Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Degumming Process of Jute Fibre PDF

Caricato da

Guarded TabletDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Degumming Process of Jute Fibre PDF

Caricato da

Guarded TabletCopyright:

Formati disponibili

Study on the Chemical Modification Process of Jute Fiber

Wei-ming Wang1,2, Zai-sheng Cai, Ph.D.1,2, Jian-yong Yu, Ph.D.3

1

Key Laboratory of Science & Technology of Eco-Textile, Ministry of Education

2

College of Chemical and Chemistry Engineering, Donghua University, Shanghai, P.R. CHINA

3

Modern Textile Institute of Donghua University, Shanghai, P.R. CHINA

Correspondence to:

Zai-sheng Cai, Ph.D. email: zshcai@dhu.edu.cn

ABSTRACT et al.1-2. Recently, due to the improvement of

Degumming of pre-chlorite treated jute fiber was peoples living standards and need for

studied in this paper. The effects of sodium environmental protection, the demand of natural

hydroxide concentration, treatment time, biodegradable and eco-friendly fibers is rising

temperature, sodium silicate concentration, worldwide day by day. Ramie, flax, hemp and

fiber-to-liquor ratio, penetrating agent TF-107B some other vegetable fibers have been used as

concentration and degumming agent TF-125A textile materials, but jute fiber is basically used for

concentration were the process conditions examined. traditional purposes such as manufacture of

With respect to gum decomposition, fineness and sackings, hessian, carpet backing and the like.

mechanical properties, sodium hydroxide Taking account of the costliness of ramie and the

concentration, sodium silicate concentration and shortage in sources of flax, and the challenges from

treatment time were found to be the most important the synthetic fibers in the traditional jute products

4

parameters. An orthogonal L9(3 ) experiment market, if jute could be used to replace ramie and

designed to optimize the conditions for degumming flax partially as textile material, not only the cost

resulted in the selection of the following procedure: could be reduced but also a new market would be

sodium hydroxide of 12g/L, sodium silicate of 3g/L, provided for jute products2-9.

TF-107B of 2g/L, TF-125A of 2g/L, treatment time

of 105 min, temperature of 100 and fiber to liquor Jute fiber is a bast fiber obtained from the bark of

ratio of 1:20. The effect of the above degumming jute plant containing three main categories of

process on the removal of impurities was also chemical compounds namely cellulose (58~63%),

examined and the results showed that degumming hemicellulose (20~24%) and lignin (12~15%), and

was an effective method for removing impurities, some other small quantities of constituents like fats,

especially hemicellulose. pectin, aqueous extract, et al. Jute fiber is composed

of small units of cellulose surrounded and cemented

INTRODUCTION together by lignin and hemi-cellulose10-11. The low

Jute is a natural biodegradable fiber with cellulose content, coarseness, stiffness, low

advantages such as high tensile strength, excellent extensibility, low grip performance and some other

thermal conductivity, coolness, ventilation function disadvantages seriously restrict the raw jute fiber

Journal of Engineered Fibers and Fabrics 1 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

from spinning. So a series of wet chemical MATERIALS AND METHODS

processing sequences are needed to improve the

spinnability of jute. The qualities of the fiber and Materials

yarn mostly depend on the degumming effect. So

degumming is one of the most important sequences Jute

12-13

in the chemical processing of jute . Lightly combed and dewaxed raw jute fiber

(Bengal).

Generally, there are three methods for degumming,

i.e., mechanical, chemical and biological methods. Chemicals

The mechanical methods such as steam Sodium chlorite and sodium silicate were supplied

2,14 15

explosion , microwave and ultrasonic have very by the Shanghai Nuotai Chemical Co., Ltd., China.

limited effect on improving the spinnability of jute Acetic acid, sodium acetate, sodium hydroxide and

fiber. Biodegumming is an eco-friendly method has sulphuric acid were purchased from the Shanghai

some advantages viz. mild conditions and high Ruiteliang Chemical Industry Co., Ltd., China.

efficiency. However, the application of enzymes for Penetrating agent TF-107B and degumming agent

degumming is hindered by some factors such as TF-125A were provided by the Zhejiang Transfar

high substrate specificity, low activity stability, high Co., Ltd., China.

16-18

cost, and low total gum decomposition . The

chemical method is the most commonly used Methods

method for degumming, but this traditional method

has some major disadvantages like serious Pre-chlorite treatment

environmental pollution, lengthy time required and The samples were treated in a bath with sodium

19

high cost . Taking account of these problems, it is chlorite 1.5g/L, pH 3, liquor ratio 1:10, and kept at

urgent to improve the degumming method for 30 for 30 min. and then thoroughly washed.

natural fibers.

Scouring

In our previous study, the pre-chlorite treatment of The pre-chlorite treated jute fiber was treated with

jute fiber before degumming has been reported to sodium hydroxide 5-30g/L, sodium silicate

lighten the burden of degumming and enhance 1.0-5.0g/L, TF-107B 0.5-6.0g/L, TF-125A

delignification20. In this paper, we report the 1.0-8.0g/L, and kept at 60-100 for 60-240 min.

chemical degumming of the pre-chlorite treated jute with fiber to liquor ratio 1:10-1:40. At the end of the

fiber. Both the gum decomposition and the desired treatment, the fibers were neutralized with

spinnabilities viz. fineness, breaking strength and sulphuric acid, and then thoroughly washed with

breaking extension were tested to optimize the distilled water.

conditions for degumming. Changes in the

constituent content of the treated jute fiber were Testing

also analyzed. Breaking strength and breaking extension were

tested using a XQ-1 fiber breaking strength machine

in a constant 20 temperature and 65% relative

humidity room (in accordance with ASTM Method

D-5035). The fineness was tested according to

Journal of Engineered Fibers and Fabrics 2 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

