Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Sheet Mortero (Grout) Epóxico Chockfast Red PDF

Caricato da

Daniel Puello RodeloTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Sheet Mortero (Grout) Epóxico Chockfast Red PDF

Caricato da

Daniel Puello RodeloCopyright:

Formati disponibili

CHOCKFAST Red

A Deep-Pour Epoxy Grout

Technical Bulletin # 617R

Product Description

CHOCKFAST Red is a three-component, high strength, 100% solids, epoxy grouting compound used to

grout large machinery and to support soleplates in all types of foundations. CHOCKFAST Red has an

extremely high compressive strength. This along with negligible shrinkage makes it ideal for installing

critically aligned machinery within very close tolerances.

Use & Benefits

CHOCKFAST Red has the following advantages when compared to conventional cement grouts:

Impervious to oil

Cures at least three times as quickly

No mixing ratios to measure

Grouts machinery in final aligned position

High physical strength

High impact strength

Resistance to many more chemicals

Strong bond to metal and concrete

Unaffected by weathering and freeze / thaw cycling

Stated physical properties assured

Superior resistance to fatigue

Design Considerations

CHOCKFAST Red is quick curing, relative to cement grouts, but the cure is thermally gentle. This allows

thick pours to be made without causing the stress cracks often associated with a hot-curing epoxy grout.

CHOCKFAST Red may be used in thickness greater than 2 inches (50mm), however, individual pours

should generally not exceed 18 inches (46cm) in thickness and 7 feet (2.2m) in length. When grouting

critically aligned machinery coupled to another machine, it is advisable to limit the final leveling pour in

accordance with the instructions in Bulletin No. 615 (latest revision).

CHOCKFAST Red contains no diluents that could interfere with the curing mechanism or that could

cause material loss during or after cure. Therefore, machinery may be positioned at its final elevation

before pouring because the shrinkage is negligible. Critical alignments are maintained during machinery

operation due to its high dimensional stability and resistance to creep and vibration.

Application Instructions

CHOCKFAST Red may be mixed with contractor's hoe and wheelbarrow or in a small portable mortar

mixer. Pre-condition resin, hardener and aggregate to 65-80F (18-27C) for 48 hrs. before mixing.

Thoroughly mix hardener with resin first before mixing in aggregate. Where a very flowable mix is

required the aggregate content may be reduced accordingly. However, in load-bearing areas a maximum

reduction to 3-1/2 bags is recommended. Please contact the CHOCKFAST Distributor or ITW Polymer

Technologies if less than 3-1/2 bags are being considered. See Bulletin No. 642 for mixing and

installation procedures.

ITW POLYMER TECHNOLOGIES

130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688

www.chockfastgrout.com

CHOCKFAST Red

Bulletin No. 617R, Page 2

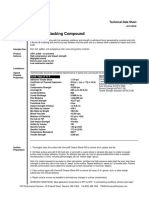

Physical Properties

COMPRESSIVE STRENGTH 15,250 psi (1,072 kg/cm2) ASTM C-579 MOD

2

COMPRESSIVE MODULUS OF ELASTICITY 2,000,000 psi (140,600 kg/cm ) ASTM C-579 MOD

LINEAR SHRINKAGE Not Measurable ASTM D-2566

-6 o o o

COEFFICIENT OF LINEAR THERMAL 11.2 x 10 / F @ 32 F to 140 F ASTM D-696

-6 o o o

EXPANSION (20.1 x 10 / C @ 0 C to 60 C)

2

FLEXURAL STRENGTH 4,025 psi (283 kg/cm ) ASTM C-580

2

FLEXURAL MODULUS OF ELASTICITY 2,000,000 psi (140,600 kg/cm ) ASTM C-580

2

TENSILE STRENGTH 1,890 psi (133 kg/cm ) ASTM D-638

IZOD IMPACT STRENGTH 4.6 in.lb/in. (0.02 N.m/mm) ASTM D-256

o o

SERVICE TEMPERATURE Up to 140 F (60 C)

FIRE RESISTANCE Self-Extinguishing ASTM D-635

SPECIFIC GRAVITY 2.06

Product Information

3 3

UNIT COVERAGE 1.6 ft or 2,765 in (45.3 Liters)

o o o o

APPLICATION TEMPERATURE 55 F (13 C) to 95 F (35 C)

