Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manta Rig Move 1 - Songkhla - E. Platform

Caricato da

s v poyilCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manta Rig Move 1 - Songkhla - E. Platform

Caricato da

s v poyilCopyright:

Formati disponibili

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

RIG ATWOOD MANTA

RIG MOVE

PROCEDURE /

VOYAGE

PLANNING

Move No:

01

From:

PPL Shipyard,

Singapore

To:

Songkhla-E Platform Location Block G5/43, Gulf of Thailand

Location: LAT: 07o 34 18.7N

Long: 100o 37 10.0 E

ETD: 1st December 2012

Tow type: Extended tow

TABLE OF CONTENT

1. INFORMATION 3

1. LOCATION INFORMATION 4

2. RESPONSIBILITIES 5

3. DEPARTING LOCATION 7

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 1 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

4. TOW ROUTE 8

5. ARRIVING DESTINATION LOCATION 12

6. PRELOADING OPERATION 13

7. COMMUNICATION 14

8. MEDIVAC PLAN DURING TOW 14

9. POSITION REPORT 14

10. EMERGENCY CONTACTS 14

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 2 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

1. INTRODUCTION

The BMC 400 Pacific class Self Elevating MODU RIG ATWOOD MANTA is scheduled to move from PPL

Shipyard, Singapore to Block G5/43 offshore Songkhla-E location in the Gulf of Thailand. The departure and

arrival coordinates are as follows:

Departure co-ordinates Latitude: 01 17' 47" N

PPL Shipyard Longitude: 103 44' 51" E

Arrival co-ordinates Latitude: 07 34' 10.913" N

Songkhla E Platform

Block G5/43 Longitude: 100 37' 21.542" E

The move will be conducted in accordance with RIG ATWOOD MANTA Marine Operations Manual.

Responsibility of the safety of personnel and integrity of the rig will at all times remain with the OIM (Offshore

Installation Manager) during elevated mode and Barge Master during a float mode.

A pre-move meeting will be held and will be attended by key personnel involved in the rig move. The meeting

will also be attended by the Captains of the towing and anchor handling vessel wherever possible. The purpose

of this meeting will be to ensure that all personnel are aware of their job function and responsibilities and to

agree on any technical aspects and constrains that may affect the operation.

Other discussion in the meeting should include the rig move procedures, voyage plan, charts, site survey

reports, tidal height predictions, surface current predictions, navigational hazards, weather prediction and

procedures prepared by the AHTS(s).

An additional pre-jacking meeting should be held on board the rig before the move to review all pre-move

checks and to ensure that all fundamental safety systems on the rig are fully operational. This will include but

not limited to ballast pumps, fire pumps, emergency generator and watertight integrity. Comprehensive pre-

move checks will have been undertaken on jacking system, winches and all associated equipment involved in

the rig move operation. Stability calculations and loading condition for the intended transit will have been

prepared and remain available for review.

Weather forecast will be provided by two independent recognizable sources. Updated weather forecast will

remain available on a 24 hours basis via email / fax. 4 days weather forecast should commence 4 days prior to

the move and should be sent to the rig twice daily.

The weather limits for jacking operations are:

Wind Speed: 25 Knots

Sea state (combination of wind, wave and swell): 1.83 m

Survey equipment should be installed and made available before the final approach to the destination location

is made. Proper functioning and accuracy of the equipment should be ensured before the final approach. All

debris items, pipelines and other sea-bed obstructions should be displayed on the navigational screen before

the final approach.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 3 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

2. LOCATION INFORMATION

Departure location: PPL Shipyard, Singapore

Rig Heading: 317

Water Depth: 5.7m

Arrival location:, Offshore Thailand Block G5/43 Songkhla- E Location

Seabed Soil Stiff clay from 5 meters

Rig Heading: + - 90 degree

Penetration Bow 4.8 meter; Port 4.8 meter; Starboard 4.8 Meter

Water Depth: 20.0 meter (66 ft.) LAT

Air Gap 2 meters

Seabed Soil Very soft clay from 0-3.0 meters

Obstructions Dockclay

Soft and surrounding

from installations

3.0-7.8 meters

Firm clay from 7.8-2.5 meters

Penetration Expected 8.5 to 11.3mtrs

Air Gap 11.5 to 27.4mtrs

Anchor chain north of location. Anchor spread from FPSO

Obstructions

North side of location. Crude oil line north side of location.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 4 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

3. RESPONSIBILITIES

3.1 Offshore Installation Manager (OIM)

O.I.M will have full responsibility for the integrity of the unit and the safety of all personnel on board when the rig

is in elevated mode.

O.I.M will have full responsibility for the integrity of the unit and the safety of all personnel on board when the

rig is in a-float mode.

When advised by Atwood senior management that the rig has been cleared for departure and having consulted

with the Barge Master and Warranty Surveyor, he will decide when it is safe and practicable to commence

moving operations within the limits of the units Marine Operations Manual.

3.2 Client / Operators representative(s)

The Operator Coastal Energy will be represented by the Drilling Supervisor who will remain clients principal

authority on board. He may be accompanied by a Marine Representative from Coastal Energy. He will liaise

with OIM / Barge Master as necessary to ensure the operator work plans are implemented properly. He will

endorse the completion of all work activities and responsible for accepting the final position of the rig at the new

location.

He will liaise between the personnel on the rig and Coastal Energy shore-base. All communications between

the rig and the operator shall pass through him via the OIM / Barge Master.

3.3 Tow Master

The Atwood approved Tow Master will be responsible to the OIM / Barge Master for safely moving the rig from

its current location to the next location. The responsibility will commence with confirmation of all preparation

checks to a point when the rig has been safely preloaded and elevated to operating air gap. His presence on

board will in no way abdicate the rig crew and OIM of their respective duties and responsibilities.

He will communicate with the towing vessels and instruct them to ensure safe voyage transition and final

positioning of the rig at the destination location.

He shall lead the discussion during pre-move meeting and pre-approach platform meeting.

He shall co-ordinate with Barge Master on aspects of stability and jacking. He will also inspect the towing

vessels to ensure their suitability.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 5 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

3.4 Barge Master

Barge Master will maintain good communication with the Operators representative on board with regard to

statutory permission to approach next location and acceptance of final position.

The Barge Master will ensure deployment of sufficient and competent rig crew for the safe and efficient conduct

of the move operation. He will ensure that the move is conducted within the outline of the Marine Operations

Manual. He will have the prime responsibility of all jacking operations.

He will prepare the stability sheets for the transit loading condition and ensure that they are available for review.

He will ensure proper and adequate sea fastening / lashing of all loose items for the sea passage.

