Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Appendix 18 Steam Blowing JSA

Caricato da

zhang75%(12)Il 75% ha trovato utile questo documento (12 voti)

2K visualizzazioni3 pagineSTEAM

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSTEAM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

75%(12)Il 75% ha trovato utile questo documento (12 voti)

2K visualizzazioni3 pagineAppendix 18 Steam Blowing JSA

Caricato da

zhangSTEAM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

&

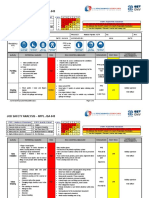

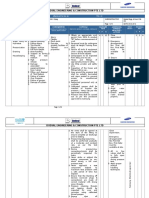

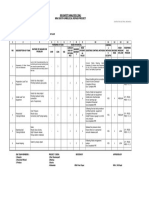

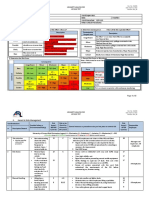

Project: Jazan Integrated Gasification Combined Cycle Project EPC #: EPC - 4

Location: JIGCC Power Block Project (Package 4) Contract #: 6600033163

Contractor: SEPCO Electric Power Construction Corporation Date: 2016/12/15

JOB SAFETY ANALYSIS

Description of Work: STEAM BLOWING

Location:

Item Activity Potential Hazard Hazard Controls

Secure necessary permit. A qualified /certified work permit

receiver to obtain work permit from an authorized issuer prior

Work permit issued to start the job, complies with all instruction specified in the

incorrectly permit.

1 Secure necessary permit

Ensure work permit procedure is followed as per SEPCO

Issuing permit without site approved work permit procedure (Ref # SES-PGB-HS-PRO-

inspection 0008).

Inspect the work location before issuance of work permit

Only trained and experienced personal will perform this job

Goggles

Helmet

2 Require for PPE

Personnel protect Insulating and non- slip shoes

Fluorescent protective and work clothing

Hearing protection

Clean work area before starting.Make sure areais well lit.

Secure and tighten all parts before starting.Use proper tool

Equipment damage and accessories.Check and replace any broken or damaged

3 Clear and clean the work area

personnel injury parts

Ensure tools and equipment used for the task have been

parked and stored properly in safe and designated storage

areas.

Injury to personal due to Only authorized operator shall operate the equipment

4 Equipment check damage tools and All tools and equipments should be in good condition

equipments and must be properly

Hearing protection is required.

Nosie hazard

Signage shall be posted at the noisy area for the awareness.

Leakage from Ensure that process lines are leak tested

flanges

5 Pump operation Injury due to Ensure that guards are provided for all the rotating

unprotected rotating parts of the machine/equipments.

parts

Adequate numbers of fire extinguishers shall be

Fire and provided in the area.All cables or extension cords

Electrocution shall be secured with GFCI and power tools shall be

properly inspected.

Wear goggles or any eye protection.

Provide sufficient water cooler and encourage consuming

more salt with food or giving Hydrolyte solution.

Working in High Temperature Heat Stress

Sun Burn Suitably amend working hours by giving more rest in peak hot

6 if applicable

summer.

Working in hight Sun stroke

Use the talk tool keep communication in case to happen the

Accident fall accident .

Full body harness is mandatory above 1.8m and 100% tie off

shall be observe

Damage of Reinstatements shall be done by the trained and

7 Reinstatement equipments due to authorized person only.

misalignment of Constant monitoring by the responsible person is

pump and moto mandatory while commencing the task.

If the permit is not properly Inform the permit issuer to close the work permit, conduct a

8 Close work permit

joint site inspection and write the date, time and name.

closed, hazard could

remain at the jobsite.

References:

CSSP-Sec-18.8 : Personal Protective Equipment (PPES)

CSSP-Sec-13.2A : Toolbox meeting

CSSP-Sec-18.14 : Manual handling

CSSP-Sec-18.6.4 : Rigging operations

CSSP-Sec-18.13 : Housekeeping

WPP : Work permit procedure (Ref # SES-PGB-HS-PRO-0008).