UNIT PACKAGING Resin (NH): 1.6 gal (6.1 L) in a 3 gal pail

Hardener (NH): 0.9 gal (3.5 L) in a plastic tray

inserted into the top of the resin can

Aggregate: (4) 46 lb. (21 kg) bags

UNIT WEIGHT Resin: 15.4 lbs (7 kg)

Hardener: 7.6 lbs (3.4 kg)

Aggregate: 184 lbs (84 kg)

SHIPPING WEIGHT 207 lbs (94 kg)

o o o o

CURE TIME (approximate) 54 hours @ 60 F (16 C); 36 hours @ 72 F (21 C)

o o o o

24 hours @ 27 C (80 F); 18 hours @ 32 C (90 F)

o o

POT LIFE Approximately 3 hours @ 21 C (70 F)

SHELF LIFE 2 years in dry storage

CLEAN UP Water or IMPAX IXT-59 or similar epoxy solvent

Date 06/2006

General: Every reasonable effort is made to insure the Suggestions concerning the use of products are not

technical information and recommendations on these data warranties. The purchaser assumes the responsibility for

pages are true and accurate to the best of our knowledge determining suitability of products and appropriate use.

at the date of issuance. However, this information is subject ITW Polymer Technologies sole liability, for breach of

to change without notice. Prior versions of this publication warranty, negligence or otherwise, shall be the

are invalid with the release of this version. Products and replacement of product or refund of the purchase

information are intended for use by qualified applicators price, at ITW Polymer Technologies election. Under no

that have the required background, technical knowledge, circumstances shall ITW Polymer Technologies be liable

and equipment to perform said tasks in a satisfactory for any indirect, incidental or consequential damages.

manner. Consult your local distributor for product Modification of Warranty: No distributor or sales

availability, additional product information, and technical representative has the authority to change the above

support. provisions. No change in the above provisions will be

Warranty: ITW Polymer Technologies, a division of Illinois Tool valid unless in writing and signed by an officer or the

Works Inc., warrants that its products meet their printed Technical Director of ITW Polymer Technologies. No

specifications. This is the sole warranty. This warranty term of any purchase order shall serve to modify any

expires one year after product shipment. provision of this document.

Warranty Claims: If any product fails to meet the above, Mediation and Arbitration: If any dispute arises relating

ITW Polymer Technologies will, at its option, either replace to products or product warranties, either the purchaser

the product or refund the purchase price. ITW Polymer or ITW Polymer Technologies may a) initiate mediation

Technologies will have no other liability for breach of under the then current Center for Public Resources

warranty, negligence, or otherwise. All warranty claims (CPR) Model Procedure for Mediation of Business

must be made in writing within one year of the date of Disputes, or b) initiate a non-binding arbitration under

shipment. No other claims will be considered. the rules of the American Arbitration Association for the

Disclaimer: ITW Polymer Technologies makes no other resolution of commercial disputes.

warranty, expressed or implied, and specifically disclaims

any warranty of merchantability or fitness for a particular

purpose.

Potrebbero piacerti anche

- Chockfast Orange PDFDocumento2 pagineChockfast Orange PDFKaharul AfandiNessuna valutazione finora

- 04 HT - Chockfast OrangeDocumento2 pagine04 HT - Chockfast OrangeGESTION Y CONTROL DE PROYECTOS IngeminNessuna valutazione finora

- Datasheet Chockfast RedDocumento2 pagineDatasheet Chockfast RedAlexander0% (1)

- Product: Chocking & Anchor Bolt Setting CompoundDocumento2 pagineProduct: Chocking & Anchor Bolt Setting CompoundFajri AnnamlaNessuna valutazione finora

- Chock FastDocumento2 pagineChock FastredsilverNessuna valutazione finora

- Prod CatalianDocumento87 pagineProd Cataliananon_591741392Nessuna valutazione finora

- Chockfast Orange DataDocumento2 pagineChockfast Orange DataDilnesa EjiguNessuna valutazione finora

- Sikadur 42 Gorut Palk LE - CaDocumento2 pagineSikadur 42 Gorut Palk LE - Carobert benavidesNessuna valutazione finora

- PS 14 Anchor Bolt TolerancesDocumento4 paginePS 14 Anchor Bolt TolerancesjebrijaNessuna valutazione finora

- EP-2 Industrial GreaseDocumento1 paginaEP-2 Industrial GreaseEnrique PeraltaNessuna valutazione finora