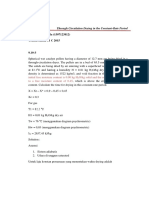

GB/T12411.3. The constituent contents were tested TABLE I. Effect of sodium hydroxide concentration on jute

according to GB/588986, and gum decomposition mechanical properties

was calculated using Eq. 1:

Sodium hydroxide Breaking Breaking Fineness/Tex

M0 M1 concentration/gL-1

strength/cN extension/

Gum Decomposition(%)= 100% (1)

M0

5 64.67 5.59 3.42

10 68.08 4.00 2.56

Where M0 is the gum content of the raw jute fiber,

15 59.94 3.44 2.68

M1 is the residual gum content of the degummed

20 67.49 4.64 2.55

jute fiber.

30 44.15 4.26 1.85

RESULTS AND DISCUSSION

Effect of Sodium Hydroxide Concentration Figure 1 shows that the gum decomposition value

In order to obtain the optimum sodium hydroxide increased up to 66.5 % with the sodium hydroxide

concentration for degumming, the pretreated jute concentration increased up to 10 g/L, but slightly

fiber was treated with different sodium hydroxide decreased when the concentration of sodium

concentration viz. 5g/L, 10g/L, 20g/L, 30g/L, and hydroxide was between 10g/L and 15g/L, and

the solution was made with sodium silicate 3.0g/L, increased again with further increase of sodium

TF-107B 2.0g/L, TF-125A 2.0g/L, fiber to liquor hydroxide concentration. And it is observed from

ratio 1:20, and treated at 98 for 120 min, Table I that the values of the breaking strength and

followed by washing and finally dried in an oven. the fineness decreased as the sodium hydroxide

After the treatment, the gum decomposition, concentration increased. Taking account of the

fineness and mechanical properties were tested to spinnability of jute fiber, which largely depends on

estimate the effect of sodium hydroxide its two important properties namely fineness and

concentration. The results are represented in Figure breaking strength21, our conclusion is that the

1 and Table I. optimum sodium hydroxide concentration should be

strictly controlled at 10g/L.

80

Effect of Time

Gum Decomposition / %

60 In order to obtain the optimum time for degumming,

the pretreated jute fiber was treated for different

40

time viz. 60 min., 90 min., 120 min., 180 min., 240

20 min., and the solution was made with sodium

hydroxide 10g/L, sodium silicate 3.0g/L, TF107-B

0

2.0g/L, TF-125A 2.0g/L, fiber to liquor ratio 1:20,

0 10 20 30 40

Sodium Hydroxide Concentration / g/L and treated at 98, followed by washing and

0g/L indicates the untreated jute fiber in all Figures finally dried in an oven. After the treatment, the

gum decomposition, fineness and mechanical

FIGURE 1. Effect of sodium hydroxide concentration on gum properties were tested to evaluate the effect of time.

decomposition The results are showed in Figure 2 and Table II.

Journal of Engineered Fibers and Fabrics 3 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

the most part, did not have major effect on the

80

Gum Decomposition / %

fineness and breaking strength. So the optimum

60 treatment time for degumming should be controlled

at 120 min.

40

20 Effect of Temperature

In order to obtain the optimum temperature for

0 degumming, the pretreated jute fiber was treated at

0 100 200 300

different temperature viz. 60, 70, 80, 90,

Time / min

100, and the solution was made with sodium

FIGURE 2. Effect of time on gum decomposition hydroxide 10 g/L, sodium silicate 3.0 g/L, TF-107B

2.0 g/L, TF-125A 2.0 g/L, fiber to liquor ratio 1:20,

and treated for 120 min, followed by washing and

TABLE II Effect of time on jute mechanical properties finally drying in an oven. After the treatment, the

gum decomposition, fineness and mechanical

Time /min Breaking Breaking Fineness/Tex properties were tested to determine the effect of

strength/cN extension/ temperature. The results are represented in Figure 3

60 44.01 4.53 3.10 and Table III.

90 42.16 3.22 3.08

120 46.62 3.66 3.15

180 37.65 3.61 3.07 80

240 46.27 3.57 3.06

Gum Decomposition / %

60

40

It can be seen from Figure 2 that gum

20

decomposition value initially increased with the

increase of treatment time, but no obvious changes

0

were observed after 120 min. It may be explained 0 20 40 60 80 100 120

that the extent of jute fiber swelling increased with Temperature /

FIGURE 3. Effect of temperature on gum decomposition

time and was fairly complete within 120 min. The

gum loosened and opened up, allowing the auxiliary

agents to easily penetrate into the fiber. As a result,

TABLE III Effect of temperature on jute mechanical properties

the auxiliary agents react sufficiently with

non-cellulose materials, and make them decompose

and dissolve in the treatment solution. At the same Temperature/ Breaking Breaking Fineness/Tex

time, it may be also explained that the strength/cN extension/

decomposable and dissolvable materials have been 60 62.88 5.26 3.96

completely removed in 120 min. So there is no need 70 65.18 4.63 3.74

to continue treatment after 120 min. 80 68.63 4.48 3.12

90 53.91 3.82 3.00

Table II further indicates that the treatment time, for 100 43.16 3.97 2.18

Journal of Engineered Fibers and Fabrics 4 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

Figure 3 shows that gum decomposition value was concentration. The results are showed in Figure 4

almost linearly increasing with the increase of and Table IV.