Special Instructions:

Obtain and follow Work Permit(s) prior to start the job.

Proper material storage at site area.

Work must be supervised for each process.

Proper House- keeping is required on a daily basis.

Lifting tools, in good condition.

Portable electric tools are in good working condition.

Appropriate barricades and safety signs must be posted around the work site.

All team members must visit the job site and understand fully the scope of work.

All workers working at the job shall be briefed about the JSA to make sure that they all are aware of the JSA.

CAUTION: All persons associated with the job shall abide by the JSA. The JSA stands cancelled once conditions change at

the job site. The team shall stop all work and revisit the JSA.

Prepared by: Reviewed by: Concurred /Reviewed by:

COMMISSIONER HSE MANAGER SAPMT

Revision 00. 31 Oct 2016. KSB

Potrebbero piacerti anche

- Jsa For HydrotestDocumento10 pagineJsa For HydrotestAnonymous CcGYhZb080% (5)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocumento2 pagineJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Jsa For Piping Hydro Test, Pneumatic TestDocumento8 pagineJsa For Piping Hydro Test, Pneumatic Testsanath adhikaryNessuna valutazione finora

- Jsa Nitrogen PurgingDocumento2 pagineJsa Nitrogen Purgingmohammedsouqi83% (6)

- JSA - Hydro-Testing of Pipe & EquipmentDocumento1 paginaJSA - Hydro-Testing of Pipe & EquipmentRajuNessuna valutazione finora

- JSA-049 Valves & Support Installation and DismantlingDocumento4 pagineJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- JSA For Washing and Air BlowingDocumento3 pagineJSA For Washing and Air BlowingMohammed MinhajNessuna valutazione finora

- JSA - Chemical CleaningDocumento4 pagineJSA - Chemical CleaningkrshhNessuna valutazione finora

- JSA - Cathodic ProtectionDocumento4 pagineJSA - Cathodic ProtectionAkash ShuklaNessuna valutazione finora

- Hydrotest & Pneumatic Test - TRADocumento6 pagineHydrotest & Pneumatic Test - TRAOws Anish100% (3)

- JSA For PiggingDocumento3 pagineJSA For PiggingMohammed Minhaj86% (7)

- JSA Tubing Leak TestDocumento1 paginaJSA Tubing Leak TestMuhammad Reza Gadran67% (3)

- Jsa Nitrogen PurgingDocumento2 pagineJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- HydroTest JHADocumento14 pagineHydroTest JHAorganicspolybond100% (2)

- JSA Cable LayingDocumento2 pagineJSA Cable Layingnishanth100% (2)

- JSA-055 Hydro-TestDocumento24 pagineJSA-055 Hydro-TestOmar Dhieb100% (7)

- Hydro Test JSADocumento2 pagineHydro Test JSAEruse Okejero88% (17)

- JSA For Holiday Testing PDFDocumento4 pagineJSA For Holiday Testing PDFMohammed Minhaj67% (3)

- JSA006 - Vacuum Box TestingDocumento5 pagineJSA006 - Vacuum Box TestingLaohan LiuNessuna valutazione finora

- JSA SplicingDocumento3 pagineJSA Splicingluis100% (4)

- Jsa For Piping and Erection RevisedDocumento1 paginaJsa For Piping and Erection RevisedAlvin Smith77% (26)

- ATLS NotesDocumento15 pagineATLS NotesXavier Fung86% (7)

- Copy of JSA For Cathodic Protection For Oily Water LineDocumento6 pagineCopy of JSA For Cathodic Protection For Oily Water LineMohammed Minhaj80% (5)

- JSA Template 2017-05-31 Cable Tray InstallationDocumento19 pagineJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNessuna valutazione finora

- JSA For Cleaning and Hydro Test of Test SeparatorDocumento7 pagineJSA For Cleaning and Hydro Test of Test SeparatorNishantMittal100% (2)

- Maternal Anatomy WilliamsDocumento52 pagineMaternal Anatomy WilliamsIrfan MohammadNessuna valutazione finora

