Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HE887HS Techdata

Caricato da

willytom1Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HE887HS Techdata

Caricato da

willytom1Copyright:

Formati disponibili

TECHNICAL DATA SHEET

887 Tropi-Cool

100% Silicone White Roof Coating

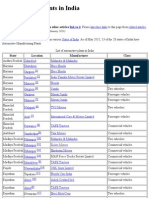

Typical Physical Properties

Appearance Glossy white Permeability 4.6 nominal

Application Temperature (Ambient) 35 F to 120 F (2 C to 49 C) Shelf Life (Unopened) 24 months

Color Bright white Solar Reflectance Index (SRI) (Initial) 111

Cure Time 2 to 6 hours Solar Reflectance (Initial) 0.88

Durometer Hardness, Shore A 42 +/- 5 points Thermal Emittance (Initial) 0.88

Elongation At Break 150% minimum Solids Content By Volume 91% +/-3

Flash Point 140.9 F (60.5 C) Tack-Free Time 1 to 2 hours

Maximum VOC 10 g/l Tensile Strength 275 psi minimum

Approvals and Certifications

ENERGY STAR certified

Cool Roof Rating Council (CRRC) rated product: Product ID# 0620-0038

Meets the requirements of California Energy Commission (CEC) Title 24 Section 118(i)3

Florida Product Approval: FL# 17412.1, 17431.3, and 17431.4

Miami-Dade County Product Control Approved: NOA# 14-1217.01, 14-1217.02, and 14-1217.03

UL Classified: Cements and coatings for roofing systems as to external fire exposure <74LM>

FM Approved: Subject to the conditions of approval as a roof coating when installed as described in the current edition of the FMRC

approval guide.

Tested and certified by NSF International in accordance with NSF Protocol P151: Health Effects from Rainwater Catchment System

Components

Meets or exceeds ASTM D7281 Standard Test Method for Determining Water Migration Resistance Through Roof Membranes.

Meets or exceeds ASTM D6694 Standard Specification for Liquid-Applied Silicone Coating Used in Spray Polyurethane Foam Roofing

Systems.

Description

HENRY 887 TROPI-COOL 100% SILICONE WHITE ROOF COATING is a premium, 100% silicone, moisture-cure coating designed to reflect the

sun's heat and UV rays as well as protect many types of roofs. While suitable for use in all climates, the 100% silicone chemistry is especially

suited for extreme tropical environments, which are exposed to some of the hottest and wettest weather with intense UV exposure. It is

specially designed to maintain maximum reflectivity of heat and UV rays as it ages. Its moisture-cure chemistry creates a very aggressive

chemical bond with the roof, which allows for permanent ponding water resistance, extreme durability, and superior capabilities of sealing

and protection.

Features

100% waterproof Excellent adhesion and flexibility

Rain-safe in 15-mintues Permanent ponding water resistant

1-coat application Superior UV resistance and weathering characteristics

Wide application temperature range from 35 F to 120 F VOC compliant solvent-free

(2 C to 49 C) Mold and mildew resistant

Lifetime limited warranty Chemically bonds with roof substrates as it cures

Saves energy by reflecting heat Easy to apply by spray, roller, or brush

Henry Company 999 N. Sepulveda Blvd., Ste. 800, El Segundo, CA 90245

Technical Services - Phone: 800-486-1278

E-mail: techservices@henry.com www.Henry.com

Rev. Date: 02/28/2017

Henry 887 TROPI-COOL 100% SILICONE WHITE ROOF COATING

Product Size

1 GALLON, 5 GALLON, 55 GALLON

Shelf Life

Unopened, 24 months from date of manufacture when stored in a cool, dry, and shaded location.

Usage

Coating can be used on many different commercial or residential roof substrates to reflect the sun's heat and UV rays, as well as to help seal

and protect the surface. It works well on low slope roofs and is suitable for pitched roofs. Acceptable roof types include:

Aged asphalt roofs including Built-Up Roofing (BUR) and Modified Bitumen (MB)

Aged single-ply and rubber roofs, including TPO, EPDM, PVC, and Hypalon roofs

Spray Polyurethane Foam (SPF) roofs

Metal roofs

Concrete roofs

Recoating previously coated roofs

RV, trailer, and mobile home roofs

Not recommended over shingles of any kind.