3.5 Warranty Surveyor

The Marine Warranty Surveyor is an independent consultant whose function is to ensure that MODU operation

does not exceed an acceptable level of risk. The extent of such risk is defined by the parameters, criteria and

limitations set forth by the rigs design, as included in the Marine Operations Manual.

The attendance of the Warranty Surveyor on board is in an advisory role only. He will issue a Certificate of

Approval for the move and will ensure that a Certificate of Approval for the location is in place. He will inspect

the towing / anchor handling vessels to ensure their suitability for the operation.

3.6 Masters of Tow Vessels

They will be responsible for ensuring that the operations of their vessels are carried out in a safe and efficient

manner with due regard to prevailing weather conditions and crew exposure on deck during rig move. The

Masters will conduct operations in line with the International Rules for the Prevention of Collision at Sea,

relevant marine regulations and good seamanship.

They are to immediately advise the Tow Master/ OIM of any concerns regarding the ongoing / planned

operations in which they feel that the vessel crew may be subjected to unacceptable risks. In addition, they are

to immediately advise of any failure of equipment or machinery where the capabilities of their vessels may be

reduced.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 6 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

4. DEPARTING LOCATION

1. Reduce manning of non-essential service personnel as applicable per the Marine Operations Manual and

Atwood policy.

2. Retract the cantilever to the stowed position and secure per the Marine Operations Manual.

3. Utilizing the pre-move checks list and Marine Operations Manual, secure the rig for tow.

4. Hold a pre-jack/pre-move meeting with available crew.

5. Once all checks are complete and all leg stations are ready, jack-up 1 foot to confirm proper operations of

the jacking system and associated machinery.

6. When suitable weather window has been established and agreed by OIM, Barge Master and GL Noble

Denton surveyor, jack down to 3 meter air gap.

7. Connect the harbour tugs as per instructions of the harbour pilots / harbour tow master. The tugs will be

connected with soft lines.

8. Lower the hull to 2 meter draft for watertight integrity checks

9. On completion of integrity checks, lower the hull to floating draft. Connect jetting lines to legs (if deemed

necessary) and commence freeing legs.

10. Confirm anchors are properly bolstered and secondary securing is in place.

11. When disengaging bottom, raise the bow leg first (2 to 3 feet) and then all legs altogether. Move off location

and berth maintaining slow speed until all legs are well clear of the bottom.

12. The unit will depart from its current location at PPL Shipyard under the direction of the harbour pilots &

harbour tow master and proceed to a pre-agreed position where the harbour tugs will hand over tow to the

designated towing vessel. Continue raising legs till the spud-cans are retracted within the hull.

13. At the pre-agreed position, the rig will be held in position by the harbour tugs to facilitate connection of the

designated towing vessel Magellan 2 to the main towing bridle. Tow vessel Pacific Bronze will be

connected to the Stbd forward auxiliary tow line. Once the towing vessel is connected, the harbour tugs will

be released.

14. The harbour pilot and harbour tow master will disembark soon after the tugs are released. The rig and tow

will proceed to the new location on the agreed tow route under directions from tow master. Towing vessel

shall log consumables on board at the time of departure.

15. If applicable, continue raising the legs until in the agreed tow position having due regard for any shallow

hazards in the area of transit. .

16. Once the legs are in the tow position the rig is to advise the lead tow vessel Master of the overall draft of the

rig.

17. Once the rig is underway, all shore base communications will be via Inmarsat phone or facsimile.

18. Integrity checks will be maintained throughout the tow on a regular basis and logged for future reference.

Any problems or discrepancies should immediately be relayed to the Barge Master and the Warranty

Surveyor.

19.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 7 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

5. TOW ROUTE

The tow will proceed from Singapore to the Songkhla-E Platform location with the tow vessel(s) connected as

directed by the tow master.

The rig will transit on the route as outlined below.

W.P. LAT. LONG. Course DIST. ETA ARR. DIST TO REMARKS

NEXT TIME GO

W.P.

PPL Pdn 01o 17.530 N 103o 45.300 E 560 PPL Shpyard

Jr 01o 16.850 N 103o 44.700 E 220 1 559 East Jurong channel

Jr jn 01o 16.500 N 103o 45.100 E 132 1 558 Selat Pandan

Sp 01o 12.500 N 103o 40.000 E 232 6.5 551.5 Rasu Buoy

023 01o 11.610 N 103o 36.500 E 256 4 547.5 N.Nipa

024 01o 06.100 N 103o 33.100 E 212 6.5 541 TSS Singapore

025 01o 02.350 N 103o 39.400 E 120 7 534 Pulau Cula

026 01o 05.050 N 103o 43.200 E 055 4.5 529.5 P.Tekong

027 01o 08.490 N 103o 46.550 E 045 4.5 525 Helen Mar Reef

028 01o 09.650 N 103o 48.300 E 057 2 523 Karang Banten

029 01o 13.600 N 103o 56.750 E 065 9.5 513.5 Teluk jodoh

030 01o 16.700 N 104o 20.000 E 082 23.5 490 T.Sading

031 01o 35.000 N 104o 40.000 E 048 27 463 Eastern Bank

032 03o 40.000 N 104o 40.000 E 360 65 398 P.Pemanggil

033 04o 00.000 N 103o 40.000 E 323 102 296 P.Kuanan

034 04o 40.000 N 103o 40.000 E 360 40 256 T.Pilur

035 05o 00.000 N 103o 30.000 E 331 23 233 Kuala Merchong

036 06o 15.000 N 103o 00.000 E 338 81 152 Tompok Putri Saadong

037 07o 15.000 N 101o 00.000 E 297 134 18 Churchill Patches

038 07o 15.000 N 100o 42.000 E 270 18 Arrival Songkhla Anchorage

The total distance between locations is 560 nautical miles and the overall draft of the tow is to be relayed to the

Master of the lead tow vessel once the legs are at the required position.

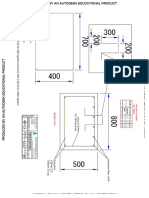

Figure 2

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 8 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

2. CHARTS USED FOR THIS PASSAGE

No. Chart Number Chart Correction update

01 3383 2012 119,1591,1592

02 3831 2012 119,177,1116,3001

03 2403 2012 1873,2044,2595,2846,3001

04 2869 2011 1341,2182,2510,2510.2511,2676

05 3445 2012 3429

06 3446 2012 3155

07 3447 2010 755,1248,3460,3681,4599

08 3542 2011 956,3266

VOY. NO. : 023 TTL DIST. 560 NM

VESSEL NAME : AHT.MAGELLAN 2

FROM : PPL Pandan, Singapore

MASTER : Capt. Mursalim Rahim

TO : Songkla, Thailand

DATE : 07 / Dec / 2012

Est. Speed : 3.0 Kts (

Steaming : Total 7 day 18 hrs 40 mnt Estimated

Est. Speed : 3.5 Kts

Steaming : Total 6 day 16 hrs Estimated

Est Speed : 4 Kts

Steaming : 5 day 20 hrs Estimated

The above tow route will have to be reviewed by the tow master, warranty surveyor, barge master and the

towing vessel master.

