse gear thrust washer BRETT

selective chart,

overs gear thus washer

Dimension C (mm {in}) Thickness (mm {in})

oes 75,0250

acm 718 00%

(0508-0: au} | 7.55 {0.297}

Re 751050)

te 750905)

Reverse gear end play

(0.25—0.35 mm {0.002—0.0059 in}

2. Install the thrust washer.

3. Install the reverse gear.

05-11B-40

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Counter Lever Shaft Assembly Note

4. Install the counter lever shaft component.

Caution

* If the counter lever shaft has been

replaced or the locknut is loose,

assemble the counter lever shaft with the

chamfer side of the shaft pointed straight

upward.

+ Apply sealant to the threads of the

locknut.

+ Ifthere is an abnormality in the 3rd/ath,

shift stroke after assembling, loosen the “ —

Jocknut and readjust. ssrisie

Locknut tightening torque:

37.3—51.9 Nom (3.81—5.29 kgf-m, 27.6—38.2 ttibt}

Reverse Idler Gear Component Assembly Note

1. Using the SSTs, install the friction damper to the

reverse idler gear.

EE

Ca

FRICTION DAMPER,

‘* Verify the depth of the friction damper 7

installation position. 1.01.8 mm (0.040-0.062 in)

FRICTION DAMPER

2, Assomble the reverse idler gear component. :

8, Measure the clearance between the retaining ring

and thrust washer.

* If not within the specification, adjust by

choosing the proper retaining ring,

Reverse idler gear end play

0.1—0.2 mm {0.0040—0.0078 in}

Reverse idler gear retaining ring

Thickness eum fo)

TE SST

76 (0.063) BSUS TOMES

> |

ia ooT

Crane

05-11B—41

MANUAL TRANSMISSION [S15M-D, S15MX-D]

4, Install the reverse idler gear component to the

transmission case,

5. Install the reverse idler gear shaft retaining bolt.

Tightening torque

78.5—117 Nom {8.01—11.9 kgf-m, 57.9—86.2

tb}

Mainshaft Rear Bearing and Countershaft Rear Bearing

1. Slide the 3rd/4th and 1st/2nd clutch hub sleeves:

to lock the transmission into 4th and 2nd gears.

2, Insert the mainshaft rear bearing into the

mainshaft and install the locknut.

3. Attach the SST to the locknut and tighten the nut to the

Caution

‘* Attach the SST with the locknut seated in

the bearing.

Tightening torque:

211—269 Nem {21.6—27.4 kgf-m, 156—198

ftbf}

05-11B-42

Locknut Assembly Note

specified torque,

(erst)

A

aaa

MANUAL TRANSMISSION [S15M-D, S15MX-D]

4, Tighten the countershatt locknut in the

counterclockwise direction.

Tightening torque:

‘Y27—-198 Nem (13.0—19.9 kgtim, 94—144

‘tit

6. Using the pin punch, stake the mainshaft rear

bearing locknut,

6. Using the pin punch, stake the countershatt rear

bearing locknut.

05-11B-43

MANUAL TRANSMISSION [S15M-D, S15MX-D]

TOP COVER COMPONENT AND EXTENSION HOUSING ASSEMBLY [S15M-D, S15MX-D]

1. Assemble in the order indicated in the table.

4x2

= “@

7 noe

1

SEE nang —

79-11.0Nm

(0112 kgtem,

70-97 nib

begea Sv oe

{(00—112 kgtem,

5 nea

70-97 ins) é we

se-a84m ©

{ri—a9 tem, ¢1—a6

Nm tg, A)

1 [Steel ball

c 3 [Reanng tig ]

Speed ave gear

2

05-11B-44

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Bush

"Top cover, shift component

4 | (cee 05-118-47 Bush Assembly Note.) 19 | (ee0 05-18-50 Top Cover Assembly Note.)

‘Oil seal (control rod) —_ ‘29 [Blind cover

5 [eee a0 0 2 Sea oral) Assombly es co 710-51 Bind Cover Assay Note)

Note.) 21 [Control case

[Sealing cap 2 | Change seat

6 [en ao soatng Cap Assembly Note) 22 |Changose

[= fester fers

= a 25_|Wave washer

— erensin asg 26_[Gastt

rosin ia

10 | (see 05~-11B-50 Extension Housing Assembly 27 _|Dust boot —

(oa 3a [Nesta oh

77 [eonroa ond 25 [Wt apt a

12_| Select spindle component 30_[ Back-up light switch ee

15 [Selon pce at [Dost boot

+a [ Suc loatopae Raia

ce. [foots 16-51 Reonse Cota, Release Fork

18 [Spring cap _ ‘Assembly Note.)

jofseliemmaoaanra Aeseby Not

16 e605 118-49 Seal Extension Housing) co | eee 19851 tease Cota Releoe Fork

. Sey Nee)

37 [Contotiover -

[eps

05-11B-45

1s7~225

(180-225, 116165)

—t

79-98Nm

(198 kgtem,

70-98 ining

02460, 232-299)

4

wae

Nam tk, ab)

Bush

(see 05-11B-47 Bush Assembly Note.)