- Jsa Non Destructive TestingDocumento2 pagineJsa Non Destructive Testingghulammohyuddin100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento17 pagineSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- Jsa Insulation WorkDocumento19 pagineJsa Insulation WorkM M PRADHAN100% (2)

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocumento7 pagineJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Documento4 pagineHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNessuna valutazione finora

- JSA of Pipe Unloading.Documento2 pagineJSA of Pipe Unloading.vijay kumar singh100% (1)

- JHA Pneumatic Test Using N2Documento4 pagineJHA Pneumatic Test Using N2Luqman Osman89% (9)

- Jsa For Air Flushin & Mech. Cleaning of PipesDocumento17 pagineJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- JSA Hydro TestingDocumento1 paginaJSA Hydro TestingZeyad RezkNessuna valutazione finora

- Blinding and De-BlindingDocumento3 pagineBlinding and De-Blindingkaremkoko33% (3)

- Jsa Hydro JettingDocumento4 pagineJsa Hydro Jettingyelsa otrebla100% (2)

- Jsa For Blowing of Air in Underground PipesDocumento4 pagineJsa For Blowing of Air in Underground PipesMohammed MinhajNessuna valutazione finora

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralDocumento2 pagineJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- Dye Penetrant Test (DPT) JsaDocumento3 pagineDye Penetrant Test (DPT) JsaDautsons Infratech75% (4)

- Jsa Psa & GisDocumento3 pagineJsa Psa & GisMohammed NouzalNessuna valutazione finora

- 12 JSA FlushingDocumento5 pagine12 JSA FlushingYosua SitumorangNessuna valutazione finora

- Tanks Confined Space JSADocumento5 pagineTanks Confined Space JSAkosoko100% (1)

- Jsa-Hot Oil FlushingDocumento2 pagineJsa-Hot Oil Flushingyelsa otrebla100% (5)

- Job Safety Analysis: Touch Up PaintDocumento3 pagineJob Safety Analysis: Touch Up PaintMuhammad Umar GondalNessuna valutazione finora

- Jsa Chemical CleaningDocumento3 pagineJsa Chemical Cleaningyelsa otrebla75% (8)

- Jsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementDocumento13 pagineJsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementKhuda Buksh100% (1)

- JSA HCK MOC Hot Tap Drilling Rev1Documento6 pagineJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- Project: Install Generator For Back Up Power Supply For Building 3056 For ShedgumDocumento11 pagineProject: Install Generator For Back Up Power Supply For Building 3056 For ShedgumAnonymous voA5Tb0Nessuna valutazione finora

- JSA Erection StructureDocumento11 pagineJSA Erection StructureJAYESH JOSHINessuna valutazione finora

- JSA For Hydro Test Activites (Generic)Documento4 pagineJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA For Flange AlignmentDocumento5 pagineJSA For Flange AlignmentHưởng Phạm100% (1)

- Hazard Identification and Risk Assessment For Pipe LoweringDocumento4 pagineHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Pre Commissioning Electrical EquipmentDocumento4 paginePre Commissioning Electrical Equipmentmohammed a hseNessuna valutazione finora

- 4..pipe Spool Air Blowing & Cleaning JSA 04Documento2 pagine4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- Blinding and Deblinding Rev1Documento41 pagineBlinding and Deblinding Rev1SaravananRamasamy67% (6)

- Jsa Pipe Cutting at Fire PumpDocumento5 pagineJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNessuna valutazione finora

- Tegner Lysholm Knee Scoring Scale - Orthopaedic ScoresDocumento2 pagineTegner Lysholm Knee Scoring Scale - Orthopaedic Scoresradu_pavalache100% (2)

- JSA - Paintng in Confined SpaceDocumento6 pagineJSA - Paintng in Confined SpaceJohnNessuna valutazione finora

- Jha New - PWHTDocumento6 pagineJha New - PWHTSalam AlkataluniNessuna valutazione finora

- ABC-EWP-JSA-PRS1-01 (Rev.0) Relocation of Existing Security FacilitiesDocumento29 pagineABC-EWP-JSA-PRS1-01 (Rev.0) Relocation of Existing Security FacilitiesRABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNessuna valutazione finora