Application

CLEAN: Before coating the roof, use a pressure washer or high pressure nozzle and water hose to wash the roof with a non-filming detergent,

such as TSP or TSP substitute. Use appropriate pressure and take caution not to inject water into the roof substrate during washing. In areas

with stubborn dirt, grease, or other contaminants, use a stiff bristle brush or broom to scrub the areas clean with additional water and non-

filming detergent. Treat algae or moss. The most effective method of cleaning algae and moss from a roof is with a 50:50 mix of laundry

strength liquid chlorine bleach and water. Apply with a sprayer and allow the solution to dwell on the roof surface for 15 to 20 minutes, and

then rinse thoroughly with low pressure water. Extended dwell times may be necessary, however, avoid letting the solution dry completely as

this may prevent complete rinsing. Take proper precautions to protect landscaping and surrounding areas from the chlorine bleach solution.

Use appropriate personal protective equipment when working with chlorine bleach. In severe cases, it may take more than one bleach

treatment to kill all of the moss. Give the roof a final rinse to ensure it is free of all detergent or anything else that could affect adhesion.

Allow roof to dry completely before application. Using a leaf blower or broom, clear any remaining dust, dirt, debris, and foreign material that

may prevent proper adhesion. Apply a test area of coating over the existing membrane to verify absence of bleed-through and proper

adhesion to membrane prior to start of application.

PREP: Repair defects, such as splits, cracks, blisters, deteriorated flashing, cracked metal edging, and any other defects affecting the

watertightness of the roof. As a preventative measure, seal all roof penetrations, curbs, flashings, transition areas, areas where dissimilar

materials intersect, and other areas that could leak with Henry 884 Tropi-Cool 100% Silicone Roof Sealant or Henry 885 Tropi-Cool 100%

Silicone Seam & Repair Roof Sealant. Ensure all roof drains and gutters are clean and clear, and cut back any vegetation that is growing above

the roof which may cause debris to fall on the roof and clog drains and gutters in the future. On metal roofs, remove rust by wire brushing.

MIXING: Coating may settle during storage. Mix well prior to and during use with a drill and mixing paddle. For 1 and 5 gallon pails, use a

minimum 3" diameter mixing paddle or hand mix with a suitable paddle until consistent viscosity is achieved. In drums, use a minimum 6"

diameter mixing paddle.

RV, Trailer, and Mobile Home Roofs: Check the manufacturers recommendations for walking on the roof. Park on a level surface. Ensure

vehicle is turned off with the parking brake set. Secure keys to ensure someone else does not move the vehicle while you are on the roof.

Henry Company 999 N. Sepulveda Blvd., Ste. 800, El Segundo, CA 90245

Technical Services - Phone: 800-486-1278

E-mail: techservices@henry.com www.Henry.com

Rev. Date: 02/28/2017

Henry 887 TROPI-COOL 100% SILICONE WHITE ROOF COATING

APPLY: Coating should only be applied to a clean, dry, frost-free, and fully prepared roof substrate as described above. It may be applied with

a 1/2" to 1" nap lint-free roller, brush, or commercial airless spray rig. Containers are packaged to keep latent moisture from prematurely

starting the curing process. After opening the container, try to use it up as soon as possible. Keep containers covered and sealed at all times

during use, when practical. If a skin forms in the container, simply remove the skin, mix the product, and use the rest. It should be applied in

one coat smoothly and evenly over the entire roof surface, including parapet walls at a minimum 1.5 gallons per 100 square feet. Dry film

thickness (DFT) should be a minimum of 22 mils. Coating must be evenly applied and pin-hole free. On steep-slopes, rough or aged surfaces,

additional coats may be required to obtain a uniform, consistent thickness. Ensure coating is fully cured prior to additional coating

installations. Cure times generally require a minimum of 2 to 6 hours depending on weather conditions. Complete additional coats within 48

hours. Waiting longer than 48 hours may require initial coat to have to be washed prior to application of additional coats. Apply subsequent

coats perpendicular in fashion to the previous coat. For example, apply 1st coat north and south; apply 2nd coat east and west. Polyurethane

foam should be coated within 24 hours of application. New concrete roofs must be allowed to cure for a minimum 28 days before coating.