Rig and tow vessels to ensure they are loaded with fuel for at least 20 days tow period to account for

unforeseen weather conditions and other possible delays.

As per the Marine Operations Manual the bollard pull requirement for a single vessel tow in the region is 150

tons. Two vessels minimum 85 tons bollard pull.

Minimum two vessels having a total bollard pull of 250 tons are required for the final approach to the platform

soft pin location

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 9 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

6. ARRIVING DESTINATION LOCATION Manta

1. When in vicinity of the destination location, a pre-approach meeting will be carried out. The rig will

approach as agreed during the pre-move meeting. Permission will be obtained from field MIC before

entering the 1000 m zone.

2. At a distance agreed by the Tow Master, Barge Master & Marine Warranty Surveyor from the

Songkhla-E platform location, the tug will shorten tow cable and alter course onto approach heading.

The final approach will be carried out at the discretion of the Tow Master and Barge Master taking into

account the weather, visibility etc.

3. At an agreed distance, by the Tow Master, Barge Master & Marine Warranty Surveyor from the

Songkhla-E platform location the rig will commence lowering legs to 30 feet off bottom. Maintain speed

of+/- 0.75 knots. An assist tug(s) will be connected to the aft end(s) of the rig at the discretion of the Tow

Master.

4. Verify proper operation of survey equipment and lower legs closer to the seabed, +/- 15 feet off

bottom, if clear. Carry out manual RPD checks and adjust as necessary. Prepare rig for pinning.

5. The rig will then be maneuvered to within the tolerance limits and stabilized on the required heading.

Once stabilized, the rig will be pinned at the designated soft pin location.

6. The rig will then achieve initial penetration at the soft pin location before deploying the four anchors at

the recommended angles and prearranged distance. (Note: anchors will be secured on deck (kam-

fork or shark jaw in locked position) of the AHTS at all times when crossing pipelines or other subsea

obstructions).

7. The rig will then be winched on to the final location in a controlled manner on the anchors. The stern will be

manned with radio communications at all times at the final approach.

8. Water depth is to be monitored while moving onto location taking into account tides and bathymetry. It is

imperative that accurate information for the tides on the day is made available to the rig and should be

sought from the survey company and/or the Operator.

9. When inside the tolerance area and agreement of all parties concerned, lower legs to 3 feet off

bottom, ready for pinning. (Note: the rig needs to be positioned in a manner and accuracy that all

platform slots can be reached required for the drilling program.

10. Maintain rig speed at less than 0.5 knots, and pin the rig as appropriate.

11. Once the rig is soft pinned, check to ensure the positioning equipment is functioning correctly prior to

requesting acceptance from the Operator Representative.

12. Each leg may be raised and lowered to release any residual torque.

13. Once the position is accepted, either the assist or the lead tow vessel will be released.

14. The rig will be jacked to a minimal air gap as recommended by the Warranty Surveyor and will

prepare for preloading operation.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 10 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

Penetration curves to paste here.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 11 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

7. PRELOADING OPERATION

Once the rig position has been accepted, jack the hull to zero air gap.

The preload operation will be carried out with the hull at a positive draft on an ebbing tide. This will allow the tide

to fall out from under the hull as the tanks are filled to maintain hull placement as close to water line as possible.

The draft will be decided by the Barge Master in consultation with the Warranty Surveyor and taking into

account the state and range of tide.

Single leg preloading at draft will commence with the bow leg. A leg footing reaction of 9266 tonnes (20,429

kips) is to be maintained during preloading of all legs .

Preload will be held for 3 hours (static test) on all legs at minimum airgap. If the leg settles, adjustments will be

made to level the hull and the 3 hours hold period will commence again. At no time during jacking should the

load exceed 370 MT per pinion.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 12 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

Continuous monitoring of applied preload against achieved penetration should be carried out. This should then

be compared to the predicted load penetration curve

Once the static holding period for all legs is completed without further settlement, all preload should be dumped.

The towing vessel should be released from the bridle and the hull elevated to operational air gap.

Level the hull at operational air gap. Engage the fixation system, secure the jacking console and release the leg

for drilling operations.

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 13 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

8. COMMUNICATION

It is imperative that lines of communication and responsibility have been clearly defined and are understood by

all concerned. It will be the responsibility of the Barge Master to ensure that these actions are complete prior to

commencement of the operation. Specific attention will be made to the interface requirements of passing and

recovering the anchors and handling wires between the rig and the anchor handling vessels when anchors and

handling wires are being used to move the rig onto location. The Barge Master will accept, or suitably delegate

responsibility, to ensure that a competent person is present on the deck while passing or recovering the tow

wire and/or anchors to/from the vessel. This person will be equipped with portable VHF communications, and

will be in direct contact with the anchor winch operator, the crane operator and the anchor-handling vessel

Captain.

9. MEDI-VAC PLAN DURING TOW

The Emergency Response Plan for the tow with contact numbers will be used in case of any emergency

requiring MEDI-VAC from the vessel during the moving operation.

10. POSITION REPORT

Position reports will be given by the lead tug every 6hrs.

11. EMERGENCY CONTACTS

MODU Shore Base Contacts

Name Title Office Mobile Email

Graham Robertson Operations Manager 8565 +66 912290831 grobertson@atwd.com

Ronald Timmerman Operations Superintendent 8566 +66 912290832 rtimmerman@atwd.com

Benn Hooper Operations Administrator 8545 +66 912290833 bhooper@atwd.com

Rhyian Manibog Manta Secretary TBA +60 863977509 CPiyathaham@atwd.com

Ku Abdullah bin Regional HSE Coordinator +60 (0) 389257471 +60(0)123823133 kosman@atwd.com

Ku Osman

Atwood Offshore Drilling Limited (Thailand Branch) Phone +66 (0)27457305

589/143 Central City Tower, 26th

Shorebase Office Floor, Bangna-Trad Road. Fax + 870773234239

Location I Address Bangna,

Inmarsat + 870773234239

Bangkok 10260

Thailand

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 14 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

MODU Contacts

Office Phone Number Office Phone Number

OIM +1 281 749- 3040

Radio Room +1 281 749- 3034 lnmarsat + 870773234239

Barge Engineer +1 281 749- 3039 Company Man TBC

STC I Medic +1 281 749- 3032 Store Keeper TBC

RMS Maint. Sup. +1 281 749- 3035

Company Corporate Contacts

Name Title Office Mobile Email

Mac Polhamus Vice President, Operations + I 281 749 7804 +I 281-210-8555 mpolhamus@atwd.com