8 | (see 05-11-49 Oil Seal (Extension Housing)

|] Oil seal (control rod) ‘Assembly Note.)

2 | (see 05-11B-48 Oil Seal (control rod) Assembly “4 _[Funnet

Note.)

[Oil seal (extension housing)

05-11B—46

MANUAL TRANSMISSION [S15M-D, S15MX-D]

Exionsion Rousing 79 _[Wansior shit Tover

(g 6-116-50 Ensen Housing Assay 20 | Shift lever

bie - 24 | Change bush

Blind cover cs

(G02 05-118-51 Blind Cover Assembly Note.) 22_[Wave washer

Transter 23 [Gasket

Breather —— 24[Dust boot ~

|(se0 05-118-51 Breather Assembly Note.) 25 _|Gontrol rod end

Breather dust oot (Oil passage

Back-up Tight switch 7 | Top cover, shift component

Neutral switch (see 05-118-50 Top Cover Assembly Note.) _

Vehicle speed sensor 28 ae boot

[4X indicator svat - clease ola

[18 [4Xaindicator wich __ | 29 | (590 05-1 18-51 Release Colla, Release Fork

‘Steel ball Sey Nee)

Spring - Release fork

Switch pin 20 | (see 05-1 18-51 Release Collar, Release Fork

Transfer neutral evitch [Assembly Note.)

Change seat

Bush Assembly Note

4x2

1. Install the bush using the SST.

Installation depth A: 1—2 mm {0.040—0.078

in}

ausH

2. Install the bush using the suitable steel bar

through the sealing cap hole as shown in the

figure.

Distance A: Approx. 200 mm {7.87 in}

Distance B: Approx. 17.0—17.5 mm {0.670—

0.688 in}

Installation depth C: 1—2 mm {0.040—0.078

in}

05-11B-47

MANUAL TRANSMISSION [S15M-D, S15MX-D]

4x4

1. Install the bush using the SST.

Front side

Installation depth A: 0—1 mm {0.0—0.039 in}

Rear side ~

Installation depth A: 1—2 mm {0.040—0.078

in}

Oil Seal (control rod) Assembly Note

4x2

1. Apply specified grease to the lip of a new oil seal.

2. Install the oil seal using the SSTs through the —

sealing cap hole as shown in the figure.

Installation depth A: 109.6—110.5 mm

{4.312—4.350 in}

lL SEAL

EIN | @

05-11B-48

MANUAL TRANSMISSION [S15M-D, S15MX-D]

axa

1. Apply specified grease to the lip of a new oil seal.

2, Install the oil seal using the SST.

Installation depth A: 2.0—3.0 mm {0.079— OIL SEAL

0.118 in}

Sealing Cap Assembly Note

1. Install the sealing cap using the SSTs.

Caution

‘* Apply silicone sealant to the sealing cap.

Installation depth A: 0.6—2.0 mm {0.020—

0.078 in}

Oil Seal (Extension Housing) Assembly Note

1. Apply specified grease to the lip of a new oil seal

2. Install the oil seal evenly and gradually using the SST and a hammer.

4x2

05-11B-49

MANUAL TRANSMISSION [S15M-D, S15MX-D)

Installation depth A: 48.5—49.5 mm {1.91—

1.94 in}

Extension Housing Assembly Note

1. Apply sealant to the contact surfaces of the

extension housing and transmission case as

shown in the figure.

2. Install the extension housing to the transmission

case.

Tightening torque:

31.4—46.0 N.m {(3.21—4.69 kgf-m, 23.2—33.9

ftlbt}

Top Cover Assembly Noto

1. Apply sealant to the contact surfaces of the

transmission case and top cover as shown in the

figure.

2, Install the top cover component to the

transmission case.

Tightening torque:

15.7—22.5 Num {1.60—2.29 kgf-m, 11.6—16.5,

ftlbf}

Control Case Assembly Note

1. Apply sealant to the contact surfaces of the

contol case and extension housing as shown in

the figure.

2, Install the control case to the extension housing

Tightening torque:

15.7—22.5 N-m {1.60—2.29 kgf-m, 11.6—16.5,

‘tt-lbf}

05-11B-50

OL SEAL

A

AE

Se

3

v3

S

Inv

TE

é

MANUAL TRANSMISSION [S15M-|

Blind Cover Assembly Note

1. Apply sealant to the contact surfaces of the blind

cover and extension housing as shown in the

figure,

2, Install the blind cover to the extension housing.