Commercial Airless Spray Rig: If spraying, a commercial airless spray rig capable of producing a minimum of 3500 psi at the spray gun tip is

required. The pump should have a minimum of 3 gallons per minute output and be fed by a 5:1 transfer pump to prevent cavitation. Always

use components rated for pump pressure. Hoses should be Buna-N jacketed for prevention of moisture contamination. Hoses should have a

minimum I.D. of 3/4" and an adequate working pressure. The spray gun should be high pressure (5000 psi) with a reverse-a-clean spray tip,

having a minimum orifice of 0.030 and a 50 fan tip. Do not use hoses that have been used for acrylics because the liners absorb moisture and

initiate the silicone cure process.

NSF PROTOCOL P151: Number of coats: 1-3. Maximum Field Use Dry Film Thickness (mils): 30 (maximum 15 per coat). Recoat Cure

Time/Temperature: 24 hours at 100 F (38 C). Final Cure Time/Temperature: 48 hours at 100 F (38 C).

Please consult Henry Product Support for any specific questions regarding the application of this product.

Coverage

Approximately 320 square feet per 5 gallon size pail (approximately 100 square feet per 1.5 gallons). Dry film thickness (DFT) should be a

minimum of 22 mils. Coverage varies depending on surface texture and porosity.

Clean-Up

Clean-up of tools and spray equipment containing uncured material may be accomplished by cleaning or flushing with VM&P Naphtha or

mineral spirits.

Spray Equipment: This product cures by reacting with moisture and should not be left in spray guns, pump equipment, and hoses for

prolonged periods unless equipment contains moisture lock hoses, fittings, and seals. Equipment without these components will transmit

sufficient moisture vapor to gradually form cured material on hose walls and at unsealed connections potentially causing an increase in

operating pressure and material flow restriction.

Precautions

DO NOT THIN. Use extreme caution when applying and walking on silicone coated surfaces. Silicone coated surfaces are extremely slippery

and can create a fall hazard resulting in death or injury. Keep away from food. Not recommended for application at temperatures below 35 F

(2 C) or if rain is expected in less than 15 minutes of application. Lower temperatures and/or less humidity will typically result in slower cure

times. When transporting, make sure the pail is secured and the lid is tight to prevent spills. Store in a cool, dry, and shaded location. Ensure

lid is completely sealed.

Henry Company 999 N. Sepulveda Blvd., Ste. 800, El Segundo, CA 90245

Technical Services - Phone: 800-486-1278

E-mail: techservices@henry.com www.Henry.com

Rev. Date: 02/28/2017

Henry 887 TROPI-COOL 100% SILICONE WHITE ROOF COATING

Warning

Causes skin irritation. Causes serious eye irritation. Suspected of damaging fertility or the unborn child. May cause respiratory irritation.

Prevention: Obtain special instructions before use. Do not handle until all safety precautions have been read and understood. Wear protective

gloves, protective clothing and eye protection. Wash thoroughly after handling. Avoid breathing vapors, mists and sprays. Use only outdoors

or in a well-ventilated area.

Response: IF EXPOSED OR CONCERNED: Get medical advice or attention. IF ON SKIN: Wash with plenty of soap and water. If skin irritation

occurs; Get medical advice or attention. Take off contaminated clothing and wash it before reuse. IF IN EYES: Rinse cautiously with water for

several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. If eye irritation persists: Get medical advice or attention.

IF INHALED: Remove person to fresh air and keep comfortable for breathing.

Storage: Store in a well-ventilated place. Keep container tightly closed. Store locked up.

Disposal: Dispose of contents/containers to an approved waste disposal plant.

See safety data sheet for further details regarding the safe use of this product.

KEEP OUT OF REACH OF CHILDREN.

FOR EXTERIOR USE ONLY.

Limited Product Warranty

For information on Henrys product limited warranty and liability disclaimer, please visit www.henry.com/warranty.

STATEMENT OF RESPONSIBILITY

The technical and application information herein is based on the present state of our best scientific and practical knowledge. As the

information herein is of a general nature, no assumption can be made as to a products suitability for a particular use or application and no

warranty as to its accuracy, reliability, or completeness either expressed or implied is given other than those required by law. The user is

responsible for checking the suitability of products for their intended use. Data sheets are updated on a regular basis; it is the users

responsibility to obtain and to confirm the most recent version. Information contained in this data sheet may change without notice.