Terry Bailey Senior Operations Manager + I 281 749 7954 +I 832 766 7954 tbailey@atwd.com

John Gidley Director, HSE + I 28 1 749 7870 +I 832 293 7922 jgidley@atwd.com

Arthur Dutton Operations HSE Manager + I 281 749 7994 +I 281 734 3799 adutton@atwd.com

Tom Hanrahan Marine Operations Manager +I 281 749 7915 thanrahan@acwd.com

Mike Koenig Marine Operations +I 281 749 7952 mkoenig@atwd.com

Superintendent

Joe Grimes Regulatory Compliance + I 28 1 749 7857 + I 832 375 4299 jgrimes@acwd.com

Atwood Oceanics

Corporate Office Phone +I 28 1 -749-7800

1 5835 Park Ten Place Drive

Location I

(77084) P.O. Box 218350 (772 18)

Address Fax +I 28 1 -715-5416

Houston, Texas USA

Administration (Flag State) Contact

Phone TBC

Marshall Islands

Fax TBC

Flag State Name (Awaiting information on which area office covers

& Address Thailand waters) E-mail TBC

Website http://www.register-iri.com

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 15 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

CEC International

EMERGENCY CONTACT LIST

CEC International, Ltd. (Thailand Branch)

39th floor Unit 3901-3904 Exchange Tower

388 Sukhumvit Road, Klongtoey, Bangkok 10110 Updated:

18/10/2012

Tel. (66) 2 610 0555 Fax (66) 2 610 0541 International call 0 = +66

Name Title Business Phone Mobile Phone E-mail Business Fax

ERCName

Bangkok 02 6100 535

Operation Conference Room Conference call from outside dial 02 610 0500 02 610 0541

Emergency Control Room

02 6100 530 then 2580#, Say name then #

02 6100 531

Songkhla Mr. Suwat P.ext.666 074 331 031 081 541 7476 suwatp@coastalenergy.com

Emergency Support Center

Mr. Thammasak N. ext. 630 074 331 030 089 669 4066 thammasakn@coastalenergy.com 074 331 029

Guard house ext. 688

John Griffith General Manager 02 610 0599 083 549 3851 johngriffith@coastalenergy.com

081 921 1061

Ken Hemmerich Operation Manager 02 610 0577 khemmerich@coastalenergy.com

084 453 5622

Rapee Kudisri Drilling Manager 02 610 0591 085 486 7458 rapeek@coastalenergy.com

John Sayre Production Manager 02 610 0515 081 830 5735 jsayre@coastalenergy.com

Ronald The Technical Manager 02 610 0508 081 732 0461 rthe@coastalenergy.com 02 610 0541

Witthaya Khemrach Marine Facilities Manager 02 610 0594 081 302 0032 witthayak@coastalenergy.com

Keith Brazier Facilities/Construction Manager 02 610 0546 081 752 4249 kbrazier@coastalenergy.com

Clifford Smith Site Construction Superintendent 02 610 0507 089 666 7002 csmith@coastalenergy.com

Pavinee Thappenthai External Affairs Manager 02 610 0595 081 558 7511 pavineet@coastalenergy.com

Suvit Putcharaporn HSE Manager 02 610 0585 081 688 1013 suvitp@coastalenergy.com

Jamras Mualchaipoom HSE Officer 02 610 0543 081 385 2321

jamrusm@coastalenergy.com

SKL-A Production Platform "Soraya"(Jackup)

Name Public telephone Internal Phone Mobile Phone E-mail Business Fax

Soraya production platform

Marine VHF Channel 16 156.8 MHz & Channel 10 156.5 MHz

skl_a@coastalenergy.com

Call Sign: SORAYA

OIM CEC Inter 02-610 0580 NCT Tie Line 580 082 428 8250 oim@coastalenergy.com

Operation Supervisor & HSE 02-610 0588 NCT Tie Line 588 skl_a@coastalenergy.com

Work Over Site Manager (WSM) 02-610 0538 NCT Tie Line 538 wsm@coastalenergy.com

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 16 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

SKL-C Production Platform "BuaBan A" (Fixed platform)

Name Title Business Phone Mobile Phone E-mail Business Fax

VHF ch. 16/10 Bridge 02-6100 503 085-370-4820

Coastal Energy Resolution FSO V-sat tel +44 2031454626 OIM 02-6100 509 cer@thomeships.com ; Bridge.cer@thomeships.com

V-sat tel +44 2031454627 Visitor 02-6100 514

Jarin K 081 813 8897

Control room Operation Supv. 02 610 0567 NCT Tie Line 567 skl_c@coastalenergy.com

Woravud 081 321 5001

SKL-D Production Platform "Seafox 3" (Jack-up)

Name Public telephone Internal Phone Mobile Phone E-mail Business Fax

VHF 16 Inter. Marine Safety, VHF 17 Working channel

Seafox production platform VHF 10 CEC Vessels, VHF 72 - CEC Vessel. Call sign: Seafox

Three

Field Superintendent 02-610 0560 NCT Tie Line 560 088-088-1827 fs@coastalenergy.com

- Rainier Verhulst is still the Operations manager +31 6642 18007 rwv@workfox.com

Bridge (OIM Office) 02-610 0570 NCT Tie Line 570 089 717 1330 oimsf3@workfox.com

Immasat phone number

Radio operator NCT Tie Line 571 radiosf3@workfox.com

00 - 881 631 643 474

SKL-E Production Platform " Richmond "

Name Public telephone Internal Phone Mobile Phone E-mail Business Fax

Marine VHF Channel 16 156.8 MHz & Channel 10 156.5 MHz

MOPU Superintendent Call Sign: Seafox Six mopusup@coastalenergy.com

Radio room 02-610 0549 NCT Tie Line 549 089 503 7516 radio.rm@coastalenergy.com

Wasan 090-969-0451

HSE 02-610 0573 NCT Tie Line 573 rm.safety@coastalenergy.com

Tanin 085-503-3825

EPTI Supv. 02-610 0565 NCT Tie Line 565 skl_g@coastalenergy.com

STORE ( Anantachai / Taweep ) 02-610 0596 NCT Tie Line 596 081-609-3567; skl_g@coastalenergy.com

086-8169428

SKL- G Production Platform "Seafox 6" (Jack-up)

Name Public telephone Internal Phone Mobile Phone E-mail Business Fax

Marine VHF Channel 16 156.8 MHz & Channel 10 156.5 MHz

Mossur Maciej/Alex Bozek seafox6@workships.nl

Call Sign: Seafox Six

Bridge (OIM Office) 02-610 0574 NCT Tie Line 574 089 503 7516 seafox6@workships.nl