D, S15MX-D]

Tightening torque:

7.9—9.8 N-m {81—99 kgf-cm, 70—86 in-tbf}

Breather Assembly Note

1. Install the new breather using the SST.

Rolease Collar, Release Fork Assembly Note

1. Apply specified grease to the areas shown in the

figure

2. Install the release collar and release fork.

Gara

05-11B-51

05-13 AUTOMATIC TRANSMISSION [5R55S]

AUTOMATIC TRANSMISSION

DISASSEMBLY[5R55S] . ..

FLUID PUMP DISASSEMBLY

[SRBBS].......

J FLUID PUMP ASSEMBLY[SRE5S]

OVERDRIVE BRAKE AND COAST

‘CLUTCH DRUM COMPONENT

DISASSEMBLY/ASSEMBLY

[5R55S] .

INTERMED!

‘CLUTCH DRUM COMPONENT

DISASSEMBLY/ASSEMBLY

[RSSS].......

FORWARD CLUTCH

DISASSEMBLY/ASSEMBLY

[SRBSS]......... +.

++ 05-13-2

05-13-24

05-13-26

++ 05-13-80

OVERDRIVE PLANETARY GEAR AND

‘ONE-WAY CLUTCH COMPONENT.

DISASSEMBLY/ASSEMBLY

[SRSSS]........... + -05-13-43

OUTPUT SHAFT RING GEAR AND HUB

‘SHAFT COMPONENT

DISASSEMBLY/ASSEMBLY

I5R55S). . seseeeee = 05-13-48

FORWARD RING GEAR COMPONENT

DISASSEMBLY/ASSEMBLY

IRB5S], weeee es 0513-49

LOW/REV! 0

‘COMPONENT DISASSEMBLY/ASSEMBLY

ISRS5S]. . + 05-13-50

CONTROL VALVE BODY

DISASSEMBLY/ASSEMBLY

[SR5SS]......... = 05-13-54

AUTOMATIC TRANSMISSION ASSEMBLY

[5RS5S]. . + 05-13-57

05-13-1

AUTOMATIC TRANSMISSION [5R55S)

AUTOMATIC TRANSMISSION DISASSEMBLY[5R55S]

Exploded View

05-13-2

AUTOMATIC TRANSMISSION [5R55S]

AUTOMATIC TRANSMISSION [5R55S]

Tam earereraaRRTE ora é

2 |Torape a 77 [id pup cover

3 [input ha | Fd pump adapor pas

4 [lad pump seat 3 | Fud pump gasket |

5_[ Fluid pump seal ring _ 70 [Seal ring ~

5-134

AUTOMATIC TRANSMISSION [5R55S]

Ti [Stator support seal 66_| Thrust bearing (a7)

12_| Fluid pump support ‘67_| Forward planetary component

18 [O-ring (68_|Input shell and sun gear component

“14 Fluid pump contrat valve 69 _|Spacer

5 [Fluid pump component _ "70_[Retaining ring

6 [Bolt 77 [Lowecreverse planetary component

17_| Sealing 72_|Outbut shaft sleeve

"18_| Thrust washer (No.7) 73 [Retaining ring

19 [Intermediate and overdrive brake band anchor strut 74_| Output sharing gear

20” [intermediate and overdrive brake band “| [8 TOutput shaft hub

[21 [Intermediato and overdrive brake band apply rut 76_| Retaining ring

22 [Intermediate and overdrive brake band adjusting 77_[Output shaft hub seal

serew 78 _| Thrust bearing (No.10)

23 |Locknut 79 [Lowireverse brake drum and one-way dutch

24_| Overdrive brake drum component

25 [Direct clutch and coast clutch piston outer seals @0_|Lowheverse brake band

26 [Direct clutch and coast clutch piston inner seals @1_| Output shaft needle bearing

27 [Direct clutch and coast clutch pistons @2_| Thrust washer (No.1)

28 | Direct clutch and coast cluteh piston spring 3 [Parking gear

29 _| Direct clutch and coast clutch piston spring retainer @4_[ Output shat (4x2)

30” [Retaining ring 85. [Parking pawl

31 [Coast clutch extemal spine plato (steel) '86_|Parking paw ratura spring

'32_| Coast clutch intornal spline friction plate ¢riction) 87_|Parking paw shatt

{33 [Direct clutch and coast clutch pressure plate {86 | Exionsion housing Gasket

‘34_| Retaining ring (seleot ft) '89_|Exension housing (42)

35 _| Carrier adapier 20_[Bott (x2)

"36 | Overdrive sun goar ‘81 [Extension housing seal (2)

37__[ Overdrive planetary gear carrier component ‘82_|Output shatt x)

38 | Thrust bearing (No.2) - 9 [Extension housing (a) |

39 [Overdrive ring gear 94 [Extension housing seal (24)

40” [Overdrive one-way clutch 95 [Bol (x4) —

“41_| Overdrive center shaft 96 [Oil pipe connector component

42_|Retaining ring 97_| Retaining ring

“43 | Overdrive centor shaft and ring gear component 96 _| Overdrive brake servo cover seal