temperature. It may be explained that penetrability

of auxiliary agents and swelling degree of fiber

increased with the increase in temperature. As a 80

Gum Decomposition / %

result, the non-cellulose compositions were

60

sufficiently decomposed by chemicals or effectively

dissolved. 40

20

Table III indicates that the breaking strength

increased slightly when the temperature increased 0

from 60 to 80, but distinctly decreased when 0 1 2 3 4 5 6

the temperature further increased. It may be Sodium Silicate Concentration / g/L

explained that when the non-cellulosic materials

were partially removed, the inter-fibrillar region FIGURE 4. Effect of sodium silicate concentration on gum

was likely less dense and less rigid, thereby making decomposition

the fibrils more capable of rearranging themselves

along the direction of tensile deformation. When

jute fiber is stretched, such rearrangement amongst TABLE IV Effect of sodium silicate concentration on jute

the fibrils should result in better load sharing by mechanical properties

them and hence result in an increase in fiber

breaking strength22. But the excessive removal of Sodium silicate Breaking Breaking Fineness/Tex

non-cellulosic materials could also be negatively concentration/gL -1

strength/cN extension/

accompanied by a formidable decrease in the

breaking strength of the jute fiber. Thankfully the 1.0 69.38 2.63 2.80

breaking strength was acceptable for spinning, so it 1.5 61.36 2.74 2.88

was concluded that the optimum temperature should 2.0 60.13 3.57 2.62

be controlled at 100. 3.0 53.57 2.78 2.06

5.0 63.40 4.64 2.58

Effect of Sodium Silicate Concentration

In order to obtain the optimum sodium silicate

concentration for degumming, the pretreated jute

It can be seen from Figure 4 that the gum

fiber was treated with different sodium silicate

decomposition value increased up to 72.6% at

concentration viz. 1.0g/L, 1.5g/L, 2.0g/L, 3.0g/L,

sodium silicate concentration 3.0g/L, but decreased

5.0g/L, and the solution was made with sodium

with further increase in the sodium silicate

hydroxide 10g/L, TF-107B 2.0g/L, TF-125A 2.0g/L,

concentration. Table IV also shows the lowest

fiber to liquor ratio 1:20, and treated at 100 for

fineness (tex) was observed at 3.0g/L, but the

120 min., followed by washing and finally drying in

breaking strength was more U-shaped for the

an oven. After the treatment, the gum

sodium silicate concentrations evaluated. As

decomposition, fineness and mechanical properties

expected, sodium silicate is an effective adsorbent,

were tested to evaluate the effect of sodium silicate

which is needed in the degumming process for the

Journal of Engineered Fibers and Fabrics 5 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

adsorption of the decomposed and dissolved gum. TABLE V Effect of fiber to liquor ratio on jute mechanical

When the sodium silicate concentration is lower properties

than 3.0g/L, the decomposed gum could not

sufficiently be adsorbed by the sodium silicate and Fiber to Breaking Breaking Fineness/Tex

might stick onto the surface of jute fiber. When the liquor ratio strength/cN extension/

treated fibers were drying, the fibers would connect 1:10 48.32 4.18 3.34

to each other again. But when the sodium silicate 1:15 62.62 2.74 3.00

concentration was further increased, the sodium 1:20 44.77 3.45 2.36

silicate with decomposed gum would be held by the 1:30 44.29 3.63 2.62

jute fiber, preventing the decomposed gum from 1:40 53.38 3.65 2.98

dissolving. So the control of sodium silicate

concentration is very critical during the degumming

process. Based on the above discussion, it was Figure 5 shows that the gum decomposition value

concluded that the optimum concentration should be obviously increased up to 63.1% with the fiber to

controlled at 3.0g/L. liquor ratio increased to 1:20, and then slightly

increased with further increase in the fiber to liquor

Effect of Fiber to Liquor Ratio ratio. It may be explained that when the fiber to

In order to obtain the optimum fiber to liquor ratio liquor ratio was lower than 1:20, the decomposed

for degumming, the pretreated jute fiber was treated gum would stick to the fiber again, thereby

with different fiber to liquor ratio viz. 1:10, 1:15, contributing to an increase in breaking strength and

1:20, 1:30, 1:40, and the solution was made with a decrease in fineness, which is confirmed by Table

sodium hydroxide 10 g/L, sodium silicate 3.0g/L, V. When the residual gum content of treated jute

TF-107B 2.0g/L, TF-125A 2.0g/L, and treated at fiber was tested, the undissolved decomposed gum

100 for 120 min, followed by washing and finally dissolved in the treatment solution, increasing the

drying in an oven. After the treatment, the gum content of the residual gum. But further raising the

decomposition, fineness and mechanical properties fiber to liquor ratio more than 1:20 was not only

were tested to determine the effect of fiber to liquor unnecessary, but a waste of energy and resources.

ratio. The results are represented in Figure 5 and Therefore, the optimum fiber to liquor ratio should

Table V. be controlled at 1:20.

Effect of TF-125A Concentration

80

By keeping a constant concentration of sodium

Gum Decomposition / %

60 hydroxide 10g/L, sodium silicate 3.0g/L, TF-107B

2.0g/L, fiber to liquor ratio 1:20, the degumming of

40

jute fiber was studied at 100 for 120 min. with

20

different concentrations of TF-125A ranging from

0 1.0 to 8.0g/L. The gum decomposition, breaking

0 10 20 30 40 50

strength, breaking extension and fineness were then

Fiber to Liquid Ratio

tested to determine the effect of TF-125A

concentration. The results are shown in Figure 6

FIGURE 5. Effect of fiber to liquor ratio on gum decomposition

and Table VI.

Journal of Engineered Fibers and Fabrics 6 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

80

sufficient to obtain a fiber with favorable

Gum Decomposition / % spinnability and little reversion would be gained by

60

using excess amounts of TF-125A.