Henry Company 999 N. Sepulveda Blvd., Ste. 800, El Segundo, CA 90245

Technical Services - Phone: 800-486-1278

E-mail: techservices@henry.com www.Henry.com

Rev. Date: 02/28/2017

Potrebbero piacerti anche

- Pentens ProductDocumento17 paginePentens ProductJohn KurongNessuna valutazione finora

- Heat Shield ™ EPX-H2O Thermal Insulation Coating: Very SimpleDocumento2 pagineHeat Shield ™ EPX-H2O Thermal Insulation Coating: Very Simpleluis pi100% (1)

- TDS Micro Seal HD 2020 v4 PDFDocumento3 pagineTDS Micro Seal HD 2020 v4 PDFLeonardo Otto CoutinhoNessuna valutazione finora

- Heat Shield™ EPX-H2O Thermal Insulation Coating: Product Data SheetDocumento2 pagineHeat Shield™ EPX-H2O Thermal Insulation Coating: Product Data SheetvtnhoemNessuna valutazione finora

- Acrylic Sealer: One Component, Low Viscosity SealerDocumento2 pagineAcrylic Sealer: One Component, Low Viscosity SealerHerul VetonkNessuna valutazione finora

- Tectyl 506 PDFDocumento4 pagineTectyl 506 PDFjaskaran singhNessuna valutazione finora

- #1300T Reflective White Plastic: DescriptionDocumento1 pagina#1300T Reflective White Plastic: DescriptionIoan CorneliuNessuna valutazione finora

- Simacover EP Unicoat 2401-00: Product Data SheetDocumento3 pagineSimacover EP Unicoat 2401-00: Product Data SheetParan baenNessuna valutazione finora

- Soudafoam 1KDocumento2 pagineSoudafoam 1KCHERIF YAHIANessuna valutazione finora

- Foster PDS 32 17 R0519 1Documento2 pagineFoster PDS 32 17 R0519 1Nashal KkNessuna valutazione finora

- rt-600 TdsDocumento3 paginert-600 Tdsbytorrent7244Nessuna valutazione finora

- Rooftex BrochureDocumento2 pagineRooftex BrochureTRAG ProjectsNessuna valutazione finora

- Epilux 155 SFDocumento2 pagineEpilux 155 SFMohamed NasifNessuna valutazione finora

- 1050 Plastigard 100 Percent Acrylic High Build CoatingDocumento1 pagina1050 Plastigard 100 Percent Acrylic High Build Coatingjustin trochezNessuna valutazione finora

- Dowsil 789 Weatherproofing SealDocumento3 pagineDowsil 789 Weatherproofing Sealsiju1974Nessuna valutazione finora

- Deltashield C 1100: Product Data SheetDocumento4 pagineDeltashield C 1100: Product Data SheetjoeNessuna valutazione finora

- Aliphatic Acrylic Polyurethane Finish CoatDocumento4 pagineAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNessuna valutazione finora

- Alcolin Fire Stop Neutral Silicone: Technical Data SheetDocumento6 pagineAlcolin Fire Stop Neutral Silicone: Technical Data SheetTonyNessuna valutazione finora

- CoolonDocumento2 pagineCoolonAnySikaNessuna valutazione finora

- 6 2 1 6 1 Polyflex PDFDocumento2 pagine6 2 1 6 1 Polyflex PDFFourier MakambioNessuna valutazione finora

- Quicseal 119: AquapoxyDocumento4 pagineQuicseal 119: AquapoxyRenaldo BunaidiNessuna valutazione finora

- iKOTE AC 40 (DEC-2023) V1.3Documento2 pagineiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNessuna valutazione finora

- Quicseal 104: Flexible Cementitious Waterproofing MembraneDocumento3 pagineQuicseal 104: Flexible Cementitious Waterproofing MembraneJet ToledoNessuna valutazione finora

- Foster90 66Documento2 pagineFoster90 66didapopescuNessuna valutazione finora

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocumento2 pagineRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNessuna valutazione finora

- Lavatex 2000...Documento2 pagineLavatex 2000...ArifNessuna valutazione finora

- Nuproof CeDocumento2 pagineNuproof CeneusadNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsMuthuKumarNessuna valutazione finora

- Data Tecnica Hydrosteel Gli9900-FrontDocumento1 paginaData Tecnica Hydrosteel Gli9900-FrontTommyCasillas-GerenaNessuna valutazione finora

- Dow Corning® 993 Structural Glazing Sealant: Product InformationDocumento4 pagineDow Corning® 993 Structural Glazing Sealant: Product InformationMohammad ALTAKINessuna valutazione finora

- Quicseal 102: Liquid Applied Elastomeric PU Waterproofing MembraneDocumento2 pagineQuicseal 102: Liquid Applied Elastomeric PU Waterproofing Membranejet toledoNessuna valutazione finora