“4a_| Thrust Bearing (No.3, No.5, Now and No.) 9__| Overdrive brake servo cover ~

45_ [Retaining ring “100_| Overdrive brake servo piston

46_|Center support 01 [Spring

47_[Nutand cage component 102_| Retaining ring

48_ [Bot [7103 intermediate brake servo cover seal

49 | Thrust bearing (No.4) 7104 [intermediate brake servo cover

'50__| Intermediate brake drum - 705 | Intermediate brake servo piston

i Direct clutch extemal spine plate (alee 706 |Tansmission case

'52_[Direct clutch internal epiine plate (riction) 707_|TSS sensor, ISS sensor and OSS sensor

53_| Forward dluteh cylinder 108 [O-ring 7

4 [Forward clutch piston 109 [Bor

{55 | Forward clutch piston spring component TO" | Vent tube (2) _|

56 [Retaining ring TH_[Lowireverse brake actuating lever

[787 | Forward clutch external spine plate (etéeh 112 | Lowireverse brake band actuating lover shaft

'56_|Forward clutch Internal spline plate (ition) “19 | Pressure tap plug (pressure control solenoid G

59 |Forward clutch pressure plate circuit)

{60__| Retaining ring (select ft) 114 | Fiuid fi plug

"61 | Thrust bearing (No.SA) ~| [[415-[ Manual shaft retaining pin 7

62_| Thrust washer (No.6B) 16_|Parking pawl actuating roc

[63 [Retaining ring “T17_ |Manual shaft outer and inner nut

64_| Forward ring gear hub 7118. | Manual valve Inner lever

5 [Forward ing gear 419" [Manual shaft seal

05-13-5

AUTOMATIC TRANSMISSION [5R55S)

720 [Manual shat Tat [Bar

721 [Digital ransmiasion range (TA) sensor 142 | Conital valve Body component

722 [Bolt and washer 143 [O-ring

128 [Manual shaft lever ee ee RS

124 | Reverse brake servo component 745 [Bot

“25_|Fleverse brake servo plate 146_[ Bot

26 | Spring = 47 [Transmission Tua iter

127 | Revorse brake seivo piston and seal 7148_[ Transmission fd pump gasket

"28 [O-ring ~ 149 | Magnet

128 | Reverse brake servo cover 750 [Bot

730_[Bor 751 [Transmission Tid pump

i] [131_| Contol valve sping retainer 182 [Drain plug

!} 482 | Spring 755_[Bot

——— 1 a a AT

|| 134 [Bor ~ 1155_| Overdrive brake and coast clutch drum component

Hh 7135 | Separating plato (bonded) 156 | Intermediate brake and direct clutch drum

| 136 | Lower contol valve body [component _

| 13 [Bat <7 Forward och compan

i 738 [ Bolt 158_| Overdrive brake servo

' 735 Detent oping 159 Iniormediate brake servo

ii 140_[Bot

Hi

|| Disassembly

| Note

| + Tag and identity all parts during disassembly.

| Place the transmission on a workbench.

Warning

+ The torque converter is heavy, especially

when full of fluid.

2. Using the SSTs, remove the torque converter.

AUTOMATIC TRANSMISSION [5R55S]

3, Remove the input shaft.

4, Using the SST, instal the transmission into the

bench with the torque converter housing facing

up.

5. Remove the sensors.

TSSSENSOR ISSSENSOR OSS SENSOR

6, Remove the manual shaft lever.

7. Remove the digital transmission range (TR)

NC]

DIGITAL TR

SENSOR

05-13-7

AUTOMATIC TRANSMISSION [5R55S]

8. Using the SST, remove the extension housing

seal. (4x2)

Caution

© The parking pawl, parking paw! return

spring and parking pawl shaft could fall

‘out during removal of the extension

housing.

9. Remove the extension housing. (4x2)

10. Using the SSTs, remove the extension housing

seal. (4x4)

Caution

* The parking pawl, parking paw! return

spring and parking paw! shaft could fall

‘out during removal of the extension

housing.

11, Remove the extension housing. (4x4)

Note

‘© 4x2 shown, 4x4 similar.

12, Remove the parking pawl component and discard

the gasket.

(1) Remove the parking paw! shaft.

(2) Remove the parking pawl.

(3) Remove the parking paw! return spring,

(4) Remove and discard the gasket.

Note

* The transmission fluid pan gasket is

reusable. Clean and inspect the gasket for

damage. if not damaged, the gasket should

_—

d

AUTOMATIC TRANSMISSION [5R55S]

13. Remove the screws, transmission fluid pan and

gasket.

14, Remove the transmission fluid filter and seal

‘component and discard.

18. Remove the detent spring.

Warning

‘© The upper and lower servo covers are

under spring tension. Use care when

removing the piston and cover

component. Failure to follow these

instructions can result in personal injury.

Remove the low/teverse brake servo component.

Caution

* Do not damage solenoid body connector

pins.