EPTI Supv. 02-610 0564 NCT Tie Line 564 skl_f@coastalenergy.com

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 17 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

Production contractors

Expro PTI Prod. Manager CHRIS CLEVELAND 090 651 0565 Chris.Cleveland@exprogroup.com

Kevin McCartan Region Mgr. Kevin - 084 454 8881 Kevin.mccartan@exprogroup.com

Deo Asst Production Manager Deo - 087 697 2797 Phathaithep.Anantapeuch@exprogrou

Kied - Admin. Manager Kied - 081 830 5281 p.com kied.kruafah@expropti.com

Kanokpan(Ying) SKL Secretary Ying - 086 888 4431 yingsongkhla@pti-thailand.com

Mr.Chayaphon Sukvivutnagorn HSE - 088 809 9592 Chayaphon.s@exprogroup.com

Gerrit Jan Smans, Operations Director +31 1 04530377 gerrit@workships.nl

SF6

Martijn le Duc, NSI +31 6 10295006 m.leduc@workships.nl

Workships Netherland

Mike Barret, Rig Master masterseafox6@hotmail.com

Rainier Verhulst, Ops. Director +31 664 218 007 rwv@workfox.com

SF3

Piet Vliek, Rig Manager +65 93 510 096

Workfox Netherland pvl@workfox.com

Guus Lemmers, Rig Manager +31 653 344 772 glm@workfox.com

Compass Energy Office Compass energy +0065-6376-1311

nitin.ahuja@compassenergy.com

Singapore

Capt. Nitin (HSE) +0065-3116-9171

Boonpen Kitiyamas 081-969 6100 boonpenk@adisorn-skl.com

Adisorn

Thawat Rattana 081-957 2926

Mr. Kittisak Rakthai 074 338558 084 387 7940 Kittisak.rakthai@sodexo.com

Sodexo Amarit

Ms. Ratchatida Loyjiw 074 338543 084 387 8456 Ratchatida.LOYJIW@sodexo.com

Randy Vissers Project Manager 085 9104 004 081 342 4830 randall.vissers@ge.com

Arkom Khundat GE SKL Sup. 089 967 4343 Arkom.Khundat@ge.com

GE Oil & Gas Peter Seddon (Base Mgr.) 089 897 8801 Peter.Seddon@ge.com

Werawan Nilvanich (Admin.) 085 669 1010 Weerawan.Nilvanich@ge.com

EMAS Energy Mr. Suttiban Hongsamart 087 743 7779 suttiban.hongsamart@emas.com

SCHLUMBERGER Thitikul Nagadhana (Account Mgr) 089-924-9135 TNagadhana@slb.com

SPIE Kabkaew Sanlee,Ms. Trinnawan 074-496923-4 088-7905717 kabkaew@spinteng.com

R.

Nalco Industrial Services Teanjuob Mahantassanapong Fax +662 2738834 Tel +662 2738838 tmahantassan@nalco.com

(Thailand)

MI SWACO, A Schlumberger Brian Burr +65 97200917 +66 8 1928 3980 bburr@slb.com

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 18 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla-E Platform Location

Rig Move No: 01 Client: Coastal energy Issue Date: November 2012

Drilling rig "Vicksburg" (Jack-up)

Name Title Business Phone Mobile Phone E-mail Business Fax

Immasat phone number: 00 - 870 764 684 341

Atwood Vicksburg

Marine VHF Channel 72 156.625 MHz Call Sign: Atwood Vicksburg - VNWD vicks_radio@atwd.com

Radio Room Public phone number: 02 610 0551

Brian Lockwood / Czar Acero STC / Medic Operations +1 281 749 8702 vicks_stc@atwd.com

Tony Wilson Superintendent Operations 089 812 7224 twilson@atwd.com

Larry W. Holloway Manager / Director 02 745 7305 087 984 9882 lholloway@atwd.com

Michael Van Keuren Rig Administrator 02 745 7305 089 529 0022

Drilling DSM 02 610 0550 dsm@coastalenergy.com

HWO WSM 02 610 0538 wsm@coastalenergy.com

Wild Well Control, Inc Mr. Ben Malina / Director +1.281.784.4700 Office +1.281.731.6880 wildwell@wildwell.com www.wildwell.co

m

Tankers & Marine Vessels

Vessel name / purpose Name / Title Business/Mobile Mobile Phone E-mail

Phone

SKL-E Tanker Sriracha Eagle Master SRE,CCR 02 610 0532 , 533 + 66 89 896 1900 sriracha.eagle@coastalenergy.com

srirachaleader@thome.co.th

SKL-G Tanker Sriracha Leader Master SRL,CCR 02 610 0575,576 + 66 81 760 5100

sriracha.leader@coastalenergy.com

SKL-C Tanker Coastal Energy

Master CER 02 610 0503,509 085-370 4803 cer@thomeships.com

Resolution

INMARSAT

master.srirachatrader@amosconnect.c

SKL-A Tanker Sriracha Trader Master SRT 02 610 0537',085-443 +873 764 884 050 om

1000 +873 764 884 282

SKL-D Tanker Sriracha Master Master SRM 02 610 0568 081-868 6146 sriracha.master@coastalenergy.com

Supply boat " Hawk K " Master Hawk K 080-868 1953 080-868-9156 charter.9v8327@globeemail.com

Supply boat " Crest Amethyst " Master Crest Amethyst Mr.Suarli Suardi 091-085 0760 crestamethyst@pacificcrest.com.sg

HWO crew boat MV.Swissco Master Swissco Seal 083-193-2285 swisscoseal@skyfile.com

Seal

Main crew boat (Spectrum) Master Spectrum 080-707 8203 081-540 0781 smsspectrum@skyfile.com

RS - 29 Tug Boat Capt. 29 080 - 673 - 1648 082 - 441 - 9366

RS - 31 Tug Boat Capt. Vichit K. 080 - 567 - 3116 rs31@hotmail.com;vichit.k@hotmail

.com

Revision No. Draft PAGE OF

Revision Date 22nd November 2012 19 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla Khoweel Location

Rig Move No: 01 Client: Coastal energy Issue Date: October 2012

Mooring Master Capt. Nataphol 081-702 0075 nathkan5@hotmail.com

PTT diesel contact Khun Thanaphon 089-969 4908

Thome in Songkhla Patrick Chan 088-399 0690

SC Marine Supervisor Khun Songkhram 081-376 2810

Marine coordinator from SC Khun Oranee 089-4929133

Thome -Thailand Khun Pongthanat 089-827 7367 080 - 085 6262 phongthanat@thome.co.th

Medical evacuations

Name Title Business Phone Mobile Phone E-mail Business Fax

SOS/AEA medical evacuations Alarm Center Thailand (24 hrs.) 02 205 7777 02 256 7151

Member 03AACM000023 Alarm Center Singapore (24 hrs.) 65 6338 7800 65 6338 7611

Alarm Center Jakarta Indonesia 62 21 750 6001 62 21750 6002

Mr. David Ball Sr. Business Development 02 2057755 ext. 3607 081 875 4792 david.ball@internationalsos.com 62 21750 6002

Manager

Rajyindee Hospital, Hatyai Admin 074-220300-4 074-221039

Emergency room 074-221040-4

074 356085

Bangkok Hospital (Hatyai) 074 272 800 074 272 840

Emergency Room 24/7 074 334 460 (direct) Provide ambulance with nurse, rescue and send patience to

Songkhla Hospital Songkhla Hospital only.