40

Effect of TF-107B Concentration

20

To examine the effect of TF-107B concentration,

0 the pretreated jute fiber was treated using sodium

0 2 4 6 8 10

hydroxide 10g/L, sodium silicate 3.0g/L, TF-125A

TF-125A Concentration / g/L

2.0g/L, fiber to liquor ratio 1:20, and kept at 100

for 120 min with different concentrations of

FIGURE 6. Effect of TF-125A (degumming agent) concentration TF-107B ranging from 1.0 to 8.0g/L. The gum

on gum decomposition decomposition, breaking strength, breaking

extension and fineness of the degummed jute fiber

TABLE VI Effect of TF-125A (degumming agent) concentration were tested to optimize the TF-107B concentration.

on jute mechanical properties The results are shown in Figure 7 and Table VII.

TF-125A Breaking Breaking Fineness/Te

concentration/gL -1

strength/cN extension/ x 80

Gum Decomposition / %

60

1.0 78.44 6.33 2.54

2 .0 66.21 5.73 2.02 40

4 .0 67.96 5.43 2.26

20

6 .0 58.68 5.05 2.24

0

8.0 51.39 4.79 2.47

0 2 4 6 8

TF-107B Concentration / g/L

It can be seen from Figure 6 that at a low level of FIGURE 7. Effect of TF-107B (penetrating agent) concentration

applied TF-125A, the gum decomposition value on gum decomposition

increased with the increasing of TF-125A

concentration. When the applied TF-125A was more

than 2.0g/L, the value of gum decomposition TABLE VII Effect of TF-107B (penetrating agent) concentration

gradually decreased. And the results in Table VI on jute mechanical properties

show that both the breaking strength value and

breaking extension value decreased almost linearly.

TF-107B Breaking Breaking Fineness/

And the minimum fineness value 2.02 tex was -1

concentration/gL strength/cN extension/ Tex

obtained at TF-125A concentration 2.0g/L. It may

be explained that the application of TF-125A could 0.5 80.76 5.67 2.73

observably enhance the degumming effect. With the 1.0 83.96 6.03 2.45

increasing of TF-125A concentration, the 2.0 73.50 5.41 2.39

decomposition of gum was accelerated and 4.0 67.35 5.32 2.21

accompanied by degradation of cellulose. Thus it 6.0 62.63 4.93 2.31

can be seen that using 2.0g/L TF-125A was

Journal of Engineered Fibers and Fabrics 7 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

It can be seen from Figure 7 that increasing the condition for degumming process. The factors,

concentration of TF-107B from 0.5 to 2.0g/L was levels and results are represented in Table VIII and

accompanied by an increase in gum decomposition. Table IX.

A further increase in TF-107B concentration gave

little reversion in the gum decomposition. Table VII TABLE VIII. Factors and Levels

shows that both the breaking strength and the

breaking extension obtained the maximum value Factors

83.96cN and 6.03% at TF-107B 1.0g/L, respectively,

Levels A: Concentration of B: Concentration C: time/min

and then gradually decreased with further increase -1

sodium hydroxide/gL of sodium

in the concentration of TF-107B. Table VII also

silicate/gL-1

shows that the fineness value of the degummed

1 8.5 2.7 105

fiber decreased almost linearly. Taking account of

2 10.0 3.0 120

all the above four indexes, it is clear that the

3 12.0 3.2 130

optimum concentration of TF-107B for degumming

should be controlled at 2.0g/L.

L9(34) Orthogonal Experiment

According to the above discussions, a L9(34)

orthogonal experiment was designed to optimize the

TABLE IX. L9(33)

Factors

S. No. Gum decomposition/% Breaking strength/cN Fineness/Tex

A B C

1 1 1 1 59.1 31.32 3.26

2 1 2 2 56.5 36.61 2.84

3 1 3 3 57.5 54.48 2.88

4 2 1 2 52.1 48.55 2.56

5 2 2 3 56.7 43.41 3.20

6 2 3 1 55.5 49.72 2.75

7 3 1 3 61.9 51.70 3.48

8 3 2 1 61.9 46.93 2.02

9 3 3 2 54.6 49.08 2.48

Gum decomposition/% Breaking strength/cN Fineness/Tex

A B C A B C A B C

Level1 57.70 57.70 58.83 40.80 43.86 42.66 2.99 3.10 2.68

Level2 54.77 58.37 54.40 47.23 42.32 44.75 2.79 2.69 2.76

Level3 59.47 55.87 58.70 49.24 51.09 49.86 2.66 2.70 3.17

Effect 4.70 2.50 4.43 8.44 8.77 7.20 0.33 0.41 0.49

Journal of Engineered Fibers and Fabrics 8 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

Table IX shows that the concentration of sodium the breaking strength can satisfy the need of

hydroxide and treatment time were the two most spinning. Therefore, the optimum condition for

important factors for gum decomposition ratio, the degumming was ascertained as A3B2C1, i. e. sodium

effect of sodium silicate was inferior to them, thus hydroxide 12 g/L, sodium silicate 3.0 g/L, time 105

the optimum condition for gum decomposition was min.

A3B2C1. And the optimum fineness index 2.02 tex

was obtained with A3B2C1. But the optimum Effect of Degumming on the Constituent

condition for degumming was A3B3C2 on the basis Contents of Jute Fiber

of the breaking strength. With the view that the The major constituents of raw and treated jute fiber

primary purpose for degumming is to remove more were assessed to analyze the effect of degumming

and more non-cellulose materials and obtain on the removing of non-cellulose. The results were

spinnable fiber with appropriate fineness, so long as shown in Table X.