- Epilux 78Documento2 pagineEpilux 78MuthuKumar100% (1)

- d2) Epilux218 4267Documento2 pagined2) Epilux218 4267Syed FaridNessuna valutazione finora

- Product Data Sheet: G 2100 - Silicone SealantDocumento2 pagineProduct Data Sheet: G 2100 - Silicone SealantShahid BhattiNessuna valutazione finora

- Tectyl 502CDocumento2 pagineTectyl 502Cmoinu85Nessuna valutazione finora

- Dow Corning RTV InfoDocumento20 pagineDow Corning RTV InfoLevent ÖnderNessuna valutazione finora

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocumento4 pagineSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNessuna valutazione finora

- Tds-Cpd-Sikalastic 601 BC-usDocumento5 pagineTds-Cpd-Sikalastic 601 BC-usgamini pereraNessuna valutazione finora

- Coal Tar Epoxy 4: DescriptionDocumento2 pagineCoal Tar Epoxy 4: DescriptionAbhisheK MishrANessuna valutazione finora

- Epilux 9 Phenolic CoatingDocumento2 pagineEpilux 9 Phenolic CoatingdineshNessuna valutazione finora

- Firefoam 1 C 3.3 Rev.5 enDocumento4 pagineFirefoam 1 C 3.3 Rev.5 enRoxana IordacheNessuna valutazione finora

- 0091 Amercoat 91 PDS May 08Documento2 pagine0091 Amercoat 91 PDS May 08donaldoguerreroNessuna valutazione finora

- Sikaflex 11FC Technical Data SheetDocumento5 pagineSikaflex 11FC Technical Data SheetIlies CristinaNessuna valutazione finora

- Berger: Product SpecificationsDocumento2 pagineBerger: Product SpecificationsAabhas UpadhyayaNessuna valutazione finora

- Thermaline 450 PDFDocumento2 pagineThermaline 450 PDFNageswara Rao BavisettyNessuna valutazione finora

- Anti Condensation CatalogueDocumento8 pagineAnti Condensation CatalogueBoBo KyawNessuna valutazione finora

- Foster Fire Resistive Aluminium Mastic: Technical Data SheetDocumento2 pagineFoster Fire Resistive Aluminium Mastic: Technical Data SheetMounir BoutaghaneNessuna valutazione finora

- Polycure W Polycure W: Water Based Curing CompoundDocumento2 paginePolycure W Polycure W: Water Based Curing CompoundMuhsin KhanNessuna valutazione finora

- Tds-Unichem AlumcoatDocumento3 pagineTds-Unichem AlumcoatAnvesh BondugulaNessuna valutazione finora

- El Hyperdesmo-ClassicDocumento4 pagineEl Hyperdesmo-ClassicΙοαννης ΡενκοNessuna valutazione finora

- Frigi-Tech: Reflective Roof CoatingsDocumento24 pagineFrigi-Tech: Reflective Roof CoatingsdeivarajeshkrishnaNessuna valutazione finora

- Interline 984+ds+eng PDFDocumento4 pagineInterline 984+ds+eng PDFMohamed NouzerNessuna valutazione finora

- Coaltar Epoxy - Epilux5 - 0474Documento2 pagineCoaltar Epoxy - Epilux5 - 0474GautamNessuna valutazione finora

- 1.2. Techseal RDL 941 EhDocumento4 pagine1.2. Techseal RDL 941 EhQuery TANessuna valutazione finora

- PDS Simacover Tar Epoxy 3404-00Documento4 paginePDS Simacover Tar Epoxy 3404-00Aulia RahmahNessuna valutazione finora

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocumento1 paginaStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNessuna valutazione finora

- Protecta Product Portfolio October 2020 1Documento24 pagineProtecta Product Portfolio October 2020 1Valentin A.Nessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Rachel Prager - CV Final 2Documento3 pagineRachel Prager - CV Final 2api-549649341Nessuna valutazione finora

- Photo EssayDocumento15 paginePhoto Essayapi-282188592Nessuna valutazione finora

- S. Rangarajan Etc Vs P. Jagjivan Ram On 30 March, 1989Documento21 pagineS. Rangarajan Etc Vs P. Jagjivan Ram On 30 March, 1989aarohanNessuna valutazione finora

- Alejandro RocesDocumento2 pagineAlejandro RocesJhoana Jane Joson60% (5)