- Gunitting Operation JSA HSE ProfessionalsDocumento1 paginaGunitting Operation JSA HSE ProfessionalsSamadov 13Nessuna valutazione finora

- Jsa For Excavation and BackfillingDocumento5 pagineJsa For Excavation and Backfillingshaibaz chafekarNessuna valutazione finora

- Satip Co 3001Documento3 pagineSatip Co 3001zhangNessuna valutazione finora

- Saudi Aramco Test Report: Commissioning of HRSG System MechDocumento2 pagineSaudi Aramco Test Report: Commissioning of HRSG System MechzhangNessuna valutazione finora

- Commissioning Completion Certificate: Attachment#4Documento3 pagineCommissioning Completion Certificate: Attachment#4zhangNessuna valutazione finora

- Saic Co 3014Documento8 pagineSaic Co 3014zhangNessuna valutazione finora

- Attachment#5 Blowdown SystemDocumento3 pagineAttachment#5 Blowdown SystemzhangNessuna valutazione finora

- Ses-Pgb-Co-Itp-0058 Itp For HRSG SystemDocumento4 pagineSes-Pgb-Co-Itp-0058 Itp For HRSG SystemzhangNessuna valutazione finora

- Attachment - #5 Valve Inspection ListDocumento4 pagineAttachment - #5 Valve Inspection ListzhangNessuna valutazione finora

- Commissioning Completion Certificate: Attachment#4Documento3 pagineCommissioning Completion Certificate: Attachment#4zhangNessuna valutazione finora

- Commissioning Completion Certificate: Attachment#4Documento3 pagineCommissioning Completion Certificate: Attachment#4zhangNessuna valutazione finora

- Installation of Main Steel Structure/ Platform & Steam SilencerDocumento4 pagineInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNessuna valutazione finora

- Attachment#9 Auxiliary SystemDocumento3 pagineAttachment#9 Auxiliary SystemzhangNessuna valutazione finora

- Satc Meh Content: ProcedureDocumento24 pagineSatc Meh Content: ProcedurezhangNessuna valutazione finora

- Attachment#6 Burner SystemDocumento3 pagineAttachment#6 Burner SystemzhangNessuna valutazione finora

- Attachmnet#8 Rotor Air SystemDocumento3 pagineAttachmnet#8 Rotor Air SystemzhangNessuna valutazione finora

- Satr Co 3008Documento1 paginaSatr Co 3008zhangNessuna valutazione finora

- Saudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003Documento2 pagineSaudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003zhangNessuna valutazione finora

- Saic Co 3014Documento18 pagineSaic Co 3014zhangNessuna valutazione finora

- Satip Co 3014Documento3 pagineSatip Co 3014zhangNessuna valutazione finora

- Steam Line SummaryDocumento9 pagineSteam Line SummaryzhangNessuna valutazione finora

- Satip Co 3014Documento3 pagineSatip Co 3014zhangNessuna valutazione finora

- Satr Co 3008Documento1 paginaSatr Co 3008zhangNessuna valutazione finora

- Saic Co 3008Documento12 pagineSaic Co 3008zhangNessuna valutazione finora

- Saic Co 3008Documento12 pagineSaic Co 3008zhangNessuna valutazione finora

- Installation of Main Steel Structure/ Platform & Steam SilencerDocumento4 pagineInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNessuna valutazione finora

- VHP Steam LineDocumento9 pagineVHP Steam LinezhangNessuna valutazione finora

- SATR-P-3413 Rev 7 FinalDocumento4 pagineSATR-P-3413 Rev 7 FinalzhangNessuna valutazione finora

- Saudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamDocumento1 paginaSaudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamzhangNessuna valutazione finora

- A10 L Iso VB 433961 105 - 01BDocumento1 paginaA10 L Iso VB 433961 105 - 01BzhangNessuna valutazione finora

- A10 A Pid Va 449162 001 - 01aDocumento1 paginaA10 A Pid Va 449162 001 - 01azhangNessuna valutazione finora