- Tyfo SCH-41 Composite: Using Tyfo S EpoxyDocumento2 pagineTyfo SCH-41 Composite: Using Tyfo S EpoxyJonAthan LimNessuna valutazione finora

- Protective & Marine Coatings: Polysiloxane 1KDocumento4 pagineProtective & Marine Coatings: Polysiloxane 1KAna CabreraNessuna valutazione finora

- Dura-Plate Uhs Primer NSF: Protective & Marine CoatingsDocumento4 pagineDura-Plate Uhs Primer NSF: Protective & Marine CoatingscerorideNessuna valutazione finora

- 226NDocumento2 pagine226NUmaibalanNessuna valutazione finora

- Especificaciones Pintura Macropoxi NavalDocumento4 pagineEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNessuna valutazione finora

- 3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Documento2 pagine3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Massimiliano VolaNessuna valutazione finora

- Acrolon 218 FTDocumento4 pagineAcrolon 218 FTEdwin VSNessuna valutazione finora

- Dupont Styrofoam Brand Highload 40, 60 and 100 Xps Foam InsulationDocumento4 pagineDupont Styrofoam Brand Highload 40, 60 and 100 Xps Foam InsulationAhmed AbdelazizNessuna valutazione finora

- 1.9.1.2-75B - BondArc WireDocumento6 pagine1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNessuna valutazione finora

- HD6200B/HD6600B High Density Polyethylene Resin Product DescriptionDocumento1 paginaHD6200B/HD6600B High Density Polyethylene Resin Product DescriptionRizaldi Nur Imani100% (1)

- Tyfo SCH-41-2X Composite: Using Tyfo S EpoxyDocumento2 pagineTyfo SCH-41-2X Composite: Using Tyfo S EpoxyAnito ShobithNessuna valutazione finora

- Duralprep A.C.: Bonding Agent and Anti-Corrosion CoatingDocumento2 pagineDuralprep A.C.: Bonding Agent and Anti-Corrosion Coatingaandueza_1Nessuna valutazione finora

- HexTow AS4C Carbon Fiber TDSDocumento2 pagineHexTow AS4C Carbon Fiber TDSJHOSDOUGLASNessuna valutazione finora

- Sher Plate 600Documento4 pagineSher Plate 6001Nessuna valutazione finora

- Acrolon 218 HsDocumento4 pagineAcrolon 218 HsKARENNessuna valutazione finora

- Catalog 68.1 Spraying EquipmentDocumento4 pagineCatalog 68.1 Spraying Equipmentanhtu8200100% (1)

- Macropoxy 646 SEDocumento4 pagineMacropoxy 646 SESleyda MunozNessuna valutazione finora

- SikaAnchorFix2Arctic PdsDocumento4 pagineSikaAnchorFix2Arctic PdsDragoș SturzoiuNessuna valutazione finora

- Description Features and CharacteristicsDocumento2 pagineDescription Features and CharacteristicsPranpath NarupantawartNessuna valutazione finora

- Technical Data: Plastic Steel Putty (A)Documento4 pagineTechnical Data: Plastic Steel Putty (A)francisNessuna valutazione finora

- Liquid Nitrogen Container Instruction ManualsDocumento25 pagineLiquid Nitrogen Container Instruction Manualsm_najmanNessuna valutazione finora

- Drill Stem Testing: Bigcat™ HP/HT Retrievable PackerDocumento1 paginaDrill Stem Testing: Bigcat™ HP/HT Retrievable PackerjaymuscatNessuna valutazione finora

- FS 600 Data SheetDocumento1 paginaFS 600 Data SheetNguyen Hong67% (3)

- SAN - KUMHO - 350-HW - TDS FDocumento4 pagineSAN - KUMHO - 350-HW - TDS FakshayNessuna valutazione finora

- High Performance Backing Compound: Technical Data SheetDocumento2 pagineHigh Performance Backing Compound: Technical Data SheetNiku SamarthNessuna valutazione finora

- Exceed™ XP 6056ML: Performance PolymerDocumento2 pagineExceed™ XP 6056ML: Performance PolymerkjmontilNessuna valutazione finora

- 1.9.1.2-80T - 18 8 Stainless SteelDocumento4 pagine1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNessuna valutazione finora