- Types of Cameras PPPDocumento19 pagineTypes of Cameras PPPLakan BugtaliNessuna valutazione finora

- Achievers A1 Diagnostic Test 111 AngeloDocumento3 pagineAchievers A1 Diagnostic Test 111 AngeloAngelo David Muñoz Semanate50% (2)

- Analysis PWD Rate Schedule 2014Documento2.144 pagineAnalysis PWD Rate Schedule 2014dxzaber80% (10)

- AHD Cameras & DVR (2015) Joney Technology PDFDocumento8 pagineAHD Cameras & DVR (2015) Joney Technology PDFNicolae SlapciuNessuna valutazione finora

- 00 - Hinduism and Buddhism PacketDocumento22 pagine00 - Hinduism and Buddhism PacketMalik ZahdehNessuna valutazione finora

- Hyperdesmo Polyurea 2K HCDocumento3 pagineHyperdesmo Polyurea 2K HCmeena nachiyarNessuna valutazione finora

- More User Manuals On: For Personal Attention From One of Our Customer Service Representatives, Please Contact Us atDocumento4 pagineMore User Manuals On: For Personal Attention From One of Our Customer Service Representatives, Please Contact Us atRAFA MARTINEZ100% (1)

- MCQ Type QuestionsDocumento2 pagineMCQ Type QuestionsAnonymous rn5Te9MwkNessuna valutazione finora

- LM6503 Stunning Doily Dream Catcher Free Crochet Pattern 2Documento4 pagineLM6503 Stunning Doily Dream Catcher Free Crochet Pattern 2MagdaNessuna valutazione finora

- Political Theory Reading List 2015Documento13 paginePolitical Theory Reading List 2015VagueBlurNessuna valutazione finora

- Vidal - Allover India - Network Hospital ListDocumento48 pagineVidal - Allover India - Network Hospital ListSRINIVASARAO JONNALANessuna valutazione finora

- Poe - A Dream Within A DreamDocumento5 paginePoe - A Dream Within A DreamGeri JaupiNessuna valutazione finora

- The Onions BassDocumento3 pagineThe Onions BassBoatman BillNessuna valutazione finora

- Chapter 7 - The Native Peoples of Canada - PowerpointDocumento27 pagineChapter 7 - The Native Peoples of Canada - Powerpointapi-295328704Nessuna valutazione finora

- Kylie MinogueDocumento2 pagineKylie MinogueJhon Ray Ganton RabaraNessuna valutazione finora

- List of Vehicle Plants in India - Wikipedia, The Free EncyclopediaDocumento3 pagineList of Vehicle Plants in India - Wikipedia, The Free EncyclopediaAjay Marya50% (2)

- Inventor Project Frame Generator Guide enDocumento16 pagineInventor Project Frame Generator Guide enHajrah SitiNessuna valutazione finora

- PTCH Class Multiplication in BoulezDocumento26 paginePTCH Class Multiplication in BoulezAndrés Moscoso100% (1)

- Flora Kidd - Tropical TempestDocumento180 pagineFlora Kidd - Tropical Tempestmistytom2891% (11)

- Language Unseen PoetryDocumento2 pagineLanguage Unseen PoetryWitchingDread10Nessuna valutazione finora

- Plastic Parts & Tooling Surface Finish - VDI 3400Documento4 paginePlastic Parts & Tooling Surface Finish - VDI 3400Selvaraj BalasundramNessuna valutazione finora

- Yoga Therapy & Integrative Medicine: Where Ancient Science Meets Modern MedicineDocumento11 pagineYoga Therapy & Integrative Medicine: Where Ancient Science Meets Modern MedicineAshu ToshNessuna valutazione finora

- Escola Secundária Teixeira de Sousa English Worksheet Name: Number: ClassDocumento2 pagineEscola Secundária Teixeira de Sousa English Worksheet Name: Number: ClassKleber MonteiroNessuna valutazione finora

- Dawn of Darkness: First BookDocumento13 pagineDawn of Darkness: First BookGodwin A.udo-akanNessuna valutazione finora

- How To Win Over WorryDocumento9 pagineHow To Win Over WorryKreshnik HAJDARINessuna valutazione finora

- Chicago/Turabian 17 Edition Format and Documentation: Formatting Your PaperDocumento4 pagineChicago/Turabian 17 Edition Format and Documentation: Formatting Your Paperpure soulNessuna valutazione finora