TABLE X. Constitutes content of the raw and degummed jute fiber

Samples Cellulose/% Hemicellulose/% Lignin/% Aqueous Fats and wax/% Pectin/%

extract/%

Raw 65.44 17.61 14.35 1.86 0.61 0.13

Degummed 84.78 4.67 9.25 0.98 0.28 0.04

It can be seen from Table X that all the treatment time were the three most important

non-cellulose constituents namely hemicellulose, parameters for degumming process, and the

lignin, aqueous extract, pectin, fat and wax were degumming process was an effective method to

obviously removed by degumming process, remove hemicellulose, lignin, pectin and some other

especially for the hemicellulose. Table X also shows non-cellulose materials. According to the results of

that the cellulose content value increased from the L9(34) orthogonal experiment, the gum

65.44 % to 84.78 % after degumming. decomposition ratio 61.9 % and fineness index 2.02

Tex were obtained with the optimum treating

CONCLUSIONS conditions such as sodium hydroxide of 12 g/L,

The degumming process is necessary for improving sodium silicate of 3.0 g/L, TF-107B of 2.0 g/L,

the textile properties of jute fiber. The pre-chlorite TF-125A of 2.0 g/L, treatment time of 105 min,

treated jute fiber was degummed by varying sodium temperature of 100 and fiber to liquor ratio of

hydroxide concentration, treatment time, 1:20.

temperature, sodium silicate concentration,

degumming agent TF-125A concentration, ACKNOWLEDGEMENT

penetrating agent TF-107B concentration and fiber This research is funded by the Special Fund for

to liquor ratio. It was found that sodium hydroxide Conversion of Technological Production of Jiangsu

concentration, sodium silicate concentration and Province.

Journal of Engineered Fibers and Fabrics 9 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

REFERENCES [10] D.P. Chattopadhyay; Introduction,

Chemistry and Preparatory Processes of

[1] Yu Hongqin; Dang Min; Yu Chongwen; A

Jute; Colourage, May 1998, 5, 23 35

preliminary Study on Chemical

Degumming of Jute and Kenaf Fibers; [11] N.C.Pan; A. Day; Kumar K. Mahalanabis;

Plant Fiber and Products 2003, 25, Chemical Composition of Jute and its

190-192 Estimation ; Man-made Textiles In India

1999, 9, 467 473

[2] P Ghosh; Effect of selective chemical

treatments of jute fiber on textile-related [12] Liu Jian; Cheng Hongzhang; Li Zuo; On

properties and processible; Indian Journal the development of research of hemp fiber

of Fibers & textile Research 2004, 29, degumming; Plant Fiber and Products

85-89 2002, 24, 39-42

[3] Zhao Min; Dyeing and finishing of Jute [13] Zheng Laijiu; Yu Chongwen; Study on

fiber; Textile Science Research 1993, 3, chemical modification of kenaf fiber and

32-37 mixed blending with cotton; Journal of

Dalian Institute of Light Industry 2002, 21,

[4] J. Jeyakodi Moses; A Study of jute fibers

145-148

treated at ambient conditions; AATCC

review 2001, 3, 34 37 [14] Bi Lei; Jiang Fengqin; Ji Yingchao;

Guangxi Textile Science & Technology

[5] S.N. Chattopadhyay; N.C. Pan; A. Day;

2006, 35, 19-21

Resuse of reactive dyes for dyeing of jute

fabric; Bioresource Technology 2006, 97, [15] Wang H M; Wang X; Bast fiber

77-83 degumming; Textil Asia 2004, 2, 28-30

[6] Y. Cai; S. K. David; M. T. Pailthorpe; [16] Liu Zhaotie; yang Yani; Zhang Lili; Study

Dyeing of Jute and Jute/Cotton Blend on the performances of ramie fiber

Fabrics with 2:1 Pre-metallised Dyes; Dyes modified with ethylenediamine;

and Pigments2000, 45, 161 - 168 Carbohydrate Polymers 2007,

[7] Hassan K. Sreenath; Arun B. Shah; Vina W. [17] Ryszard Kozlowski; Jolanta Batog; Wanda

Yang; Enzymatic Polishing of Jute/Cotton Konczewicz; Enzymes in bast fibrous plant

Blended Fabrics; Journal of Fermentation processing; Biotechnology Letters 2006

and Bioengineering 1996,81 , 18 20

[18] Zheng Lianshuang; Du Yumin; Zhang

[8] G. Basu; S. N. Chattopadhyay; Ambient Jiayao; Biobleaching effect of xylanase

Temperature Bleaching of Jute fiberIts preparation from an alkalophilic bacillus

Effect on Yarn Properties and Dyeing sp. On ramie fibers; Biotechnology letters

Behaviour; Indian Journal of Fiber & 2000, 22, 1363-136

Textile Research 1996, 21, 217 - 222

[19] Yang Yingxian; The status quo and strategy

[9] N.C. Pan;S.N. Chattopadhyay;A. Day; Jute of hemp bast degumming; Shandong

Yarn Bleaching at Ambient Temperature Textile Science & Technology 2005, 1,

with Different Pretreatments; Textile Asia 51-54

2001, 3, 40 - 43

Journal of Engineered Fibers and Fabrics 10 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

[20] Wang Weiming; Cai Zaisheng; Pre-chlorite

treatment and scouring of jute fiber;

IFDC-TSE 2006

[21] S Majumdar; Prediction of fiber quality

from anatomical studies of jute stem: Part

Prediction of strength; Indian Journal

of Fiber & Textile Research 2002, 27,

254-258

[22] Mukherjee; P.K. Ganguly; D. Sur;

Structural mechanics of jute: The effects of

hemicellulose or lignin removal; J. Text.