- Kapton HN Data SheetDocumento5 pagineKapton HN Data Sheet谢朋亨Nessuna valutazione finora

- Sika - 42 GroutDocumento2 pagineSika - 42 GroutBill MurrayNessuna valutazione finora

- Chersterton Arc 982 PDFDocumento2 pagineChersterton Arc 982 PDFMohamed NouzerNessuna valutazione finora

- ASCO 20 ISO Tank ContainersDocumento5 pagineASCO 20 ISO Tank ContainersJay McKearnNessuna valutazione finora

- Cap Screws: Sae J429 Grade IdentificationDocumento6 pagineCap Screws: Sae J429 Grade IdentificationHomer SilvaNessuna valutazione finora

- Tairilac ABS Resin Properties and CharacteristicsDocumento3 pagineTairilac ABS Resin Properties and CharacteristicsDiegoTierradentroNessuna valutazione finora

- Tairilac ABS Resin: Properties (1/3)Documento3 pagineTairilac ABS Resin: Properties (1/3)DiegoTierradentroNessuna valutazione finora

- Bangchak HydraulicDocumento1 paginaBangchak HydraulicSouthern MTSNessuna valutazione finora

- Tyfo SCH-7UP Composite: Using Tyfo S EpoxyDocumento2 pagineTyfo SCH-7UP Composite: Using Tyfo S Epoxyyusak santosoNessuna valutazione finora

- Sikadur®-42 Grout Pak Multi-Flo: Pre-Proportioned, Epoxy Base Plate, Grouting SystemDocumento2 pagineSikadur®-42 Grout Pak Multi-Flo: Pre-Proportioned, Epoxy Base Plate, Grouting SystemnedNessuna valutazione finora

- Nci Test DataDocumento21 pagineNci Test DataPig DookNessuna valutazione finora

- Duraplate Uhs EnglishDocumento4 pagineDuraplate Uhs EnglishLuis JaraNessuna valutazione finora

- Protective & Marine Coatings: Acrolon™ 218 HsDocumento4 pagineProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNessuna valutazione finora

- Loctite PC 9020I: Technical Data SheetDocumento3 pagineLoctite PC 9020I: Technical Data SheetLuis Sebastian Castillo100% (1)

- Plastic Steel Putty A v3Documento2 paginePlastic Steel Putty A v3feri.ferdianto02Nessuna valutazione finora

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Documento3 pagineStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNessuna valutazione finora

- KOPA KN126 enDocumento1 paginaKOPA KN126 enJagadeesh WaranNessuna valutazione finora

- Garlock Hi TempDocumento4 pagineGarlock Hi Temprock starNessuna valutazione finora

- 2427 2428 Slow Infusion Epoxy Kit Tds 04 - 27 - 2020Documento2 pagine2427 2428 Slow Infusion Epoxy Kit Tds 04 - 27 - 2020darwin rolonNessuna valutazione finora

- Sikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorDocumento2 pagineSikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorMarkNessuna valutazione finora

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocumento1 paginaGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNessuna valutazione finora

- Aeropoxy ES6209 DATASHEETDocumento2 pagineAeropoxy ES6209 DATASHEETWalter AhrensNessuna valutazione finora

- Revised Guidelines for Fixed Water-Based Firefighting SystemsDocumento13 pagineRevised Guidelines for Fixed Water-Based Firefighting SystemsmlevNessuna valutazione finora

- Martin's Procket Special Features Section IVDocumento16 pagineMartin's Procket Special Features Section IVEzequiel CastroNessuna valutazione finora

- Pumps AG 7 - 1 PDFDocumento4 paginePumps AG 7 - 1 PDFquiron2010Nessuna valutazione finora

- FMDS1317 - Gas Turbines PDFDocumento15 pagineFMDS1317 - Gas Turbines PDFDaniel Puello RodeloNessuna valutazione finora

- Components: See Price List For Items Carried in StockDocumento46 pagineComponents: See Price List For Items Carried in StockDaniel Puello RodeloNessuna valutazione finora

- Special Features PDFDocumento21 pagineSpecial Features PDFDaniel Puello RodeloNessuna valutazione finora

- Special Features PDFDocumento21 pagineSpecial Features PDFDaniel Puello RodeloNessuna valutazione finora

- Technical Reference Guide Fastenal K Factor and MoreDocumento62 pagineTechnical Reference Guide Fastenal K Factor and Moredlight0Nessuna valutazione finora