Ambulance + nurse 074 338 100 ext. 1200

02 591 9769 Provide ambulance with nurse, rescue and send patience to

Na-rain-torn Emergency Nationwide communication center any hospital upon request.

02 591 8873

Response 24/7

Marine Police Songkhla

Name Title Business Phone Mobile Phone Title / Name Business Fax

Onshore Commander

Marine Police Superintendent: Colonel Pramote Prom-rung-rueng 074 311 140

Police Inspector: Major Decha Aupaja 081 898 4679

Oil spill response support agencies and associations

Tier 1 - Tier 2

Name Title Business Phone Mobile Phone E-mail Business Fax

Marine Department Bkk. Emergency Call Center (24 hours) 1199

Marine Department Songkhla Provincial Office Songkhla 074 311615

Royal Thai Navy Songkhla Emergency Call Center (24 hours) 074 325804-5

Directorate of Operations, 02 472 1897

Royal Thai Navy Bangkok Bangkok 02 465 0024

IESG Oil Industry Environmental Safety Group 02 239-7918, 55-6 089 674 8656 areerat_tha@hotmail.com 02 239-7917

OSRL - EARL Singapore 65-6-266-1566 65 6 266-2312 65-6-2662312

Revision No. Draft PAGE OF

Revision Date 25th August 2012 20 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla Khoweel Location

Rig Move No: 01 Client: Coastal energy Issue Date: October 2012

Oil spill equipment supply contractor - SAFTROL Co. Ltd.

27 Charoennakorn 39 Rd., Klongsarn, Bangkok 10600

Oil Spill Response Support

Name Title Business Phone Mobile Phone E-mail Business Fax

Mr. Suthi Suksophonsonthi Managing Director 081 8020996 suthi@saftrol.com

Mr. Thossapon Sukroengruen Marketing Manager 02 8940577 - 8 081 5501121 thossapon@saftrol.com 02 437 6254

Mr. Jorm Standby specialist Songkhla 087 065 5271

Logistics - Bkk./ Songkhla - MMSVS GROUP

Logistics & Transportation Support

978 Srinakarin Road, Kwang Suanluang, BKK 10250

Name Title Business Phone Mobile Phone E-mail Business Fax

Pongsiri S. General Manager 081 834 9378 pongsiri@mmsvs.com

02 322 7979 02 322 7117

Srisak V. CEO 081 826 1750 srisak@mmsvs.com

Logistics - Sattahip - MMSVS GROUP

MML Transport Co., Ltd.

C/o Port of Sattahip-Royal Thai Navy, Warehouse #13_2002/1 Moo 2, Tambol Samaesarn, Amphur Sattahip, Chonburi 20180 Thailand

Name Title Business Phone Mobile Phone E-mail Business Fax

Jumrieng Naimuang (JJ) Operation Manager 038 431 358 081 803 1834 mmsth@mmsvs.com 038 431 355

Helicopter

SFS Aviation Company Ltd.

Name Title Business Phone Mobile Phone E-mail BusinessFax

Sikorsky S76 C+ Phone operational hours (Monday to Saturday from 05:30 to 18:00;

(Daytime-only Medevac services Sunday 08:00 to 17:00): +66 (0)7432-6210.

between DD7 and SFS Base at skl.flt.ops@sfs.co.th

Fax: +66 (0)7432-5793

Songkhla Navy Airport.) Cell phone 24/7: +66 (0)8-9466-8388

Thawatchai Tangtam 02 254 3210 081 804 6915 thawatchai.tangtam@schemgroup.com

Weather Information Service

Name Title Business Phone Mobile Phone E-mail Business Fax

Offshore Weather Services

Phil Atkinson 61-3-988-78613 OWS@OffshoreWeather.com.au 61-3-988-67216

(OWS)

Thai Government Meteorological Department, Weather Information

Center (24 hrs) 02-3994012 http://www.tmd.go.th/en/

Revision No. Draft PAGE OF

Revision Date 25th August 2012 21 22

RIG ATWOOD MANTA

Rig Move Procedures

Singapore to Block G5/43 Songkhla Khoweel Location

Rig Move No: 01 Client: Coastal energy Issue Date: October 2012

Revised 22 Oct 2012

Songkhla Governor

Mr. KRITSADA BOONYARAT ; T. : 074 - 323 874 ; Mobile : 089 - 203 0480

DMF Emergency Call

Department of Mineral Fuels

21st - 22nd Floor Energy Complex Building B

555/2 Vipavadeerangsit Road 10900

Tel: 02 794 3000

Director General Mr. Songpope Polachan: 02 791 8301 Fax: 02 791 8303

Director of Petroleum Operations and Technology Division

Mr. Veerasak: 02 791 8344 mobile: 089 969 0137

Focal point for CEC International

Dr. Nuntasak: 02 791 8365 mobile: 081 810 1053

Mr. Porrasak: 081 825 2767 porasak@dmf.go.th

Prepared by:

Signature Name Position

Reviewed by:

Signature Name Position

Approved by:

Signature Name Position

Revision No. Draft PAGE OF

Revision Date 25th August 2012 22 22

Potrebbero piacerti anche

- LNG Risk Based Safety: Modeling and Consequence AnalysisDa EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNessuna valutazione finora

- Rig Move from Singapore to Thailand Oil BlockDocumento22 pagineRig Move from Singapore to Thailand Oil BlockCaptIsqanNessuna valutazione finora

- Quayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)Documento35 pagineQuayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)cliff1234Nessuna valutazione finora

- ADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Documento15 pagineADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Mohamed MostafaNessuna valutazione finora

- 2011construction ReportDocumento8 pagine2011construction ReportKenaouia BahaaNessuna valutazione finora

- Rig Move Warranty Survey Code of Practice and Scope of Work SummaryDocumento22 pagineRig Move Warranty Survey Code of Practice and Scope of Work SummaryImran Siddiqui100% (1)

- Muhammad Ayub Bin Khalid: Personal DataDocumento5 pagineMuhammad Ayub Bin Khalid: Personal DataAnwarul Shafiq AwalludinNessuna valutazione finora

