Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Types of Damage

Caricato da

tazjuan10 valutazioniIl 0% ha trovato utile questo documento (0 voti)

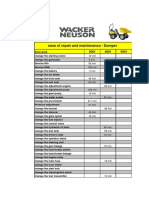

11 visualizzazioni1 paginaWacker Tipo de daños en orugas

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoWacker Tipo de daños en orugas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni1 paginaTypes of Damage

Caricato da

tazjuan1Wacker Tipo de daños en orugas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 1

BmoGesTone

Steel Cord Breakage |

Definition

» Embedded steel cord breakage

Location of Damage

» Carcass

Corrective Solution

» Replace rubber track

Causes of Damage

» There are several causes for this type of damage such as: over-tension, steel cord damage,

and a combination of both.

» Over-tension can occur during the following situations:

When the rubber track partially or completely de-tracks; the idler, rollers or sprocket can ride

up onto the steel embed projections (guide teeth) (Fig. 1).

When a rubber track de-tracks, the track can become lodged between the undercarriage and

the main body of the machine.

When large objects such as: rocks, timber, and other debris or foreign materials enter the

undercarriage, they can cause packing between the track and undercarriage components.

This can exert very high stress on the steel cords leading to steel cord breakage (Fig.2).

When the recoil/tensioning system does not function properly.

» Steel cord damage can occur in the following circumstances:

When the rubber track gets a deep cut or open crack, that reaches the steel cords.

When debris such as: sand, rocks and packed soil enter the undercarriage, steel cord

abrasion can occur.

When moisture and some chemicals contact the steel cords, corrosion can occur.

=a

n Fig. 1 Fig. 2

Preven

» Regular monitoring of track tension (See machine's maintenance manual).

© Be alert to foreign objects on the ground and avoid sharp, hard or large objects.

» Avoid unnecessary quick or hard turns to prevent de-tracking.

» By minimizing sharp turns less material will enter the undercarriage.

» Regularly wash the undercarriage to remove dirt and foreign material.

3

Potrebbero piacerti anche

- LP Inglês 3tnv82a-Gge YANMARDocumento27 pagineLP Inglês 3tnv82a-Gge YANMARtazjuan1Nessuna valutazione finora

- Service KitsDocumento22 pagineService Kitstazjuan1Nessuna valutazione finora

- Service Kit Contents 380.480.680.780.750. 1150.350.550 & 650 All New MachinesDocumento13 pagineService Kit Contents 380.480.680.780.750. 1150.350.550 & 650 All New Machinestazjuan1Nessuna valutazione finora

- En Dumper Maintenance TimeDocumento3 pagineEn Dumper Maintenance Timetazjuan1Nessuna valutazione finora

- SHB 501s en 1000155663 1 0Documento164 pagineSHB 501s en 1000155663 1 0tazjuan1100% (1)

- Calculation of Maintenance Work According To The Maintenance Plan A B or CDocumento101 pagineCalculation of Maintenance Work According To The Maintenance Plan A B or Ctazjuan1Nessuna valutazione finora

- SHB 701 en 1000164190 2 0Documento301 pagineSHB 701 en 1000164190 2 0tazjuan1100% (4)

- 06 WN Trackinfo Compact en 23 OkDocumento23 pagine06 WN Trackinfo Compact en 23 Oktazjuan1Nessuna valutazione finora

- SHB 3001 en 1000156004 2 0Documento214 pagineSHB 3001 en 1000156004 2 0tazjuan1Nessuna valutazione finora

- Operator's Manual: DumpersDocumento141 pagineOperator's Manual: Dumperstazjuan1Nessuna valutazione finora

- BA 3001 en 1000172672Documento140 pagineBA 3001 en 1000172672tazjuan1Nessuna valutazione finora

- SHB 1501 en 1000144667 1 0Documento142 pagineSHB 1501 en 1000144667 1 0tazjuan1Nessuna valutazione finora

- Principles of Mobile HydraulicDocumento101 paginePrinciples of Mobile Hydraulictazjuan1100% (1)

- CE Special Tools Service enDocumento5 pagineCE Special Tools Service entazjuan1Nessuna valutazione finora

- A6vm Ha1r1Documento7 pagineA6vm Ha1r1tazjuan1Nessuna valutazione finora

- Electrical System p9000Documento50 pagineElectrical System p9000tazjuan1Nessuna valutazione finora

- PTX Pte300Documento2 paginePTX Pte300tazjuan1Nessuna valutazione finora

- Ufm Interpretation Synopsis PDFDocumento1 paginaUfm Interpretation Synopsis PDFtazjuan1100% (1)

- AL4000DDocumento74 pagineAL4000Dtazjuan1Nessuna valutazione finora

- CompactlogixDocumento56 pagineCompactlogixtazjuan1Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)