17, Remove the solenoid body component by iting

on the body and pushing the connector from the

other side of the case.

AUTOMATIC TRANSMISSION [5R55S]

48. Remove the main control valve body, separator

plate and gasket.

19. Using the SST, remove the fluid pump seal

Caution

‘* Failure to loosen the overdrive brake

band adjusting screw prior to pump

Femoval may cause damage to the pump

and overdrive brake band.

* Throw the locknut away. The locknut are

not reusable for assembly.

20. Remove and discard the locknut, and loosen the

overdrive brake band adjusting screw.

ee

ee int

PRM

21, Remove and tag the overdrive brake band anchor,

strut for assembly.

Caution

* The screws are not reusable for

‘assembly. Discard the screws. if the

screws are reused, the housing may

become separated from the

transmission.

22. Remove and discard the screws.

AUTOMATIC TRANSMISSION [5R55S}

e 23. Install the SST. — -

Pp

5

2p

24, Using the SST, remove the fluid pump.

Caution

‘« Servo cover is under spring tension.

25. Using the SST, remove the retaining ring and

overdrive brake servo cover.

26. Remove the overdrive brake servo piston and

spring.

_ MOMS

LJ

r= jie

5? \\ WAL

27. Remove the screw.

05-13-11

™®

AUTOMATIC TRANSMISSION [5R55S]

28.

30.

31

Compress the overdrive brake band and remove

the apply strut

Note

* Tag and identity parts for reassembly,

Caution

* Identify the anchor and apply ends of the

overdrive brake band.

. Flemove and inspect the overdrive brake band.

‘Check the following conditions for installing a new

band:

* Inspect for glazing.

* Inspect for missing friction material

‘+ Inspect for material flaking,

‘* Inspect for damage to the anchor pins.

Note

© The new overdrive brake band is dark in

color. This is a normal condition of the band.

Hairline cracks in the band are also

considered normal. Do not install a new

band based solely on the color.

Remove the overdrive brake and coast clutch

drum component.

Caution

* Do not bend the trigger wheel.

Remove the overdrive planetary gear carrier.

Note

‘© The thrust bearing (No.12) is in this

component,

05-13-12

AUTOMATIC TRANSMISSION [5R55S]

" 2. Remove the thrust bearing (No.2)

33. Remove the over overdrive o

ropecheanpsn ent an center shaft a

34, Remove the thrust bearing (No.3).

Note

* Tagan identty he must bearing No.) for

sembly.

Caution

the Genter support nut could fal int the

remaining assembly I notre

35. Remove the screw.

36. Remove the nut and cage.

05-13-13

AUTOMATIC TRANSMISSION [5R55S)

87. Remove the retaining ring,

38, Remove the center support.

Note

‘+ The center support is repaired as an

assembly, Any damage requires installing a

new component.

+ When removing the center support, pull

evenly around the center support web.

‘89, Inspect the center support component for wear or

damage.

(1) Inspect the thrust surfaces for wear or

damage.

(2) Inspect the center support sealing surface.

(@) Inspect the fluid passage for blockage or

damage.

40. Inspect the seal rings for damage,

41. Inspect the bearing for missing rollers or damage.

AUTOMATIC TRANSMISSION [5R55S]

42, Inspect the direct clutch feed hole for blockage or

(1) Rotate the center support bearing to locate

the direct clutch feed hole.

(2) Inspect the direct clutch feed hole for

blockage or damage.

43. Remove the thrust bearing (No.4).

Note

‘© Tag and identify the thrust bearing (No.4,

‘« Failure to loosen the intermediate brake

band adjusting screw prior to pump

removal may cause damage to the pump

and intermediate brake bar

» Throw the locknut away. TI

not reusable for assembl

44. Remove and discard the locknut, and loosen the

intermediate brake band adjusting screw.

‘> Servo cover is under spring tension.

48. Using the SST, remove the retaining ring and

intermediate brake servo cover.

46. Remove the intermediate brake servo piston and

locknut are

A

|

cA

)

Fae Lae

©

AIL

05-13-15

AUTOMATIC TRANSMISSION [5R55S]

47. Remove and tag the intermediate brake band

anchor strut for assembly. £ qu

s

Caution

‘= Identity the anchor and apply ends of the

intermediate brake band. iE

Note eg

‘+ The new intermediate brake band is dark in (coe

color. This is a normal condition of the band. a

a SB

Hairline cracks in the band are also

considered normal. Do not install a new

band based solely on the color. TCT

48, Remove and inspect the intermediate brake band.

Check the following conditions for installing a new

band:

‘+ Inspect for glazing.

i ‘+ Inspect for missing friction material.

| + Inspect for material flaking.

‘i * Inspect for damage to the anchor pins.

I

ain

49, Remove and tag the intermediate brake band

apply strut for assembly.

RSE

50. Remove the screw.

05-13-16

)

AUTOMATIC TRANSMISSION [5R55S]

51. Remove the intermediate brake and direct clutch

drum component.