- Royal IHC Pipelaying Brochure PDFDocumento11 pagineRoyal IHC Pipelaying Brochure PDFRoo FaNessuna valutazione finora

- NDI 0027 - Rev03 - Guidelines For Lifting Operations by Floating Crane VesselDocumento39 pagineNDI 0027 - Rev03 - Guidelines For Lifting Operations by Floating Crane VesselRonalNessuna valutazione finora

- MarineDocumento52 pagineMarineAnonymous GpwnHXNessuna valutazione finora

- Numerical Modelling of Installation Aids For Platform InstallationDocumento20 pagineNumerical Modelling of Installation Aids For Platform InstallationMathew SimonNessuna valutazione finora

- Logistica Offshore BrascoDocumento34 pagineLogistica Offshore BrascoJorge CiprianoNessuna valutazione finora

- V.001 Vryhof Product Brochure STEVSHARK REX For WebDocumento6 pagineV.001 Vryhof Product Brochure STEVSHARK REX For WebVinicius Prado100% (1)

- Jackup Rig Whitepape FINAL LoRes SpreadsDocumento5 pagineJackup Rig Whitepape FINAL LoRes SpreadsRicky Ocktavi RizkyNessuna valutazione finora

- Deep-water Pipelay ToolsDocumento25 pagineDeep-water Pipelay ToolsSalmanNessuna valutazione finora

- GustoMSC Inside 13 April 2009Documento28 pagineGustoMSC Inside 13 April 2009dafoozzNessuna valutazione finora

- Java StarDocumento1 paginaJava StarSyaifudin Comunity Jupi'zNessuna valutazione finora

- Global Ultimate Strength Analysis SBA KNPG-B - Rev0Documento104 pagineGlobal Ultimate Strength Analysis SBA KNPG-B - Rev0Pei Shing OoiNessuna valutazione finora

- IHC Engineering Business Ltd Company ProfileDocumento35 pagineIHC Engineering Business Ltd Company ProfileSatyavan L RoundhalNessuna valutazione finora

- MWA ReportDocumento75 pagineMWA ReportCyrus HongNessuna valutazione finora

- Asigmnet 1 - ShipyardDocumento28 pagineAsigmnet 1 - Shipyardulzzang looNessuna valutazione finora

- BRUCE MK4 Handling ProcedureDocumento81 pagineBRUCE MK4 Handling ProcedureSamo SpontanostNessuna valutazione finora

- Offshore AcronymsDocumento40 pagineOffshore AcronymsmaxNessuna valutazione finora

- AMIR KABIR SSDU IWS Report Rev01Documento6 pagineAMIR KABIR SSDU IWS Report Rev01saeed ghafoori0% (1)

- RIGZONE - Offshore Rig Day RatesDocumento2 pagineRIGZONE - Offshore Rig Day RatesFrancesco CauzNessuna valutazione finora

- Design Considerations Multipurpose Jackup Spudcans - Gusto MSCDocumento31 pagineDesign Considerations Multipurpose Jackup Spudcans - Gusto MSCOffshore JackupNessuna valutazione finora

- Marine Department - MCVS&RDocumento5 pagineMarine Department - MCVS&REliza's Soothing Sounds100% (1)

- ABS MODU Part3-Hull Const & EquipDocumento64 pagineABS MODU Part3-Hull Const & EquipGoodD11Nessuna valutazione finora

- List of Some Sample Projects Executed by Sges PDFDocumento6 pagineList of Some Sample Projects Executed by Sges PDFPrashanth Talkad RajagopalNessuna valutazione finora

- Flexible Pipe Solutions – a competitive approach for Shallow water developmentDocumento23 pagineFlexible Pipe Solutions – a competitive approach for Shallow water developmentprateekchopra1Nessuna valutazione finora

- Materials Handling Equipment Flexible Hoisting AppliancesDocumento36 pagineMaterials Handling Equipment Flexible Hoisting AppliancesabubekerNessuna valutazione finora

- PPL Shipyard in SingaporeDocumento5 paginePPL Shipyard in SingaporeIrfan SuhaimiNessuna valutazione finora

- Rig Stacking Strategies for Long Term LayupDocumento14 pagineRig Stacking Strategies for Long Term LayupJeril PhilipNessuna valutazione finora

- Drilling and Workover Division FinalDocumento15 pagineDrilling and Workover Division FinalThem Bui XuanNessuna valutazione finora

- Multibeam Surveys Along The Container Terminal in BremerhavenDocumento23 pagineMultibeam Surveys Along The Container Terminal in BremerhavenJoost F. BoersNessuna valutazione finora

- Not To Copy - No Disseminate Without Written AgreementDocumento55 pagineNot To Copy - No Disseminate Without Written Agreementrinni m15Nessuna valutazione finora

- 5 - When Things Go Wrong - Lessons and Mitigations - tcm14-80218 PDFDocumento50 pagine5 - When Things Go Wrong - Lessons and Mitigations - tcm14-80218 PDFFoad MirzaieNessuna valutazione finora

- Om05 SepoctDocumento44 pagineOm05 SepoctSơn Nguyễn-LêNessuna valutazione finora

- Condições Climáticas Bacia de CamposDocumento85 pagineCondições Climáticas Bacia de CamposÍcaro ReisNessuna valutazione finora

- Lamprell Rig Services CatalogDocumento2 pagineLamprell Rig Services CatalogtxcrudeNessuna valutazione finora

- Structural Design and Analysis of FPSO Topside Module SupportsDocumento10 pagineStructural Design and Analysis of FPSO Topside Module SupportsSettuNessuna valutazione finora

- Regulation Concerning Deck CranesDocumento25 pagineRegulation Concerning Deck Cranesaiyubi2Nessuna valutazione finora

- Skate 3D REV2Documento47 pagineSkate 3D REV2harrys manaluNessuna valutazione finora

- Drilling Rigs Built in The U.SDocumento9 pagineDrilling Rigs Built in The U.SalmirNessuna valutazione finora

- CM22-IV-204-1203 Report On Lightship Weight CalculationDocumento11 pagineCM22-IV-204-1203 Report On Lightship Weight CalculationAli MohamedNessuna valutazione finora

- IHC Hydrohammer Onshore BrochureDocumento15 pagineIHC Hydrohammer Onshore BrochurensaifulNessuna valutazione finora

- OCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atDocumento4 pagineOCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atRobson PaixãoNessuna valutazione finora

- Trailing Suction Hopper Dredger SpecificationDocumento51 pagineTrailing Suction Hopper Dredger SpecificationuygarkoprucuNessuna valutazione finora

- KSY Shipyard ReportDocumento48 pagineKSY Shipyard Reportisrat jahanNessuna valutazione finora