- Satr-P-3219 Rev 7 FinalDocumento7 pagineSatr-P-3219 Rev 7 FinalzhangNessuna valutazione finora

- Eye Care in Developing NationsDocumento273 pagineEye Care in Developing NationsNirav Sharma100% (1)

- Extensor Tendon Injuries 2010 The Journal of Hand SurgeryDocumento8 pagineExtensor Tendon Injuries 2010 The Journal of Hand SurgeryProfesseur Christian DumontierNessuna valutazione finora

- ContractDocumento55 pagineContractZayd ZaynNessuna valutazione finora

- Sports Medical History FormDocumento2 pagineSports Medical History Formgilikarn9960Nessuna valutazione finora

- Principios de La RehabilitacionDocumento17 paginePrincipios de La RehabilitacionJessica PelazzoNessuna valutazione finora

- Physical Injuries of Oral CavityDocumento57 paginePhysical Injuries of Oral Cavitygud4nothing50% (2)

- Bodylastics P90X TipsDocumento4 pagineBodylastics P90X TipsgohbangruiNessuna valutazione finora

- Anatomy of The Thyroid GlandDocumento5 pagineAnatomy of The Thyroid GlandShienna Marie SalvioNessuna valutazione finora

- Case Report A Rare Acromioclavicular Joint Injury in A Twelve-Year-Old Boy. ADocumento5 pagineCase Report A Rare Acromioclavicular Joint Injury in A Twelve-Year-Old Boy. AKirubakaran Saraswathy PattabiramanNessuna valutazione finora

- KonasDocumento30 pagineKonasRonAlNessuna valutazione finora

- W3, W5 User ManualDocumento61 pagineW3, W5 User ManualDiogenesNessuna valutazione finora

- Wounded in The Womb: An English Woman'S Healing Story by Karen Melton 1Documento3 pagineWounded in The Womb: An English Woman'S Healing Story by Karen Melton 1Myzyr AlkebulanNessuna valutazione finora

- 01 Afialda vs. Hisole DigestDocumento1 pagina01 Afialda vs. Hisole DigestNoreen AquinoNessuna valutazione finora

- Dancing Men MineDocumento24 pagineDancing Men MineLopamudra MandalNessuna valutazione finora

- Gambar Membran TimpaniDocumento6 pagineGambar Membran TimpaniMilya SariNessuna valutazione finora

- Língua Inglesa Simulado 3º BimestreDocumento15 pagineLíngua Inglesa Simulado 3º BimestreOziel LeiteNessuna valutazione finora

- Pancoast TumourDocumento2 paginePancoast TumourobligatraftelNessuna valutazione finora

- NCM 116a: Skills Learning Material 4Documento17 pagineNCM 116a: Skills Learning Material 4Ryrey Abraham PacamanaNessuna valutazione finora

- When The House Is EmptyDocumento1 paginaWhen The House Is EmptyReina AureoNessuna valutazione finora

- Workplace, Equipment, and Tool DesignDocumento33 pagineWorkplace, Equipment, and Tool Designdanang.suhandoyoNessuna valutazione finora

- Animal Welfare Board of India Vs A. Nagaraja PDFDocumento40 pagineAnimal Welfare Board of India Vs A. Nagaraja PDFKaushlya DagaNessuna valutazione finora

- Primeros Auxilios AHADocumento17 paginePrimeros Auxilios AHACarolina LópezCamperoNessuna valutazione finora

- Process Safety Incident ScoresheetDocumento2 pagineProcess Safety Incident ScoresheetNoe AranelNessuna valutazione finora

- Sample of An Actual Legal OpinionDocumento2 pagineSample of An Actual Legal OpinionindaiclerrNessuna valutazione finora

- FMT DFX WorkbookDocumento25 pagineFMT DFX WorkbookSaurav SinghNessuna valutazione finora

- Performance Checklist - ROMDocumento3 paginePerformance Checklist - ROMCrishaGarraNessuna valutazione finora

- Broadcast Wo ToppatsureDocumento37 pagineBroadcast Wo ToppatsureYona Yohana SNessuna valutazione finora