Note

* The thrust bearing (No.5) may come out with

the intermediate brake and direct clutch

drum.

52. Remove the thrust bearing (No.5), tag and

identity,

53. Remove the forward clutch cylinder.

Note

‘The thrust bearing (No.6A) may come out

with the cylinder. Tag for reassembly.

54, Remove the thrust bearing (No.6A).

Note

+ The thrust bearing (No.6A) may have come

‘out with the forward clutch cylinder.

85, Remove the forward ring gear and hub as an

assembly.

Note

‘* The thrust bearing (No.7) may come out with

the forward ring gear and hub component.

05-13-17

AUTOMATIC TRANSMISSION [5R55S]

56, Remove the thrust washer (No. 6B) from the

forward ring gear hub.

57. Remove the thrust bearing (No.7).

Note

* The thrust bearing (No.7) may come out with

the forward ring gear and hub component.

58. Remove the forward planetary component.

59. Remove the input shell and sun gear component.

60. Remove the spacer.

05-13-18

AUTOMATIC TRANSMISSION [5R55S]

“61. Remove the thrust bearing (No.8).

Note

‘= Tag and identify the thrust bearing (No.8).

62. Remove the retaining ring.

63. Remove low/reverse planetary component.

64. Remove the thrust bearing (No.9).

Note

‘« Tag and identify the thrust bearing (No.9).

65. Using a small pick, remove the output shaft

sleeve.

Note

‘* Use slots located around the outside of the

sleeve.

Warning

+ The output shaft may fall out after

removing the retaining ring. Failure to

follow these instructions may result in

personal injury.

05-13-19

AUTOMATIC TRANSMISSION [5R55S]

Caution

* Discard the retaining ring. A new retaining ring must be used for assembly.

66. While holding the output shaft, remove and

discard the retaining ring.

em

67. Remove the output shaft and park gear.

68. Remove the output shaft thrust washer.

Note

‘* Tag and identify the thrust washer (No.11).

69. Remove the output shaft ring gear and hub.

€

AUTOMATIC TRANSMISSION [5R55S]

| 70. Remove the thrust bearing (No.10)..

ee aOR eo oe

>) Note

Caution

‘+ Do not pry on the outer edge of the case

or damage to the gasket sealing surface

could occur.

71. Using a pair of vice grips, hold the flat spots on

the low/revorse brake band actuating lever shatt,

wiggle it back and forth and remove the low!

reverse brake band actuating lever shaft

Note

«+ Itmay be necessary to grind flat spots on the

edges of the lowireverse brake band

actuating lever shaft in order to remove it.

72, Remove the low/reverse brake band actuating

lever component.

73. Remove the lowireverse brake drum and one-way

clutch component by rotating it clockwise.

Note

‘¢ The inner race of the rear one-way clutch is

not removable. Itis repaired in the case.

74, Inspect the lowireverse brake drum component

and install a new low/reverse brake drum

‘component if damaged.

(1) Inspect the low/reverse brake drum sprags.

(2) Inspect the low/reverse brake drum rollers.

(3) Inspect the low/reverse brake drum.

«The reverse one-way olutch is part of the

ow/reverse brake drum component. Install a

new low/reverse brake drum as an assembly

only.

OWIREVERS BRAKE

BAND ACTUATING

05-13-21

AUTOMATIC TRANSMISSION [5R55S]

75. Remove the low/reverse brake band.

Caution

* To avoid damage, make sure the wrench

does net strike the manual valve Inner

lever pin.

76. Remove the nut.

77. Remove the manual shaft retaining pin.

78. Remove the manual shaft,

79. Disconnect the manual valve inner lever from the

parking lever actuating rod.

05-13-22

AUTOMATIC TRANSMISSION [5R55S]

“90. Remove the manual valve inner lever.

_ 81. Remove the parking lever actuating rod.

Caution

.

| __* Do not damage the bore.

82. Remove the manual shaft seal.

05-13-23

AUTOMATIC TRANSMISSION [5R55S]

FLUID PUMP DISASSEMBLY[SR55S]

1. Remove the fluid pump gasket, fluid pump seal

ring and the No.1 thrust washer,

(1) Remove and discard the fluid pump gasket.

(2) Remove and discard the fluid pump seal ring

(square cut).

(8) Remove and tag the thrust washer (No.1).

2. Remove the fluid pump support seal ring.

3. Remove the seal rings.

4. Remove the fluid pump support from the fluid

pump cover.

"s, Remove the fluid pump gears.

Note

‘« A rough casting on the pump surface

crescent is not a flaw.

« The fluid pump gears are part of the pump

‘component and are not repaired separately.

- 6, Remove the drive gear seal ring and discard,

Inspect the fluid pump gears for cracks and

scoring.

7. Inspect the overdrive pump.

‘+ Inspect the overdrive pump support gear

pockets for scoring and wear.