- Loc Survey ReportDocumento26 pagineLoc Survey Reportluckystrike9008100% (1)

- Offshore Jack UpsDocumento5 pagineOffshore Jack Upsfle92100% (1)

- Counter Weight DrawingDocumento1 paginaCounter Weight Drawingrajaguru20003Nessuna valutazione finora

- Offshore Findings Observations For An AuditDocumento1 paginaOffshore Findings Observations For An AuditP DanarajNessuna valutazione finora

- IGSDC-2014 FoundationsforOffshoreDocumento34 pagineIGSDC-2014 FoundationsforOffshoreanilsmg09100% (1)

- ERKE Group, Brochure Offshore PilingDocumento20 pagineERKE Group, Brochure Offshore PilingerkegroupNessuna valutazione finora

- Theroadtosaqqara 131105123308 Phpapp02 PDFDocumento63 pagineTheroadtosaqqara 131105123308 Phpapp02 PDFMILADNessuna valutazione finora

- DY-300 Men Accommodation Work BargeDocumento21 pagineDY-300 Men Accommodation Work BargeBinh PhamNessuna valutazione finora

- GN Rope Fittings CatalogueDocumento71 pagineGN Rope Fittings CatalogueMarios DiasNessuna valutazione finora

- SNEPCo Deepwater Projects Guidelines for The Operation of Subsea Production SystemDocumento95 pagineSNEPCo Deepwater Projects Guidelines for The Operation of Subsea Production SystemPaul OhiorNessuna valutazione finora

- Rig Move from Singapore to ThailandDocumento22 pagineRig Move from Singapore to ThailandCaptIsqan100% (1)

- Mud 1Documento36 pagineMud 1s v poyilNessuna valutazione finora

- Brines Fluids and FiltrationDocumento90 pagineBrines Fluids and Filtrationqmax78Nessuna valutazione finora

- 4 Drilling Mud PDFDocumento12 pagine4 Drilling Mud PDFs v poyilNessuna valutazione finora

- Universal ValuesDocumento36 pagineUniversal Valuess v poyilNessuna valutazione finora

- Well (C-23) Activity During 8 " Hole DrillingDocumento2 pagineWell (C-23) Activity During 8 " Hole Drillings v poyilNessuna valutazione finora

- PBR Packer Setting StepsDocumento6 paginePBR Packer Setting Stepss v poyilNessuna valutazione finora

- Rig Move ManualDocumento45 pagineRig Move Manualjrladdu100% (24)

- Spe 112950 MS PDocumento11 pagineSpe 112950 MS Ps v poyilNessuna valutazione finora

- Formate Brine TableDocumento12 pagineFormate Brine Tables v poyil100% (1)

- Brine FluidsDocumento16 pagineBrine Fluidspeol12280% (5)

- DMDW Mod3@AzDOCUMENTS - inDocumento56 pagineDMDW Mod3@AzDOCUMENTS - inRakesh JainNessuna valutazione finora

- Quality Management in Digital ImagingDocumento71 pagineQuality Management in Digital ImagingKampus Atro Bali0% (1)

- Tension field beams: Aircraft wing spar analysisDocumento19 pagineTension field beams: Aircraft wing spar analysisPrajeesh RajNessuna valutazione finora

- Annamalai International Journal of Business Studies and Research AijbsrDocumento2 pagineAnnamalai International Journal of Business Studies and Research AijbsrNisha NishaNessuna valutazione finora

- Malware Reverse Engineering Part 1 Static AnalysisDocumento27 pagineMalware Reverse Engineering Part 1 Static AnalysisBik AshNessuna valutazione finora

- Sharp Ar5731 BrochureDocumento4 pagineSharp Ar5731 Brochureanakraja11Nessuna valutazione finora

- JurnalDocumento9 pagineJurnalClarisa Noveria Erika PutriNessuna valutazione finora

- Jfif 1.02Documento9 pagineJfif 1.02Berry Hoekstra100% (1)

- Why Genentech Is 1Documento7 pagineWhy Genentech Is 1panmongolsNessuna valutazione finora

- Pita Cyrel R. Activity 7Documento5 paginePita Cyrel R. Activity 7Lucky Lynn AbreraNessuna valutazione finora

- Marshal HMA Mixture Design ExampleDocumento2 pagineMarshal HMA Mixture Design ExampleTewodros TadesseNessuna valutazione finora

- Multiple Choice: CH142 Sample Exam 2 QuestionsDocumento12 pagineMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNessuna valutazione finora

- GlastonburyDocumento4 pagineGlastonburyfatimazahrarahmani02Nessuna valutazione finora

- Manual Analizador Fluoruro HachDocumento92 pagineManual Analizador Fluoruro HachAitor de IsusiNessuna valutazione finora

- Logic and Set Theory PropositionDocumento3 pagineLogic and Set Theory PropositionVince OjedaNessuna valutazione finora

- Biology Mapping GuideDocumento28 pagineBiology Mapping GuideGazar100% (1)

- Fernandez ArmestoDocumento10 pagineFernandez Armestosrodriguezlorenzo3288Nessuna valutazione finora

- Social Media Exposure and Its Perceived Impact On Students' Home-Based Tasks ProductivityDocumento9 pagineSocial Media Exposure and Its Perceived Impact On Students' Home-Based Tasks ProductivityJewel PascuaNessuna valutazione finora

- PRODUCTDocumento82 paginePRODUCTSrishti AggarwalNessuna valutazione finora

- HCW22 PDFDocumento4 pagineHCW22 PDFJerryPNessuna valutazione finora

- Survey Course OverviewDocumento3 pagineSurvey Course OverviewAnil MarsaniNessuna valutazione finora

- Astera Data Integration BootcampDocumento4 pagineAstera Data Integration BootcampTalha MehtabNessuna valutazione finora

- Rtsa 2012Documento7 pagineRtsa 2012Justin RobinsonNessuna valutazione finora

- Wi FiDocumento22 pagineWi FiDaljeet Singh MottonNessuna valutazione finora

- Chem 102 Week 5Documento65 pagineChem 102 Week 5CAILA CACHERONessuna valutazione finora

- If V2 would/wouldn't V1Documento2 pagineIf V2 would/wouldn't V1Honey ThinNessuna valutazione finora

- Case Study Hotel The OrchidDocumento5 pagineCase Study Hotel The Orchidkkarankapoor100% (4)

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDocumento35 pagineMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićNessuna valutazione finora

- Mtle - Hema 1Documento50 pagineMtle - Hema 1Leogene Earl FranciaNessuna valutazione finora

- Pre Job Hazard Analysis (PJHADocumento2 paginePre Job Hazard Analysis (PJHAjumaliNessuna valutazione finora