Inst. 1993, 84, 348-353

AUTHORS ADDRESSES

Wei-ming Wang; Zai-sheng Cai, Ph.D.

Key Laboratory of Science & Technology of

Eco-Textile, Ministry of Education & College of

Chemical and Chemistry Engineering

Donghua University

2999 North Renmin Road

Shanghai 201620

P.R. CHINA

Jian-yong Yu, Ph.D.

Modern Textile Institute of Donghua University

2999 North Renmin Road

Shanghai 201620

P.R. CHINA

Journal of Engineered Fibers and Fabrics 11 http://www.jeffjournal.org

Volume 3, Issue 2, 2008

Potrebbero piacerti anche

- Perhitungan Package Boiler 2007 UA (ALHAMDULILLAHFIX)Documento23 paginePerhitungan Package Boiler 2007 UA (ALHAMDULILLAHFIX)Fakhri FachrezaNessuna valutazione finora

- Database CP Delta H Delta GDocumento18 pagineDatabase CP Delta H Delta GsafinaNessuna valutazione finora

- Data Sumber Ta FixDocumento55 pagineData Sumber Ta FixWanda YunitaNessuna valutazione finora

- Downterm ADocumento2 pagineDownterm Awiyatmi0% (1)

- Analysis of The Adsorption Process and of Desiccant Cooling SystemsDocumento155 pagineAnalysis of The Adsorption Process and of Desiccant Cooling SystemsRajesh VyasNessuna valutazione finora

- Frequency Domain Analysis of Dynamic Systems: Jos E C. GeromelDocumento43 pagineFrequency Domain Analysis of Dynamic Systems: Jos E C. Geromelblister_xbladeNessuna valutazione finora

- Chapter 4 م. احسان حبيبDocumento22 pagineChapter 4 م. احسان حبيبعبد اللهNessuna valutazione finora

- Butadiene SulfoneDocumento58 pagineButadiene SulfoneChunchu AnilNessuna valutazione finora

- 123dok PRARANCANGAN+PABRIK+MONOBASIC+POTASSIUM+PHOSPHATE+DARI+ASAM+FOSFAT+DAN+POTASSIUM+HIDROKSIDA+KAPASITA - DikonversiDocumento190 pagine123dok PRARANCANGAN+PABRIK+MONOBASIC+POTASSIUM+PHOSPHATE+DARI+ASAM+FOSFAT+DAN+POTASSIUM+HIDROKSIDA+KAPASITA - DikonversiIndra Setio PujiNessuna valutazione finora

- Appendix F - SteamTable PDFDocumento68 pagineAppendix F - SteamTable PDFEirojram MarjorieNessuna valutazione finora

- Company Profile PT. Intesco Global InternusaDocumento45 pagineCompany Profile PT. Intesco Global InternusaES RouzaNessuna valutazione finora

- Neraca Massa Sherena & IkaDocumento45 pagineNeraca Massa Sherena & IkaEVA KUSMAYANTINessuna valutazione finora

- tmp7F33 TMPDocumento11 paginetmp7F33 TMPFrontiersNessuna valutazione finora

- Presentasi TRK Topik 3 - Kelompok 8Documento19 paginePresentasi TRK Topik 3 - Kelompok 8Martha IvanaNessuna valutazione finora

- Boiler DraftDocumento22 pagineBoiler DraftJAY PARIKHNessuna valutazione finora

- Ideal Gas Non Ideal LiquidDocumento21 pagineIdeal Gas Non Ideal Liquidt_ntiNessuna valutazione finora

- Leblanc ProcessDocumento5 pagineLeblanc ProcessvrosalioNessuna valutazione finora

- Ullia Nurul Ismala - 1507123812 - Soal - 9-10-3Documento3 pagineUllia Nurul Ismala - 1507123812 - Soal - 9-10-3Ullia IsmalaNessuna valutazione finora

- Material Safety Data Sheet Dibutyl PhthalateDocumento4 pagineMaterial Safety Data Sheet Dibutyl PhthalateKameliza Saranghe Choi-siwon SujuelfNessuna valutazione finora

- Hexamine 1Documento66 pagineHexamine 1Pradhita Ramdani HNessuna valutazione finora

- Netralizer Koil JozDocumento44 pagineNetralizer Koil JozPradika WibowoNessuna valutazione finora

- Proposal KP HolcimDocumento27 pagineProposal KP HolcimPutu Trisnayadhi DharmawanNessuna valutazione finora

- Diagram Alir Proses Pada Stasiun Pemurnian: Single Tray Clarifier DSM Screen Flash TankDocumento1 paginaDiagram Alir Proses Pada Stasiun Pemurnian: Single Tray Clarifier DSM Screen Flash TankFadhillah UNessuna valutazione finora

- Ocw Chapter 4Documento48 pagineOcw Chapter 4Agam HanasichulaNessuna valutazione finora

- TorefaksiDocumento4 pagineTorefaksirifkasyaputriNessuna valutazione finora

- Chemical Engineering Projects Can Be Divided Into Three TypesDocumento25 pagineChemical Engineering Projects Can Be Divided Into Three Typestrungson1100% (1)

- Kopp Rules Heat Capacity Solid PDFDocumento134 pagineKopp Rules Heat Capacity Solid PDFMouad ArradNessuna valutazione finora

- Steam Balance TCDDocumento12 pagineSteam Balance TCDSaifuddinHidayatNessuna valutazione finora

- Astm D-2361Documento4 pagineAstm D-2361Claudia Da Rolt0% (1)

- EKOTEKDocumento6 pagineEKOTEKDHILA AYUNINGTYASNessuna valutazione finora

- Prarancangan Pabrik Polivinil Alkohol Dari PolivinDocumento163 paginePrarancangan Pabrik Polivinil Alkohol Dari PolivinDizaichaNessuna valutazione finora