- Aspen Energy Analyzer: Tutorial GuideDocumento102 pagineAspen Energy Analyzer: Tutorial GuideDaniel Puello RodeloNessuna valutazione finora

- Pulley Selection 1 PDFDocumento8 paginePulley Selection 1 PDFAnonymous uXdS9Y7Nessuna valutazione finora

- Modular Plastic Screw Conveyors Improve ProductivityDocumento4 pagineModular Plastic Screw Conveyors Improve ProductivityDaniel Puello RodeloNessuna valutazione finora

- Best Practices Anchor Bolts (v0 2) 11 April 2014Documento227 pagineBest Practices Anchor Bolts (v0 2) 11 April 2014Daniel Puello RodeloNessuna valutazione finora

- Soldadura General - Catalog-(S) PDFDocumento262 pagineSoldadura General - Catalog-(S) PDFDaniel Puello RodeloNessuna valutazione finora

- Shell and Tube Heat Exchanger DesignDocumento41 pagineShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Data Sheet Mortero (Grout) Epóxico Chockfast Red PDFDocumento2 pagineData Sheet Mortero (Grout) Epóxico Chockfast Red PDFDaniel Puello RodeloNessuna valutazione finora

- Aspen Energy Analyzer: Tutorial GuideDocumento102 pagineAspen Energy Analyzer: Tutorial GuideDaniel Puello RodeloNessuna valutazione finora

- Gnucash Help PDFDocumento230 pagineGnucash Help PDFDaniel Puello RodeloNessuna valutazione finora

- Gnucash Guide PDFDocumento288 pagineGnucash Guide PDFDaniel Puello RodeloNessuna valutazione finora

- (Springer Texts in Business and Economics) Kolmar, Martin-Principles of Microeconomics - An Integrative Approach-Springer (2017)Documento338 pagine(Springer Texts in Business and Economics) Kolmar, Martin-Principles of Microeconomics - An Integrative Approach-Springer (2017)Phạm Phương ThảoNessuna valutazione finora

- Best Practices in Compressor MountingDocumento9 pagineBest Practices in Compressor MountingDaniel Puello RodeloNessuna valutazione finora

- Resistencia A Productos Químicos Del Grout ChockfastDocumento5 pagineResistencia A Productos Químicos Del Grout ChockfastDaniel Puello RodeloNessuna valutazione finora

- Aging Relief SystemsDocumento6 pagineAging Relief SystemsDaniel Puello RodeloNessuna valutazione finora

- Toyota's Kaizen012201Documento6 pagineToyota's Kaizen012201SasaNessuna valutazione finora

- Resistencia A Productos Químicos Del Grout ChockfastDocumento5 pagineResistencia A Productos Químicos Del Grout ChockfastDaniel Puello RodeloNessuna valutazione finora

- How To Find Optimum Exchanger SizeDocumento2 pagineHow To Find Optimum Exchanger SizeDaniel Puello RodeloNessuna valutazione finora

- HEI - Steam Surface CondensersDocumento88 pagineHEI - Steam Surface CondensersDaniel Puello RodeloNessuna valutazione finora

- Steam Generation Thermodynamics: Efficiency Improvements Can Quickly Be Identified With Back-Of-The-Envelope CalculationsDocumento4 pagineSteam Generation Thermodynamics: Efficiency Improvements Can Quickly Be Identified With Back-Of-The-Envelope CalculationsDaniel Puello RodeloNessuna valutazione finora

- Flexible Heat Exchangers NetworkDocumento7 pagineFlexible Heat Exchangers NetworkDaniel Puello RodeloNessuna valutazione finora

- Gnucash Guide PDFDocumento288 pagineGnucash Guide PDFDaniel Puello RodeloNessuna valutazione finora

- 11 Chemistry Test Papers PDFDocumento231 pagine11 Chemistry Test Papers PDFAnonymous tdtTl8KypNessuna valutazione finora

- 18 - Irreducible Tensor Operators and The Wigner-Eckart Theorem PDFDocumento30 pagine18 - Irreducible Tensor Operators and The Wigner-Eckart Theorem PDFUltrazordNessuna valutazione finora

- 17 TonsDocumento8 pagine17 Tonsabuzahrau100% (3)