+ Clean and inspect the overdrive and rear

input shaft bushings.

8, Inspect the fluid pump adapter plate for scoring

and wear.

9, Remove and discard the fluid pump control vaive.

od

|

05-13-25

AUTOMATIC TRANSMISSION [5R55S]

10. Inspect the fluid pump-to-converter housing

bushing.

FLUID PUMP ASSEMBLY[5R55S]

costco

1. Inspect the fluid pump components for the following:

Pump body and case for burrs

Fluid passages for obstructions

Note

‘+ Minor burrs and scoring may be removed with crocus cloth. if damage is found, install a new assembly.

2. Install a new seal onto the SST.

Note

'* Check and make sure that the garter spring

in the seal has not popped off of the

converter hub seal

3. Using the SST, install the converter hub seal

4. Install a new seal ring in fluid pump drive gear,

Caution

* Lubricate the SST with multi-purpose

grease.

05-13-26

AUTOMATIC TRANSMISSION [5R55S]

Caution

) '* The chamber on the inside edge of the

small gear must be UP when in the pump

; housing gear pocket. The dimple on the

;

| 55, Using the SST, seat the O-ring in the pump gear.

larger gear must be DOWN when in the

pump housing gear pocket

:

6. Install the pump gears into the fluid pump

housing. Apply multi-purpose grease to the pump.

gear to prevent scoring at start up.

7. Install a new O-ring on the new fluid pump control

valve.

8. Install a new valve with the tab facing down.

9. First install the fluid pump adapter plate and then

the alignment pins in their correct location.

Caution

* The SST must be used to correctly align

the pump with the adapter plate to reduce

gear noise, bushing failure and leakage.

a

05-13-27

10. Using the SST, align the fluid pump to the adapter,

plate.

11. Using the SST, assemble the fluid pump.

12. Loosoly install the fluid pump housing serews in

their correct location and remove the SSTs.

13. Install the 2 remaining screws and tighten all the

screws in a star pattern,

Tightening torque

22—28 N.m {2.32.8 kgt-m, 17—20 ft: Ibf}

14. Install a new fluid pump seal ring.

AUTOMATIC TRANSMISSION [5R55S]

an

_|

AUTOMATIC TRANSMISSION [5R55S]

15, Install the new seal rings.

Caution

i ) * Be careful not to overstretch the seal ring

past the seal ring groove. Damage to the

seal will occur.

16. Using the SST, install the fluid pump seal ring

Caution

* Verify correct seal installation.

17. Verify that the seal is installed correctly.

Note

© Make sure seal grooves are clean and free

of burrs, Make sure that the seal is seated

> Inwothe groove.

Caution

‘* Failure to correctly size the seal will

cause damage to the seal when the

torque converter is installed.

18. Using the SST, size the seal to the correct size.

Leave the SST on the seal ring for 2 min to obtain

the correct seal size,

05-13-29

AUTOMATIC TRANSMISSION [5R55S]

OVERDRIVE BRAKE AND COAST CLUTCH DRUM COMPONENT DISASSEMBLY/ASSEMBLY[SRS5S]

Overdrive Brake and Coast Clutch Drum Component

[Overdrive brake drum 7__ [Retaining ring

2 _| Coast clutoh piston outer seal ring Coast clutch external spline plate (steal)

‘3 [Coast clutch piston inner seal ring 9 [Coast cluich internal spline plate (fiction)

[Coast clutch piston 10 [Coast clutch pressure plate

5 _| Overdrive piston spring T1_[ Retaining ring (select ft)

[6 [Coast ciutch piston spring relainer €

Disassembly

1. Remove the coast clutch pressure plate.

(1) Remove the retaining ring.

(2) Remove the coast clutch pressure plate.

2. Remove the coast clutch disc pack.

* Inspect for wear, install a new pack as

necessary.

Warning

+ Use caution when releasing tool pressure

on the piston spring. Failure to follow

these instructions may result in personal

Injury.

Caution

+ Donotfully compress the SST ordamage = |____ €

to the spring retainer may occur. oman @&

05-13-30

AUTOMATIC TRANSMISSION [5R55S]

3, Using the SST, remove the retaining ring.

4 Relieve the coast clutch spring tension and

remove the SST.

5, Remove the coast clutch piston springs.

(1) Remove the coast clutch piston spring

retainer.

(2) Remove the coast clutch piston springs.

Warning

‘Air pressure must not exceed 138 kPa

{1.4 kgt/cm?, 20 psi}. Wear safety glasses

when using compressed air and make

the drum is facing down as shown.

Failure to follow these instructions may

result in personal injury.

6, Remove the coast clutch piston

‘+ Apply air pressure to the hoie in the drum to fp:

remove the coast clutch piston while blocking

the other hole with a finger. A

a

7. Remove and discard the coast clutch piston inner

seal and the coast clutch piston outer seal. X

ea

Assembly

Caution

‘© The lip seals must be positioned as shown. Care must be taken to prevent rollover of the lip seal.