- NM Doni BaruDocumento47 pagineNM Doni BaruAhmad SupraptoNessuna valutazione finora

- Ejercicios de Ingeniería EconómicaDocumento2 pagineEjercicios de Ingeniería EconómicaDiego MoralesNessuna valutazione finora

- Optimally Economic Design of Flare Systems PDFDocumento5 pagineOptimally Economic Design of Flare Systems PDFMedaculoNessuna valutazione finora

- Methods For The Determination of HumidityDocumento2 pagineMethods For The Determination of HumidityMuhammad SalmanNessuna valutazione finora

- Jurnal Kromatograf KolomDocumento8 pagineJurnal Kromatograf KolomVia PujianingsihNessuna valutazione finora

- Makalah Termodinamika IIIDocumento33 pagineMakalah Termodinamika IIIdata laptop asusNessuna valutazione finora

- Silica Plastic BlockDocumento5 pagineSilica Plastic Blockdharshini deivasigamaniNessuna valutazione finora

- Tabel Antoine 1Documento3 pagineTabel Antoine 1atikaindrnNessuna valutazione finora

- Pengolahan Limbah Cair Industri Karet deDocumento9 paginePengolahan Limbah Cair Industri Karet deludira luckyNessuna valutazione finora

- Perhitungan Neraca Panas Di Clinker CoolerDocumento3 paginePerhitungan Neraca Panas Di Clinker CoolerPutri Hanifah SNessuna valutazione finora

- Risky Septian Proposal KP PT Salim Ivomas Pratama TBKDocumento12 pagineRisky Septian Proposal KP PT Salim Ivomas Pratama TBKRisky SeptianNessuna valutazione finora

- Msds KaraginanDocumento3 pagineMsds Karaginanharum ambariyantiNessuna valutazione finora

- PK Kel 4Documento3 paginePK Kel 4SheilaNessuna valutazione finora

- Kelompok 4 TRK 2Documento5 pagineKelompok 4 TRK 2Katharina AjengNessuna valutazione finora

- Pra-Rancangan Pabrik Produksi Etilen Dari Gas Alam Berkapasitas 400.000 TON/TAHUNDocumento1 paginaPra-Rancangan Pabrik Produksi Etilen Dari Gas Alam Berkapasitas 400.000 TON/TAHUNiknaiw27Nessuna valutazione finora

- Spray Tower Loop ReactorDocumento6 pagineSpray Tower Loop ReactorCh'ng Ying YingNessuna valutazione finora

- PDF (All-In-One) MK Perancangan Pabrik Kimia (Copyright - R.Turton and J. Shaeiwitz 2012) PDFDocumento564 paginePDF (All-In-One) MK Perancangan Pabrik Kimia (Copyright - R.Turton and J. Shaeiwitz 2012) PDFSaputra Purnawan0% (1)

- Asih Ayu Nitiwati - Tugas Surface 2Documento8 pagineAsih Ayu Nitiwati - Tugas Surface 2asih ayuNessuna valutazione finora

- Optimalisasi Kompresor SentrifugalDocumento27 pagineOptimalisasi Kompresor SentrifugalDea Amelia100% (1)

- Design & Simulation of Nitrobenzene Manufacturing Process: Name of Student: Kasar Khanadal MheDocumento23 pagineDesign & Simulation of Nitrobenzene Manufacturing Process: Name of Student: Kasar Khanadal Mheکبری ادریس رسولNessuna valutazione finora

- PFD PT. Semen Indonesia (Persero) TBKDocumento12 paginePFD PT. Semen Indonesia (Persero) TBKOdi Saputra IhsanNessuna valutazione finora

- Perhitungan Furnace Efesiesnsi Furnace CDU 11-F-101Documento40 paginePerhitungan Furnace Efesiesnsi Furnace CDU 11-F-101Aditya PratomoNessuna valutazione finora

- Heat Capacity of Liquids - Critical Review and Recommended ValuesDocumento404 pagineHeat Capacity of Liquids - Critical Review and Recommended ValuesDoris AngNessuna valutazione finora

- Rase - Chemical Reactor Design For Process Plants - VII - ShifterDocumento18 pagineRase - Chemical Reactor Design For Process Plants - VII - ShifterKathryn HarrisNessuna valutazione finora

- Study On The Chemical Modification Process of Jute Fiber: Zshcai@dhu - Edu.cnDocumento11 pagineStudy On The Chemical Modification Process of Jute Fiber: Zshcai@dhu - Edu.cnRonald PascualNessuna valutazione finora

- Treatment of Date Palm Bres Mesh: in Uence On The Rheological and Mechanical Properties of Bre-Cement CompositesDocumento13 pagineTreatment of Date Palm Bres Mesh: in Uence On The Rheological and Mechanical Properties of Bre-Cement CompositesMalek GolNessuna valutazione finora

- Mechanical, Thermal and Interfacial Properties of Jute Fabric-Reinforced Polypropylene Composites: Effect of Potassium DichromateDocumento8 pagineMechanical, Thermal and Interfacial Properties of Jute Fabric-Reinforced Polypropylene Composites: Effect of Potassium Dichromateakashdruva892Nessuna valutazione finora

- 23-04-2021-1619176657-8-Ijans-7. Ijans - Comparative Study On Physico-Chemical Properties of Roselle - Hibiscus Sabdariffal - and Ramie FibreDocumento8 pagine23-04-2021-1619176657-8-Ijans-7. Ijans - Comparative Study On Physico-Chemical Properties of Roselle - Hibiscus Sabdariffal - and Ramie Fibreiaset123Nessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Serverless Ops PDFDocumento62 pagineServerless Ops PDFJuangui JordánNessuna valutazione finora