- Free Vibration Experiment (Nabil)Documento3 pagineFree Vibration Experiment (Nabil)Muhammad Nabil Farhan0% (1)

- Michelson-Morley ExperimentDocumento23 pagineMichelson-Morley ExperimentKamalakanth RvNessuna valutazione finora

- University of Steel Technology & ManagementDocumento26 pagineUniversity of Steel Technology & ManagementAviNessuna valutazione finora

- Newton's Laws Problem Solving Strategy for Mechanics Problems Under 40 CharactersDocumento4 pagineNewton's Laws Problem Solving Strategy for Mechanics Problems Under 40 Characterstahapak93Nessuna valutazione finora

- Uodguzikvcsz) FszkjadDocumento30 pagineUodguzikvcsz) FszkjadG M Ali KawsarNessuna valutazione finora

- Problem Set 1Documento2 pagineProblem Set 1ISmi Nurlatifah0% (1)

- Physics 102 Course Unit 1 Mechanics Motion and KinematicsDocumento16 paginePhysics 102 Course Unit 1 Mechanics Motion and KinematicsShdzoo ZoroNessuna valutazione finora

- Che g8 q3 w4 d4 RevDocumento7 pagineChe g8 q3 w4 d4 RevRowena Sta MariaNessuna valutazione finora

- Sample P1Documento12 pagineSample P144shaurysinghXII-BNessuna valutazione finora

- Conv. Calculation - BHEL Maitree Bangladesh - Part 1 - CEMA 6 - 07.08.18Documento3 pagineConv. Calculation - BHEL Maitree Bangladesh - Part 1 - CEMA 6 - 07.08.18Bimal DeyNessuna valutazione finora

- Unit 10-Short QuestionsDocumento5 pagineUnit 10-Short QuestionssajjaddrNessuna valutazione finora

- Method of Testing Determination of Aggregates Crushing Value (ACV)Documento2 pagineMethod of Testing Determination of Aggregates Crushing Value (ACV)shahrilzainul77Nessuna valutazione finora

- Mechanism Acceleration ExamplesDocumento38 pagineMechanism Acceleration ExamplesApple VidalNessuna valutazione finora

- Ceramic crystallization and mechanical propertiesDocumento11 pagineCeramic crystallization and mechanical propertiesPhước TrầnNessuna valutazione finora

- GW Theory IntroDocumento18 pagineGW Theory IntroBhat SaqibNessuna valutazione finora

- Merged-PCM-923, 023, 2123 A-Lot RW GCM RR (14.07.21)Documento8 pagineMerged-PCM-923, 023, 2123 A-Lot RW GCM RR (14.07.21)Heath LedgerNessuna valutazione finora

- TWI Ultrasonic Inspection Coursework 5 PDFDocumento4 pagineTWI Ultrasonic Inspection Coursework 5 PDFHassanSobohNessuna valutazione finora

- Grade 11 Physical Science Course of StudyDocumento3 pagineGrade 11 Physical Science Course of StudyJobeth Presto AlonzoNessuna valutazione finora

- COMSOL Multiphysics Models For Teaching Chemical Engineering FundamentalsDocumento20 pagineCOMSOL Multiphysics Models For Teaching Chemical Engineering FundamentalsHabli MawardiNessuna valutazione finora

- Schrödinger's Cat Clarifications Ita+EngDocumento4 pagineSchrödinger's Cat Clarifications Ita+EngLeonardo RubinoNessuna valutazione finora

- Din 1522 PDFDocumento17 pagineDin 1522 PDFKuldeep Jangra100% (1)

- Einstein, Bohr and QuantumDocumento3 pagineEinstein, Bohr and QuantumaimtotestingNessuna valutazione finora

- Newton's Views On Aether and Gravitation - L. RosenfeldDocumento9 pagineNewton's Views On Aether and Gravitation - L. Rosenfelddavid199415Nessuna valutazione finora

- MHS Physics Problems Chapter 1Documento27 pagineMHS Physics Problems Chapter 1Dina Ashraf0% (1)

- 9701 s09 QP 5Documento12 pagine9701 s09 QP 5Hubbak KhanNessuna valutazione finora

- Marco HID Architectural Downlighting Catalog 1991Documento88 pagineMarco HID Architectural Downlighting Catalog 1991Alan MastersNessuna valutazione finora

- Ligand Field N MOTDocumento12 pagineLigand Field N MOTLata Sharma100% (1)