05-13-31

AUTOMATIC TRANSMISSION [5R55S]

1. Install the new coast clutch piston inner and outer

seal.

2. Verily the check ball is free to move.

Caution

‘* Care must be taken to prevent damage to

the seals during installation.

8. Using the SST, install the coast clutch piston.

‘+ Lubricate the seals with transmission fluid

4. Install the coast clutch piston springs.

(1) Install the coast clutch piston springs.

(2) Install the coast clutch piston spring retainer,

Caution

*+ Do not fully compress the SST or damage

to the coast clutch piston spring retainer

may occur.

5. Using the SST, install the spring retainer ring

Caution

‘= Coast clutch friction plates are

directional and must be installed with

grooves clockwise (ID to OD). The word |

TOP should face up.

+ If new clutch plates are being used, they

should be soaked in clean ATF before

assembly.

05-13-32

AUTOMATIC TRANSMISSION [5R55S]

6. When installing friction plates, the word TOP

should face up. If reusing plates, grooves must be

installed clockwise. Install the coast clutch disc

pack.

7. Install the 2 steel clutch plates and 2 friction

clutch plates in alternating order starting with a

steel clutch plate.

Caution

© The retaining ring is select fit.

8, Install the coast clutch pressure plate.

(1) Install the coast clutch pressure plate.

(2) Install the original retaining ring.

Warning

« Air pressure must not exceed 138 kPa

{1.4 kgt/cm?, 20 psi}. Wear safety glasses

when using compressed air and make

sure drum is facing down as shown.

Failure to follow these instructions may

result in personal injury.

9. Air check the assembly.

‘* Apply air pressure to the hole in the drum

while blocking the other hole with a finger.

10. Check the coast clutch disc pack free play.

(1) Push down on the coast pressure plate.

(2) Check clearance between the coast clutch

retaining ring and coast pressure plate.

Clearance should be 1.32.0 mm {0.051—

0.079 in}. If clearance is not within the

specification, install a correct coast clutch

retaining ring that will provide the correct free

play adjustment.

Coast clutch clearance

‘Standard: 1.3—2.0 mm {0.051—0.079 in}

13-20mm

{0.510.079 in}

STE

05-13-33

AUTOMATIC TRANSMISSION [5R55S]

9 ring size for coast clutch clearance

Thickness Diameter

mm in iam in

137 | 00588 [760.1 | ee €

173] ~0eei | —te0.1 | 122

208 | 00819 | 10.1] S08

24aa__| 00961 | —tao.r | 5 122

INTERMEDIATE BRAKE AND DIRECT CLUTCH DRUM COMPONENT DISASSEMBLY/ASSEMBLY[SRS5S) .

ostacdeai9

Intermediate Brake and Direct Clutch Drum Component

I

®@ ©

intermediate brake drum 7_[ Retaining ring

2 [Direct clutch piston outer searing [8 [Direct clutch external spline plate (etealy

3 [Direct clutch piston Inner seal ring 9 [Direct clutch intemal spine plates (rictiony

4 [Direct clutch piston 10__|Direct clutch pressure plate

5 Direct cluten piston spring (20 required) 11 [Retaining ring (select it

6 [Direct clutch piston spring retainer

Disassembly

Caution

* The retaining ring is a select fit. See assembly procedure if installation of new ring or clutch pack

Is required,

1. Remove the retaining ring and the direct clutch

pressure plate.

(1) Remove the retaining ring,

(2) Remove the direct clutch pressure plate.

Caution

‘+ Clutch plates are directional. Note the

direction of the grooves for installation.

05-13-34

AUTOMATIC TRANSMISSION [5R55S]

2, Remove the direct clutch disc pack. oS :_.1F

« Inspect and install new friction plates if worn,

damaged or overheated,

© Measure and record the thickness of the steel

plates for assembly.

Warning

© After removing the retaining ring, use

care when releasing the pressure on the

springs. Failure to follow these

Instructions may result in personal

jury.

Caution

* Donot fully compress the SST or damage

to the spring retainer may occur.

|

8. Using the SST, remove the retaining ring,

4, Relieve the direct clutch spring tension and

remove the SST.

5. Remove the direct clutch piston spring retainer

and the direct clutch piston springs.

(1) Remove the direct clutch piston spring

retainer.

(2) Remove the direct clutch piston springs.

Warning

‘© Air pressure must not exceed 138 kPa

{1.4 kat/om?, 20 psi}. Wear safety glasses

When using compressed air, and make

sure the drum is facing down as shown.

Failure to follow these instructions may -

result in personal injury. = me

6. Using compressed alr, remove the direct clutch ||| ~-———= —

on from the intermediate brake drum. -

= Apply air pressure to the hole in the drum i)

while blocking the other hole with a finger.

05-13-35

|

AUTOMATIC TRANSMISSION [5R55S]

| oO