- Patterson Software Installation GuideDocumento55 paginePatterson Software Installation GuideGuarded TabletNessuna valutazione finora

- NYC Minimum WageDocumento2 pagineNYC Minimum WageGuarded TabletNessuna valutazione finora

- Thermoregulatory Characteristics of Bamboo Lyocell FabricsDocumento8 pagineThermoregulatory Characteristics of Bamboo Lyocell FabricsGuarded TabletNessuna valutazione finora

- Thermoregulatory Characteristics of Bamboo Lyocell FabricsDocumento8 pagineThermoregulatory Characteristics of Bamboo Lyocell FabricsGuarded TabletNessuna valutazione finora

- Photovoltaic System James Dunlop Cover and Contents PageDocumento10 paginePhotovoltaic System James Dunlop Cover and Contents PageGuarded Tablet0% (5)

- MongoDB and Mongoose in NodeJSDocumento35 pagineMongoDB and Mongoose in NodeJSGuarded Tablet100% (2)

- Rohs Material Confirmation CertificateDocumento2 pagineRohs Material Confirmation Certificateimtiyaz aliNessuna valutazione finora

- Iso 10993 23 2021Documento15 pagineIso 10993 23 2021Katerin MartínezNessuna valutazione finora

- Texture AnalyzerDocumento5 pagineTexture AnalyzerNur FadhilahNessuna valutazione finora

- CE6306-Strength of Materials Part-A EditDocumento15 pagineCE6306-Strength of Materials Part-A EditgoldencometNessuna valutazione finora

- Nota Sains Tahun 5Documento46 pagineNota Sains Tahun 5mohdfirdaushada100% (2)

- DocumentDocumento89 pagineDocumentRajeev Sharma100% (1)

- T.O. 33b-1-2 - NDT General Procedures and Process ControlsDocumento138 pagineT.O. 33b-1-2 - NDT General Procedures and Process ControlsJuan Carlos Romero Susunaga89% (9)

- Astm E945 - 12Documento4 pagineAstm E945 - 12ChristianNessuna valutazione finora

- 2012-3 National Chemistry OlympiadDocumento14 pagine2012-3 National Chemistry OlympiadRSLNessuna valutazione finora

- Silicon ExicipientDocumento12 pagineSilicon ExicipientArif ShaikhNessuna valutazione finora

- Isolation and Characterization of Proteins: 2.2 ObjectivesDocumento4 pagineIsolation and Characterization of Proteins: 2.2 ObjectivesJiyongNessuna valutazione finora

- Design of A Gauge MetrologyDocumento8 pagineDesign of A Gauge MetrologyQuality HosurNessuna valutazione finora

- Physics Cheat Sheet 1 Units 5 More Motion FormulasDocumento1 paginaPhysics Cheat Sheet 1 Units 5 More Motion FormulasMuhammad Pathan AbroNessuna valutazione finora

- PD Cen TR 15314 2006 (En)Documento16 paginePD Cen TR 15314 2006 (En)Ramzi BEN AHMEDNessuna valutazione finora

- 10128H95Documento152 pagine10128H95MarbuejuNessuna valutazione finora

- Stoeber (2012) Effects of Maximum Particle Size and Sample Scaling On The MEchanical Behavior of Mine Waste Rock A Critical State ApproachDocumento300 pagineStoeber (2012) Effects of Maximum Particle Size and Sample Scaling On The MEchanical Behavior of Mine Waste Rock A Critical State ApproachJustin StoeberNessuna valutazione finora

- BAKER Drilling - Products Fluid End Expandable Parts PDFDocumento56 pagineBAKER Drilling - Products Fluid End Expandable Parts PDFAnonymous GjCOVlgNessuna valutazione finora

- Emeterio-Federica Gerez National High School: Jhs Learning Activity SheetDocumento3 pagineEmeterio-Federica Gerez National High School: Jhs Learning Activity SheetChelleyOllitroNessuna valutazione finora

- Sop PH Meter.Documento4 pagineSop PH Meter.Brian HawkinsNessuna valutazione finora

- Anomalous Properties of LithiumDocumento4 pagineAnomalous Properties of LithiumAbdul AynanNessuna valutazione finora

- 1 - Gas LawsDocumento10 pagine1 - Gas LawsDavid King-HopeNessuna valutazione finora

- Sartorius Biostat Cultibag RM 20 BrochureDocumento8 pagineSartorius Biostat Cultibag RM 20 BrochureJesujobaNessuna valutazione finora

- Combustion R.ADocumento39 pagineCombustion R.ARitanshu Anand100% (1)

- Ial WCH05 01 Nov19 PDFDocumento28 pagineIal WCH05 01 Nov19 PDFsammam mahdi samiNessuna valutazione finora

- General Catalog en GrindingDocumento10 pagineGeneral Catalog en GrindingkarthikNessuna valutazione finora

- BS en 1560Documento13 pagineBS en 1560Mustafa KorkutNessuna valutazione finora

- 01-Experiment-The Effect of PH On Food PreservativeDocumento9 pagine01-Experiment-The Effect of PH On Food Preservativejul.cotrimNessuna valutazione finora

- Evolution of Oilfield BatteriesDocumento16 pagineEvolution of Oilfield BatteriesPasquale CutriNessuna valutazione finora

- Automatic Grease Lubricators White PaperDocumento5 pagineAutomatic Grease Lubricators White PaperPaul RuckNessuna valutazione finora

- ErDocumento27 pagineErAsif UllahNessuna valutazione finora